Thrust Washers: The Ultimate Guide to Self-lubricating Solutions

Thrust washers, often overlooked but undeniably essential, play a pivotal role in the realm of mechanical components. These flat bearings ensure that the movement between a rotating component and a stationary one is smooth, efficient, and free of wear. As technology has advanced, so has the need for more specialized thrust washers, leading to the development of self-lubricating washers. Here’s a deep dive into the world of these special washers, their benefits, and their applications. The evolution of self-lubricating thrust washers showcases how engineering advancements can lead to practical solutions that simplify operations, reduce costs, and enhance performance. Whether you’re involved in heavy machinery, automotive design, or any field that relies on moving parts, considering the type of thrust washer can make a significant difference in the efficiency and longevity of the system.

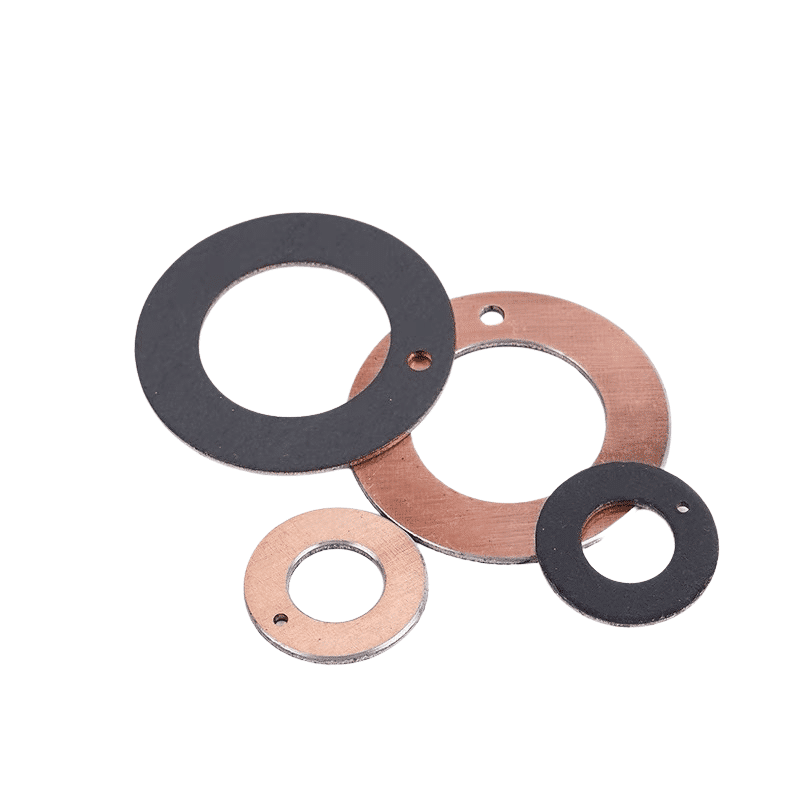

Custom Thrust Washer Metal-Polymer Anti-Friction Plain Bearing

What are Self-lubricating Thrust Washers? Types of Thrust Washers, Self-Lubricating Thrust Washers

Simply put, these are thrust washers designed to operate without the need for additional lubrication. Thanks to the inclusion of materials like PTFE (Polytetrafluoroethylene) and certain proprietary filled tapes, these washers can function smoothly in environments where traditional lubrication might be a challenge. In an age where efficiency, longevity, and maintenance-free operation are more than just buzzwords, self-lubricating thrust washers stand out as the epitome of modern engineering solutions. Whether you’re an engineer looking to design a new system or someone seeking replacements, these washers promise performance that’s a cut above the rest.

Looking for more information or need a customized solution? Talk to our expert engineers. We specialize in designing and manufacturing tailor-made composite thrust washers and bearings to meet your exact requirements. Trust in our expertise and experience to provide you with the best in the world of thrust washers. Different types of thrust washers cater to various industrial needs, but self-lubricating thrust washers stand out for their unique properties.

