Brass Bushing For Sale, Self-Lubricating Bearings – Extreme long lifetime, high temp bushings

About Us

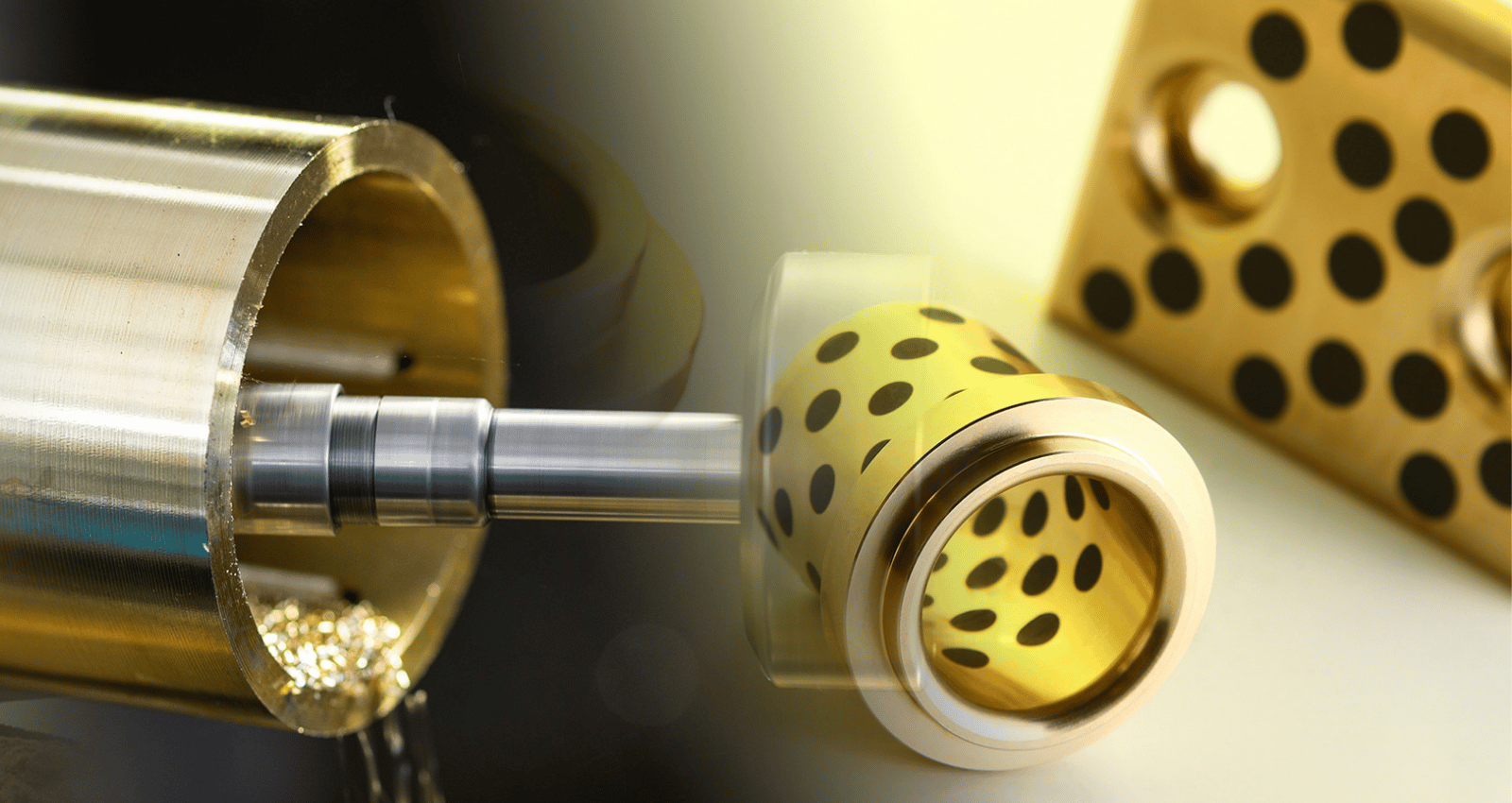

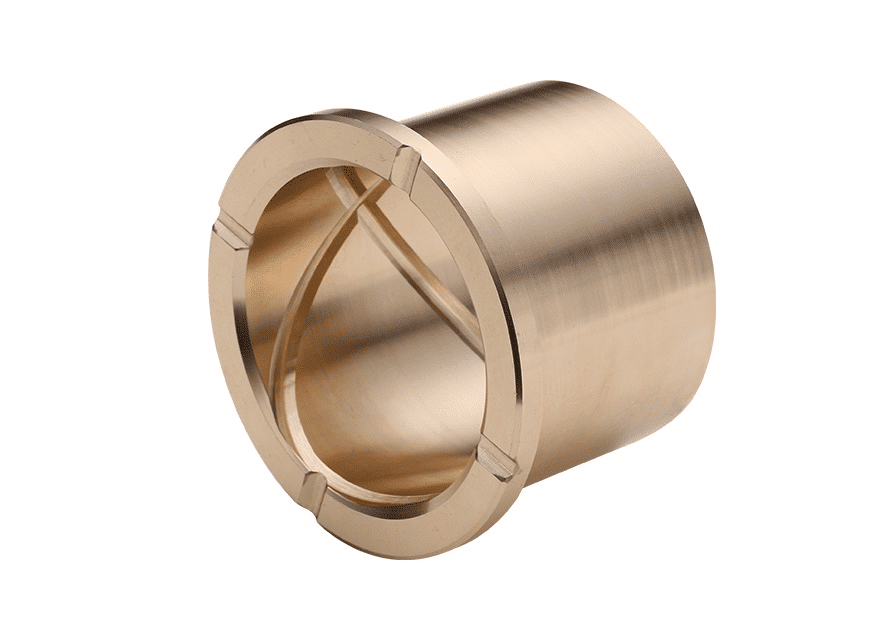

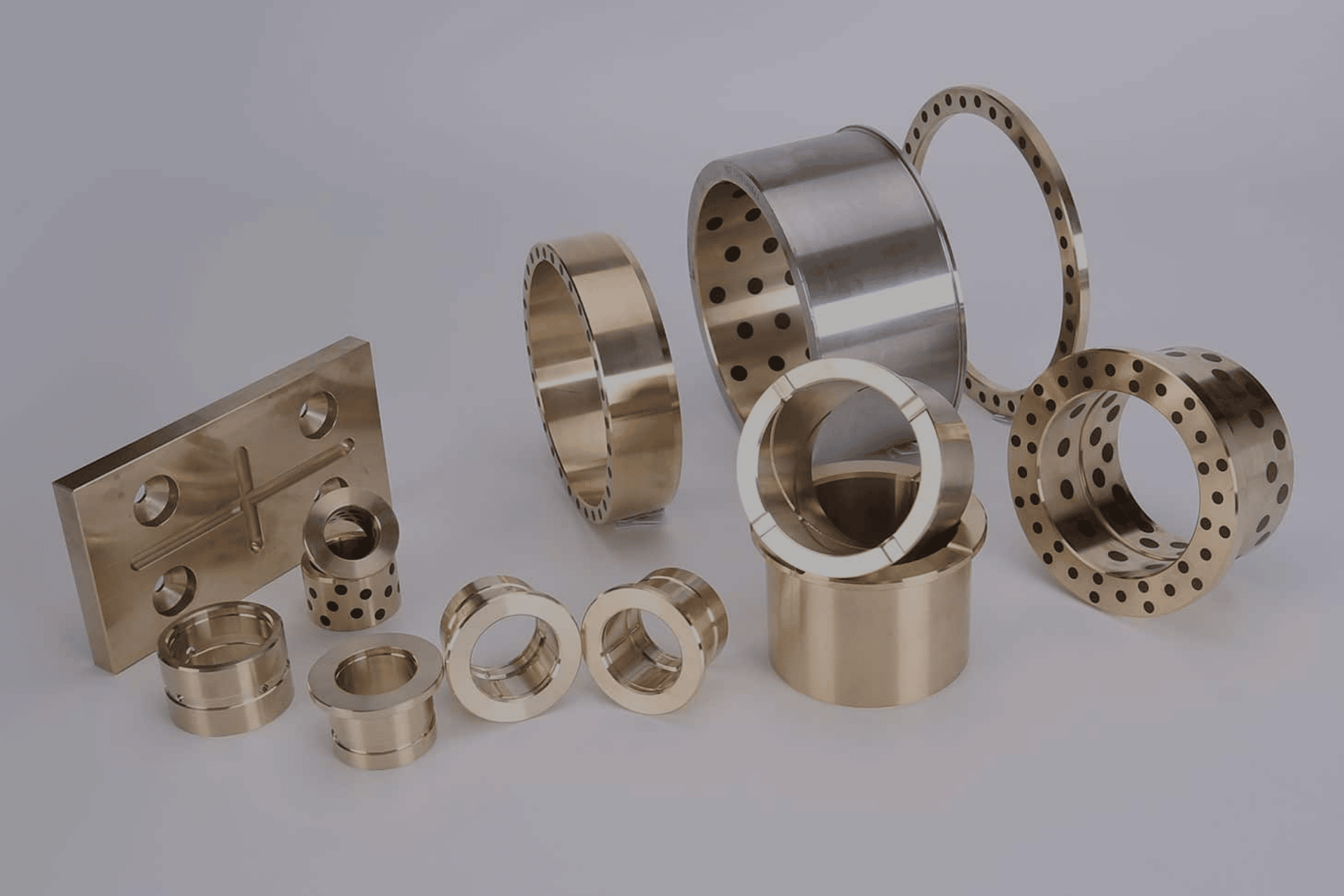

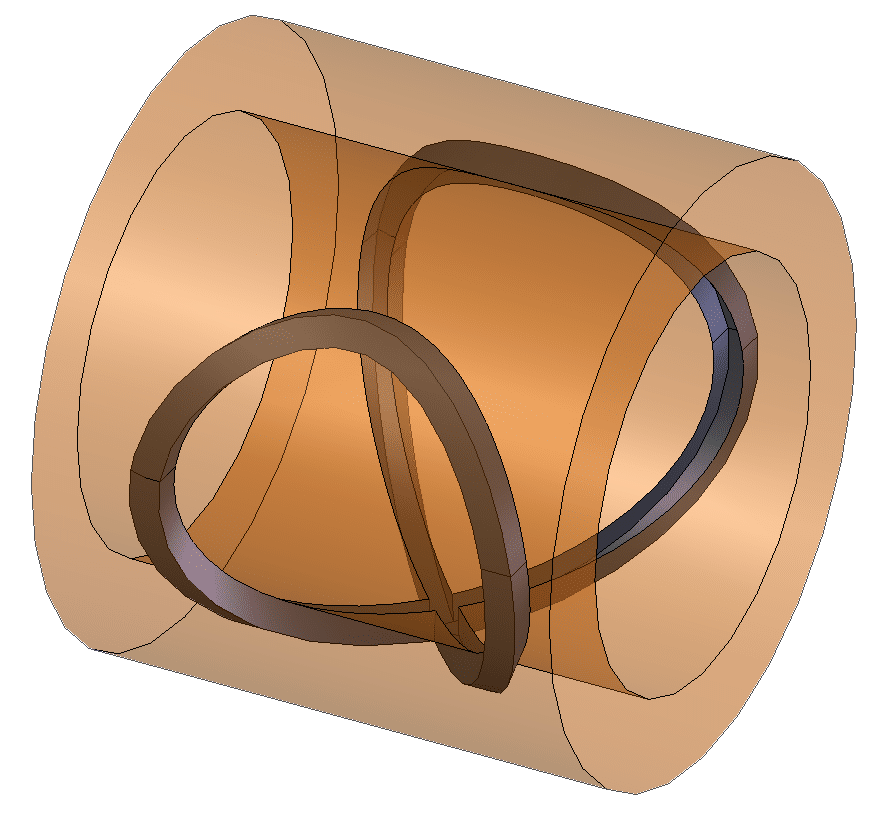

Oilless bushing with grease groove made of high tensile brass alloy. We are a customizable brass bushing manufacturer and supplier. Explore our selection of sleeve bearings, quick disconnect bushings, and flanged sleeve bearings online for industrial and scientific applications. Our maintenance-free, self-lubricating bearings are ideal for demanding applications in industries such as hydro power, oil & gas, wind energy, construction, and mining.

Custom Parts Services and Prototyping!

Leaded, Phosphor And Aluminium Bronze Bearing, Search Our Material Alloy

Innovative self-lubricating brass bearing solution for linear motion & automation, high temp bushings

Real-life strategy to reach your goals.

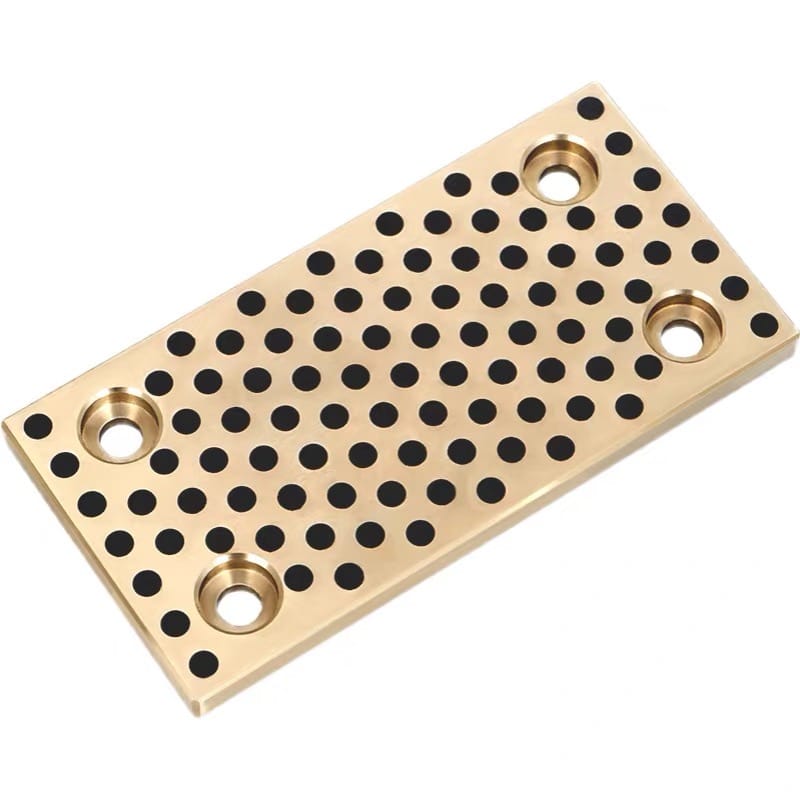

Brass Bushing and Slide Plate, The Brass Bearings for CNC Save Cost, Improve Reliability, maintenance-free operation and a very low noise level: these are the main strengths of viiplus brass bushing self-lubricating. These are plugged graphite and High load capacity,Brass bushing are used in a wide variety of applications, like water pumps to electric motors. We offers customizable brass bushing stock bushings to meet any needs. Oil Free Bushings With Oil Groove Volume Discount.

