Let’s keep downtime

to

a minimum.

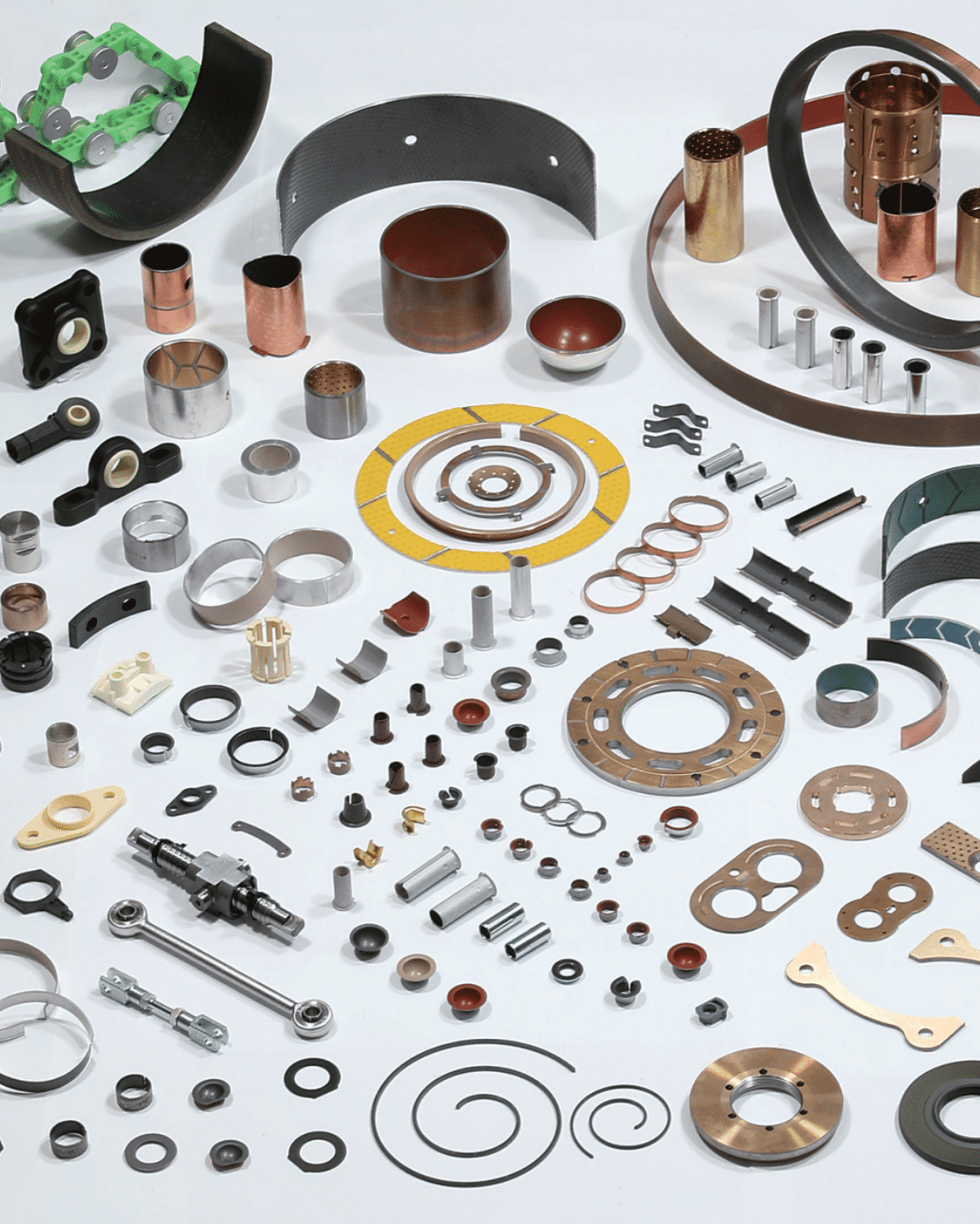

minimum.As a self-lubricating bearings manufacturing company that built our first customized bushing in a residential garage over 25 years ago, we understand the value of making bearing bushing the old fashioned way; by focusing on lubricated bearings quality, oilless bearing materials and design above all else, we’re able to offer finish custom bearing bushing that are completely unique to anything else on the tribology market.These aren’t your average service bearings. They’re not only self-lubricating, they’ll outperform in the harshest and high temperature resistance and they’re designed to survive decades of service with high load and high-performance, with their ability to be rebuilt over time.