Custom Thrust washer Applications, Thrust Washer, Self-Lubricating: A Comprehensive Guide

Composite dry sliding thrust washers are particularly beneficial in spaces where:

- Axial space is limited.

- Traditional maintenance is not feasible.

- The environment is dusty or dirty, making traditional lubrication ineffective.

Furthermore, the lubrication-free nature of these washers makes them a boon for environments where contaminants can interfere with the functioning of traditional lubricants.

Key Advantages of Self-Lubricating Thrust Washers: Reduced Maintenance: No need for frequent lubrication or checks, ideal for inaccessible areas.

- Versatility: Suitable for dry running and lubricated conditions.

- Durability: Enhanced lifespan due to reduced wear and tear.

- Environmental Benefits: Reduced dependence on external lubricants means fewer chances of environmental contamination.

- Economic: Lower maintenance and longer lifespan translate to cost savings in the long run.

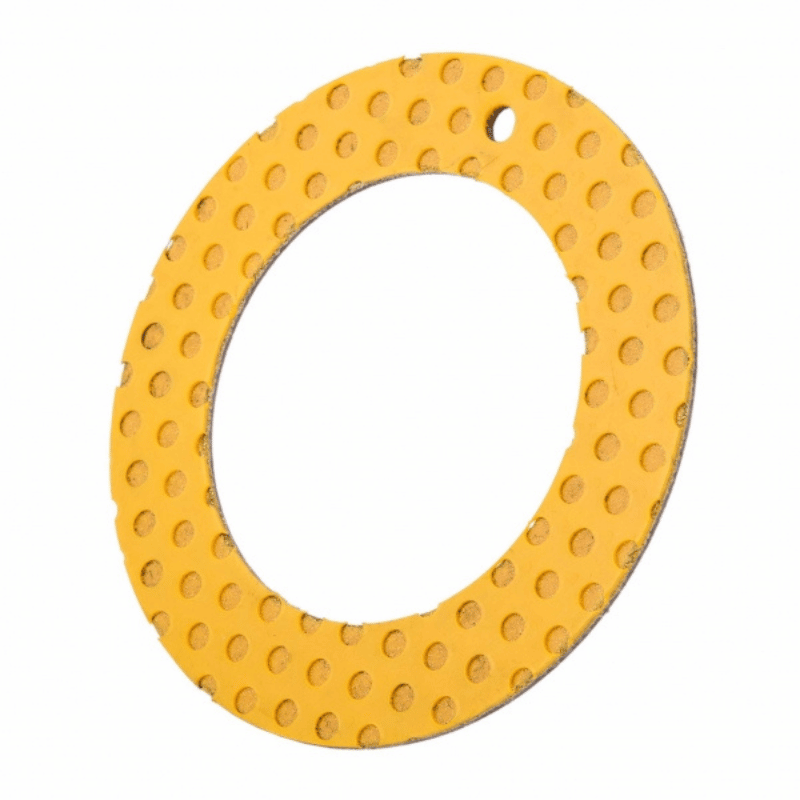

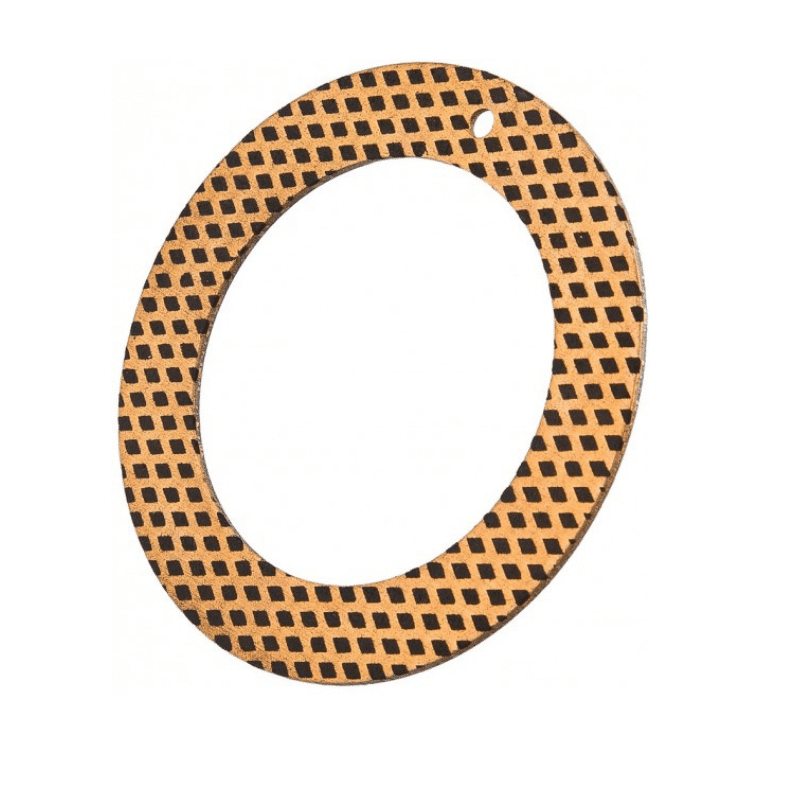

An Insight into Self-Lubricating Thrust Washer Types

fitting to prevent undue stress and wear.

Maintenance Tips

Although self-lubricating washers require less maintenance, regular inspections are recommended to ensure their integrity and performance. This includes checking for wear and tear and ensuring the surrounding components are in good condition.

Selection Criteria

Choosing the right self-lubricating thrust washer involves several considerations to ensure optimal performance and longevity.

Size and Load Capacity

Selecting a washer with the appropriate size and load capacity is crucial for it to function effectively in the intended application. This ensures the washer can handle the axial loads without failing.

Environmental Considerations

Self-lubricating thrust washers represent a significant advancement in the field of mechanical components. Their ability to operate efficiently with minimal maintenance under various conditions makes them a valuable addition to numerous applications. As material science progresses, we can expect these washers to become even more versatile and environmentally friendly, continuing to revolutionize machinery efficiency.The operating environment, including temperature, humidity, and exposure to corrosive elements, should be considered when selecting a thrust washer. Some materials are better suited for certain environments than others.

