Bearing Bronze Alloys: Characteristics and Selection Guide

Bearing Bronze Solutions – Tailored for Efficiency & Strength

Tin Bronze

Leaded Bronzes

Aluminium Bronzes

High Tensile Brasses

Special Bronze Alloys

Special bronze alloys are engineered materials that are specifically designed to meet the demanding requirements of various industrial applications, particularly in the manufacturing of bearings. These alloys offer a unique combination of properties, such as high strength, excellent wear resistance, good conductivity, and corrosion resistance, which make them ideal for use in harsh environments and under extreme conditions.

bearings Bronze Standards

We manufacture bronze parts and self-lubricating bronze components including:Plain Bushings,Flanged Bushings,Washers, Plates,Bearings. Each product is crafted to meet specific industry standards and client requirements.

Bearing Bronze in Industry: Uses and Advantages

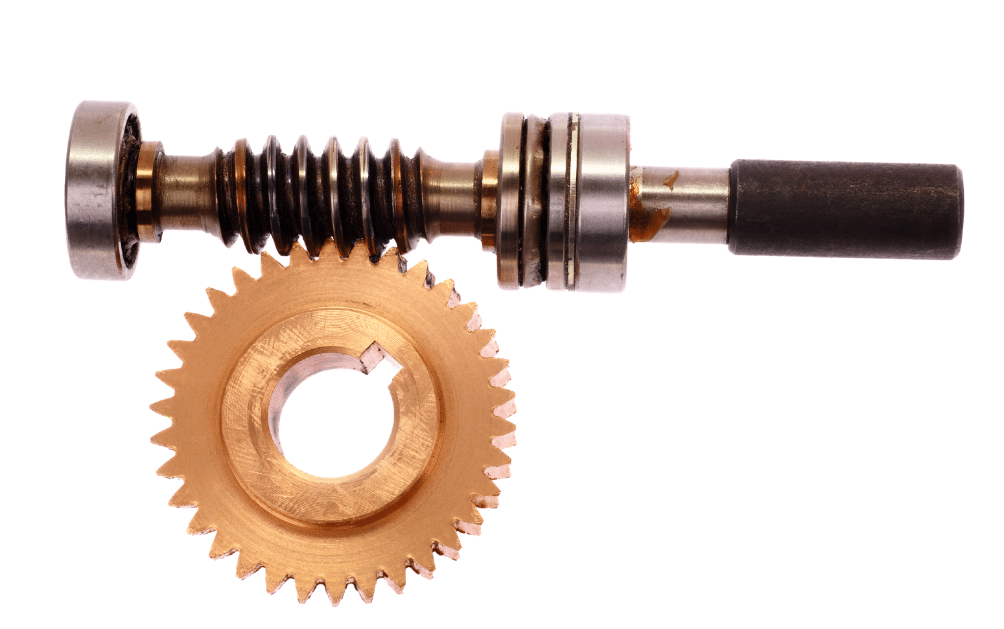

Pre-lubrication Bearing Bronze Bearing, CuSn7Zn4Pb7, also known as leaded tin bronze or “standard” bearing bronze, is a high-performance material specifically designed for heavy-duty applications where plain bearings are required. This alloy is characterized by its excellent mechanical properties and its ability to withstand the demands of rigorous operational conditions. Here’s a detailed overview of the alloy and its suitability for heavy-duty plain bearing applications:

Innovations in Bearing Bronze Technology and the Impact

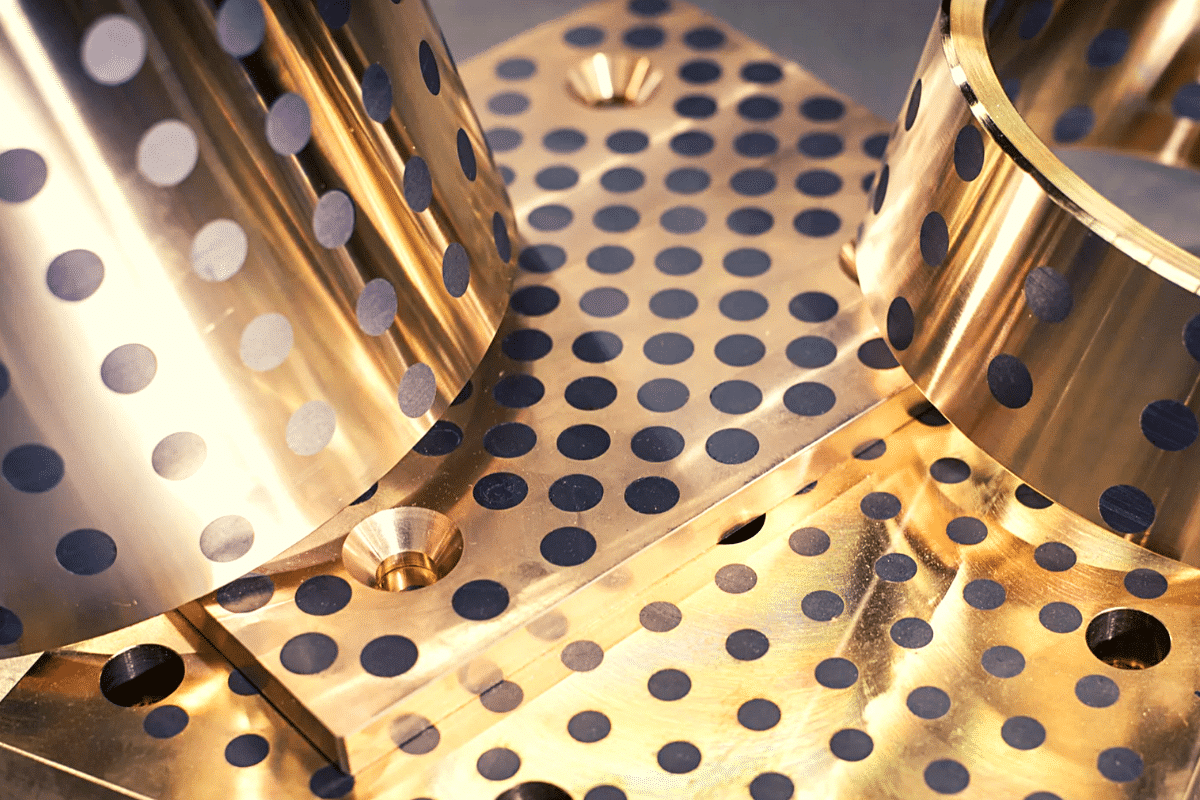

Solid bushing, bronze with lubricant plugs embedded, DIN 1850/ISO 4379, Maintenance-free: In industrial applications, maintenance-free solid bronze bushings are a highly popular component designed to reduce maintenance needs and enhance overall system reliability. These bushings are typically manufactured according to DIN 1850/ISO 4379 standards and feature embedded lubricant plugs to provide long-term lubrication after installation.

maintenance-free solid bronze bushings offer a reliable, durable, and cost-effective solution suitable for applications that require reduced maintenance and enhanced operational efficiency. By selecting the appropriate materials and designs, these bushings can meet the stringent demands of specific applications, ensuring long-term stable operation of the equipment.

custom manufacturing of bronze and self-lubricating bronze components

We specialize in custom manufacturing of bronze and self-lubricating bronze components, precisely tailored to client specifications. Our process involves creating bespoke parts directly from clients’ technical drawings, ensuring each product meets their exact requirements in terms of design, functionality, and performance. This approach allows us to deliver highly specialized components ideal for a variety of applications, with each piece designed for optimal performance and longevity.

Applications: This range is suitable for cranes, mining equipment, construction machinery, as well as offshore and marine applications. It is also ideal for use in steel plants and hydro power or hydro mechanical facilities.

The Future of Bearing Bronze in Engineering and Design

About us

Understanding Bearing Bronze: Composition and Common Uses

We specialize in manufacturing bronze alloys in accordance with the ASTM B505 continuous casting and ASTM B271 centrifugal casting standards. We maintain a stock of alloys that either meet these standards directly or possess similar characteristics.

Our most popular product is the C932 Bearing Bronze. This alloy is known for its excellent anti-friction properties, strength, and hardness, making it an ideal general-purpose bearing alloy. Additionally, we offer the CuSn7Zn4Pb7-C (also known as CC493K or CB493K), a bronze alloy characterized by its precise chemical composition and mechanical properties, which are specifically tailored for use in plain bearings.