We strive for diversity across the globe

Self-lubricating bronze bushing for longer life – bronzelube.com

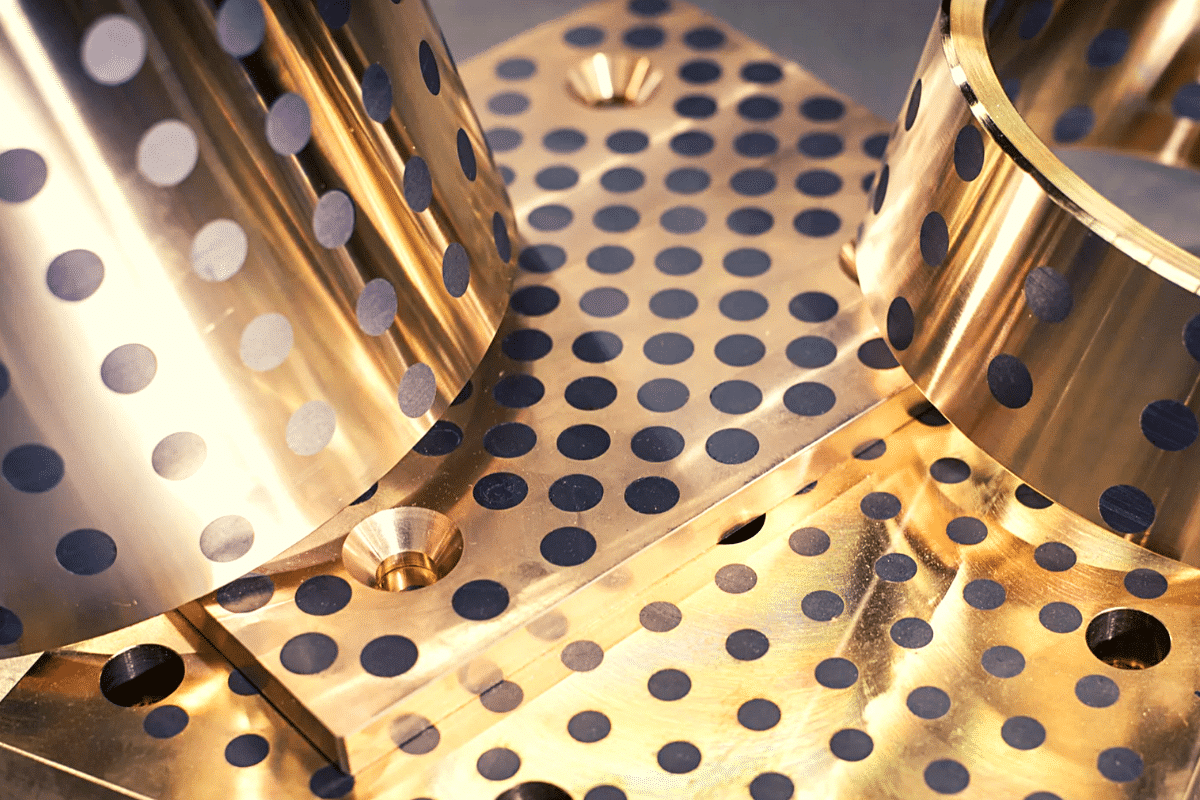

Graphite-plugged high tensile brass bushings bring a suite of benefits such as exceptional strength, durability, and self-lubricating features. The high tensile strength of the brass alloy ensures superior bearing and lubrication performance, making these bushings ideal for industrial uses that demand resistance to constant wear, pressure, and friction. The incorporation of graphite plugs within the bushings significantly diminishes the need for frequent maintenance, thereby prolonging their service life and recognized to savings in labor, downtime, and lubrication costs. Additionally, the synergy of high tensile brass and graphite plugs provides a remarkable load-bearing capability, resistance to corrosion, and efficient operation across a broad temperature spectrum. These bushings are widely utilized in several sectors, including the automotive, aerospace, heavy machinery, and industrial equipment industries.

Heavy Duty Self-lubricating Bearing and Brass Bushing, Our strong bearing bushing support and service network, both locally and internationally, enables us to work closely with the customer. This has made all the difference to our customers and sets viiplus apart from competitors.

Maintenance Free, Self-Lubricating Brass Bushing is the global recognized and well-known manufacturer of Maintenance-free, Self-lubricating Bearings for demanding applications. Our products stand out by high performance and advanced material technology and are suitable in demanding environments where temperature, corrosion or the demand for long lifetime are challenging. Are you looking for brass bushing for your applications? Brass bushings near me, brass bushings for sale, brass shoulder bushing and straight bushing, metric brass bushings and inch brass bushing.

Oil Free Bushings – Standard / Thin Wall, I.D. E7 O.D. r6

Our Expert is extremely qualified to help your business grow, can solve your challenges

What’s your challenge? Every new customer need is an opportunity to tackle a new challenge. Let’s learn from each other and join forces to advance progress – through ingenuity, vision and teamwork – for a world in constant motion and keep it moving with viiplus. We ensure your success.

Graphite Impregnated

Brass Bushing

Plain & Self-Lubricating Bearings(Bushing Material:Graphite Impregnated Brass)The most standard type in the Copper Alloy series. self-lubricating bearings are used in various applications, such as wind, oil-and gas, hydro power, steel production, mining and construction machinery.

Self-Lubricating Brass Bushing

Sleeve Brass Bearings,Graphite Bush

Improves automation, Brass Bearing with different configurations and sizes. Available with flange, straight or thrust washer, slide plate for different precision and requirements. Graphite brass bearing or wear plate for different load capacities and critical environments.

Oil Free Brass Bushing

– Brass Alloy, Straight, and brass shoulder bushing

Shop Bushing Material Graphite Impregnated Brass – Plain & Self-Lubricating Bearings at bronzelube.com, Material: High Tensile Brass Alloy. Solid Lubricant Embedded Bearings. Maintenance Free, Self-Lubricating Bearings Highly wear resistant bronze cast alloys equipped with 20%~25% solid lubricant plugs.

Bronze Composition: C86300 Brass Bushings Solid Lubricant Plug- Reduce Costs, high temp bushings

C86300 High Strength Brass Bushing is a copper based oilless self-lubricating brass bearing for heavy load applications into which solid lubricant plugs are embedded. Bushing Inner Diameter: 8 to 160 mm), Flange Solid Lubricant Plug self-lubricating brass bearing (Bushing Inner Diameter: 8 to 120 mm) for General industrial machinery and heavy industrial facilities. Manganese bronze bushings, ZCuZn25Al6Fe3Mn3 Similar or Equivalent Specification. Other Brass bushing material ZCuSn6Zn6Pb3, CuSn5Zn5Pb5, CuZn25Al5, Standard Bronze Alloys. Maximum working temperature depends upon the properties of the bronze alloy.

- d8: For General Use (High Load)

- e7: For General Use (Light Load)

- f7: For High-precision Use

Bushings & Brass Bearings – Sleeve, Flange, Thrust, high temp bushings

Real-life strategy to reach your goals.

Customer specifications dictate the way we think and act; that’s why we offer a wide range of innovative and performance-based self-lubricating brass bearing products and plain brass bushing bearing materials that allow for a high degree of individual customization. Designed starting from your specific needs. Different configurations available and different brass material for any application. Choose from our selection of brass bushings in a wide range of styles and sizes. In stock and ready to ship.

Self-lubricating High tensile brass bushings, ALLOY: C86300 Manganese Bronze Bushing – The High Tensile Brass Bushing You Need

When it comes to industrial machinery, having the right parts is crucial for maintaining optimal performance and preventing costly downtime. One such important part is the bushing, which helps reduce friction and wear between two moving parts. Among the different types of bushings available, the ALLOY: C86300 Manganese Bronze Bushing stands out as a high tensile brass bushing that offers exceptional strength, durability, and wear resistance.

What is ALLOY: C86300 Manganese Bronze Bushing?

ALLOY: C86300 is a type of Manganese Bronze, which is a high-strength alloy of copper, zinc, and small amounts of iron and manganese. This material is known for its outstanding tensile and yield strength, excellent wear resistance, and high corrosion resistance. Manganese Bronze is often used in heavy-duty applications where reliability and durability are crucial, such as in marine equipment, construction machinery, and mining equipment.

The ALLOY: C86300 Manganese Bronze Bushing is a type of bushing made from this high-strength alloy. It is specifically designed to handle heavy loads and provide long-lasting performance even in harsh environments. The bushing is self-lubricating, which means that it does not require additional lubrication to function properly. This feature makes it ideal for applications where maintenance and lubrication are difficult, time-consuming, or impossible.

Why Choose ALLOY: C86300 Manganese Bronze Bushing?

ALLOY: C86300 Manganese Bronze Bushing offers several advantages over other types of bushings. Firstly, it is highly resistant to wear and corrosion, which means that it can withstand heavy loads, high temperatures, and exposure to moisture, saltwater, and chemicals without degrading or failing prematurely. Secondly, it has excellent dimensional stability, which means that it maintains its shape and size even under extreme pressure and temperature. This feature ensures that the bushing fits snugly and securely in the housing, preventing unwanted movement or vibration. Finally, it is easy to install and replace, which means that it can be quickly and easily swapped out without requiring special tools or equipment.

Applications of ALLOY: C86300 Manganese Bronze Bushing

ALLOY: C86300 Manganese Bronze Bushing is widely used in a variety of heavy-duty applications where high strength, durability, and wear resistance are critical. Some common applications include:

- Marine equipment such as propeller shafts, stern tubes, and rudder bearings

- Construction machinery such as excavators, loaders, and bulldozers

- Mining equipment such as crushers, conveyors, and ball mills

- General industrial machinery such as pumps, valves, and gearboxes

If you need a high tensile brass bushing that can handle heavy loads, high temperatures, and harsh environments, ALLOY: C86300 Manganese Bronze Bushing is an excellent choice. Its outstanding strength, durability, and wear resistance make it a popular choice for a variety of heavy-duty applications. So why settle for anything less when you can have the best? Choose ALLOY: C86300 Manganese Bronze Bushing and enjoy reliable, long-lasting performance that you can count on.

High tensile brass bushings are an important component in various industrial applications, where they are used for bearing, lubrication and corrosion protection. These bushings are made from a high-quality brass material that is known for its durability, strength and resistance to corrosion.

High tensile brass is an alloy of copper and zinc that has a high tensile strength and good resistance to corrosion. It is often used in applications where high mechanical strength, good dimensional stability and resistance to wear and tear are required. The high tensile strength of the brass makes it ideal for use in high stress applications such as bushings, which are subjected to constant pressure and friction.

Brass bushings are used in a wide range of industrial applications, including machinery, automotive and aerospace. They provide a smooth and low friction surface between two moving parts, reducing the wear and tear on the components and improving their overall performance and longevity. In addition, the brass material provides excellent corrosion resistance, ensuring that the bushings will remain functional even in harsh environments.

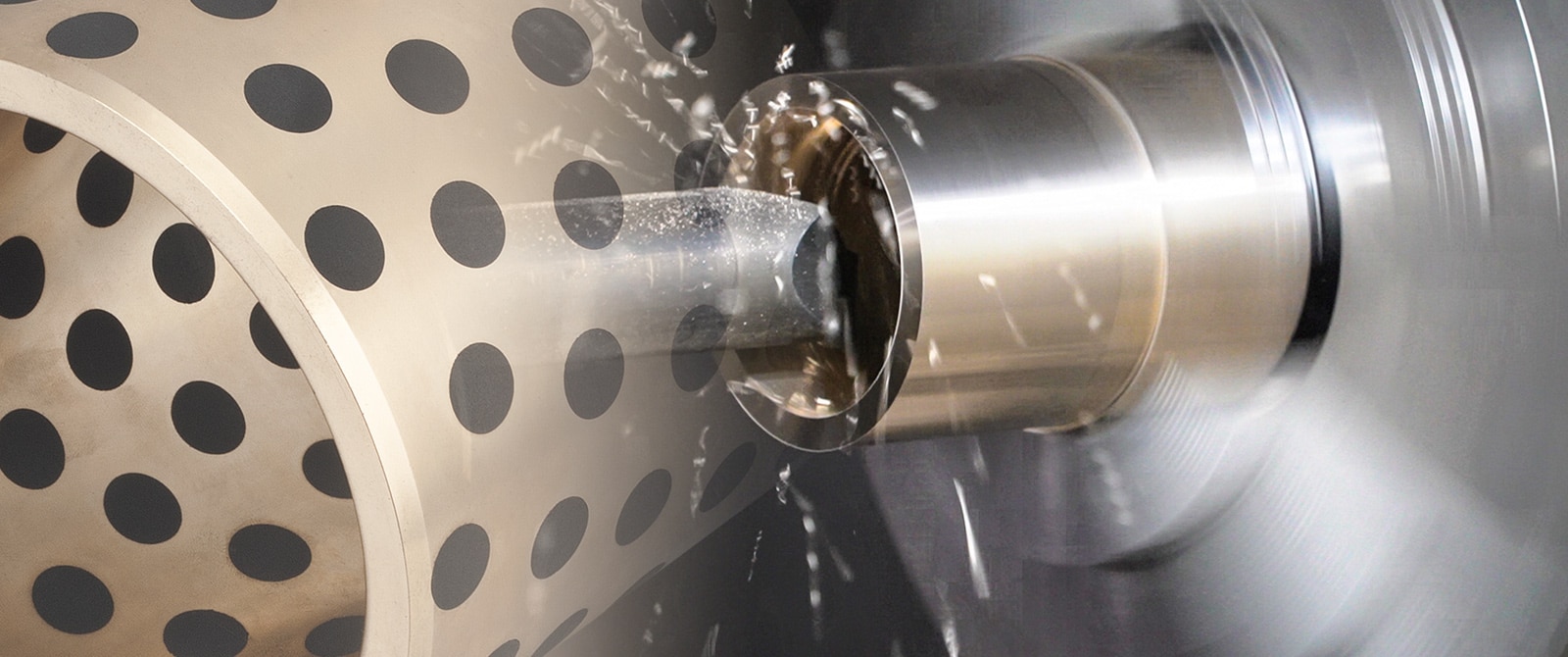

The manufacturing process of high tensile brass bushings involves casting the brass material into the desired shape and then undergoing a series of precision machining operations to ensure that the finished product meets the exact specifications required for the intended application. The bushings are then subjected to rigorous testing to ensure their strength, durability and corrosion resistance, and only those that meet the required standards are accepted for use in industrial applications.

