bearing alloys

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

bearing alloys

high performance Bearing Alloy

Bearing alloys are materials used to make bearings, which are mechanical components that reduce friction between moving parts. Bearings are essential components of many machines, from simple devices such as bicycles to complex machinery such as airplanes and power plants. Bearings can be made from a variety of materials, including metals, plastics, ceramics, and composites. Among these materials, bearing alloys are some of the most commonly used.

high performance sleeve bearings

bearing

Alloy Material

Bearing alloys are typically composed of two or more metals, such as copper, tin, lead, and zinc. These metals are chosen for their ability to resist wear and corrosion, as well as their ability to provide good friction properties. The specific alloy composition will depend on the intended application of the bearing, as different alloys have different properties. High-performance flanged sleeve bearings are a type of bearing used to support rotating shafts and reduce friction between the shaft and the surrounding machinery. These bearings are typically made from materials such as bronze, brass, or steel, and are designed to withstand high loads and speeds. To ensure high performance, flanged sleeve bearings must be properly installed and maintained. This includes regular lubrication, monitoring for wear and damage, and proper alignment of the shaft and bearing. High-performance straight sleeve bearings are a type of bearing designed to provide efficient and reliable support for rotating shafts. They are typically used in heavy-duty applications such as industrial machinery, turbines, and automotive engines.

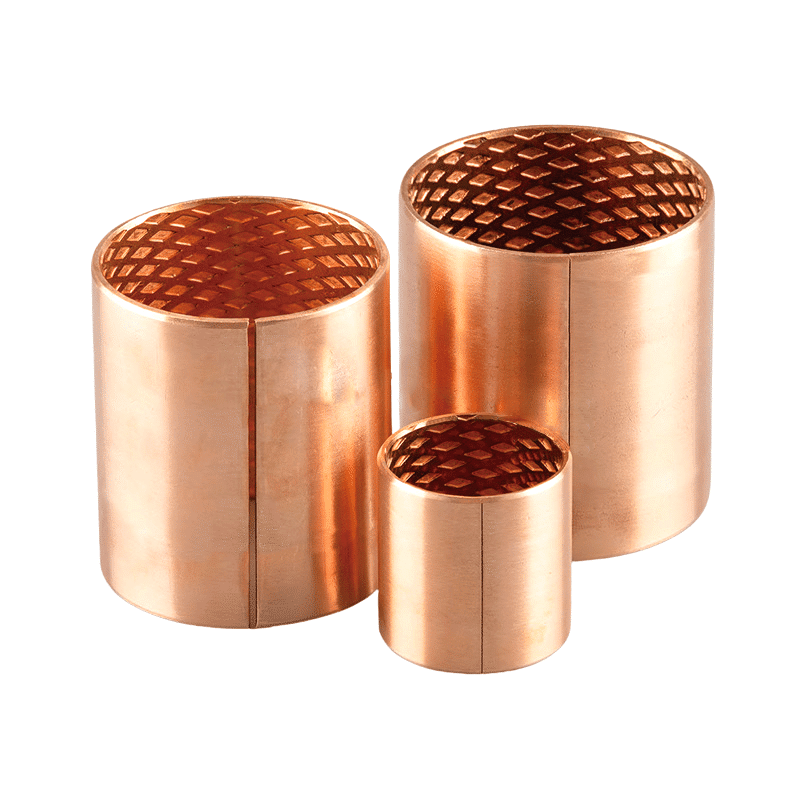

Bimetallic bearing bushing

Bimetal Bearing

Alloy layer

Another commonly used bearing alloy is bimetal, which is an alloy of bronze, and steel. Bimetal is softer than bronze, which makes it a good choice for bearings that operate at lower speeds and lower loads. Bimetal also has good conformability, which allows it to adapt to the shape of the shaft it is supporting. This helps to reduce friction and wear between the bearing and the shaft. Lead-based bearing alloys are also used in some applications. These alloys typically contain lead, tin, and copper, and they have good wear resistance and good friction properties. However, lead-based alloys can be toxic, which limits their use in certain applications.

In addition to the metals used in the alloy, the microstructure of the alloy can also affect its properties. For example, the size and distribution of the metal grains in the alloy can affect its strength, toughness, and wear resistance. The heat treatment and processing of the alloy can also affect its properties.

high performance sleeve bearings

bushing Bearing

Alloy Material

Bearing alloys are important materials that play a critical role in the performance of many machines. The choice of alloy will depend on the specific application, as different alloys have different properties. However, common factors such as wear resistance, corrosion resistance, and friction properties are important considerations for all bearing alloys. As technology advances, new alloys and processing techniques may be developed that further improve the performance of bearings, leading to more efficient and reliable machines. In addition to their durability and performance characteristics, flanged sleeve bearings are also preferred for their ease of installation and low maintenance requirements. They are commonly used in a variety of industrial applications, including machinery, automotive, and marine equipment. In addition to material selection, proper lubrication is essential to ensuring optimal performance of sleeve bearings. Lubrication helps to reduce friction and wear, which can extend the lifespan of the bearing and prevent premature failure.