We provide a diverse range of bearing bronze products, including straight and flanged bushings, slide plates, and various sizes tailored to meet specific requirements. All our alloys are produced according to the EN 1982 standard, ensuring they meet European specifications.

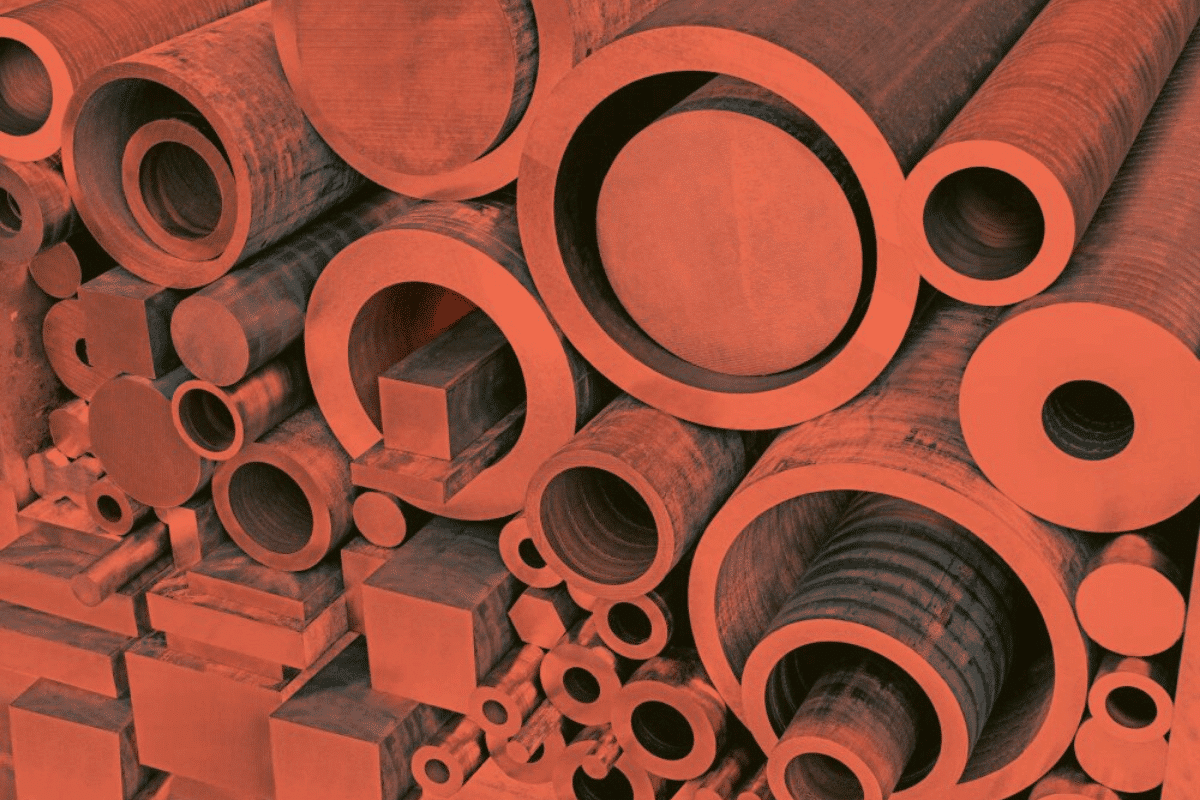

Our production capabilities extend to a comprehensive selection of continuous and centrifugal cast bearing bronzes as per the EN 1982 European standard. We manufacture a variety of components such as bushes, rings, and sleeves, utilizing copper alloys that comply with global standards.

Specialized Manufacturing of Bearing Bronze Parts

We are industry specialists in the production of bearing bronze parts and self-lubricating bronze, meticulously crafted based on client specifications. Our expertise extends to machining both standard and self-lubricating bronze to meet unique client needs.

