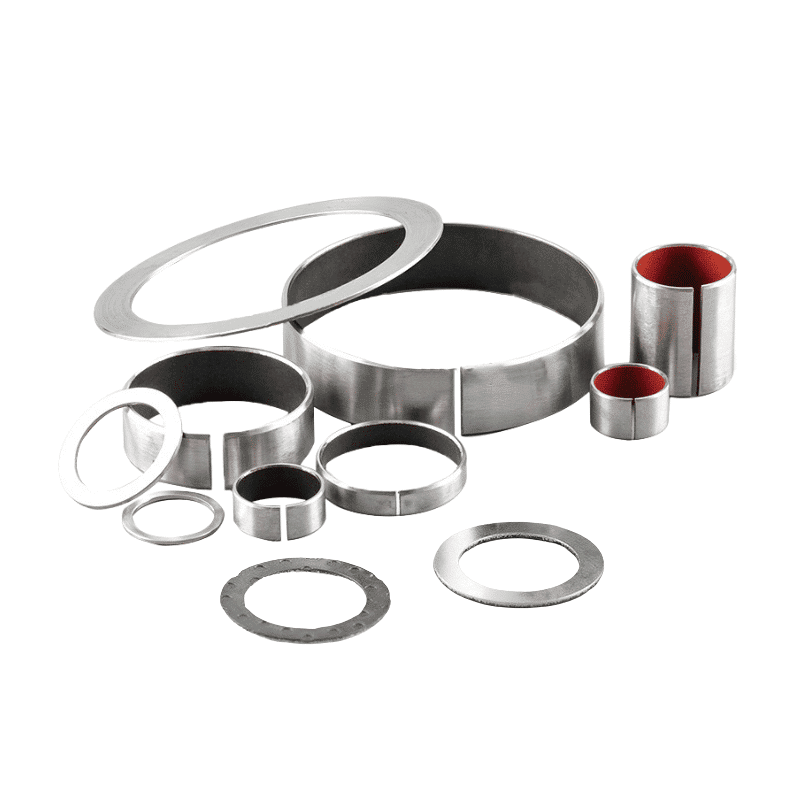

stainless steel (aisi 304) teflon bushing

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

stainless steel (aisi 304) teflon bushing

Shop Stainless steel bushings – bronzelube.com Official Site We develop & manufacture plain bushings & bearings for customer’s requirements.

Viiplus stainless steel (aisi 304) bushing help maximize your work while lowering your operating costs for your bearing solutions. Steel-Backed PTFE Lined Sleeve Bearings – METRIC AND INCH SIZE. Designed to be self-lubricating bushings they are rolled bushings composed of a steel backing, for structural strength, with bonded layers of sintered bronze bearings. PTFE slide bearings are carbon steel or bronze backed with a sintered bronze layer in the middle and an interior polytetrafluoroethylene (PTFE) layer, …

Browse & discover the stainless steel backed bushing available – Quote in 5 minutes, Teflon Bushing Solutions, On Our Official Site: www.bronzelube.com

Sed porttitor lectus nibh. Vivamus magna justo, lacinia eget consectetur sed, convallis.