In conclusion, high tensile brass bushings are an essential component in many industrial applications, providing excellent bearing and lubrication performance, and protection against corrosion. With their high strength and durability, these bushings are an excellent investment for industries looking for long-lasting and reliable components.

Self-lubricating brass bushing – The Ultimate FAQ Guide

What is the purpose of Self-lubricating brass bushing?

Brass is the best metal for making bushings because it is flexible and malleable, while still being a hard metal. In addition, it will not bond with steel. Self-lubricating brass bushing come in a variety of sizes because they can fit thick-walled, thin-walled, flanged, sintered, and cylindrical shapes. Self-lubricating brass bushing can be used for a variety of applications, including pump bushings, electric motors and plain bearings.

Water Pump Bushings

Most automotive engines have a water pump with a Self-lubricating brass bushing in the main shaft. Brass is useful due to its anti-rust and anti-friction properties.

Electric motors

The self-lubricating brass bushing can also be used on both sides of the armature of an electric motor. Its purpose is to support the motor shaft. This is perfect for engines because brass is cheap, it is anti-friction and this metal is easy to produce.

Sliding bearings

Some machines have shafts that slide rather than rotate. Self-lubricating brass bushing are used in these types of mechanisms.

A few other examples of where bushings can be found are in fishing reels, stage lights, printer rollers, ATMs, escalators, and surveillance systems.

What are the main types of Self-lubricating brass bushing?

Sleeve Bearings

Also known as Self-lubricating brass bushings, these bearings are used in the movement between two components and are designed to limit friction and any potential vibration. An important feature is that they can withstand high temperatures and are self-lubricating.

Self-lubricating brass Flanged bearings

The purpose of flanged self-lubricating brass bushing is to allow rotation within an enclosed area. One is bolted into the housing unit, while the other is unattached. They are best used for lighter-duty work.

Thrust Bearings

Thrust bearings are also known as thrust washers and they are used for rotational needs. They rotate along the moving parts.

Self-lubricating brass bushing

Self-lubricating bronze bushing

What is the difference between brass or bronze?

First of all, brass bearings and bronze bearings are similar in that they are both metal alloys, which means they are made of two or more metals. Brass bushing material consists of zinc and copper, while bronze consists of tin and copper.

Brass is also lighter yellow, while bronze portrays a warmer red tone. Bronze bushings are very durable and will last through severe impact and corrosion. However, it is important to note that these bronze bushings require the use of an external lubricant.

Where can you find self-lubricating brass bushings?

Our company manufactures some of the world’s most customizable self-lubricating brass bushings. Best of all, they are oil-free bearings and are available in large or small brass bushings.

Trusted premier supplier of self-lubricating brass bushings and all other types of bushings

Standard sizes range from 0.7 to 3 inches, however, we can customize bushings to fit your needs, changing the size and weight to match your custom design.

For more information on pricing and lead times, don’t hesitate to contact our professional sales team!

Bronze vs Brass ? What’s the difference? How to choose?

Bronze and brass are both alloys, or mixtures of metals, used for various purposes, but they have different compositions and properties.

Bronze is typically made of an alloy of copper and tin, sometimes with other elements added, and is known for its hardness, strength, and durability. It is commonly used in applications where these properties are important, such as in sculpture, coinage, and bearings.

Brass, on the other hand, is an alloy of copper and zinc, sometimes with small amounts of other elements added. It is known for its yellow color and malleability, and is often used in applications where these properties are desirable, such as in musical instruments, locks, and plumbing fixtures.

In summary, while both bronze and brass are alloys with copper as a common element, they have different properties due to the specific elements they are made of, which makes them suited for different purposes.

Brass Bushing, Self-Lubricating Bearings – Extreme long lifetime

why is brass used for bushings?

Brass bushing: brass bushing is a wear-resistant parts in machinery and equipment, brass bushing is more widely used.

Brass bushing more centrifugal casting process, the color is mainly yellow, brass material wear resistance is relatively good, the internal organization is relatively tight, will not appear large loosening phenomenon, the appearance looks brighter, the important thing is that its hardness is relatively high, in addition to corrosion resistance and pressure resistance is relatively strong, is the majority of mining machinery equipment on the accessories.

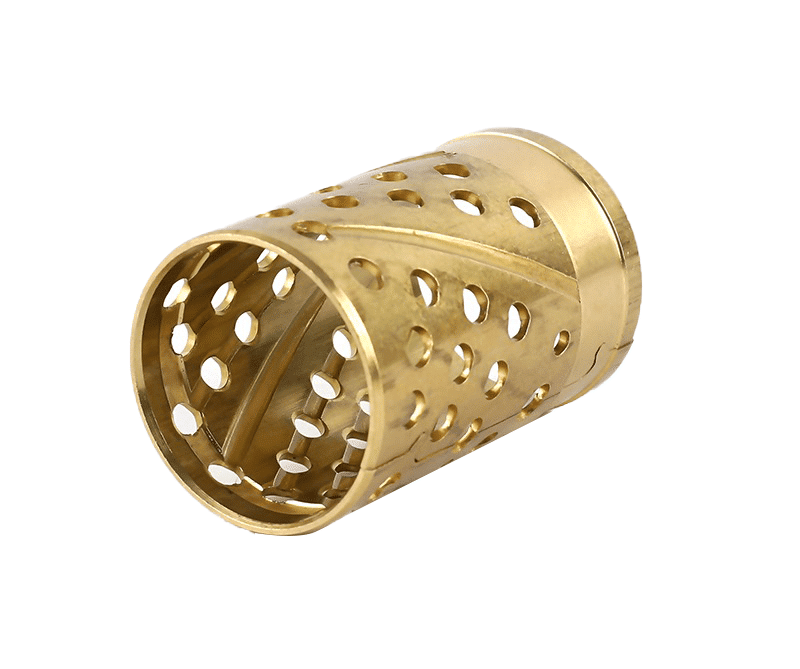

Brass bush: brass bush is a barrel-shaped mechanical parts set on the rotating shaft, is a component of the slide bearing. Generally speaking, brass bushings and bearing seat using interference fit, and with the shaft using clearance fit.

Brass slide: Brass slide is mainly used in: automobile industry, motorcycle, all kinds of hydraulic machinery, metallurgical machinery, forging machinery, oilfield machinery, engineering machinery, mining machinery, electric power facilities, etc.

Copper bush: Copper bush is used in various large and heavy machinery, and is an important component of machinery. It has high hardness, excellent wear resistance, not easy to produce bite phenomenon, good casting performance and cutting performance, and good corrosion resistance in the atmosphere and fresh water.

why is brass used for bushings?

Brass bushing: brass bushing is a wear-resistant parts in machinery and equipment, brass bushing is more widely used.

Brass bushing more centrifugal casting process, the color is mainly yellow, brass material wear resistance is relatively good, the internal organization is relatively tight, will not appear large loosening phenomenon, the appearance looks brighter, the important thing is that its hardness is relatively high, in addition to corrosion resistance and pressure resistance is relatively strong, is the majority of mining machinery equipment on the accessories.

Brass bush: brass bush is a barrel-shaped mechanical parts set on the rotating shaft, is a component of the slide bearing. Generally speaking, brass bushings and bearing seat using interference fit, and with the shaft using clearance fit.

Brass slide: Brass slide is mainly used in: automobile industry, motorcycle, all kinds of hydraulic machinery, metallurgical machinery, forging machinery, oilfield machinery, engineering machinery, mining machinery, electric power facilities, etc.

Copper bush: Copper bush is used in various large and heavy machinery, and is an important component of machinery. It has high hardness, excellent wear resistance, not easy to produce bite phenomenon, good casting performance and cutting performance, and good corrosion resistance in the atmosphere and fresh water.

Bushing Types & selection of self-lubricating bearings

Gas lubricated bearing is a kind of solid lubricating bearing, which is based on wear-resistant metal materials, and reduces the friction coefficient by adding various lubricating materials to achieve self-lubrication.

With the development of industrial technology and the advancement of science and technology, under some special harsh working conditions, the performance and reliability requirements of bearings are getting higher and higher. For example: low temperature, high temperature, vacuum, underwater, heavy load, etc., due to the failure of grease lubrication and the ineffective formation of oil film, traditional grease-lubricated rolling bearings are difficult to carry and reduce friction. However, plain bearings relying on solid lubricating materials can still show excellent performance in this environment.

Mosaic self-lubricating bearing, as a solid lubricating bearing, is based on wear-resistant metal materials, and is self-lubricating by adding various lubricating materials to reduce the friction coefficient. The material structure combines the advantages of high load, good impact resistance and non-metallic low friction coefficient, and is suitable for different working conditions. Inlaid solid lubricated bearings are suitable for low speed and high load, and can maintain a very low coefficient of friction when the grease cannot maintain a complete lubricating film such as swing, reciprocating motion, and frequent starting.

1. Copper base inlaid self-lubricating bearings:

Copper alloy inlaid self-lubricating bearings (national standard GB/T23894-2009) are the most widely used products in inlaid self-lubricating bearings. This material structure combines high metal load, good impact resistance, low non-metal friction coefficient and self-lubricating properties of solid lubricants, and is suitable for different working conditions.

No need to refuel and maintain during use. Products are widely used in high-load, intermittent or swinging motions, such as steam locomotive production lines, water turbines, reservoir work/accident doors, plastic machinery, etc.

Steel base inlaid self-lubricating bearings:

Steel base inlaid self-lubricating bearing is a reinforced product with high compressibility. It can discharge lubricating particles during the working process, form a diaphragm between the bushings, has better blocking resistance than single oil lubrication, better anti-seizure performance than single oil lubrication, and has high compression performance and The ability to expel lubricating particles during operation. It is especially suitable for supporting parts of hoisting machinery.

For example: winch bracket, crane bracket, but not suitable for water or acid and alkali applications.

Cast iron inlaid self-lubricating bearings:

Cast iron embedded bearing is a new solid lubricant product based on HT 250, which is a typical material saving product. If the pressure is less than 14.5N/mm~2 or mechanical performance requirements, it can be used as a substitute for JDB-2 material, which can greatly reduce the cost and meet the use requirements.

For example: mold guide posts, injection molding machine mold bases and other fields can be fully used.

4. Steel-based copper alloy inlaid self-lubricating bearings:

The self-lubricating steel-based copper alloy bearing is used as the basic material of the bearing, and the high-strength copper alloy is cast on the surface of high-quality carbon steel. The solid bearing adopts the manufacturing process to fully combine the surface of copper and steel joints with gold, and cast high-strength copper alloy on the surface of high-quality carbon steel as the basic material of the bearing. It not only reduces material cost, but also increases its load-carrying capacity. Embedding the solid lubricant into the working surface can greatly reduce the friction coefficient of the bearing and achieve the purpose of self-lubrication.

5. Copper alloy inner ring self-lubricating sliding bearing:

Copper alloy inner ring self-lubricating sliding bearing is a sliding bearing with self-lubricating properties, which can rotate or swing freely. The inner ring of the bearing is made of special copper alloy, the spherical surface of the inner ring is inlaid with solid lubricant, and the outer ring is made of bearing steel, which is phosphated or chrome-plated after heat treatment and polished.

6. Bimetal spiral inlaid self-lubricating bearing;

Bimetal spiral inlaid self-lubricating bearing is a kind of continuous sliding bearing produced by solid bearing. It is a new type of thin-walled solid lubricating bearing, which is made of bimetallic plate as the base, and the alloy layer is embedded with special solid lubricant. Due to the use of high-strength bearing alloy material as the matrix, the ideal filler material is wear-resistant agent, reasonable diamond block lubrication design, the lubrication area is greater than 25%, which can play a good role in lubrication and wear resistance.

Bimetal self-lubricating bearings are used in automobile gearboxes, generators, elevators, cranes and gold control machinery.

7. Copper alloy inlaid self-lubricating bearings:

Copper alloy spiral inlaid self-lubricating bearing is also a continuous plain bearing. The solid lubricated bearing is made of high-density copper alloy strip with special formula, and the solid lubricant embedded on the surface is made by coiling, forming and other methods. Since the copper alloy material with high elongation is used as the matrix, an ultra-thin spiral sleeve can be made, and the ideal filler material can be used as a lubricant.