Integrated Production Process

Our integrated manufacturing process encompasses every step from raw material procurement to final product delivery, ensuring stringent control and certification at every phase:

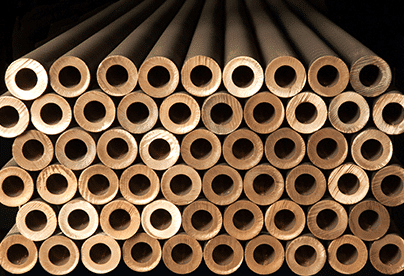

- Raw Material Acquisition

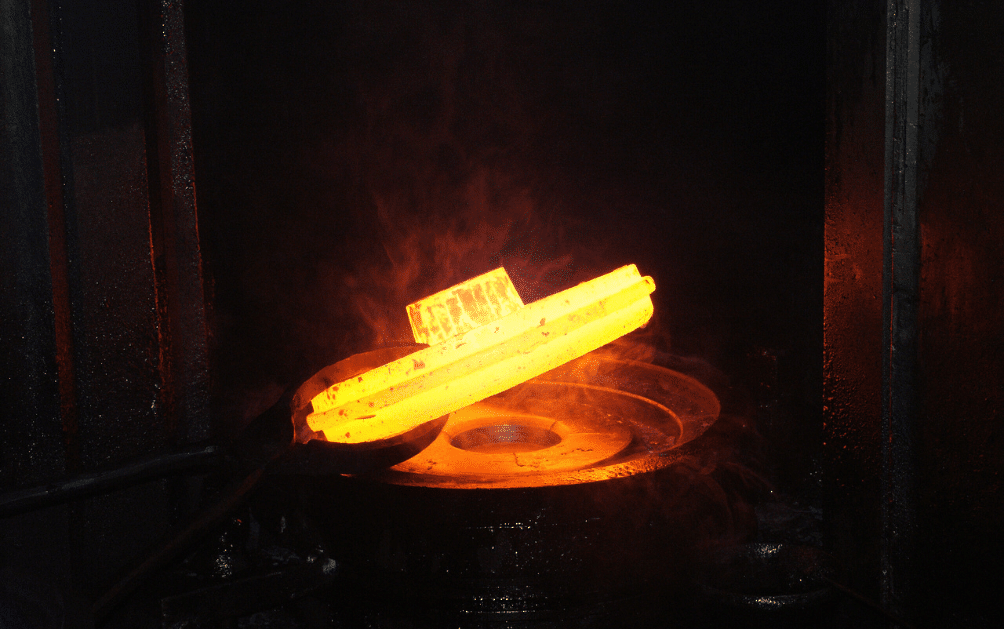

- Casting

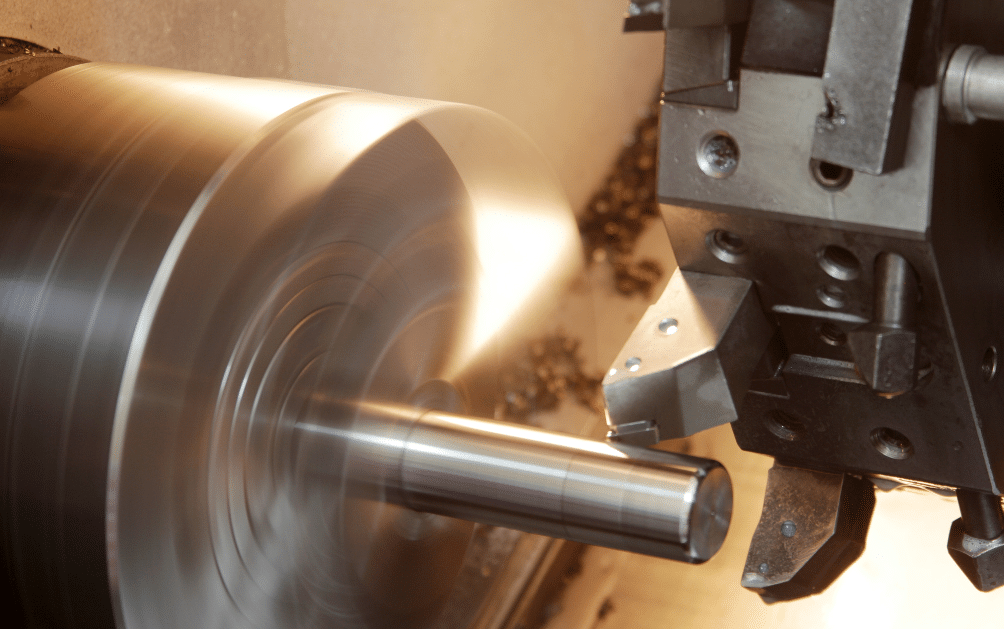

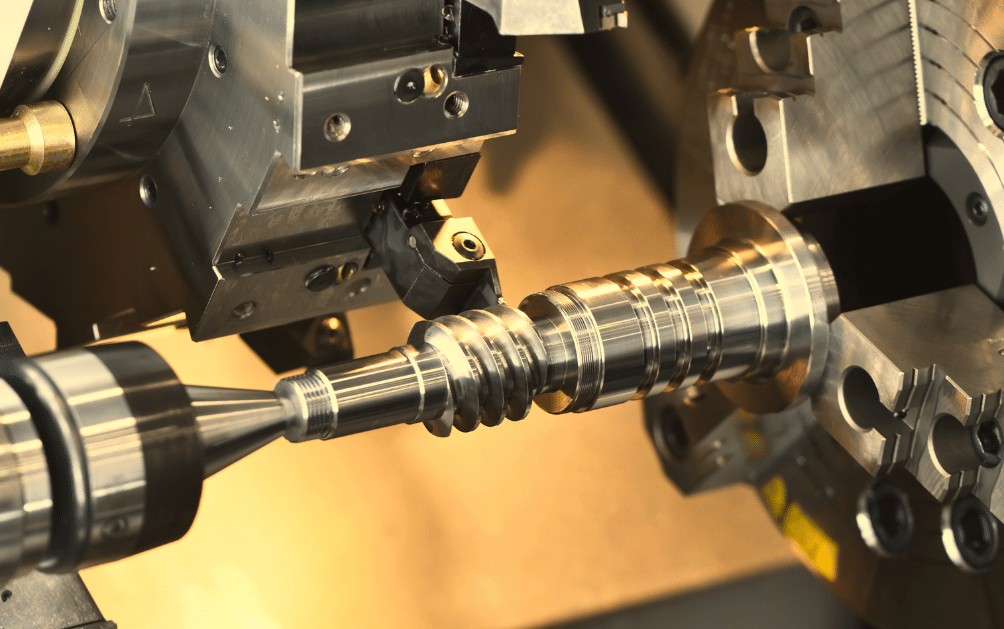

- Machining

- Inspection

- Client Delivery

This fully integrated approach guarantees high-quality outcomes tailored to client specifications.

Customized Solutions and Flexibility

We are committed to flexibility, adapting to various client demands regarding product specifications, technical solutions, delivery schedules, pricing agreements, and payment options. Our facility is equipped with advanced manufacturing technology, including numerically controlled lathes and machining centers, alongside modern verification and control equipment.

Our skilled technical department excels in providing consultancy and resolving any technical challenges, ensuring that every product is crafted to function optimally under the specified working conditions.

Capabilities and Product Offerings

With our flexible production capacity, we are capable of supplying both single unit pieces and larger series within tight deadlines. We manufacture a wide range of bronze parts and self-lubricating bronze components, including:

- Plain bushings

- Flanged bushings

- Washers

- Plates

- Bearings

- And other custom parts

For more detailed information on our capabilities and how we can assist with your specific requirements, please contact us.