Compatibility with Other Components

It’s important to ensure that the washer material is compatible with the materials of the adjacent components to avoid galvanic corrosion or other detrimental interactions.

Innovations and Future Trends

Recent Technological Advancements

Recent advancements in material science have led to the development of more efficient and durable self-lubricating thrust washers. These innovations include the use of advanced polymers and composites.

Future Developments in Material Science

The future of self-lubricating thrust washers lies in continuous material innovation, aiming to enhance performance, reduce environmental impact, and cater to more demanding applications.

Case Studies

Real-World Application Examples

Several case studies demonstrate the successful implementation of self-lubricating thrust washers in various industries, showcasing their benefits in terms of efficiency and cost savings.

Success Stories

These case studies not only highlight the practical applications but also serve as success stories that inspire further adoption and development in the field.

Environmental Impact

Sustainability Aspects

The long lifespan and reduced maintenance requirements of self-lubricating thrust washers contribute to their sustainability, as they lead to less waste and resource consumption.

Recycling and Disposal

Issues surrounding the recycling and disposal of these washers are also important, with ongoing research focusing on making them more eco-friendly.

Thrust Washers: An Overview and Their Importance in Modern Machinery

In the intricate world of machinery, every component plays a crucial role, ensuring the overall system functions smoothly. Among these components, thrust washers, though small, hold significant importance. If you’re unfamiliar with thrust washers or want to understand their relevance, you’re in the right place. Let’s dive in!

What is a Thrust Washer?

A thrust washer is a flat bearing that rotates between the components of a machine to prevent movement along the axis. Simply put, it’s a type of bearing that supports axial loads (loads parallel to the shaft). Made from various materials, these washers can be found in numerous applications where there’s a need to control and limit the movement of parts in an axial direction.