In order to solve the lubrication problems of high temperature, low speed, heavy load, high dust, water washing, shock and vibration in mechanical equipment, oil-free self-lubricating bearings are selected.

1. The structure of the bearing Self-lubricating bearing is a kind of composite bearing, which forms holes of appropriate size and sequence on the metal friction surface of the bearing base, and embeds molybdenum disulfide and graphite into the composite self-lubricating slider on the metal sleeve to make composite bearing. The friction area of solid lubricants is 25%/65%. The solid self-wetting slider can work normally at 280°C. However, due to its low mechanical strength, weak bearing capacity, and easy deformation, embedding it in a metal groove can suppress this defect and form a metal part as a bearing capacity, while the self-wetting slider The lubricating block acts as a lubricant.

The lubrication mechanism of self-lubricating bearings is that in the sliding friction between the bushings, part of the self-lubricating material molecules are transferred to the metal surface of the shaft, filling the slightly uneven surface and forming a more stable solid lubricating film. The solid lubricating film is worn between to prevent the shaft and the sleeve from being adhered and worn. This rational combination combines the complementary advantages of copper alloys and non-metallic anti-wear materials and is especially suitable for range of motion in oil-free, high temperature, high load, low speed, antifouling, corrosion resistance and strong radiation environments. As well as penetrating into water or other solutions, it cannot be lubricated at all under special working conditions.

2. The specific surface area of the self-lubricating block is larger than that of the self-lubricating block, which is related to the running speed, bearing strength, low working speed, high bearing strength, and large metal occupied area. For example, the self-lubricating block area of the trolley walking wheel self-lubricating block is about 25%, the shaft bearing of the main shaft mechanism is fully lubricated, the bearing strength is not large, and the self-lubricating block occupies about 65% of the area.

3. Bearing material technical requirements: The self-lubricating bearing sleeve is made of alloy copper. The inner lining should have high hardness, and the hardness should not be less than HRC45.

Geometry and structural requirements of self-lubricating blocks. There are two types of self-lubricating sliders, cylindrical and rectangular. Self-lubricating can be cylindrical according to the size of the area, and rectangular on the other hand. Any shape must be trimmed securely to prevent it from falling off during work.

5. The linear expansion coefficient of a self-lubricating block with a clearance value between the bushing and the shaft is about 10 times that of steel. In order to adapt to the change of bearing temperature, the gap between the shaft and the bushing is 0.032-0.15mm of the original metal piece, and an increase of 0.45-0.5mm. The self-lubricating block protrudes 0.2-0.4mm from the bushing metal on the side of the friction pair. This will generate adequate lubrication and reduce power consumption during the initial grinding phase of bearing operation.

Self-lubricating bushing – Oilless Self-lubricating Tech

Strives to Offer Cost-saving, Stable Performance Bearings and Bushings. Contact Us. High Quality Guaranteed. Worldwide On-time Shipping. View Our Products. Contact Us Today. Long-term Wear Resistance. Extreme Stable & Durable.

While oil is used in exceptional cases, solid bronze bushings custom brass bushing are typically grease lubricated. To protect the bushing and lubricant. Since bearings usually receive a lot of frictional resistance that generates heat, lubricants such as oil or grease are used to prevent the seizing or abnormal wear that this frictional heat could otherwise cause. Lubrication-free brass bushings don’t need lubricating oil because the bronze bearing body has a lubricating structure made possible by lubricating oil in the bearing body, or by embedded solid lubricant or the like. Since they don’t need lubricating oil, lubrication-free brass bushings are often used for applications such as precision machinery that makes lubricating oil refilling difficult, and equipment with poor affinity to oil. They also greatly reduce maintenance costs by eliminating the need for regular lubrication and enabling stable operation over long periods. Lubrication-free brass bushings come in a variety of shapes that can be used for different applications as needed. Examples include “Self-lubricating”, ” lubrication-free” straight bushings, collar bushings, flange bushings and housing bushings.

Our Experts Will Determine The Most Efficient Manufacturing Method And The Ideal Bronze Bearings Material To Meet Your Specific Requirements. Visit Our Webpage To Get Started Today. Oilless Bearings Catalogs And Brochures Available. Graphite Filled Bronze Bushes Plug Graphite Bearings Are Primarily Used In Applications That Need Continual Lubrication In Hard To Reach Areas. Self-Lubricating Materials For Plain Bearings – Custom Bearing Solutions – Graphite-Filled To Meet A Broad Range Of Bronze Alloy Materials.

Overview- high tensile brass bushings, solid bronze bushings can be lubricated with either oil or grease. The lubricant not only improves the sliding properties but also reduces wear. A variety of alloys composed of two or more elements are called special brass. Such as copper alloys composed of aluminum, lead, tin, manganese, nickel, iron, and silicon, and high-strength brass is one of them. High-strength brass has strong wear resistance, high-strength brass, high strength, high hardness, and strong chemical corrosion resistance. There are also excellent cutting mechanical properties. High-strength brass is often made into sheet, strip, bar, pipe, casting parts, etc.

Brass bushing chemical composition

The chemical formula of high-strength brass is ZCuZn25Al6Fe3Mn3, the copper content is about 65%, and the zinc content is about 24%. Zinc can improve the strength, hardness and corrosion resistance of brass. There are three room temperature structures of brass: brass with a zinc content of less than 35%, the microstructure at room temperature is composed of a single-phase α solid solution, called α brass;

Pressure processing performance

High-strength brass has good plasticity and can withstand hot and cold processing, but it is prone to medium temperature brittleness during hot processing such as forging. Its specific temperature range varies with the Zn content, generally between 200 and 700 °C. Therefore, the temperature during hot working should be higher than 700°C.

Self lubricating Brass Bearing Mechanical properties

High-strength brass has different zinc content and different mechanical properties. For α brass, with the increase of zinc content, both σb and δ increase continuously. Therefore, copper-zinc alloys containing more than 45% zinc have no practical value. The standard high-strength brass has a Brinell hardness greater than 200, compressive strength greater than 600MPa, and elongation greater than 10%.

Development History

The word “brass” first appeared in the “Shenyi Jing Zhonghuang Jing” written by Dongfang Shuo in the Western Han Dynasty: “There is a palace in the northwest, with brass as the wall, and the title of the palace of the emperor of the sun and the earth. What kind of copper alloy this “brass” refers to is yet to be tested. “New Book of Tang, Food and Goods” also has the titles of “bronze” and “brass”, which refer to the color of the ore and the smelted product respectively, not copper and tin Alloys with copper-zinc alloys. Song Hong Zikui’s “Daye Fu” also includes “it is brass, the pit has a special name, and the mountains are numerous and simple”, which refers to pure copper refined by fire.

The term brass refers specifically to copper-zinc alloys, which began in the Ming Dynasty, and its records are found in the “Ming Hui Dian”: “In Jiajing, there are 6 million yuan in Tongbao money, and 47,270 in two-fire brass. Two catties…” Through the analysis of the composition of copper coins in the Ming Dynasty, it was found that the real brass in the “Ming Hui Dian” appeared much later than other copper alloys. It is difficult to obtain metallic zinc.

Zinc oxide can be quickly reduced to metallic zinc at a high temperature of 950°C to 1000°C, while liquid zinc has already boiled at 906°C, so the reduced metallic zinc exists in the form of vapor. The reaction is reversed during cooling, and the vapor zinc is oxidized to zinc oxide by carbon dioxide in the furnace, so a special condensing device is necessary to obtain metallic zinc. This is why the metal zinc was used much later than copper, lead, tin, and iron, and one of the reasons why brass coinage appeared later.

However, brass sheets and pipes containing more than 20% zinc have been unearthed in the Yangshao Cultural Site of Jiangzhai, and two kinds of brass cones have also been unearthed in the strata of the Longshan Culture of Sanli River in Jiao County, Shandong Province. Obviously, the appearance of these brass utensils does not mean that people mastered the smelting technology of brass in prehistoric times, but that people obtained them accidentally when using copper-zinc symbiotic ore.

The zinc content of bronzes in the Shang and Zhou dynasties was very low, generally in the order of 10-z. In the coins of the Western Han Dynasty and Xinmang, there are individual copper-zinc coins, and the content of zinc in some coins reaches 7%, but this does not mean that brass coins were produced in the Xinmang period of the Western Han Dynasty. Because these copper-zinc alloys are very individual phenomena, their zinc content is generally much smaller than that of brass in the true sense of 15% to 40%. Therefore, we believe that these copper coins containing zinc were produced when the copper-zinc symbiotic ore was used in the “Jishan Casting Coins” in the Han Dynasty. According to the investigation of relevant mines, it is found that Changwei, Yantai, Linyi, Hubei, and other places in Shandong have copper-zinc symbiotic minerals rich in resources, which makes the smelted copper contain a small part of zinc. In the Tang Dynasty, due to the standardization of coinage materials, the content of zinc in coins minted was constant.

Brass products were popular in Europe for about 300 years from about 1230 AD because they were much cheaper than larger sculptures. died 1231

The bronze statue of Archbishop Wilp in 2000 is the earliest known bronze statue made of brass. The process of casting brass products is as follows: First, crushed zinc ore and charcoal are mixed with copper blocks and heated, so that the zinc and copper are combined together, and then the alloy is melted by heating, and then the copper liquid is poured into the casting mold. The earliest British brassware was imported, mainly from Tournay. The consignor can order complete tombstones already in beautiful baseplates or marble bases from Tournay. The way to make a bronze tombstone is to first cast a bronze statue, usually the silhouette of the surrounding canopy, and then put it in a prefabricated slate, and use a knife to carve the details of the person on the bronze statue. Sometimes alabaster or other inlay materials are used for the hands and faces of bronze statues. After the statue is safely made, it is fastened to the stone base with dowels housed in lead bolts. The bronze statue itself rests on a layer of asphalt. Large bronze statues are cast in sections and then joined together.

Application field

High-strength brass is widely used. It is cast into bearing bushes and bushings. The solid-lubricated oil-free bearings (referred to as solid-lubricated bearings) mainly made of high-strength brass in China are based on high-strength and high-strength brass. , and radially embedded and arranged cylindrical polymer fillers are friction materials (generally graphite, molybdenum disulfide, polytetrafluoroethylene, engine oil and other lubricants), and its advantages are mainly in that it makes copper alloys and non-metallic materials. The anti-friction materials have their own complementary advantages. They not only have high bearing capacity, but also break through the limit of general bearings relying on oil film and grease lubrication to achieve oil-free lubrication. The embedded solid lubrication is easy to form a lubricating film, which plays a role in its friction and wear performance Great improvement, stable, reliable and cost-effective. Compared with composite oil-free bearings, it has the advantages of good machinability, high precision, strong bearing capacity and good wear resistance. This self-lubricating guide sleeve guide plate can be used in many fields such as: construction machinery joints, such as excavators, mining scrapers, rotary drilling rigs, concrete pump trucks, rock drilling machinery, hoists, port cranes, etc., as well as metallurgical Mechanical continuous casting machinery, water conservancy machinery, conveying machinery, rolling mill, bottle blowing machine, film blowing machine, crosshead clamping differential for injection molding machine, tire vulcanizing machine, trailer balance beam, vacuum switch, etc.

Cuzn25Al5 High Tensile Brass Bushing,C86300 Bronze Bearing With Oil Grooves, SAE430b Bronze Bushing , Find Complete Details about Cuzn25al5 High Tensile

Find out the technical details &

select your Brass Bushing Bearing Parts

Wherever the application revolves around motion, VIIPLUS creates the solution. Our self-lubricating brass bushings bearing technology has served a variety of applications and fields worldwide for many years, making us a leader in these markets.

the right partner For Your Company

Fast Engineering Support, Brass Bushing Freedom of design.

Simple mounting

Mounting

Fast Quoting, Fast Delivery Time. Brass Bushing Stock, Ready to use!

Custom Services

Focus

Fast Service, Our Experts can solve your challenges. C86300 Bronze Bearing & Brass Bush.

Personal Assistance

Low Costs of Ownership, Design with No Limits. Self-Lubricating Bearings – Extreme long lifetime

Bronze Bushings & Bearings – Reduced Costs & DowntimeFind A Custom Brass Bushings!

Find A Custom Brass Bushing Bearing, Manufacturer & Supplier Of Bronze Bushing: Graphite Infused Bronze Bushing And Self-lubricating Brass Bearings Suited For Submerged And High-Temperature Applications. Increased Productivity. Reduced Costs & Downtime. Services: Custom Design, Engineering Support, Short Lead Times. Let Us Help You Design Custom Brass Bearings Out Of Our High-Strength Bronze & High Tensile Brass Materials.

Standard-Stocked Alloys: Flanged Bronze Bearing, Self lubricating!

Standard material fulfills most application requirements: High load capacity, Copper-based self-lubricating bearing for heavy load applications into which solid lubricant plugs are embedded.Please contact us for customized size bronze bushings needs related to Mining and Earthmoving Components, Custom and Oilfield Manufacturing. All the advantages of a ready made solution designed for you with many years expertise in self-lubricating brass bushing bearing:

- engineered and tested solution

- short assembly time and service

- low maintenance and additional warranties

taxation planning

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

Custom-made self-lubricating brass Bushing & bronze Bearing products

High tensile brass bushings are components used in various industrial applications due to their high strength and wear resistance. They are particularly useful in scenarios that involve high loads and in environments where corrosion might be an issue.

Multiple bushing bearing alloy material configurations. Our self-lubricating brass bushing bearing ad bushings solution can be assembled in several different configurations. Solid bronze brass bushing bearings features: Excellent corrosion and chemical resistance. This solid lubricant self-lubricating brass bushing bearing can be used in river or sea water; in liquids where chemical resistance of the metal base and solid lubricant is needed; and in gas where oil supply is difficult. Excellent impact resistance.