| Bearing Bronze Alloy | TIN BEARING BRONZE | |||||

|---|---|---|---|---|---|---|

| En 1982 | CC493K CuSn7Zn4Pb7-C |

CC482K CuSn11Pb2-C |

CC483K CuSn12-C |

CC333G CuAl10Fe5Ni5-C |

CC762S CuZn25Al5Mn4Fe3-C |

|

| Material characteristics | Tensile strength MPa |

260 | 280 | 300 | 650 | 750 |

| Yield point 0,2% MPa |

120 | 150 | 150 | 280 | 480 | |

| Elongation 5D% | 12 | 5 | 6 | 13 | 5 | |

| Hardness HBW 10/1000 | 70 | 90 | 90 | 150 | 190 | |

| Max Temperature C | 150 | 170 | 180 | 250 | 250 | |

| Max Pressure MPa | 30 | 50 | 50 | 80 | 98 | |

| Max Speed (m/min) | 20 | 18 | 18 | 18 | 15 | |

| P x V max | 60 | 80 | 80 | 120 | 180 | |

| ASTM B505 | Equivalent Alloys | Closest Alloys | Type of Alloy | Details |

|---|---|---|---|---|

| C83600 | C83600 / C836 / CDA836 | CC491K – CuSn5ZnPb5-C | See | |

| C84400 | C84400 / C844 / CDA844 | CC490K – CuSn3Zn8Pb5-C | See | |

| C86200 | C86200 / C862 / CDA862 | CC764S – CuZn34Mn3Al2Fe1-C | High tensile brasses | See |

| C86300 | C86300 / C863 / CDA863 | CC762S – CuZn25Al5Mn4Fe3-C | High tensile brasses | See |

| C90300 | C90300 / C903 / CDA903 | – | Tin bronzes | See |

| C90500 | C90500 / C905 / CDA905 | – | See | |

| C90700 | alternative | CC483K – CuSn12-C | See | |

| C92200 | – | Tin bronzes | See | |

| C92700 | C92700 / C927 / CDA927 | CC480K – CuSn10-C | See | |

| C93200 | C93200 / C932 / CDA932 | CC493K – CuSn7Zn4Pb7-C | See | |

| C93600 | C93600 / C936 / CDA936 | – | See | |

| C93700 | C93700 / C937 / CDA937 | CC495K – CuSn10Pb10-C | See | |

| C93800 | C93800 / C938 / CDA938 | CC496K – CuSn7Pb15-C | Lead bronzes | See |

| C93900 | C93900 / C939 / CDA939 | – | Lead bronzes | See |

| C94100 | C94100 / C941 / CDA941 | CC497K – CuSn5Pb20-C | See | |

| C95200 | C95200 / C952 / CDA952 | CC331G – CuAl10Fe2-C | See | |

| C95400 | C95400 / C954 / CDA954 | – | Aluminium Bronzes | See |

| C95500 | C95500 / C955 / CDA955 | CC333G – CuAl10Fe5Ni5-C | See | |

| C95520 | C95520 / C955 / CDA955 | – | See | |

| C95800 | C95800 / C958 / CDA958 | – | Aluminium Bronzes | See |

| C95900 | C95900 / C959 / CDA959 | – | See |

This table organizes the ASTM B505 standards, lternative alloys, and the types of alloys, adding a “See” link for further details where applicable.

| ASTM B22 | Closest Alternative Alloys | Closest Alloys | Type of Alloy | Details |

|---|---|---|---|---|

| C86300 | – | High tensile brasses | See | |

| C90500 | – | Aluminium Bronzes | See | |

| C91100 | – | Tin bronzes | See | |

| C93700 | – | Lead bronzes | See |

This table neatly organizes the ASTM B22 standards, showing which types of alloys are associated with each, even though alternative alloy specifics aren’t listed here.

When selecting materials for sliding bearings, in addition to traditional copper alloys, a variety of additional alloys are available that offer distinct performance characteristics to meet the needs of specific applications. Here are some common additional alloys and their properties:

- CuSn7ZnPb (RG7): Also known as Leaded Tin Bronze, this alloy provides excellent mechanical performance and wear resistance. The addition of lead offers superior self-lubricating properties, making it suitable for high-load and high-speed applications.

- CuSn10: A bronze alloy with a higher tin content, offering increased hardness and strength, suitable for applications requiring high load capacity and wear resistance.

- CuSn12: This alloy contains 12% tin, providing enhanced wear resistance and corrosion resistance, making it suitable for bearing manufacturing in marine and chemical environments.

- CuPb10Sn: This alloy combines the advantages of lead and tin, providing good self-lubrication and high load capacity, suitable for heavy-load and shock-load applications.

- CuPb15Sn: An alloy with higher contents of lead and tin, offering excellent sliding performance and self-lubrication, suitable for bearings requiring excellent wear resistance.