Self-Lubricating Thrust Washers

Traditional thrust washers require external lubrication to minimize friction and wear. However, advancements in material science have led to the development of self-lubricating thrust washers. As a supplier of these innovative components, you provide a solution that embeds lubricating agents directly into the washer material. This design ensures continuous lubrication, reducing maintenance and extending the washer’s lifespan.

Benefits of Self-Lubricating Thrust Washers

- Lower Maintenance: One of the standout features of self-lubricating thrust washers is the reduced maintenance requirement. There’s no need for periodic re-lubrication, which can be time-consuming and costly.

- Extended Service Life: With consistent lubrication, the wear and tear on the washer are minimized, leading to a longer operational life.

- Consistent Performance: The embedded lubricants ensure that the washer’s performance doesn’t deteriorate over time, providing reliable operation throughout its lifespan.

- Environmental Benefits: Reduced external lubrication means fewer chemicals released into the environment, making self-lubricating thrust washers a greener choice.

- Economical: Despite the potentially higher upfront cost, the savings in maintenance and the extended service life often make self-lubricating thrust washers a cost-effective choice in the long run.

Applications of Self-Lubricating Thrust Washers

Self-lubricating thrust washers are versatile and find their way into various applications, including:

- Automotive: Used in transmissions, suspensions, and steering systems.

- Industrial Equipment: Featured in machinery where axial loads need to be managed, like conveyor systems.

- Electronics: Employed in devices where there’s rotational movement but axial movement needs to be constrained.

- Aerospace: Used in various aircraft components to ensure smooth operation.

Conclusion

Thrust washers, particularly self-lubricating variants, are unsung heroes in many machines and devices we use daily. They ensure that our systems run efficiently while reducing the need for maintenance. As a supplier of self-lubricating thrust washers, you play a pivotal role in advancing the machinery industry, making operations smoother, more reliable, and more sustainable.

Flanged Thrust Washers: An Overview

In the world of mechanical components, thrust washers play a crucial role in managing axial loads and reducing friction between moving parts. Among the various types, flanged thrust washers stand out for their unique design and specific applications. Let’s delve into the world of flanged thrust washers and explore their significance, construction, and benefits.

What are Flanged Thrust Washers?

Flanged thrust washers are similar to standard thrust washers but come with an added radial flange. This flange provides additional surface area, which can be beneficial in certain applications for distributing loads, locating components, or even serving as an axial bearing surface.

Key Features:

- Integrated Flange: The primary distinguishing feature, the flange, extends radially from the central washer portion.

- Varied Materials: Just like other thrust washers, flanged variants can be made of metals, composites, or even self-lubricating materials, depending on the application’s requirements.

- Different Sizes: They are available in a variety of sizes and flange dimensions to cater to various applications.

Benefits of Flanged Thrust Washers:

- Enhanced Load Distribution: The flange provides an increased surface area, helping distribute axial loads over a larger area, reducing wear and prolonging the component’s life.

- Precise Component Location: The flange can act as a locating feature, ensuring that components are correctly aligned and positioned during assembly.

- Additional Axial Bearing Surface: The flange can serve as an additional bearing surface, especially useful in applications where axial loads change direction or where multiple loads need to be managed.

- Reduced Wear: By providing a larger surface area for load distribution, flanged thrust washers can reduce wear and tear on the components they interface with.

- Versatility: Suitable for a variety of applications, including automotive, machinery, and gear assemblies.

Applications:

Flanged thrust washers are particularly useful in:

- Gearboxes: To manage axial loads and maintain gear alignment.

- Automotive Systems: In suspension components, steering systems, and other areas where precise component positioning is crucial.

- Pumps and Valves: To handle varying axial loads and ensure smooth operation.

- Industrial Machinery: In various components where axial load management and component positioning are essential.