The promise of cast bronze bearings high quality, meet your requirement.

Save your purchasing manganese bronze bushing & brass bearing budget for your project. Special Solid Bronze Bearing Processes, Know what you’re looking for? Or need help figuring out what you need? Quality & Certification! Fully accessorized: A large quantity of brass bushing sizes is available, such as:

- flange brass bushing

- straight brass bushing

- slide bearing plates for assembly

- lubrication brass bushings bearing

- brass thrust washer

- cast bronze groove type

Prototype Bronze Bushing Solutions

High tensile brass bushings and Plate, Tech up, Cost down! high temp Plate

Real-life strategy to reach your goals.

Sizes: High tensile brass bushings are available in a range of sizes, including various inner diameters and overall lengths, suitable for different applications.

The Self-Lubricating Plate, For applications where standard brass bearing & bushing alloys are not suitable, we are able to supply special materialsWe supply a wide range of rotary straight bushes, flange brass bushing, manganese bronze bushing, wear plate, thrust washer in custom design, engineering and fabrication services to meet customer needs. Any other special material requirements are available upon request. We provide Full Material Test Reports and any additional Testing Certificates are available on all products.

We strive for diversity across the globe

Graphite Brass Bushings & Bearings – Reduced Costs & Downtime

High-Quality oil groove brass bushing To Your Specifications: Offering Superior Performance In Hundreds Of Applications Replacing Bearings. Increased productivity. Services: Custom Design, Engineering Support, Short Lead Times. Brass Graphite Bushing is Suited for Submerged and High Temperature Applications. Increased productivity. Grooved Cast Bronze Bushings Reduced costs & downtime. Services: Custom Design, Engineering Support, Short Lead Times. Grooved Cast Bronze Bushings. Choose from our selection of self-lubricating bushings, including oil-embedded sleeve bearings. Contact Us! Need Assistance? Call Or Email Us, Engineering Support Available. Self-Lubrication Options for Bronze Bearings.

Need help with a project or application?

High Tensile Brass Bearings Design

Maintenance-free self-lubricating brass bronze bearing and guide bushes, bronze with solid lubricant plugged graphite

✔C86300 SAE 430B CAST BRONZE BRASS BUSHING BEARING BRONZE AND HIGH TENSILE BRASS FOUNDRY

✔ Material: CuZn25Al5Mn4Fe3, The closest international standard is the ASTM B505 C86300.Cu 60% min.

✔ STANDARD-STOCKED CAST BRASS BUSHING BEARINGS

Self-lubricating Brass Bushing Technical Parameters

| Chemical composition | CuZn25A16Fe3Mn4 | Friction coefficient μ | <0.16 |

| Dynamic load limit | 100N/mm² | Max.temp | 300 ℃ |

| Hardness | HB 210~270 | Maximum sliding speed | Dry0.4m/s oil5m/s |

Chemical Composition

| Cu%1 | Pb% | Sn% | Zn% | Fe% | Ni%2 | Al% | Mn% | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Chemical Composition according to ASTM B505/B505M-18

|

|||||||||||

| 60.00- 66.00 |

0.20 | 0.20 | 22.00- 28.00 |

2.00- 4.00 |

1.00 | 5.00- 7.50 |

2.50- 5.00 |

||||

CAST BRONZE BEARING BUSHING

High strength brass self-lubricating

Custom Bronze Prototyping Services, self-lubricating Brass Bearings OEM parts

Any alloy consisting of more than two elements is called special brass. Such as aluminum, lead, tin, manganese, nickel, iron, and silicon composed of copper alloy, and high-strength brass is one of them. High strength brass has strong wear resistance, high strength brass, high hardness, and strong chemical corrosion resistance. And machining mechanical properties are also very superior. High-strength brass is often made to manufacture sheets, bars, bars, pipe, casting parts, and so on.

Chemical composition: The chemical formula of high-strength brass is ZCuZn25AI6Fe3Mn3, containing about 65% copper and about 25% zinc. Aluminum improves the strength, hardness, and corrosion resistance of brass. There are three types of brass at room temperature: brass with less than 35% zinc content. The microstructure at room temperature is composed of a single-phase A solid solution and is called A brass.

Price and delivery time on request

- Bronze Brass Bushing Material: Special Brass (SO#50SP2)

- Self-lubricating: Yes

- Lubricant: Graphite Surface

- Pressure P:100 N/mm²

- Sliding speed v:30 m/minP*v-value:200 N/mm² x m/min

- Operating temperature:-50°C / +200°C (max. 300°C)

- Friction coefficient:0,07

Self-lubricating Brass Sleeve Bearings – Always self-lubricating & grease-free, Customized self-lubricating brass bushing bearings – We will manufacture the exact self-lubricating brass bushing you need at a low cost. Simple design – Cost-effective

Our company is specialized in manufacturing and selling oil-free brass bushing, composite bushing bearing, self-lubricating brass bushing, oil-free brass sleeve , inlaid graphite brass bearing, copper sleeve, dry brass sleeve, sliding bearing, axle bush, bushing, guide sleeve, sliding plate, and can be customized according to user requirements.

Plain & Self-Lubricating Bearings(Bushing Material: Graphite Impregnated Brass)

Oil-Free Bushing – Brass Alloy, ShoulderedShouldered bronze bushing to prevent itself from being removed from the plate.

- Volume Discount is available

- More configuration options are available now, Available in Metric Size Custom Bearing Design

Oil-Free Bearing – Brass Alloy, Straight Bushing, I.D. F7

| Material Composition and Properties | ||||

| Grade | Bronze Bushing | |||

| Material | CuZn25Al5Mn3Fe3 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn12 |

| Density | 8 | 8.9 | 7.8 | 8.9 |

| Hardness HB | >210 | >70 | >150 | >95 |

| Tensile strength N/mm² | >750 | >200 | >600 | >260 |

| Yield strength N/mm² | >450 | >90 | >260 | >150 |

| Elongation % | >12 | >25 | >10 | >8 |

| Coefficient of linear expansion | 1.9×10-5/℃ | 1.8×10-5/℃ | 1.6×10-5/℃ | 1.8×10-5/℃ |

| Max. temp ℃ | -40~+300 | -40~+400 | -40~+400 | -40~+400 |

| Max.load N/mm² | 100 | 60 | 50 | 70 |

| Max.speed (Dry) m/min | 15 | 10 | 20 | 10 |

| Max.PV(Lubrication) N/mm² *m/min | 200 | 60 | 60 | 80 |

| Compression deformation 300N/mm² | <0.01mm | <0.05mm | <0.04mm | <0.05mm |

Slide Bearings & self-lubricating, Guides, Slide Plate

✔ High Tensile Brass Bearing, Maintenance-free bearings with lubricating plugs/C86300 Alloy, C863 Manganese Brass Bearings, The design rules for the most cost-effective parts designs apply to plain bearings in particular, to wear parts in general and to all other components.

✔ Manganese bronze alloy bearings such as C86300 bronze lubrication bearings can operate under very high loads and speeds.Besides excellent mechanical qualities, cast bronze alloy parts have good corrosion resistance.

✔Materials:The maintenance-free plain bearings with lubricating plugs are made from CuZn25Al5 and are fitted with lubricating plugs. CuZn25Al5 is brass that has copper and zinc as its basis and is a construction material characterized by a high static load capability. As well as CuZn25Al5, there are many other alloys suitable for both the bearing and the lubricating plugs.

Use Inexpensive and Easy-to-Process Bronze Materials Whenever Possible

Lubricated Bearings Demand, Copper Alloy +Solid Lubricant Bearing Type

✔High tensile Bearings, Solid bushing, bronze with lubricant plugs embedded, DIN 1850/ISO 4379, Maintenance-free

✔ MATERIALS:CuZn25Al5Mn4Fe3

✔ Sliding layer: Solid lubricant graphite surface: app. 25-30% Other bronze alloy bearings.

✔ Quality Custom Machined Bronze Bushings & Bearings Delivered On Time And On Budget

Solid lubricant plug bronze bearings for use at high temperature (above 250 ℃) and is made to order.

(Sliding Bushing Inner Diameter: small size 8mm to 160 mm)

Maintenance-free bronze bearing size chartequivalent and guide bushes, bronze with solid lubricant plugged graphite, SOB bushing equivalent, Sankyo oilless Alternatives