- CuAl10Ni: Nickel Aluminum Bronze is favored for its excellent corrosion resistance and high strength, suitable for bearings and structural parts in marine and chemical environments.

- CuSn10Zn (RG10): This alloy combines the benefits of tin and zinc, providing good strength and wear resistance, suitable for high-load and high-speed applications.

- CuZn25Al5: Known as Aluminum Brass, this alloy is renowned for its high strength, good thermal conductivity, and corrosion resistance, suitable for applications requiring high wear resistance and reliability.

- CuSn5ZnPb (RG5): This alloy offers good sliding performance and self-lubrication, suitable for medium-load and speed applications.

When choosing an alloy, it is crucial to consider the specific requirements of the application, including load, speed, temperature, environmental conditions, and lubrication. These additional alloys provide a diverse range of options that can meet the demands of various industrial applications. By making informed choices and applying these materials appropriately, equipment efficiency and reliability can be significantly improved, extending their operational lifespan.

| EN 1982 | Replacement Alloy | Closest ASTM B505 Alloy | Type of Alloy | Details |

|---|---|---|---|---|

| CC330G – CuAl9-C | Aluminium Bronzes | See | ||

| CC331G – CuAl10Fe2-C | W-AlFe | C95200 | See | |

| CC332G – CuAl10Ni3Fe2-C | See | |||

| CC333G – CuAl10Fe5Ni5-C | W-AlNi | C95500 | See | |

| CC334G – CuAl11FeNi6-C | Aluminium Bronzes | See | ||

| CC480K – CuSn10-C | W-10 | C90700, C92700 | See | |

| CC481K – CuSn11P-C | Tin bronzes | See | ||

| CC482K – CuSn11Pb2-C | W-12Zn | See | ||

| CC483K – CuSn12-C | W-12 | C90700 | See | |

| CC484K – CuSn12Ni2-C | W-12Ni | See | ||

| CC491K – CuSn5ZnPb5-C | W-5 | C83600 | Tin bronzes | See |

| CC492K – CuSn7Zn2Pb3-C | See | |||

| CC493K – CuSn7ZnPb | W-7 | C93200 | See | |

| CC494K – CuSn5Pb9-C | See | |||

| CC495K – CuSn10Pb10-C | W-Pb10 | C93700 | See | |

| CC496K – CuSn7Pb15-C | W-Pb15 | C93800 | See | |

| CC497K – CuSn5Pb20-C | W-Pb20 | C94300 | Lead bronzes | See |

| CC499K – CuSn5Zn5Pb2-C | Lead bronzes | See | ||

| CC762S – CuZn25Al5Mn4Fe3-C | W-255 | C86300 | High tensile brasses | See |

| CC764S – CuZn34Mn3Al2Fe1-C | W-342 | C86200 | High tensile brasses | See |

| CC765S – CuZn35Mn2Al1Fe1-C | See |

This table organizes the EN 1982 alloy designations alongside their replacement alloys, closest ASTM B505 alloys, type descriptions where applicable, and provides a link for further details.

When selecting materials for sliding bearings, copper alloys stand out as an ideal choice due to their exceptional properties. CuZn25Al5, CuAl10Ni, CuSn12Pb, and CuSn7ZnPb are several commonly used bronze alloys, each with unique characteristics suitable for different application scenarios.

CuZn25Al5 (Aluminum Brass) The CuZn25Al5 alloy is renowned for its high strength, excellent thermal conductivity, and corrosion resistance. The addition of aluminum increases the hardness and strength of the alloy, while zinc provides extra corrosion resistance. This alloy’s sliding layer can withstand pressures of about 25-30% (N/mm²), making it an ideal material for sliding bearings in heavy-load applications. Moreover, the high thermal conductivity of aluminum brass aids in heat dissipation, which is crucial for maintaining the stability of bearings during prolonged operation.

CuAl10Ni (Nickel Aluminum Bronze) The CuAl10Ni alloy contains a higher proportion of nickel, which significantly enhances the alloy’s corrosion resistance and strength. Nickel aluminum bronze performs particularly well in marine environments, making it frequently used in the manufacturing of bearings for ships and marine engineering equipment. Additionally, this alloy also has good sliding characteristics, suitable for applications requiring a low coefficient of friction.