Other factors that can affect the performance of sleeve bearings include proper installation, alignment, and maintenance. For example, proper alignment between the bearing and the shaft can help to reduce vibration and noise, while regular maintenance can help to prevent contamination and ensure proper lubrication.

Batch order production reduce production cost

Slide-Bearing Alloys

The choice of the slide-bearing alloy depends on various factors, such as the application, load, speed, and temperature. The design engineer needs to select the appropriate material that can provide the desired performance and reliability while minimizing wear and tear.

about the company

Self-lubricating plain bearings

Self-lubricating plain bearings are designed to operate without the need for external lubrication, making them a popular choice in various industrial applications. They are made up of a composite material, typically consisting of a metal shell, a porous sintered layer, and a sliding layer. The sliding layer is impregnated with solid lubricants, such as graphite or PTFE (polytetrafluoroethylene), which provide the required lubrication during operation. Self-lubricating plain bearings offer several benefits, including reduced maintenance requirements, longer service life, and improved performance.

Product Quality Index

Energy Generation

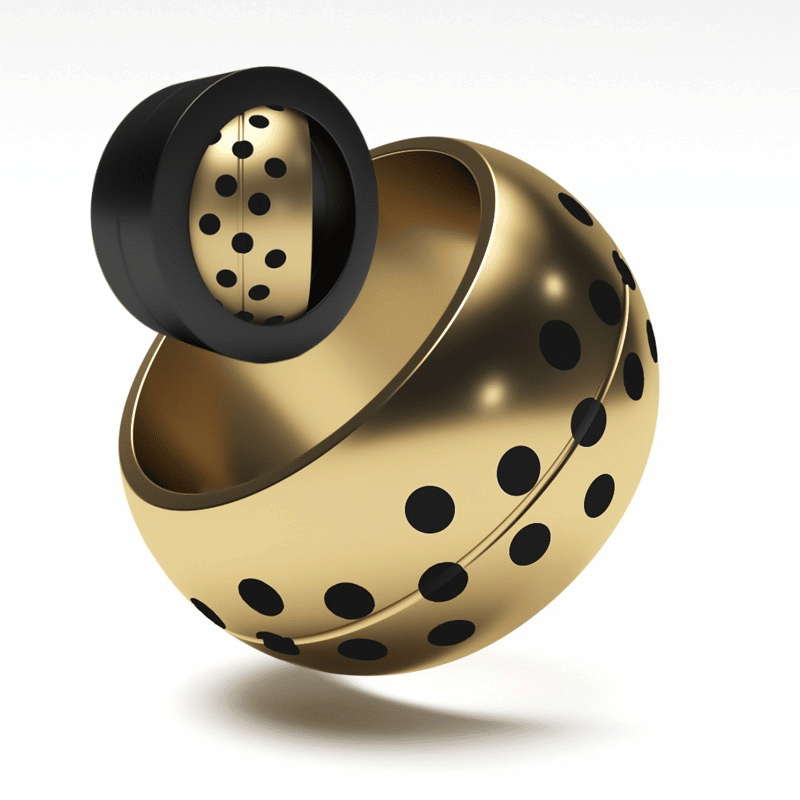

Graphite Plugged Bushings or Alloy Bearings

Graphite Plugged Bushings or Bearings are a type of self-lubricating bushings that are designed to perform well in heavy load, high temperature environments where standard lubrication is impractical or not feasible. These bushings are manufactured from a variety of bronze alloys, such as C95400 Aluminum Bronze Alloy, C93200 Bearing Bronze Alloy, and C86300 Manganese Bronze Alloy, which provide excellent wear resistance, strength, and durability. The unique feature of these bushings is the graphite plugs that are embedded within the bronze matrix. These plugs act as a solid lubricant, which allows the bushings to self-lubricate without the need for external lubrication. This makes them ideal for applications where access for maintenance is limited or where the use of external lubricants is not possible or practical. Graphite Plugged Bushings are suitable for use in a wide range of applications, including heavy machinery, construction equipment, automotive components, and agricultural machinery. They are capable of performing well under various types of loads, speeds, and operations and can resist corrosive and hostile environments. Moreover, they have excellent performance in medium to high-temperature applications, up to 600° F, which makes them a suitable choice for applications that involve exposure to high temperatures.