Conclusion:

Flanged thrust washers, with their unique design, offer a blend of functionality and durability. They not only manage axial loads efficiently but also provide added benefits in terms of component positioning and load distribution. Whether you’re an engineer designing a new system or involved in maintenance, understanding the role and advantages of flanged thrust washers can lead to more efficient and longer-lasting mechanical systems

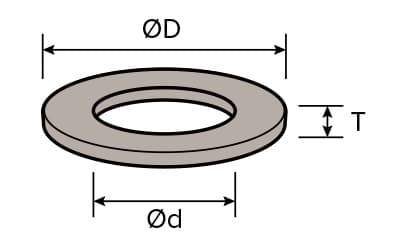

Thrust Washer Size Chart: A Comprehensive Guide

When delving into the realm of machinery and engineering, the significance of precise component dimensions cannot be overstated. Thrust washers, in particular, play an instrumental role in various applications. These small, yet crucial, components ensure that machines operate smoothly by preventing friction between rotating elements. In this guide, we will comprehensively explore the sizes of thrust washers and their relevance in different applications.

Understanding Thrust Washers

Before we dive into the size chart, it’s essential to grasp the fundamental role of thrust washers. They are flat, circular, or donut-shaped components that provide a bearing surface for rotary applications. By doing so, they prevent wear and tear between machine elements and ensure longevity.

Why Size Matters

The size of a thrust washer is crucial because an incorrect size can lead to inefficiencies, premature wear, and potential damage to the machinery. For instance:

- Diameter: The diameter of the thrust washer must match the specifications of the machinery component it’s paired with. An oversized washer could hinder movement, while an undersized one may not provide adequate support.

- Thickness: The thickness of the thrust washer can affect the gap between components. An overly thick washer might cause binding, while a thin one may not prevent contact between parts effectively.

The Size Chart: Navigating Through Dimensions

Given the paramount importance of correct sizing, we present a detailed size chart for thrust washers:

Standard Sizes for Circular Thrust Washers

| Diameter (mm) | Thickness (mm) |

|---|---|

| 10 | 1.5 |

| 15 | 2.0 |

| 20 | 2.5 |

| 25 | 3.0 |

(Note: This is a hypothetical chart. Actual sizes may vary based on manufacturer specifications and application requirements.)

Standard Sizes for Donut-Shaped Thrust Washers

| Outer Diameter (mm) | Inner Diameter (mm) | Thickness (mm) |

|---|---|---|

| 20 | 10 | 1.5 |

| 25 | 15 | 2.0 |

| 30 | 20 | 2.5 |

| 35 | 25 | 3.0 |

(Note: This is a hypothetical chart. Actual sizes may vary based on manufacturer specifications and application requirements.)

Selecting the Right Size: Factors to Consider

While the size chart serves as a foundational reference, it’s imperative to consider several factors when selecting the ideal thrust washer size:

- Application Requirements: Different machinery and applications might have unique sizing needs. Always refer to the manufacturer’s guidelines or consult with an engineer.

- Material: The material of the thrust washer can impact its size. For example, metal-polymer thrust washers might have different dimensions than those made purely of metal.

- Load and Speed: Depending on the load and speed of the machinery, the thrust washer size might need adjustments. High-speed applications may require thinner washers, while high-load scenarios might benefit from thicker ones.

Customization: Beyond Standard Sizes

In many scenarios, off-the-shelf thrust washer sizes might not suffice. Customized thrust washers allow for precision in unique applications. Many manufacturers offer customization services, ensuring that the thrust washer perfectly fits the machinery’s requirements.

Conclusion

Thrust washers, while seemingly simple components, are vital for the efficient and prolonged operation of machinery. The correct size ensures that these components fulfill their role effectively, preventing undue wear and tear. By understanding and referencing the thrust washer size chart and considering application-specific requirements, one can ensure optimal machine performance and longevity.