Professional Bearings Service: Engineered for Superior Performance in Demanding Environments.

At bronzelube.com Design, we specialize in crafting self-lubricated bearings and bushing sliding plates to precise standards. Additionally, we offer comprehensive service support to technicians utilizing our products in the field.

Enhancing Your Efficiency: Our Commitment.

Why compromise?

You perfect bearing manufacturing design awaits.

We’re focused on reducing your total bearing life-cycle cost.

STANDARD & CUSTOM BUSHING

Ultimate in productivity. The best in small-volume bearing manufacturing self-lubrication bearings. You shouldn’t have to compromise. We take your productivity and efficiency seriously. Building the high quality bushing for the project is what we do. We offer many type of bushing for your markets. We’ve got a bearings solution for your custom size material and code type.

Bushing Type

Constantly challenging

industry expectations.

Metal & Bi-metal Bushing Type: Our precision bimetal bearing is key to reducing fuel consumption and emission values. At the same time, they extend maintenance intervals and service life, while also enhancing driving comfort and driving dynamics.

Custom-made. Bushing for Commercial Vehicles. Available in Various Size & Material. Specification: Customized Bushings. Bring the bearing store to your field. Custom Solutions!

Quality First Installation

Precision Bimetal Bearing for Engines in Passenger Cars and Commercial Vehicles. The promise of different types of bushes high quality, meet your requirement.

Metal & Bimetal Bearing

Components and Bimetal Bearing for Engines, Small minimum order value & quantity, fast delivery.

We are experts in all self-lubricating customized bearing bushings – why not leave the part of bearing materials and dimensions you set up to us? We look for often overlooked product features that are self-lubricating, maintenance-free, reduce downtime and smoothly complete your project with our in-house design, manufacturing and machining facilities.

Ready to take your business to the next level?

Superior Wrapped Bronze Bushing Quality: Satisfied Customers Are Our Top Priority

Wrapped Bronze Series Metric Bronze Bearings Type: Bronze Bushing Material: CuSn8P0.3 or CuSn6.5P0.1. Economic solution for bronze bearing type due to a thin wall thickness. Special bronze bushing dimensions and imperial sizes are available on request!

We Do Even More: Our Support Services, Online Design bronze flange bushings.

Yoga takes you into the present moment. The only place where life exists.

Bronze bearing is wrapped by bronze strip. The material is made of particular formulation with high specific gravity and on its surface may be incorporated with spherical or diamond shaped indentations or oil grooves as required by customers.It is of high load capacity and long life.It can act as substitution of traditional bronze bushing for low cost and performance of anti-higher compact.It is widely used in hoisting machines, construction machines, automobiles, tractors, trucks, machine tools and some mining industry.

Providing Plain Bushes and Oilless Bearing for Your Success

Custom Self-lubricating BearingSolutions for Demanding Technical Requirements. Your Bushing Type Development Partner. Types of bushes: Bushes, Cost-effective and durable, maintenance-free, Always tested. Always proven. Global website: www.bronzelube.com

25%

“Custom sleeve bearing experience what makes us different.”

Bushing design is a critical aspect of industrial and mechanical engineering, as the proper design of a bushing can significantly impact the performance and longevity of equipment. A bushing is a type of bearing component that is used to reduce friction and wear between moving parts, and to provide support and stability for rotary applications. In this article, we will take a closer look at the key elements of bushing design, including material selection, size, and shape.

Material selection

One of the most important aspects of bushing design is material selection. The material used for a bushing must be able to withstand the loads and conditions it will be subjected to in service, while also providing adequate lubrication to reduce friction and wear. Common materials used for bushings include bronze, steel, and plastic.