Self-lubricating Bushing Type. Maintenance-free. Tribologically Optimized.

Materials consist of highly wear-resistant copper and brass alloys with sliding surfaces that are uniformly equipped with solid lubricant deposits.

Choose Your Bearing Bronze Material / Alloy

Graphite Plugged Bushings are compatible with most viscous lubricants, oil, and grease applications, which makes them versatile and easy to use. They are also cost-effective, as they require less maintenance and do not require regular lubrication, which can reduce downtime and increase productivity.

C93200 Bearing Bronze

C95400 Aluminum Bronze

C86300 Manganese Bronze (solid lubrication inlaid bearings)

frequently asked questions

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

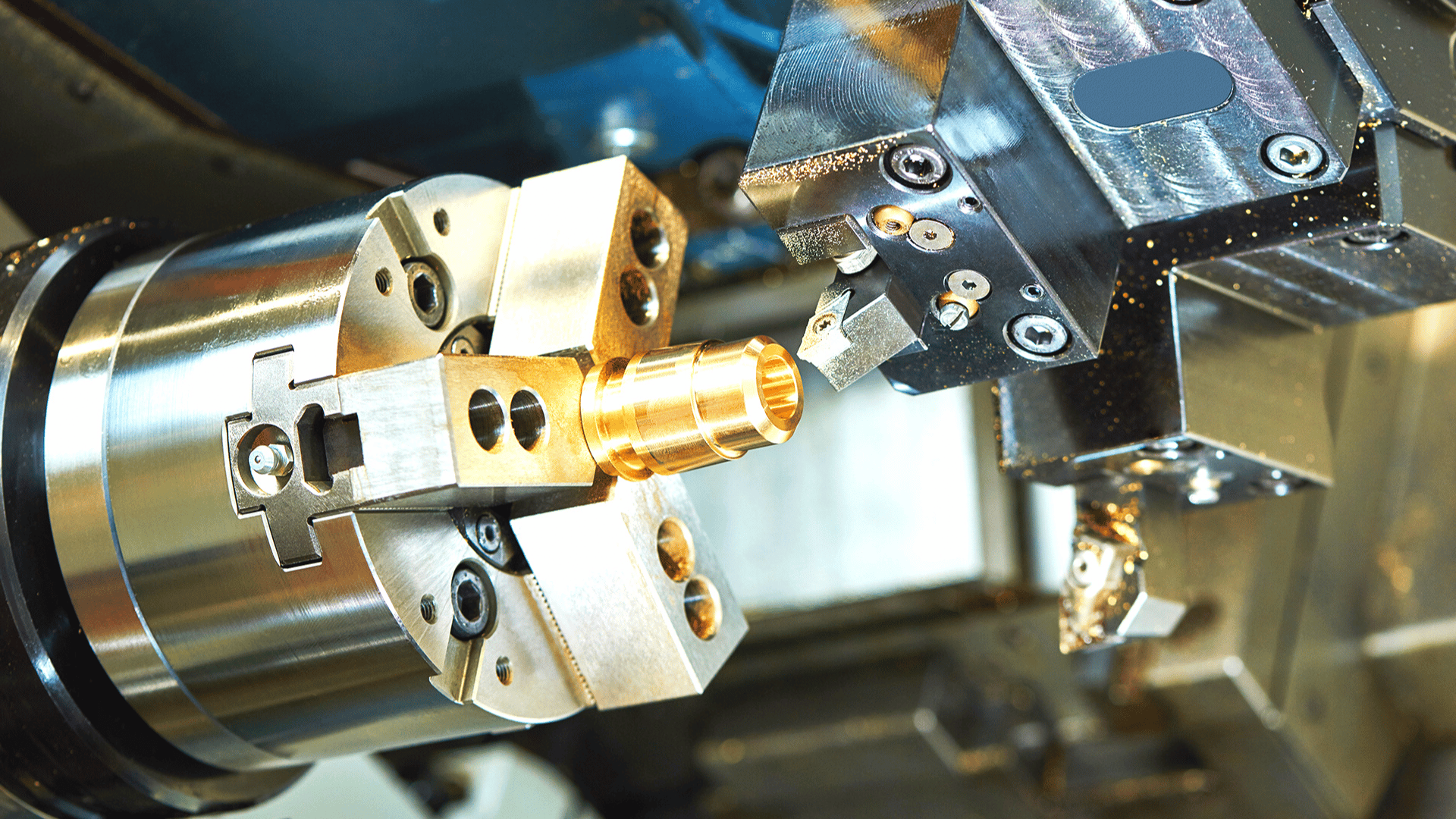

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.