| SOB 8-12-8 | 8 | 12 | 8 | 0,5 | 0,5 | ||

| SOB 6-10-12 | 6 | 10 | 12 | 0,5 | 0,5 | ||

| SOB 8-12-10 | 8 | 12 | 10 | 0,5 | 0,5 | ||

| SOB 8-12-12 | 8 | 12 | 12 | 0,5 | 0,5 | ||

| SOB 8-12-15 | 8 | 12 | 15 | 0,5 | 0,5 | ||

| SOB 10-14-8 | 10 | 14 | 8 | 0,5 | 0,5 | ||

| SOB 10-14-10 | 10 | 14 | 10 | 0,5 | 0,5 | ||

| SOB 10-14-12 | 10 | 14 | 12 | 0,5 | 0,5 | ||

| SOB 10-14-15 | 10 | 14 | 15 | 0,5 | 0,5 | ||

| SOB 10-14-20 | 10 | 14 | 20 | 0,5 | 0,5 | ||

| SOB 10-15-10 | 10 | 15 | 10 | 0,5 | 0,5 | ||

| SOB 12-18-8 | 12 | 18 | 8 | 0,5 | 0,5 | ||

| SOB 12-18-10 | 12 | 18 | 10 | 0,5 | 0,5 | ||

| SOB 12-18-12 | 12 | 18 | 12 | 0,5 | 0,5 | ||

| SOB 12-18-15 | 12 | 18 | 15 | 0,5 | 0,5 | ||

| SOB 12-18-16 | 12 | 18 | 16 | 0,5 | 0,5 | ||

| SOB 12-18-19 | 12 | 18 | 19 | 0,5 | 0,5 | ||

| SOB 12-18-20 | 12 | 18 | 20 | 0,5 | 0,5 | ||

| SOB 12-18-25 | 12 | 18 | 25 | 0,5 | 0,5 | ||

| SOB 12-18-30 | 12 | 18 | 30 | 0,5 | 0,5 | ||

| SOB 13-19-10 | 13 | 19 | 10 | 0,5 | 0,5 | ||

| SOB 13-19-12 | 13 | 19 | 12 | 0,5 | 0,5 | ||

| SOB 13-19-15 | 13 | 19 | 15 | 0,5 | 0,5 | ||

| SOB 13-19-16 | 13 | 19 | 16 | 0,5 | 0,5 | ||

| SOB 13-19-20 | 13 | 19 | 20 | 0,5 | 0,5 | ||

| SOB 13-19-25 | 13 | 19 | 25 | 0,5 | 0,5 | ||

| SOB 14-20-10 | 14 | 20 | 10 | 0,5 | 0,5 | ||

| SOB 14-20-12 | 14 | 20 | 12 | 0,5 | 0,5 | ||

| SOB 14-20-15 | 14 | 20 | 15 | 0,5 | 0,5 | ||

| SOB 14-20-20 | 14 | 20 | 20 | 0,5 | 0,5 | ||

| SOB 14-20-25 | 14 | 20 | 25 | 0,5 | 0,5 | ||

| SOB 14-20-30 | 14 | 20 | 30 | 0,5 | 0,5 | ||

| SOB 15-21-10 | 15 | 21 | 10 | 0,5 | 0,5 | ||

| SOB 15-21-12 | 15 | 21 | 12 | 0,5 | 0,5 | ||

| SOB 15-21-15 | 15 | 21 | 15 | 0,5 | 0,5 | ||

| SOB 15-21-16 | 15 | 21 | 16 | 0,5 | 0,5 | ||

| SOB 15-21-20 | 15 | 21 | 20 | 0,5 | 0,5 | ||

| SOB 15-21-25 | 15 | 21 | 25 | 0,5 | 0,5 | ||

| SOB 15-21-30 | 15 | 21 | 30 | 0,5 | 0,5 | ||

| SOB 16-22-10 | 16 | 22 | 10 | 0,5 | 0,5 | ||

| SOB 16-22-12 | 16 | 22 | 12 | 0,5 | 0,5 | ||

| SOB 16-22-15 | 16 | 22 | 15 | 0,5 | 0,5 | ||

| SOB 16-22-16 | 16 | 22 | 16 | 0,5 | 0,5 | ||

| SOB 16-22-19 | 16 | 22 | 19 | 0,5 | 0,5 | ||

| SOB 16-22-20 | 16 | 22 | 20 | 0,5 | 0,5 | ||

| SOB 16-22-25 | 16 | 22 | 25 | 0,5 | 0,5 | ||

| SOB 16-22-30 | 16 | 22 | 30 | 0,5 | 0,5 | ||

| SOB 16-22-35 | 16 | 22 | 35 | 0,5 | 0,5 | ||

| SOB 16-22-40 | 16 | 22 | 40 | 0,5 | 0,5 | ||

| SOB 17-23-15 | 17 | 23 | 15 | 0,5 | 0,5 | ||

| SOB 18-24-10 | 18 | 24 | 10 | 0,5 | 0,5 | ||

| SOB 18-24-12 | 18 | 24 | 12 | 0,5 | 0,5 | ||

| SOB 18-24-15 | 18 | 24 | 15 | 0,5 | 0,5 | ||

| SOB 18-24-16 | 18 | 24 | 16 | 0,5 | 0,5 | ||

| SOB 18-24-20 | 18 | 24 | 20 | 0,5 | 0,5 | ||

| SOB 18-24-25 | 18 | 24 | 25 | 0,5 | 0,5 | ||

| SOB 18-24-30 | 18 | 24 | 30 | 0,5 | 0,5 | ||

| SOB 18-24-35 | 18 | 24 | 35 | 0,5 | 0,5 | ||

| SOB 18-24-40 | 18 | 24 | 40 | 0,5 | 0,5 | ||

| SOB 19-26-15 | 19 | 26 | 15 | 0,5 | 0,5 | ||

| SOB 19-26-20 | 19 | 26 | 20 | 0,5 | 0,5 | ||

| SOB 20-28-10 | 20 | 28 | 10 | 0,5 | 0,5 | ||

| SOB 20-28-12 | 20 | 28 | 12 | 0,5 | 0,5 | ||

| SOB 20-28-15 | 20 | 28 | 15 | 0,5 | 0,5 | ||

| SOB 20-28-16 | 20 | 28 | 16 | 0,5 | 0,5 | ||

| SOB 20-28-19 | 20 | 28 | 19 | 0,5 | 0,5 | ||

| SOB 20-28-20 | 20 | 28 | 20 | 0,5 | 0,5 | ||

| SOB 20-28-25 | 20 | 28 | 25 | 0,5 | 0,5 | ||

| SOB 20-28-30 | 20 | 28 | 30 | 0,5 | 0,5 | ||

| SOB 20-28-35 | 20 | 28 | 35 | 0,5 | 0,5 | ||

| SOB 20-28-40 | 20 | 28 | 40 | 0,5 | 0,5 | ||

| SOB 20-28-50 | 20 | 28 | 50 | 0,5 | 0,5 | ||

| SOB 20-30-10 | 20 | 30 | 10 | 0,5 | 0,5 | ||

| SOB 20-30-12 | 20 | 30 | 12 | 0,5 | 0,5 | ||

| SOB 20-30-15 | 20 | 30 | 15 | 0,5 | 0,5 | ||

| SOB 20-30-16 | 20 | 30 | 16 | 0,5 | 0,5 | ||

| SOB 20-30-20 | 20 | 30 | 20 | 0,5 | 0,5 | ||

| SOB 20-30-25 | 20 | 30 | 25 | 0,5 | 0,5 | ||

| SOB 20-30-30 | 20 | 30 | 30 | 0,5 | 0,5 | ||

| SOB 20-30-35 | 20 | 30 | 35 | 0,5 | 0,5 | ||

| SOB 20-30-40 | 20 | 30 | 40 | 0,5 | 0,5 | ||

| SOB 20-30-70 | 20 | 30 | 70 | 0,5 | 0,5 | ||

| SOB 22-32-12 | 22 | 32 | 12 | 0,5 | 0,5 | ||

| SOB 22-32-15 | 22 | 32 | 15 | 0,5 | 0,5 | ||

| SOB 22-32-20 | 22 | 32 | 20 | 0,5 | 0,5 | ||

| SOB 22-32-25 | 22 | 32 | 25 | 0,5 | 0,5 | ||

| SOB 25-33-12 | 25 | 33 | 12 | 0,5 | 0,5 | ||

| SOB 25-33-15 | 25 | 33 | 15 | 0,5 | 0,5 | ||

| SOB 25-33-16 | 25 | 33 | 16 | 0,5 | 0,5 | ||

| SOB 25-33-20 | 25 | 33 | 20 | 0,5 | 0,5 | ||

| SOB 25-33-25 | 25 | 33 | 25 | 0,5 | 0,5 | ||

| SOB 25-33-30 | 25 | 33 | 30 | 0,5 | 0,5 | ||

| SOB 25-33-35 | 25 | 33 | 35 | 0,5 | 0,5 | ||

| SOB 25-33-40 | 25 | 33 | 40 | 0,5 | 0,5 | ||

| SOB 25-33-50 | 25 | 33 | 50 | 0,5 | 0,5 | ||

| SOB 25-33-60 | 25 | 33 | 60 | 0,5 | 0,5 | ||

| SOB 25-35-12 | 25 | 35 | 12 | 0,5 | 0,5 | ||

| SOB 25-35-15 | 25 | 35 | 15 | 0,5 | 0,5 | ||

| SOB 25-35-16 | 25 | 35 | 16 | 0,5 | 0,5 | ||

| SOB 25-35-20 | 25 | 35 | 20 | 0,5 | 0,5 |

| SOB 25-35-25 | 25 | 35 | 25 | 0,5 | 0,5 | ||

| SOB 25-35-30 | 25 | 35 | 30 | 0,5 | 0,5 | ||

| SOB 25-35-35 | 25 | 35 | 35 | 0,5 | 0,5 | ||

| SOB 25-35-40 | 25 | 35 | 40 | 0,5 | 0,5 | ||

| SOB 25-35-50 | 25 | 35 | 50 | 0,5 | 0,5 | ||

| SOB 28-38-20 | 28 | 38 | 20 | 0,5 | 0,5 | ||

| SOB 28-38-25 | 28 | 38 | 25 | 0,5 | 0,5 | ||

| SOB 28-38-30 | 28 | 38 | 30 | 0,5 | 0,5 | ||

| SOB 28-38-40 | 28 | 38 | 40 | 0,5 | 0,5 | ||

| SOB 30-38-12 | 30 | 38 | 12 | 1 | 1 | ||

| SOB 30-38-15 | 30 | 38 | 15 | 1 | 1 | ||

| SOB 30-38-20 | 30 | 38 | 20 | 1 | 1 | ||

| SOB 30-38-25 | 30 | 38 | 25 | 1 | 1 | ||

| SOB 30-38-30 | 30 | 38 | 30 | 1 | 1 | ||

| SOB 30-38-35 | 30 | 38 | 35 | 1 | 1 | ||

| SOB 30-38-40 | 30 | 38 | 40 | 1 | 1 | ||

| SOB 30-38-50 | 30 | 38 | 50 | 1 | 1 | ||

| SOB 30-38-60 | 30 | 38 | 60 | 1 | 1 | ||

| SOB 30-40-12 | 30 | 40 | 12 | 1 | 1 | ||

| SOB 30-40-15 | 30 | 40 | 15 | 1 | 1 | ||

| SOB 30-40-20 | 30 | 40 | 20 | 1 | 1 | ||

| SOB 30-40-25 | 30 | 40 | 25 | 1 | 1 | ||

| SOB 30-40-30 | 30 | 40 | 30 | 1 | 1 | ||

| SOB 30-40-35 | 30 | 40 | 35 | 1 | 1 | ||

| SOB 30-40-40 | 30 | 40 | 40 | 1 | 1 | ||

| SOB 30-40-50 | 30 | 40 | 50 | 1 | 1 | ||

| SOB 30-40-60 | 30 | 40 | 60 | 1 | 1 | ||

| SOB 31,5-40-30 | 31,5 | 40 | 30 | 1 | 1 | ||

| SOB 31,5-40-40 | 31,5 | 40 | 40 | 1 | 1 | ||

| SOB 32-42-15 | 32 | 42 | 15 | 1 | 1 | ||

| SOB 32-42-20 | 32 | 42 | 20 | 1 | 1 | ||

| SOB 32-42-30 | 32 | 42 | 30 | 1 | 1 | ||

| SOB 32-42-40 | 32 | 42 | 40 | 1 | 1 | ||

| SOB 35-44-20 | 35 | 44 | 20 | 1 | 1 | ||

| SOB 35-44-25 | 35 | 44 | 25 | 1 | 1 | ||

| SOB 35-44-30 | 35 | 44 | 30 | 1 | 1 | ||

| SOB 35-44-35 | 35 | 44 | 35 | 1 | 1 | ||

| SOB 35-44-40 | 35 | 44 | 40 | 1 | 1 | ||

| SOB 35-44-50 | 35 | 44 | 50 | 1 | 1 | ||

| SOB 35-44-60 | 35 | 44 | 60 | 1 | 1 | ||

| SOB 35-45-15 | 35 | 45 | 15 | 1 | 1 | ||

| SOB 35-45-20 | 35 | 45 | 20 | 1 | 1 | ||

| SOB 35-45-25 | 35 | 45 | 25 | 1 | 1 | ||

| SOB 35-45-30 | 35 | 45 | 30 | 1 | 1 | ||

| SOB 35-45-35 | 35 | 45 | 35 | 1 | 1 | ||

| SOB 35-45-40 | 35 | 45 | 40 | 1 | 1 | ||

| SOB 35-45-50 | 35 | 45 | 50 | 1 | 1 | ||

| SOB 35-45-60 | 35 | 45 | 60 | 1 | 1 | ||

| SOB 38-48-30 | 38 | 48 | 30 | 1 | 1 | ||

| SOB 38-48-40 | 38 | 48 | 40 | 1 | 1 | ||

| SOB 40-50-15 | 40 | 50 | 15 | 1 | 1 | ||

| SOB 40-50-20 | 40 | 50 | 20 | 1 | 1 | ||

| SOB 40-50-25 | 40 | 50 | 25 | 1 | 1 | ||

| SOB 40-50-30 | 40 | 50 | 30 | 1 | 1 | ||

| SOB 40-50-35 | 40 | 50 | 35 | 1 | 1 | ||

| SOB 40-50-40 | 40 | 50 | 40 | 1 | 1 | ||

| SOB 40-50-50 | 40 | 50 | 50 | 1 | 1 | ||

| SOB 40-50-60 | 40 | 50 | 60 | 1 | 1 | ||

| SOB 40-50-70 | 40 | 50 | 70 | 1 | 1 | ||

| SOB 40-50-80 | 40 | 50 | 80 | 1 | 1 | ||

| SOB 40-55-15 | 40 | 55 | 15 | 1 | 1 | ||

| SOB 40-55-25 | 40 | 55 | 25 | 1 | 1 | ||

| SOB 40-55-30 | 40 | 55 | 30 | 1 | 1 | ||

| SOB 40-55-35 | 40 | 55 | 35 | 1 | 1 | ||

| SOB 40-55-40 | 40 | 55 | 40 | 1 | 1 | ||

| SOB 40-55-50 | 40 | 55 | 50 | 1 | 1 | ||