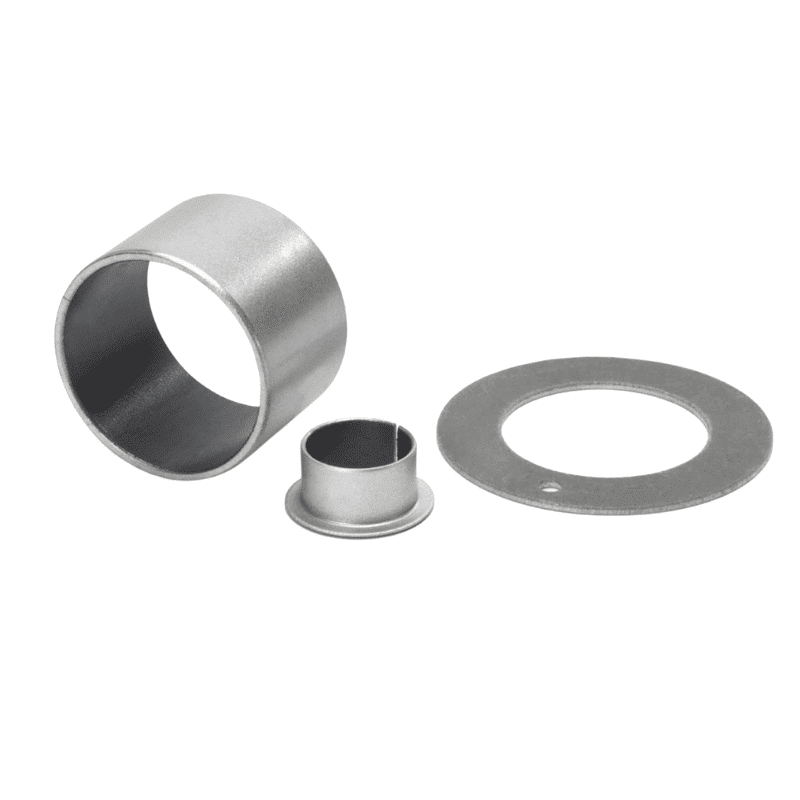

Quality Wrapped Steel Bushes, Steel/PTFE Sleeve Bearing, Stainless Steel Bushings – Custom Size Options

Stainless Steel Self Lubricating Bearing Structure: steel backing – porous bronze – PTFE. the role of each layer. Steel backing: assembly positioning and pressure bearing; porous bronze: connects plastic and assists in reducing friction; With low wear and excellent corrosion- and water-resistance, plain and flanged wrapped steel bushes are affordable and highly effective. Browse Stainless Steel Bushings Now!

High performance bushing bearing materials

PTFE layer acts as a wear-resistant and self-lubricating layer. Features: oil-free self-lubrication, low noise, thin-walled design, small structure, long-term wear resistance. It is a new type of bearing to replace needle roller bearings, powder metal bearings and copper alloy bearings.

Maintenance-free solution

Factory Highlights: High-end equipment production; strong automatic production capacity; small tolerance of product wall thickness; high precision of product formulation and advanced technology; Experienced Manufacturer Manufacturing Sliding Bearing, Call Our Team of Experts

Quality Guaranteed

Quality and Innovation, Stainless Steel Sleeve Bushing Quality Guaranteed Worldwide On-time Shipping, Working condition simulation test can be conducted according to customers’ requirements. Choose from our selection of stainless steel bushings in a wide range of material and sizes. In stock and ready to ship.

Bushing Bearing Selection

316 stainless steel bushing – Complete Specification, Slide Bushing (Standard Type), Get Special Offers & Savings

Stainless Steel Sleeve Bushings & Thrust Washer Bearing Wholesale Suppliers Online

Experienced Stainless steel PTFE bushing sleeve Manufacturer & Supplier in China. Guaranteed Top Quality & Service. Wholesale stainless steel bushing bearing directly from China, cost-competitive, short delivery time. Contact now Get a quote. 316 stainless steel bearings: Type 316 stainless steel is austenitic chromium nickel stainless steel and heat resistant steel with superior corrosion resistance compared to other chromium nickel steels when exposed to many types of chemical corrosion such as sea water, brine solutions and the like.

Is your equipment Stainless steel Bearing Bushing rusty?

The bushings, if rusted, will cause the bearings to run stuck and also affect the positioning accuracy and even greatly affect the life of its bearing equipment as well. In fact, a metal part in another metal part on the smooth movement, lubrication is necessary, commonly used is lubricating oil and grease. Without these lubricating substances or without regular relubrication, the system will fail. Grease, however, does keep metal bearings running properly, but it can also be extremely troublesome in many applications. Grease on the operator’s fingers is one thing, grease in the surrounding environment is another. In the production and packaging of food or pharmaceutical products, in clean rooms where highly sensitive chips are produced, as well as in the medical technology sector and in the paper industry, lubricating grease is seen as contamination rather than an unavoidable harmful substance. A hundred attempts have been made to solve this problem.

Plain Bearings & Gear Bearings – Low Friction Bearings flange Bushing

Metal self-lubricating bearing plain bearing: Plain bearings made of high-performance metal oil-free bearings can solve the conflict between lubricating grease and a hygienic and clean environment. This self-lubricating bearing already has a solid lubricant built into the manufacturing process, so no additional external lubrication is required.