CuSn12Pb (Lead Tin Bronze) The CuSn12Pb alloy is a classic bearing material, characterized by approximately 12% tin and a small amount of lead. The inclusion of lead endows this alloy with excellent sliding properties and self-lubricating characteristics, allowing it to maintain good performance under heavy loads and high-speed rotation. Lead tin bronze is widely used in various industrial machinery, automotive, and railway transportation equipment.

CuSn7ZnPb (Tin Zinc Lead Bronze) The CuSn7ZnPb alloy is a bronze containing tin, zinc, and lead, with a composition that can be adjusted according to the specific requirements of the application. This alloy has good mechanical properties and wear resistance, suitable for manufacturing bearings, bushings, and other components that require high wear resistance and reliability. Tin zinc lead bronze is particularly popular in the industrial and automotive sectors because it offers a long service life and stable performance.

When choosing materials for sliding bearings, it is essential to consider the specific requirements of the application, including load, speed, temperature, environmental conditions, and lubrication status. The aforementioned bronze alloys all have outstanding performance capabilities that can meet the needs of various industrial applications. By selecting and applying these materials appropriately, the efficiency and reliability of equipment can be effectively enhanced, extending its service life.

solid bushing, bronze with lubricant plugs embedded, DIN 1850/ISO 4379, Maintenance-free

Material Characteristics

- Bronze Alloy: Solid bronze bushings are usually made from special bronze alloys like CuSn7ZnPb (a tin, zinc, and lead-containing bronze), which offers excellent wear resistance and load-bearing capacity. The high copper content in the bronze alloy provides good thermal conductivity, aiding in heat dissipation and reducing heat generation from friction.

- Lubricant Plugs: A key feature of solid bronze bushings, these embedded plugs contain pre-filled solid lubricants, such as graphite or molybdenum disulfide (MoS2). These lubricants are gradually released over the lifespan of the bushing, providing continuous lubrication, reducing wear, and lowering friction.

Advantages of Maintenance-Free Operation

- Reduced Maintenance: Thanks to the pre-filled and slowly releasing lubricants, solid bronze bushings can operate for extended periods without the need for additional lubrication, thus reducing the frequency of routine maintenance.

- Increased Reliability: Maintenance-free bushings reduce the risk of failures due to insufficient lubrication, enhancing the reliability and performance of mechanical equipment.

- Extended Lifespan: Ongoing lubrication helps extend the life of both the bushings and other mechanical components, decreasing the frequency of replacements and associated costs.

Applications Maintenance-free solid bronze bushings are used across various industrial sectors, including but not limited to:

- Automotive Industry: For manufacturing steering knuckles, suspension systems, and engine components.

- Mechanical Engineering: Installed in pumps, fans, and other heavy machinery.

- Construction and Agricultural Machinery: Used in various construction and agricultural equipment for hinges, bearings, and sliders.

CAC301, CAC302, CAC303, CAC304, CAC701, CAC702, and CAC703 are designations for different grades of bronze alloys. These grades are typically used to specify the chemical composition and mechanical properties of the bronze material, which can vary depending on the intended use. Here’s a brief overview:

- CAC301: Known as common brass, it is often used for general applications where moderate strength and good corrosion resistance are required.

- CAC302: Similar to CAC301 but typically has a slightly different composition to alter properties like strength or machinability.

- CAC303: This grade might offer properties suited for specific forming processes or enhanced corrosion resistance compared to CAC301 and CAC302.

- CAC304: Often characterized by a different balance of elements to provide unique properties such as improved wear resistance or lower friction.

- CAC701, CAC702, CAC703: These grades are generally part of a different series or type of bronze alloys, possibly with higher tin content or special additives for applications requiring higher strength, better wear resistance, or superior corrosion resistance.

Each grade is tailored for specific applications ranging from general hardware, decorative items, to components in marine environments and heavy industrial machinery. The exact composition and properties can vary by manufacturer and specific industry standards.

Electrical Engineering: Serve as insulating and conductive components in motors and generators.

Maintenance Free, Bearing Bronze Components

In hac habitasse platea dictumst nam quam nunc, blandit vel, luctus pulvinar.