| SOB 40-55-60 | 40 | 55 | 60 | 1 | 1 | ||

| SOB 45-55-30 | 45 | 55 | 30 | 1 | 1 | ||

| SOB 45-55-35 | 45 | 55 | 35 | 1 | 1 | ||

| SOB 45-55-40 | 45 | 55 | 40 | 1 | 1 | ||

| SOB 45-55-50 | 45 | 55 | 50 | 1 | 1 | ||

| SOB 45-55-60 | 45 | 55 | 60 | 1 | 1 | ||

| SOB 45-56-30 | 45 | 56 | 30 | 1 | 1 | ||

| SOB 45-56-35 | 45 | 56 | 35 | 1 | 1 | ||

| SOB 45-56-40 | 45 | 56 | 40 | 1 | 1 | ||

| SOB 45-56-50 | 45 | 56 | 50 | 1 | 1 | ||

| SOB 45-56-60 | 45 | 56 | 60 | 1 | 1 | ||

| SOB 45-60-30 | 45 | 60 | 30 | 1 | 1 | ||

| SOB 45-60-35 | 45 | 60 | 35 | 1 | 1 | ||

| SOB 45-60-40 | 45 | 60 | 40 | 1 | 1 | ||

| SOB 45-60-50 | 45 | 60 | 50 | 1 | 1 | ||

| SOB 45-60-60 | 45 | 60 | 60 | 1 | 1 | ||

| SOB 45-60-70 | 45 | 60 | 70 | 1 | 1 | ||

| SOB 45-60-80 | 45 | 60 | 80 | 1 | 1 | ||

| SOB 50-60-20 | 50 | 60 | 20 | 1 | 1 | ||

| SOB 50-60-25 | 50 | 60 | 25 | 1 | 1 | ||

| SOB 50-60-30 | 50 | 60 | 30 | 1 | 1 | ||

| SOB 50-60-35 | 50 | 60 | 35 | 1 | 1 | ||

| SOB 50-60-40 | 50 | 60 | 40 | 1 | 1 | ||

| SOB 50-60-50 | 50 | 60 | 50 | 1 | 1 | ||

| SOB 50-60-60 | 50 | 60 | 60 | 1 | 1 | ||

| SOB 50-60-70 | 50 | 60 | 70 | 1 | 1 | ||

| SOB 50-60-80 | 50 | 60 | 80 | 1 | 1 | ||

| SOB 50-62-30 | 50 | 62 | 30 | 1 | 1 | ||

| SOB 50-62-35 | 50 | 62 | 35 | 1 | 1 | ||

| SOB 50-62-40 | 50 | 62 | 40 | 1 | 1 | ||

| SOB 50-62-50 | 50 | 62 | 50 | 1 | 1 | ||

| SOB 50-62-60 | 50 | 62 | 60 | 1 | 1 | ||

| SOB 50-62-70 | 50 | 62 | 70 | 1 | 1 | ||

| SOB 50-62-80 | 50 | 62 | 80 | 1 | 1 |

| SOB 50-65-30 | 50 | 65 | 30 | 1 | 1 | ||

| SOB 50-65-40 | 50 | 65 | 40 | 1 | 1 | ||

| SOB 50-65-50 | 50 | 65 | 50 | 1 | 1 | ||

| SOB 50-65-60 | 50 | 65 | 60 | 1 | 1 | ||

| SOB 50-65-70 | 50 | 65 | 70 | 1 | 1 | ||

| SOB 50-65-80 | 50 | 65 | 80 | 1 | 1 | ||

| SOB 50-65-100 | 50 | 65 | 100 | 1 | 1 | ||

| SOB 55-70-30 | 55 | 70 | 30 | 1 | 1 | ||

| SOB 55-70-35 | 55 | 70 | 35 | 1 | 1 | ||

| SOB 55-70-40 | 55 | 70 | 40 | 1 | 1 | ||

| SOB 55-70-50 | 55 | 70 | 50 | 1 | 1 | ||

| SOB 55-70-60 | 55 | 70 | 60 | 1 | 1 | ||

| SOB 55-70-70 | 55 | 70 | 70 | 1 | 1 | ||

| SOB 60-74-30 | 60 | 74 | 30 | 1 | 1 | ||

| SOB 60-74-35 | 60 | 74 | 35 | 1 | 1 | ||

| SOB 60-74-40 | 60 | 74 | 40 | 1 | 1 | ||

| SOB 60-74-50 | 60 | 74 | 50 | 1 | 1 | ||

| SOB 60-74-60 | 60 | 74 | 60 | 1 | 1 | ||

| SOB 60-74-70 | 60 | 74 | 70 | 1 | 1 | ||

| SOB 60-74-80 | 60 | 74 | 80 | 1 | 1 | ||

| SOB 60-74-100 | 60 | 74 | 100 | 1 | 1 | ||

| SOB 60-75-30 | 60 | 75 | 30 | 1 | 1 | ||

| SOB 60-75-35 | 60 | 75 | 35 | 1 | 1 | ||

| SOB 60-75-40 | 60 | 75 | 40 | 1 | 1 | ||

| SOB 60-75-50 | 60 | 75 | 50 | 1 | 1 | ||

| SOB 60-75-60 | 60 | 75 | 60 | 1 | 1 | ||

| SOB 60-75-70 | 60 | 75 | 70 | 1 | 1 | ||

| SOB 60-75-80 | 60 | 75 | 80 | 1 | 1 | ||

| SOB 60-75-100 | 60 | 75 | 100 | 1 | 1 | ||

| SOB 63-75-60 | 63 | 75 | 60 | 1 | 1 | ||

| SOB 63-75-70 | 63 | 75 | 70 | 1 | 1 | ||

| SOB 63-75-80 | 63 | 75 | 80 | 1 | 1 | ||

| SOB 65-80-40 | 65 | 80 | 40 | 1 | 1 | ||

| SOB 65-80-50 | 65 | 80 | 50 | 1 | 1 | ||

| SOB 65-80-60 | 65 | 80 | 60 | 1 | 1 | ||

| SOB 65-80-70 | 65 | 80 | 70 | 1 | 1 | ||

| SOB 65-80-80 | 65 | 80 | 80 | 1 | 1 | ||

| SOB 70-85-30 | 70 | 85 | 30 | 1 | 1 | ||

| SOB 70-85-35 | 70 | 85 | 35 | 1 | 1 | ||

| SOB 70-85-40 | 70 | 85 | 40 | 1 | 1 | ||

| SOB 70-85-50 | 70 | 85 | 50 | 1 | 1 | ||

| SOB 70-85-60 | 70 | 85 | 60 | 1 | 1 | ||

| SOB 70-85-70 | 70 | 85 | 70 | 1 | 1 | ||

| SOB 70-85-80 | 70 | 85 | 80 | 1 | 1 | ||

| SOB 70-85-100 | 70 | 85 | 100 | 1 | 1 | ||

| SOB 70-90-50 | 70 | 90 | 50 | 1 | 1 | ||

| SOB 70-90-60 | 70 | 90 | 60 | 1 | 1 | ||

| SOB 70-90-70 | 70 | 90 | 70 | 1 | 1 | ||

| SOB 70-90-80 | 70 | 90 | 80 | 1 | 1 | ||

| SOB 70-90-100 | 70 | 90 | 100 | 1 | 1 | ||

| SOB 75-90-50 | 75 | 90 | 50 | 1 | 1 | ||

| SOB 75-90-60 | 75 | 90 | 60 | 1 | 1 | ||

| SOB 75-90-70 | 75 | 90 | 70 | 1 | 1 | ||

| SOB 75-90-80 | 75 | 90 | 80 | 1 | 1 | ||

| SOB 75-90-100 | 75 | 90 | 100 | 1 | 1 | ||

| SOB 75-95-60 | 75 | 95 | 60 | 1 | 1 | ||

| SOB 75-95-70 | 75 | 95 | 70 | 1 | 1 | ||

| SOB 75-95-80 | 75 | 95 | 80 | 1 | 1 | ||

| SOB 75-95-100 | 75 | 95 | 100 | 1 | 1 | ||

| SOB 80-96-20 | 80 | 96 | 20 | 1 | 1 | ||

| SOB 80-96-40 | 80 | 96 | 40 | 1 | 1 | ||

| SOB 80-96-50 | 80 | 96 | 50 | 1 | 1 | ||

| SOB 80-96-60 | 80 | 96 | 60 | 1 | 1 | ||

| SOB 80-96-70 | 80 | 96 | 70 | 1 | 1 | ||

| SOB 80-96-80 | 80 | 96 | 80 | 1 | 1 | ||

| SOB 80-96-100 | 80 | 96 | 100 | 1 | 1 | ||

| SOB 80-96-120 | 80 | 96 | 120 | 1 | 1 | ||

| SOB 80-100-40 | 80 | 100 | 40 | 1 | 1 | ||

| SOB 80-100-50 | 80 | 100 | 50 | 1 | 1 | ||

| SOB 80-100-60 | 80 | 100 | 60 | 1 | 1 | ||

| SOB 80-100-70 | 80 | 100 | 70 | 1 | 1 | ||

| SOB 80-100-80 | 80 | 100 | 80 | 1 | 1 | ||

| SOB 80-100-100 | 80 | 100 | 100 | 1 | 1 | ||

| SOB 80-100-120 | 80 | 100 | 120 | 1 | 1 | ||

| SOB 80-100-140 | 80 | 100 | 140 | 1 | 1 | ||

| SOB 85-100-25 | 85 | 100 | 25 | 1 | 1 | ||

| SOB 85-100-60 | 85 | 100 | 60 | 1 | 1 | ||

| SOB 85-100-80 | 85 | 100 | 80 | 1 | 1 | ||

| SOB 90-110-30 | 90 | 110 | 30 | 1 | 1 | ||

| SOB 90-110-50 | 90 | 110 | 50 | 1 | 1 | ||

| SOB 90-110-60 | 90 | 110 | 60 | 1 | 1 | ||

| SOB 90-110-70 | 90 | 110 | 70 | 1 | 1 | ||

| SOB 90-110-80 | 90 | 110 | 80 | 1 | 1 | ||

| SOB 90-110-90 | 90 | 110 | 90 | 1 | 1 | ||

| SOB 90-110-100 | 90 | 110 | 100 | 1 | 1 | ||

| SOB 90-110-120 | 90 | 110 | 120 | 1 | 1 | ||

| SOB 100-115-100 | 100 | 115 | 100 | 1,5 | 1,5 | ||

| SOB 100-120-40 | 100 | 120 | 40 | 1,5 | 1,5 | ||

| SOB 100-120-50 | 100 | 120 | 50 | 1,5 | 1,5 | ||

| SOB 100-120-60 | 100 | 120 | 60 | 1,5 | 1,5 | ||

| SOB 100-120-70 | 100 | 120 | 70 | 1,5 | 1,5 | ||

| SOB 100-120-80 | 100 | 120 | 80 | 1,5 | 1,5 | ||

| SOB 100-120-90 | 100 | 120 | 90 | 1,5 | 1,5 | ||

| SOB 100-120-100 | 100 | 120 | 100 | 1,5 | 1,5 | ||

| SOB 100-120-120 | 100 | 120 | 120 | 1,5 | 1,5 | ||

| SOB 100-120-140 | 100 | 120 | 140 | 1,5 | 1,5 | ||

| SOB 110-130-50 | 110 | 130 | 50 | 1,5 | 1,5 | ||

| SOB 110-130-70 | 110 | 130 | 70 | 1,5 | 1,5 | ||

| SOB 110-130-80 | 110 | 130 | 80 | 1,5 | 1,5 | ||

| SOB 110-130-100 | 110 | 130 | 100 | 1,5 | 1,5 |

| SOB 110-130-120 | 110 | 130 | 120 | 1,5 | 1,5 | ||

| SOB 120-140-70 | 120 | 140 | 70 | 1,5 | 1,5 | ||

| SOB 120-140-80 | 120 | 140 | 80 | 1,5 | 1,5 | ||

| SOB 120-140-90 | 120 | 140 | 90 | 1,5 | 1,5 | ||

| SOB 120-140-100 | 120 | 140 | 100 | 1,5 | 1,5 | ||

| SOB 120-140-120 | 120 | 140 | 120 | 1,5 | 1,5 | ||

| SOB 120-140-140 | 120 | 140 | 140 | 1,5 | 1,5 | ||

| SOB 125-145-100 | 125 | 145 | 100 | 1,5 | 1,5 | ||

| SOB 125-145-120 | 125 | 145 | 120 | 1,5 | 1,5 | ||

| SOB 130-150-80 | 130 | 150 | 80 | 1,5 | 1,5 | ||

| SOB 130-150-100 | 130 | 150 | 100 | 1,5 | 1,5 | ||

| SOB 130-150-130 | 130 | 150 | 130 | 1,5 | 1,5 | ||

| SOB 140-160-100 | 140 | 160 | 100 | 1,5 | 1,5 | ||

| SOB 140-160-140 | 140 | 160 | 140 | 1,5 | 1,5 | ||

| SOB 150-170-100 | 150 | 170 | 100 | 1,5 | 1,5 | ||

| SOB 150-170-150 | 150 | 170 | 150 | 1,5 | 1,5 | ||

| SOB 160-180-80 | 160 | 180 | 80 | 1,5 | 1,5 | ||

| SOB 160-180-100 | 160 | 180 | 100 | 1,5 | 1,5 | ||

| SOB 160-180-150 | 160 | 180 | 150 | 1,5 | 1,5 | ||

| SOB 170-190-100 | 170 | 190 | 100 | 1,5 | 1,5 | ||

| SOB 170-190-150 | 170 | 190 | 150 | 1,5 | 1,5 | ||

| SOB 180-200-100 | 180 | 200 | 100 | 1,5 | 1,5 | ||

| SOB 180-200-150 | 180 | 200 | 150 | 1,5 | 1,5 | ||

| SOB 190-210-100 | 190 | 210 | 100 | 1,5 | 1,5 | ||

| SOB 190-210-150 | 190 | 210 | 150 | 1,5 | 1,5 | ||

| SOB 200-230-150 | 200 | 230 | 150 | 1,5 | 1,5 | ||

| SOB 200-230-200 | 200 | 230 | 200 | 1,5 | 1,5 |

(Flange Solid Bronze Bushing Inner Diameter: 8 to 120 mm)

Choose your Inner diameter, Flanged bush, self-lubricating equivalent, Sankyo oilless Alternatives, Price and delivery time on request,