Bushing with solid lubricant: From a technical point of view, self-lubricating bearings can also meet the high requirements of precision and hardness, so a lubrication-free self-lubricating bearing solution is perfectly feasible and also helps prevent unnecessary lubricating grease from polluting the environment. If you’re still busy with rail descaling and maintenance, it’s time to make a change! Replace with stainless steel self-lubricating bearings

Find the right plain bearings for your application

Selecting the Right Stainless Steel Bushing. Shop a large range of lead free stainless steel backed bushing plain bearing at Bronzelube.com China Industrial Supply. Bronzelube.com Industrial supply is here to support all your metal bushings and maintenance repair needs. Innovative metal composite thrust bearings containing Teflon continue to expand the diversity of bearing materials, providing the industry with a complete range of high-performance, maintenance-free, oil-free bearing solutions, from spacecraft to new energy vehicles.

Ease of maintenance is another key benefit of stainless steel bushings. Unlike other types of mechanical components, stainless steel bushings do not require frequent oiling or lubrication, which saves time and money. Bearings maintenance is vitally important to your machine performance, cost and uptime.

Providing a custom red PTFE bushings solution for Filling machine & Packing machine…

Stainless steel bushings are a perfect example of engineering excellence, blending strength, corrosion resistance, and durability. They have found their place in various industries, proving their worth time and again. By understanding their properties and ensuring proper maintenance, industries can ensure seamless operations and extend the life of their machinery.

Metric bearings and imperial DP4 plain bushings made to order: Standard ptfe bushing forms in special sizes, half-bushings, stamped/deep drawn shapes, bearings with locating notches, lubricant holes and grooves, customized designs

DP4 low friction bushings offer good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

- Very good performance in lubricated applications

- Good performance in greased applications

- Suitable for linear, oscillating and rotating movements

Ready to growth your business?

Trust by Quality teflon bushing,We are fully engaged in the ptfe bushing industry and our service and support are of the same high standard. The outer cylinder of the standard-type sleeve bushing and the flange easily assemble, directly to the housing. reduce weight and cost! Bushing will be stainless steel based Lead free with a teflon liner!

Specialists in Stainless Steel Bearing Self Lubricating Bush

Beautifully crafted leather products.

Stainless steel bushings stand as a testament to the confluence of strength, durability, and corrosion resistance. Often an unsung hero in various machinery, these bushings play a pivotal role in ensuring smooth operations. Let’s embark on a journey to understand the significance, applications, and advantages of stainless steel bushings.

Specialists in Customized Metric & Inch Size, Customer bearing bushing! 316 stainless steel bearing corrosion resistance is better than 304 stainless steel, pulp and paper production process has good corrosion resistance. And 316 stainless steel is also resistant to marine and aggressive industrial atmospheres. Customized oil-free bearings

We manufacturing teflon stainless steel backed bushings tailored to your needs.

Stainless steel bearing and ordinary bearing difference

Stainless steel bearings and ordinary bearings are both used for various industrial and mechanical applications, but there are some key differences between them:

Material: Stainless steel bearings are made from a type of steel that contains chromium and other alloys that provide resistance to rust and corrosion, making them ideal for applications in harsh environments. Ordinary bearings, on the other hand, are typically made from carbon steel, which is less resistant to corrosion but less expensive.

Durability: Stainless steel bearings tend to have a longer lifespan than ordinary bearings due to their resistance to corrosion and rust. This makes them a good choice for applications where extended service life is required.

Load capacity: The load capacity of a bearing depends on its size and material, but in general, stainless steel bearings have a higher load capacity than ordinary bearings. This is because stainless steel has a higher yield strength than carbon steel.

Cost: Stainless steel bearings are typically more expensive than ordinary bearings due to the cost of the material and the manufacturing process. However, the increased durability and resistance to corrosion can offset this higher cost over the long term.

In summary, the choice between stainless steel bearings and ordinary bearings depends on the specific requirements of the application, including the environment, load capacity, and cost considerations.

The difference between stainless steel 316 bushings & stainless steel 304 bushings

Stainless steel bushings are commonly used in various applications due to their resistance to corrosion, durability and strength. However, there are different grades of stainless steel available for use in these bushings, and two of the most commonly used grades are 304 and 316. While both grades offer similar properties, there are some key differences between the two that may make one more suitable than the other, depending on the application.