Bronze bushings are a popular choice for many applications, as they offer a good balance of strength and durability, while also providing excellent lubrication properties. Steel bushings, on the other hand, are often used in high-load applications, where their high strength-to-weight ratio is critical. Plastic bushings are used in applications where low weight and high-load capacity are important, and where the bushing will be exposed to corrosive environments.

Size and shape

Another important aspect of bushing design is size and shape. The size of a bushing must be carefully chosen to ensure that it can withstand the loads it will be subjected to, while also providing adequate support and stability. The shape of the bushing is also important, as it can impact its ability to reduce friction and wear, as well as its ability to accommodate changes in temperature and humidity.

There are several different types of bushings available, including flanged, sleeve, and thrust bushings. Flanged bushings provide additional stability and support for rotary applications, while sleeve bushings are cylindrical components that fit over a shaft. Thrust bushings are designed to handle axial loads, making them ideal for use in applications where movement is limited to a single axis.

Lubrication

Lubrication is another critical aspect of bushing design. A properly lubricated bushing will reduce friction and wear, helping to extend the life of the equipment and improve its performance. The type of lubrication used, as well as the frequency and amount of lubrication, will depend on the specific requirements of the application.

Conclusion

Bushing design is a critical aspect of industrial and mechanical engineering, as the proper design of a bushing can significantly impact the performance and longevity of equipment. By considering factors such as material selection, size and shape, and lubrication, engineers can design bushings that meet the specific requirements of their applications, helping to ensure that equipment runs smoothly and efficiently for years to come.

Self-lubricating Bearing Bushings Designs

The various bushing types, its designs, and materials are described in the following:

Select your bushing size

- PTFE composite bushings

- POM composite bushings

- Solid bronze bushings

- Split bronze bushings

- Plugged graphite bronze bushings

- Bimetal bearings bushings

Intentions are perfect. It started with customer needs and finally in customer satisfaction!

Quality – gaining confidence in the weight is the key to winning the competition, and is the starting point for infinite demand, value, and dignity.

Choose the bushing design material & environment

The most important factors to take into account when choosing the material and the surface finish of the counter surface on which the ring slides are the load conditions such as the load, the angle of oscillation, the type of movement and environmental influences.

If there is a risk of corrosion, the counter surface should be sufficiently resistant. Corrosion scars on the counter surface and, for example, abrasive particle contamination as a by-product of corrosion increase the surface roughness and accelerate wear. In these cases, the use of stainless steel or a surface treatment such as hard chrome, nickel plating, or electrolytic oxidation should be considered.

Related Self-lubricating Bearings Design PV value bearings

1、Definition Load Pressure P: Load pressure equals to the result gained by making the value of load pressure divide the vertical shade projected by the load-shouldering surface of the bushing (Unit N/mm2). Running Velocity V: Defined running velocity as the relative linear velocity against the mating surface (Unit: N/mm2). PV Value Define PV value as the result gained by multiplying the load value P and the velocity V (Unit N/mm2-m/s). Permissible PV value:Max permissible value shall be smaller than the value gained by multiplying the max permissible pressure and the max permissible velocity(Unit N/mm2-m/s).

2、Max permissible PV value The bushing can run for a short time when achieves its max PV value. It*s the running service ife requirement that decides the requirement for tbe value. In bushing design, we require that the max permissible PV value shall be smaller than the value gained by multiplying the max permissible load pressure and the max permissible running velocity;

Get your free quote!

MAINTENANCE SELF-LUBRICATING DESIGN BUSHING’S DIMENSION

1、Inside diameter of the bushing

The inside diameter of the bushing depends on the diameter of its mating axis.

2、Length of the bushing

The length of the bushing depends on the size of the pressure-shouldering surface.

The longer the bushing, the less pressure at the surface, for the longer bushing, the load on the bushing is relatively lessened- But simultaneously, it may result in deviation contact or lower cooling efficiency and thus shorten the service life of the bushing. On the contrary if the length of the bushing is too short, lubricating grease may quickly flow out of the bushing. Therefore, it hardly forms a grease film and capability of the bushing is accordingly debased.