All dimensions in mm

THRUST WASHER METRIC SIZE

| Part No. | Inside-O D; |

Outside-0 D。 |

Thickness s- | Dowel Hole | Recess Depth Ha |

|||

| ①do | PCD-Od. | |||||||

| min. | max. | max. | min. | max. min. |

max. min. |

max. min. |

max. min |

|

| WC08 THRUST WASHER BEARING | 10.00 | 10.25 | 20.00 | 19.75 | 1.50 1.45 |

No Hole | No Hole | 1.20 0.95 |

| WC10 THRUST WASHER BEARING | 12.00 | 12.25 | 24.00 | 23.75 | 1.875 1.625 |

18.12 17.88 |

||

| WC12 THRUST WASHER BEARING | 14.00 | 14.25 | 26.00 | 25.75 | 2.375 2.125 |

20.12 19.88 |

||

| WC14 THRUST WASHER BEARING | 16.00 | 16.25 | 30.00 | 29.75 | 22.12 21.88 |

|||

| WC16 THRUST WASHER BEARING | 18.00 | 18.25 | 32.00 | 31.75 | 25.12 24.88 |

|||

| WC18 THRUST WASHER BEARING | 20.00 | 20.25 | 36.00 | 35.75 | 3.375 3.125 |

28.12 27.88 |

||

| WC20 THRUST WASHER BEARING | 22.00 | 22.25 | 38.00 | 37.75 | 30.12 29.88 |

|||

| WC22 THRUST WASHER BEARING | 24.00 | 24.25 | 42.00 | 41.75 | 33.12 32.88 |

|||

| WC24 THRUST WASHER BEARING | 26.00 | 26.25 | 44.00 | 43.75 | 35.12 34.88 |

|||

| WC25 THRUST WASHER BEARING | 28.00 | 28.25 | 48.00 | 47.75 | 4.375 4.125 |

38.12 37.88 |

||

| WC30 THRUST WASHER BEARING | 32.00 | 32.25 | 54.00 | 53.75 | 43.12 42.88 |

|||

| WC35 THRUST WASHER BEARING | 38.00 | 38.25 | 62.00 | 61.75 | 50.12 49.88 |

|||

| WC40 THRUST WASHER BEARING | 42.00 | 42.25 | 66.00 | 65.75 | 54.12 53.88 |

|||

| WC45 THRUST WASHER BEARING | 48.00 | 48.25 | 74.00 | 73.75 | 2.00

1.95 |

61.12 60.88 |

1.70

1.45 |

|

| WC50 THRUST WASHER BEARING | 52.00 | 52.25 | 78.00 | 77.75 | 65.12 64.88 |

|||

| WC60 THRUST WASHER BEARING | 62.00 | 62.25 | 90.00 | 89.75 | 76.12 75.88 |

|||

THRUST WASHER INCH SIZE

| Part No. | Inside-O D; |

Outside-0 D。 |

Thickness

ST |

Dowel Hole | Recess Depth Ha |

|||

| ①do | PCD-O dp | |||||||

| max. | min. | max. | min. | max. min. |

max. min. |

max. min. |

max. min |

|

| THRUST WASHER BEARING PTFE WASHER06 | 0.510 | 0.500 | 0.875 | 0.865 | 0.063 0.061 |

0.077 0.067 |

0.692 0.682 |

0.050 0.040 |

| THRUST WASHER BEARING PTFE WASHER07 | 0.572 | 0.562 | 1.000 | 0.990 | 0.786 0.776 |

|||

| THRUST WASHER BEARING PTFE WASHER08 | 0.635 | 0.625 | 1.125 | 1.115 | 0.109 0.099 |

0.880 0.870 |

||

| THRUST WASHER BEARING PTFE WASHER09 | 0.697 | 0.687 | 1.187 | 1.177 | 0.942 0.932 |

|||

| THRUST WASHER BEARING PTFE WASHER10 | 0.760 | 0.750 | 1.250 | 1.240 | 1.005 0.995 |

|||

| THRUST WASHER BEARING PTFE WASHER11 | 0.822 | 0.812 | 1.375 | 1.365 | 1.099 1.089 |

|||

| THRUST WASHER BEARING PTFE WASHER12 | 0.885 | 0.875 | 1.500 | 1.490 | 0.140 0.130 |

1.192 1.182 |

||

| THRUST WASHER BEARING PTFE WASHER14 | 1.010 | 1.000 | 1.750 | 1.740 | 1.380 1.370 |

|||

| THRUST WASHER BEARING PTFE WASHER16 | 1.135 | 1.125 | 2.000 | 1.990 | 0.171 0.161 |

1.567 1.557 |

||

| THRUST WASHER BEARING PTFE WASHER18 | 1.260 | 1.250 | 2.125 | 2.115 | 1.692 1.682 |

|||

| THRUST WASHER BEARING PTFE WASHER20 | 1.385 | 1.375 | 2.250 | 2.240 | 1.817 1.807 |

|||

| THRUST WASHER BEARING PTFE WASHER22 | 1.510 | 1.500 | 2.500 | 2.490 | 0.202 0.192 |

2.005 1.995 |

||

| THRUST WASHER BEARING PTFE WASHER24 | 1.635 | 1.625 | 2.625 | 2.615 | 2.130 2.120 |

|||

| THRUST WASHER BEARING PTFE WASHER26 | 1.760 | 1.750 | 2.750 | 2.740 | 2.255 2.245 |