Stainless Steel 304

Stainless Steel 304, also known as A2 stainless steel, is one of the most commonly used grades of stainless steel. It is an austenitic steel that contains a minimum of 18% chromium and 8% nickel, making it highly resistant to corrosion and rust. This grade of steel is also known for its good formability, making it easy to work with.

Stainless Steel 304 is widely used in various applications including construction, kitchenware, and medical equipment. It is also commonly used in the food and beverage industry due to its resistance to corrosion from exposure to food, salt and other substances.

Stainless Steel 316

Stainless Steel 316, also known as marine-grade stainless steel, is a higher grade of stainless steel than 304. It contains a minimum of 16% chromium, 10% nickel, and 2% molybdenum, making it even more resistant to corrosion and rust than 304. This makes it ideal for use in harsh marine environments and other applications where exposure to corrosive substances is high.

One of the main advantages of Stainless Steel 316 is its resistance to pitting and crevice corrosion, which can occur when stainless steel is exposed to salt and other corrosive substances. This makes it a suitable choice for use in marine environments and other applications where exposure to salt is high.

Differences between 304 and 316

The main difference between Stainless Steel 304 and 316 is their composition. Stainless Steel 316 contains molybdenum, which provides it with improved corrosion resistance over 304. Additionally, 316 also contains a higher nickel content, which further increases its resistance to corrosion.

Another difference between 304 and 316 is their overall strength. Stainless Steel 316 is generally stronger and more durable than 304, making it a better choice for applications where high levels of stress and pressure are present.

In terms of cost, Stainless Steel 304 is generally cheaper than 316. However, the added corrosion resistance of 316 may make it a better choice for applications where exposure to corrosive substances is high.

Conclusion

In conclusion, both Stainless Steel 304 and 316 are highly versatile grades of stainless steel that are commonly used in various applications due to their resistance to corrosion and durability. While both grades offer similar properties, there are some key differences between the two that may make one more suitable than the other, depending on the application. When choosing between 304 and 316 for a specific application, it is important to consider factors such as cost, strength, and resistance to corrosion.

Stainless Steel Self-Lubricating Bearings: The Future of Industrial Motion

Stainless steel self-lubricating bearings are a type of bearing that combines the strength and durability of stainless steel with the low-maintenance and friction-reducing benefits of self-lubrication. This innovative technology has revolutionized the world of industrial motion by providing a solution for applications that require reliable and efficient operation in harsh environments.

Traditionally, bearings have been lubricated with oil or grease to reduce friction and wear. However, this requires regular maintenance and can lead to contamination and increased friction in harsh environments. Self-lubricating bearings, on the other hand, are designed to continuously lubricate themselves without the need for external lubrication.

Stainless steel self-lubricating bearings are made of a composite material consisting of a metallic backing layer and a self-lubricating layer. The metallic backing layer provides strength and durability, while the self-lubricating layer, typically made of a polymeric material, releases lubricant under high loads and temperatures. This unique combination provides a low-friction and low-maintenance solution for demanding industrial applications.

One of the key benefits of stainless steel self-lubricating bearings is their ability to operate in harsh environments. The metallic backing layer provides resistance to corrosion, making these bearings suitable for use in harsh chemical and corrosive environments. Additionally, the self-lubricating layer provides consistent lubrication, even in high temperature and high load applications, reducing the risk of seizure and failure.

Another advantage of stainless steel self-lubricating bearings is their low maintenance requirements. Unlike traditional bearings that require regular lubrication, these bearings can operate for long periods of time without the need for maintenance. This not only saves time and resources, but it also reduces the risk of equipment failure, increasing reliability and reducing downtime.

In addition to their benefits in harsh environments and low maintenance requirements, stainless steel self-lubricating bearings are also highly efficient. The self-lubricating layer reduces friction and wear, improving the overall efficiency of the system and reducing energy consumption. This makes these bearings an ideal solution for high-speed and high-load applications, where traditional bearings may experience excessive wear and failure.