| SOBF 8-12-10 | 8 | 12 | 10 | 20 | 2 | 0,5 | |||

| SOBF 8-12-12 | 8 | 12 | 12 | 20 | 2 | 0,5 | |||

| SOBF 8-12-15 | 8 | 12 | 15 | 20 | 2 | 1 | |||

| SOBF 10-14-10 | 10 | 14 | 10 | 22 | 2 | 1 | |||

| SOBF 10-14-12 | 10 | 14 | 12 | 22 | 2 | 1 | |||

| SOBF 10-14-15 | 10 | 14 | 15 | 22 | 2 | 1 | |||

| SOBF 10-14-17 | 10 | 14 | 17 | 22 | 2 | 1 | |||

| SOBF 10-14-20 | 10 | 14 | 20 | 22 | 2 | 1 | |||

| SOBF 12-18-10 | 12 | 18 | 10 | 25 | 3 | 1 | |||

| SOBF 12-18-12 | 12 | 18 | 12 | 25 | 3 | 1 | |||

| SOBF 12-18-15 | 12 | 18 | 15 | 25 | 3 | 1 | |||

| SOBF 12-18-20 | 12 | 18 | 20 | 25 | 3 | 1 | |||

| SOBF 12-18-25 | 12 | 18 | 25 | 25 | 3 | 1 | |||

| SOBF 12-18-30 | 12 | 18 | 30 | 25 | 3 | 1 | |||

| SOBF 13-19-10 | 13 | 19 | 10 | 26 | 3 | 1 | |||

| SOBF 13-19-12 | 13 | 19 | 12 | 26 | 3 | 1 | |||

| SOBF 13-19-15 | 13 | 19 | 15 | 26 | 3 | 1 | |||

| SOBF 13-19-20 | 13 | 19 | 20 | 26 | 3 | 1 | |||

| SOBF 13-19-25 | 13 | 19 | 25 | 26 | 3 | 1 | |||

| SOBF 13-19-30 | 13 | 19 | 30 | 26 | 3 | 1 | |||

| SOBF 14-20-15 | 14 | 20 | 15 | 27 | 3 | 1 | |||

| SOBF 14-20-20 | 14 | 20 | 20 | 27 | 3 | 1 | |||

| SOBF 14-20-25 | 14 | 20 | 25 | 27 | 3 | 1 | |||

| SOBF 15-21-10 | 15 | 21 | 10 | 28 | 3 | 1 | |||

| SOBF 15-21-12 | 15 | 21 | 12 | 28 | 3 | 1 | |||

| SOBF 15-21-15 | 15 | 21 | 15 | 28 | 3 | 1 | |||

| SOBF 15-21-20 | 15 | 21 | 20 | 28 | 3 | 1 | |||

| SOBF 15-21-25 | 15 | 21 | 25 | 28 | 3 | 1 | |||

| SOBF 15-21-30 | 15 | 21 | 30 | 28 | 3 | 1 | |||

| SOBF 16-22-12 | 16 | 22 | 12 | 29 | 3 | 1 | |||

| SOBF 16-22-15 | 16 | 22 | 15 | 29 | 3 | 1 | |||

| SOBF 16-22-18 | 16 | 22 | 18 | 29 | 3 | 1 | |||

| SOBF 16-22-20 | 16 | 22 | 20 | 29 | 3 | 1 | |||

| SOBF 16-22-23 | 16 | 22 | 23 | 29 | 3 | 1 | |||

| SOBF 16-22-25 | 16 | 22 | 25 | 29 | 3 | 1 | |||

| SOBF 16-22-30 | 16 | 22 | 30 | 29 | 3 | 1 | |||

| SOBF 16-22-35 | 16 | 22 | 35 | 29 | 3 | 1 | |||

| SOBF 16-22-40 | 16 | 22 | 40 | 29 | 3 | 1 | |||

| SOBF 18-24-15 | 18 | 24 | 15 | 32 | 3 | 1 | |||

| SOBF 18-24-20 | 18 | 24 | 20 | 32 | 3 | 1 | |||

| SOBF 18-24-25 | 18 | 24 | 25 | 32 | 3 | 1 | |||

| SOBF 18-24-30 | 18 | 24 | 30 | 32 | 3 | 1 | |||

| SOBF 18-24-35 | 18 | 24 | 35 | 32 | 3 | 1 | |||

| SOBF 18-24-40 | 18 | 24 | 40 | 32 | 3 | 1 | |||

| SOBF 20-30-15 | 20 | 30 | 15 | 40 | 5 | 1 | |||

| SOBF 20-30-20 | 20 | 30 | 20 | 40 | 5 | 1 | |||

| SOBF 20-30-25 | 20 | 30 | 25 | 40 | 5 | 1 | |||

| SOBF 20-30-30 | 20 | 30 | 30 | 40 | 5 | 1 | |||

| SOBF 20-30-35 | 20 | 30 | 35 | 40 | 5 | 1 | |||

| SOBF 20-30-40 | 20 | 30 | 40 | 40 | 5 | 1 | |||

| SOBF 25-35-15 | 25 | 35 | 15 | 45 | 5 | 1 | |||

| SOBF 25-35-20 | 25 | 35 | 20 | 45 | 5 | 2 | |||

| SOBF 25-35-25 | 25 | 35 | 25 | 45 | 5 | 2 | |||

| SOBF 25-35-30 | 25 | 35 | 30 | 45 | 5 | 2 | |||

| SOBF 25-35-35 | 25 | 35 | 35 | 45 | 5 | 2 | |||

| SOBF 25-35-40 | 25 | 35 | 40 | 45 | 5 | 2 | |||

| SOBF 25-35-50 | 25 | 35 | 50 | 45 | 5 | 2 | |||

| SOBF 30-40-20 | 30 | 40 | 20 | 50 | 5 | 2 | |||

| SOBF 30-40-25 | 30 | 40 | 25 | 50 | 5 | 2 | |||

| SOBF 30-40-30 | 30 | 40 | 30 | 50 | 5 | 2 | |||

| SOBF 30-40-35 | 30 | 40 | 35 | 50 | 5 | 2 | |||

| SOBF 30-40-40 | 30 | 40 | 40 | 50 | 5 | 2 | |||

| SOBF 30-40-50 | 30 | 40 | 50 | 50 | 5 | 2 | |||

| SOBF 31,5-40-20 | 31,5 | 40 | 20 | 50 | 5 | 2 | |||

| SOBF 31,5-40-30 | 31,5 | 40 | 30 | 50 | 5 | 2 | |||

| SOBF 31,5-40-35 | 31,5 | 40 | 35 | 50 | 5 | 2 | |||

| SOBF 31,5-40-40 | 31,5 | 40 | 40 | 50 | 5 | 2 | |||

| SOBF 35-45-20 | 35 | 45 | 20 | 60 | 5 | 2 | |||

| SOBF 35-45-25 | 35 | 45 | 25 | 60 | 5 | 2 | |||

| SOBF 35-45-30 | 35 | 45 | 30 | 60 | 5 | 2 | |||

| SOBF 35-45-35 | 35 | 45 | 35 | 60 | 5 | 2 | |||

| SOBF 35-45-40 | 35 | 45 | 40 | 60 | 5 | 2 | |||

| SOBF 35-45-50 | 35 | 45 | 50 | 60 | 5 | 2 | |||

| SOBF 40-50-20 | 40 | 50 | 20 | 65 | 5 | 2 | |||

| SOBF 40-50-25 | 40 | 50 | 25 | 65 | 5 | 2 | |||

| SOBF 40-50-30 | 40 | 50 | 30 | 65 | 5 | 2 | |||

| SOBF 40-50-35 | 40 | 50 | 35 | 65 | 5 | 2 | |||

| SOBF 40-50-40 | 40 | 50 | 40 | 65 | 5 | 2 | |||

| SOBF 40-50-50 | 40 | 50 | 50 | 65 | 5 | 2 | |||

| SOBF 45-55-30 | 45 | 55 | 30 | 70 | 5 | 2 | |||

| SOBF 45-55-35 | 45 | 55 | 35 | 70 | 5 | 2 | |||

| SOBF 45-55-40 | 45 | 55 | 40 | 70 | 5 | 2 | |||

| SOBF 45-55-50 | 45 | 55 | 50 | 70 | 5 | 2 | |||

| SOBF 45-55-60 | 45 | 55 | 60 | 70 | 5 | 2 | |||

| SOBF 50-60-30 | 50 | 60 | 30 | 75 | 5 | 2 | |||

| SOBF 50-60-35 | 50 | 60 | 35 | 75 | 5 | 2 | |||

| SOBF 50-60-40 | 50 | 60 | 40 | 75 | 5 | 2 | |||

| SOBF 50-60-50 | 50 | 60 | 50 | 75 | 5 | 2 | |||

| SOBF 50-60-60 | 50 | 60 | 60 | 75 | 5 | 2 | |||

| SOBF 55-65-40 | 55 | 65 | 40 | 80 | 5 | 2 | |||

| SOBF 55-65-60 | 55 | 65 | 60 | 80 | 5 | 2 | |||

| SOBF 60-75-40 | 60 | 75 | 40 | 90 | 7,5 | 3 | |||

| SOBF 60-75-50 | 60 | 75 | 50 | 90 | 7,5 | 3 | |||

| SOBF 60-75-80 | 60 | 75 | 80 | 90 | 7,5 | 3 | |||

| SOBF 65-80-60 | 65 | 80 | 60 | 95 | 7,5 | 3 | |||

| SOBF 70-85-50 | 70 | 85 | 50 | 105 | 7,5 | 3 | |||

| SOBF 70-85-80 | 70 | 85 | 80 | 105 | 7,5 | 3 | 1 | ||

| SOBF 75-90-60 | 75 | 90 | 60 | 110 | 7,5 | 3 | 1 | ||

| SOBF 80-100-60 | 80 | 100 | 60 | 120 | 10 | 3 | 1 | ||

| SOBF 80-100-80 | 80 | 100 | 80 | 120 | 10 | 3 | 1 |

TARGET PROPERTIES

| Structure | Sliding Layer Component | Wear Resistance | Load Resistance | ||||

|---|---|---|---|---|---|---|---|

| No Lubrication | Grease | Boundary and Fluid | No Lubrication | Grease | Boundary and Fluid | ||

| Solid | Copper Alloy + Solid Lubricant Burying Type | 4 | 5 | 5 | 5 | 5 | 5 |

| Tolerance of Foreign Particles | Sliding Speed | Friction Coefficient | Effect of Various Atmospheres | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No Lubrication | Grease | Boundary and Fluid | No Lubrication | Grease | Boundary and Fluid | In Air | In Vacuum | In Water | In Vapor | In Acid or Alkali | |

| 4 | 3 | 4 | 4 | 3 | 4 | 4 | 5 | 3 | 3 | 4 | 3 |

- 5=Excellent 4=Very good 3=Good 2=Inadequate 1=Failure

- ※ In an acid/alkaline atmosphere, the evaluation may bring different results. We recommend a sample test in such case. Please feel free to contact us with questions about the application under special conditions.

Copper manganese bronze bearings, A 430B bronze manganese bronze bushes at a good price in china

Find here online price details of companies selling Manganese Bronze Bushing. Get info of manganese bronze bearings supplier, manufacturer, exporter of Manganese Bronze Bushes

Manganese cast bronze bushing, A wide variety of bronze bearing material options are available to you.

C86300 Alloy, C863 Manganese Brass Bushing

Manganese Brass alloys, such as C863, can operate under very high loads and speeds. The standard alloy in this group is high tensile C86300.

C86300 Manganese Bronze (SAE 430B) is a high-strength alloy used as bushings, bearings, bridge plates, and hydraulic cylinder parts. This alloy is generally used in heavy load applications. It performs best at low speeds with reliable lubrication.

Manganese Bronze Alloy C86300

The service life and sealing effect of the oil seal ring, and the material of the oil seal ring have a direct impact on its service life and effect. The new material is called a fierce bronze alloy. The oil seal ring made of this material has better life and effect than the above, and its chemical composition is introduced as follows:

Cu: 57~60%

Mn. 20~35%

A1; 0.5~2.0%

Ni. 1.0—2.5%

Pb. 0.5%

Sn: 0.3% or less

Si: 0.7~1.2%

Zn: Residual (rest)

Manufacturing process of oil seal ring:

1. Casting

2. The car goes to the black skin

3. Forging at 700~750°C, forging ratio <7

4. Fire at 300°C, 2 hours

5. Rough car

6. Quenching at 700~750°C, oil cooling for 30 minutes

7. Sharp flat groove

8. Shaping treatment: deburring, annealing at 300~430°C, oil cooling for 2 hours.

9. Fine car

10. Drilling

11. Grinding plane

Material performance test: tensile strength 60 kg/mm% elongation 9%.

The material can also be used to make piston rings, gear thrust rings, etc. The piston ring made with this has good use effect, and it is reported that the service life is as high as 8000 hours.

Oil-Free Brass Bushings – Straight, Copper Alloy

Embedded lubricant Graphite- Oil-Free Bushings

We offer a free quotes for the plugged graphite parts, short lead times & competitive pricing. Shop Embedded lubricant Graphite Self-lubricating Brass Bushing Bearing.

| Material | Copper alloy | Embedded lubricant | Graphite | Type | Oilless Bushing:

Straight/Flanged/Washer |

|---|---|---|---|---|---|

| Heat resistance temperature | 450℃ or lower |

The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer bronze bushing catalogs.

Bronze Bushing- Quick, Finished & Machined

Bronze Bearing- Quick, Finished & Machined, High quality and fast delivery.

Product Overview: Oil Free Bushing – Brass Alloy, Shouldered and Flanged, finishing copper alloy bushings provide a simple, economical way to use bearings with high bearing, good corrosion resistance, size and other characteristics of any process. Meanwhile we can provide different grades of copper alloy according to different conditions, and in accordance with the requirements of processing different forms, it has a higher accuracy than the size class copper rolling bearings. Manganese bronzes alloys C863 can operate under very high loads and speeds. The standard alloy in this group is high tensile C86300 Bronze Bearing. Supply the commonly used forms of copper and its alloys including sheet, plate, machining bar & hollow bar, flat bar, hexagon bar and tube. In addition to a comprehensive range of standard sizes, We custom the specific items and customer specials. We also provides a complete range of processing services including bronze bar, tube & pipe cutting and plate processing. Also includes aluminium bronze, tin bronze bearing in semifinished forms. The bronze alloy and lubricant selected for a particular bearing are based on the requirements of the specific application and operating conditions. bearings consist of a support structure cast from one of four available high-quality bronze alloys. Embedded in this structure are solid lubricant inserts or plugs, providing continuous lubrication for low friction and wear rates and long service life. The inserts, supplemented with an applied running-in film, are arranged for optimal distribution of the lubricant over the life of the bearing. This structure provides an ultra-low coefficient of friction, maximum wear resistance, extended service and corrosion resistance, even in wet, dirty environments and exposure to seawater. The bronze alloy and lubricant selected for a particular bearing are based on the requirements of the specific application and operating conditions!

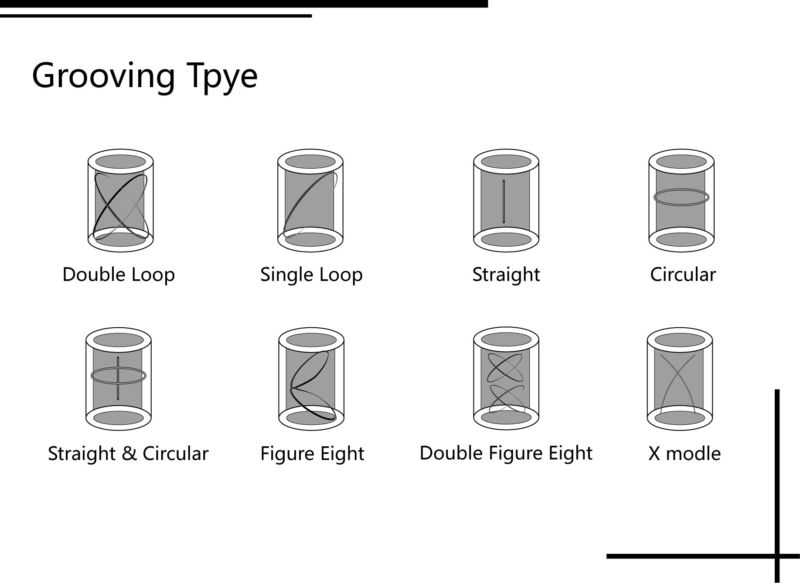

Custom & Special Groove Patterns

Grooving Type

| STANDARD GROOVES | OIL & GREASE | ||||||||

|---|---|---|---|---|---|---|---|---|

| Groove Type | Single Loop | Figure Eight | Straight & Circular | Double Loop | Double Figure Eight | Half Figure Eight | Straight | Circular |

Metal Comparisons: Brass vs. Bronze

What Is Bronze?

Composition — Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals

- Leaded bronze

- Phosphor bronze

- Aluminum bronze

- Tin bronze

- Manganese bronze

What Is Brass?

Brass is a non-ferrous, red metal and an alloy that is composed of copper and zinc. The proportions of copper and zinc can be varied in order to achieve different desired mechanical and electrical properties. … Brass is a good conductor of heat with a low melting point.

The Differences Between Bronze and Brass

The Differences Between Bronze and Brass