|||

| THRUST WASHER BEARING PTFE WASHER28 | 2.010 | 2.000 | 3.000 | 2.990 | 0.093 0.091 |

2.505 2.495 |

0.080 0.070 |

|

| THRUST WASHER BEARING PTFE WASHER30 | 2.135 | 2.125 | 3.125 | 3.115 | 2.630 2.620 |

|||

| THRUST WASHER BEARING PTFE WASHER32 | 2.260 | 2.250 | 3.250 | 3.240 | 2.755 2.745 |

|||

| Material | Part Number | Inner Diameter | Outer Diameter | Thickness | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 10 | 10.2 | 30 | 3 | cast high-strength bronze using a specially formed graphite plug as lubricant |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 12 | 12.2 | 40 | 3 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 13 | 13.2 | 40 | 3 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 14 | 14.2 | 40 | 3 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 15 | 15.2 | 50 | 3 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 16 | 16.2 | 50 | 3 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 18 | 18.2 | 50 | 3 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 20 | 20.2 | 50 | 5 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 25 | 25.2 | 55 | 5 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 30 | 30.2 | 60 | 5 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 35 | 35.2 | 70 | 5 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 40 | 40.2 | 80 | 7 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 45 | 45.3 | 90 | 7 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 50 | 50.3 | 100 | 8 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 55 | 55.3 | 110 | 8 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 60 | 60.3 | 120 | 8 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 65 | 65.3 | 125 | 8 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 70 | 70.3 | 130 | 10 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 75 | 75.3 | 130 | 10 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 80 | 80.3 | 150 | 10 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 90 | 90.5 | 170 | 10 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 100 | 100.5 | 190 | 10 | |

| Oilless Washer Bronze Thrust Washers Graphite | Oilless Solid Lubricant Thrust Washers JTW 120 | 120.5 | 200 | 10 |

Oilless Thrust Washer – Bronze Graphite

Description: The Oilless Thrust Washer is a high-quality bearing specifically designed for applications requiring smooth, uninterrupted operation without the need for regular lubrication. This thrust washer is constructed from bronze, a material known for its durability and strength. A distinctive feature of this washer is its embedded graphite. This graphite acts as a self-lubricant, ensuring the longevity of the washer and the machinery it supports.

Manufacturer: Oilless Slide Bearing Bushing Manufacturer

Key Features:

- Material: Durable bronze

- Lubrication: Embedded graphite for self-lubrication

- Maintenance: Low-maintenance due to its oilless nature

- Applications: Ideal for scenarios requiring consistent and smooth operation

Benefits:

- Extended Lifespan: The graphite reduces friction, thereby increasing the lifespan of both the washer and the machinery it’s used in.

- Cost-Efficient: Reduces the need for regular lubrication, leading to savings in maintenance costs.