In conclusion, stainless steel self-lubricating bearings are the future of industrial motion. With their ability to operate in harsh environments, low maintenance requirements, and high efficiency, these bearings are revolutionizing the world of industrial applications. From the food and beverage industry to the aerospace and defense industries, stainless steel self-lubricating bearings are providing reliable and efficient solutions for demanding applications.

Stainless steel corrosion-resistant bearing

Stainless Steel Backing Bearing Bushing Structure:Stainless steel backed — sintered corrosion-resistant alloy powder—PTFE(lead free) Stainless steel self-lubricating bearings feature

- Oil resistance

- Acid resistance

- Alkali resistance

- Sea water resistance

- Wear resistance

Stainless Steel Backed Bushing Technical Parameters

Stainless steel rolled bushing is a very effective corrosion resistant bearing with stainless steel material as the substrate, sintered spherical bronze powder layer in the middle and rolled PTFE-based low friction material on the surface. It has the characteristics of oil resistance, acid resistance, alkali resistance, seawater resistance and wear resistance, and the PTEE material on the surface does not contain lead components. In the food and beverage machinery, printing and dyeing machinery, chemical machinery, marine industry corrosion-resistant sliding parts are most suitable for use.

- Maximum bearing pressure: 140N/mm2

- Applicable temperature range: -195~+280 degrees Celsius

- Maximum sliding speed: 2m/s

- Friction coefficient: 0.04~0.20

- Allow the highest PV value (dry): 3.6N/mm2 .m / s

- Allowed maximum PV value (oil): 50N/mm2 .m/s

High quality plain bearing PTFE lead free, Professional leader in high performance bearing solutions.

Environment-friendly “lead-free bearings”.Composite bearings, oil-free bearings, do not require any lubricant PTFE in all resins used, have excellent low friction characteristics, and also optimize the metal properties such as strength and dimensional stability. Lead free bushing characteristics: Bearing surface has such a low static and dynamic friction coefficient, the surface is smooth, no lubrication, in addition, the so-called stick-slip phenomenon is eliminated the bearing can also be used in oil. Operating temperature range from -200 to ~ ±280. Suitable for high load, impact load, intermittent operation and reciprocating operation. Bearing surfaces are highly resistant to most industrial chemicals and solvents, such as petroleum and alcohol. The bearing will not damage the surface of the engaging parts (shafts). Increase of service life The bearings are light and thin (3 mm thick), require small space, and allow for compact equipment design. Bearings minimize working noise.

Sed porttitor lectus nibh. Vivamus magna justo, lacinia eget consectetur sed, convallis.

Our capabilities include component design, self-lubricating material selection, prototype, production and manufacturing.

Self-lubricating metal-backed system for rigorous applications.

Custom Plain Bearings Components

Components manufactured to your exact specifications

Sliding Bearing Materials

Improve & extend the performance of plain bearing & bushings, Self-lubricating composite for high load, low speed applications.

Ask The Expert

Engineering assistance & self-lubricating material selection support.

Stainless Steel AISI 304 Teflon Bushings: A High-Performance Solution for Demanding