3、Bushing thickness

The main advantage of standard composite self-lubricating bushings rest with their thin wall thickness.

Standard bushings thickness can be 0.5mm, 0.75mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm.

Self-lubricated Bushings Design Design of the Mating Axis

Surface roughness, hardness and plating of the mating axis will have great influence on the capability of the self-lubricating bushing. High-quality surface of the mating axis can prolong the life of the bushing while rough surface will shorten the life of the bushing.

1、Surface roughness of the mating axis When self-lubricating bushings being used in the condition of fluid lubrication and the surface of the mating axis is rough, the convex points on the bushing and its axis will cut the oil film and thus the surface of the axis and the bushing will directly contact with each other therefore, to improve the capability of the bushing, it requires polishing the surface of the mating axis as smooth as a mirror; thus can reduce the clearance of the oil film and make the film work well For most self-lubricating bushings applied in the condition of dry friction or marginal lubrication^ controlled roughness from 0.32 to 1.25 is acceptable and there is no need ta polish the surface of the mating axis as smooth as a mirror.

2、Hardness of the mating axis If there is no hard article in the lubricating condition, good performance can be achieved by using bushing materials and hardness recommended in the following form. If not, it would be better to use the harder material for the mating axis.

Self-lubricating Bushings Design

Interference for bushing fixing

With the exception of being burnt, the service life of self-lubricating bushing depends on the abrasion degree of the bushing’s inner diameter. In conditions like dry friction, boundary lubrication and oil lubrication, the abrasion of the same bushing will be different Main factors that may influence the service life are character and direction of the load, lubrication condition, running speed, environment temperature, hardness of the mating axis, roughness of the mating surface material of the mating axis, air quality around etc Therefore, it’s difficult to calculate the actual abrasion quantity. Regardless the factors like influence from the load and speed, difference caused by running direction, kinds of lubricating oil, mating clearance, roughness and impurities penetration degree, the abrasion W can be calculated by the following formula.

Related Bushing Type Design

Interference for bushing fixing

Before the bushing is pressed into the housing: as the outside diameter of the bushing is bigger than the inside diameter of the housing, strong pressure can be available in the housing. And also this kind of fixing can assure the roundness of the bushing and make the bushing well fixed avoiding abrasion caused by sliding of the bushing in the housing. The interference can be calculated by the following formula:

Min interference Min OD of the bushing-Max ID of the housing

Max interference Max OD of the bushing-Min ID of the housing

Related Self-lubricating Design

Calculation assembled diameter

After bushing mounting, providing that there is no expansion of the housing, the calculation can be carried out by the following formula.

Min ID of the bushing d=Min ID of the housing D-2 x Max thickness of the bushing

Max ID of the bushing d=Min ID of the housing D-2 x Min thickness of the bushing

Related Self-lubricating Bushing Type Design

Bushing fixing

Related Self-lubricating Bearings Design

Maintenance after assembly

For the first running after bushing was fixed the bushing shaM be worked under situations of light load and low speed, which will have the following benefits:

1) Smooth the surface of the bushing and its mating axis and smooth the partial convex part that shoulder load.

2) Rectify fixing tolerance caused by bushing deformation; smooth the surface and increase contact surface.

Related Self-lubricating Bearings Design

Bushing Store

Here are some situations in which self-lubricating and pre-lubricating bearings should be considered by a designer. The need to reduce maintenance or increase reliability is often encountered in practice. Inaccessible bearings in all types of equipment are ready candidates for self-lubrication, as are pieces of equipment in remote locations. By replacing metal bearings with self-lubricating bearings, substantial savings can be achieved. Likewise, self-lubrication can improve the useful life of equipment that should be neglected, such as consumer appliances.

Intentions, perfect. It began in customer needs, and finally customer satisfaction!

Quality – is to get the trust of weight is the key to winning the competition, is the starting point for endless most demand, value and dignity.

Related Bushings Design

Checking methods

We’re serious about keeping downtime to a minimum.

Tribology bearing service experience what makes us different.

If you need immediate assistance,

You can also send us an e-mail, or call us today! We want to hear from you.