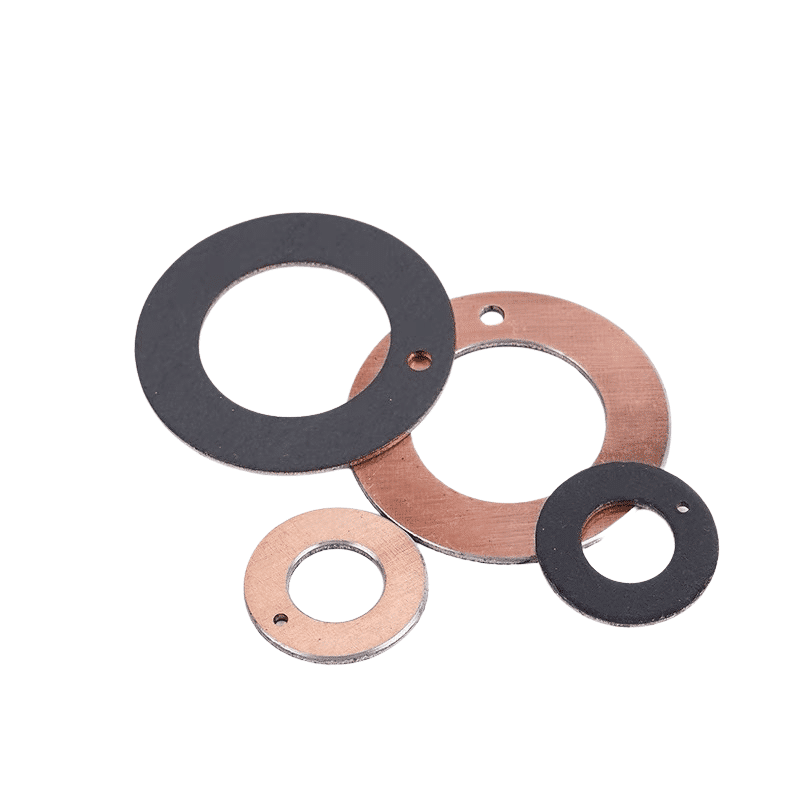

Stainless Steel AISI 304 Teflon Bushings with Red PTFE: A High-Performance Solution for Demanding Applications

Introduction

Stainless steel AISI 304 Teflon bushings with red PTFE lining are an innovative solution for applications that demand high performance, reliability, and durability. These bushings combine the excellent mechanical properties of stainless steel with the low friction and wear resistance of PTFE (Polytetrafluoroethylene), offering an ideal solution for demanding industrial environments.

Material Properties

Stainless Steel AISI 304 is one of the most widely used stainless steel grades, known for its excellent corrosion resistance, weldability, and formability. Its austenitic structure provides excellent mechanical properties, including high tensile strength and good resistance to pitting and crevice corrosion.

Red PTFE is a modified version of PTFE, a high-performance polymer with exceptional chemical resistance, low friction, and excellent wear properties. The red pigment is often added to improve visibility during assembly and maintenance. It also provides the material with an increased resistance to deformation under load, which is particularly important in high-pressure applications.

Benefits of Stainless Steel AISI 304 Teflon Bushings with Red PTFE

-

Corrosion Resistance: AISI 304 stainless steel offers excellent corrosion resistance, making these bushings ideal for use in environments where exposure to moisture, chemicals, or corrosive agents is a concern.

-

Low Friction and Wear Resistance: The red PTFE lining provides a low coefficient of friction, reducing energy consumption and extending the service life of mating components.

-

High Load Capacity: Stainless steel AISI 304 Teflon bushings with red PTFE can withstand high loads due to the combination of the mechanical strength of stainless steel and the load-bearing capabilities of PTFE.

-

Wide Operating Temperature Range: These bushings can operate effectively in a wide temperature range, from cryogenic temperatures up to 260°C, making them suitable for various applications.

-

Chemical Resistance: Both stainless steel AISI 304 and PTFE exhibit excellent chemical resistance, allowing these bushings to be used in aggressive chemical environments without degradation.

-

Ease of Installation and Maintenance: Stainless steel AISI 304 Teflon bushings with red PTFE are easy to install and require minimal maintenance due to their self-lubricating properties.

Applications

Stainless steel AISI 304 Teflon bushings with red PTFE are suitable for a wide range of applications across various industries, including:

- Food and beverage processing equipment, where hygiene and corrosion resistance are critical

- Chemical processing and pharmaceutical equipment, due to their excellent chemical resistance

- Marine and offshore equipment, where corrosion resistance and durability are essential

- Automotive components, for reduced friction and wear resistance

- Aerospace components, for their high load capacity and wide operating temperature range

Conclusion

Stainless steel AISI 304 Teflon bushings with red PTFE offer a high-performance solution for demanding applications that require corrosion resistance, low friction, and durability. By combining the strengths of stainless steel and PTFE, these bushings provide an effective solution for industries seeking reliable and efficient components.

Lead-free advantage

“Lead-free” is not an absolute ban on the existence of lead, but the lead must be reduced to less than 1,000 parts per million (<0.1%), and means that electronics manufacturing must meet the requirements of the lead-free assembly process.” Electronic lead-free” is also commonly used to refer to the content of six toxic and hazardous materials, including lead, which must be controlled within the level of 1,000 parts per million.

Lead-free materials generally perform better in oscillation conditions, particularly in conditions of high amplitude, low-frequency oscillation.

Lead-free plain bearing advantages

- The mixture of PTFE and fiber can form a good transfer film to protect the grinding shaft when moving.

- It is harmless to humans because it does not contain lead.

- It has good load-bearing capacity and wear resistance.

- Copper and steel plates have good thermal conductivity.

- The coating on the surface has good corrosion resistance.

Lead-free plain bearing application

Stainless steel bearing is widely used in strong acid and alkaline situations, such as chemical industry, pumps, and valves.

In addition to widely used in general machinery, the lead-free bearing is especially suitable for food machinery, pharmaceutical machinery, tobacco machinery, lead-free effect in line with European environmental protection requirements, is the development direction of oil-free sliding bearings.

- Run Dry Bushing and Keep on Running

- Thousands of Pumps Bushing

- Pumps Fitted with PTFE /POM Wear Parts Design

- Pump bushings

- For pumps that may run dry or accidentally flash, Bronzelube.com offers a self-lubricating composite bearing and worn part surface to protect the pump from multiple types of failure. In addition, the use of self-lubricating bearings can be designed to be closer to the clearance, helping to reduce vibration and generally improving seal life.

- Graphite bushing copper bushing is a graphite/metal alloy, with vibration reduction, no wear, corrosion resistance, dimensional stability and other advantages. The use of graphite self-lubricating bearings reduces the cost of operation and maintenance.

- For more information about pump bushings and wear parts, please visit this page.

- Do you have a problem that needs to be solved immediately? Please call or email us. Or use our enquiry form to provide details of your application.

- We are dedicated to our customers and clients.

- Metal-Polymer Composite Bushing Material

- Steel Backed Bushing + Porous Bronze Sinter +

- PTFE + Fillers

| Property | Type 316 (S31600) | Type 316L (S31603) |

|---|---|---|

| Yield Strength 0.2% Offset psi MPa | 30,000 205 | 25,000 170 |

| Ultimate Tensile Strength psi MPa | 75,000 515 | 70,000 485 |

| Percent Elongation in 2 in. or 51mm | 40.0 | 40.0 |

| Hardness, Max. Brinell RB | 217 95 | 217 95 |

What’s the difference between 304 and 316 stainless steel?

316 STAINLESS STEEL VS 304

316 has many similar chemical and mechanical properties to 304 stainless steel. To the naked eye, both metals look the same. However, the chemical composition of 316, which consists of 16% chromium, 10% nickel and 2% molybdenum, is the main difference between 304 and 316 stainless steel.

304 and 316 are both types of stainless steel, which are commonly used in a wide range of applications due to their excellent corrosion resistance and durability.

The main difference between 304 and 316 stainless steel is their chemical composition. 304 stainless steel contains 18% chromium and 8% nickel, while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum.

The addition of molybdenum to 316 stainless steel gives it improved corrosion resistance, especially in environments with high levels of chloride, such as coastal regions and areas with saltwater exposure. This makes 316 stainless steel a popular choice for marine applications and other industries where corrosion resistance is critical.

In addition, 316 stainless steel has higher tensile strength and is more heat-resistant than 304 stainless steel, making it suitable for applications where high temperatures and/or high stresses are expected.

However, 304 stainless steel is generally less expensive than 316 stainless steel, making it a more cost-effective option in some applications where corrosion resistance is not the primary concern.

Overall, the choice between 304 and 316 stainless steel will depend on the specific application requirements, such as the environment, temperature, and stress levels.

Maintenance-free plain bearing bushing solutions.

Find out how the bearing solution you need! Most extensive range of high performance, maintenance-free plain bearing solutions! DP4 bushing suitable for dry running with low coefficient of friction, low wear rate, good sliding characteristics, the transfer film created will protect the mating metal surface. Suitable for rotary and oscillating movements, high chemical resistance, lower water absorption and reduced swelling.

Low Friction Bearings Self-lubricated Steel Backed PTFE Bushes

Stainless Steel Sleeve Bearings Products & Suppliers

Stainless Steel Plain Bearing,We’re here to help!

Always tested. Always proven. Always Bronzelube.com, These bushings are made of stainless steel for corrosion resistance. Choose from our selection of stainless steel bushings in a wide range of styles and sizes.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.