Your Short Lead Time For Standard Bushing Parts

We have the best instructors

‘Bushing Made to Ordered Today – immediately Production, Fast dispatched‘. Our qualified specialists, optimized logistics and transport processes, as well as optimally networked logistic partners, guarantee you the shortest lead times.

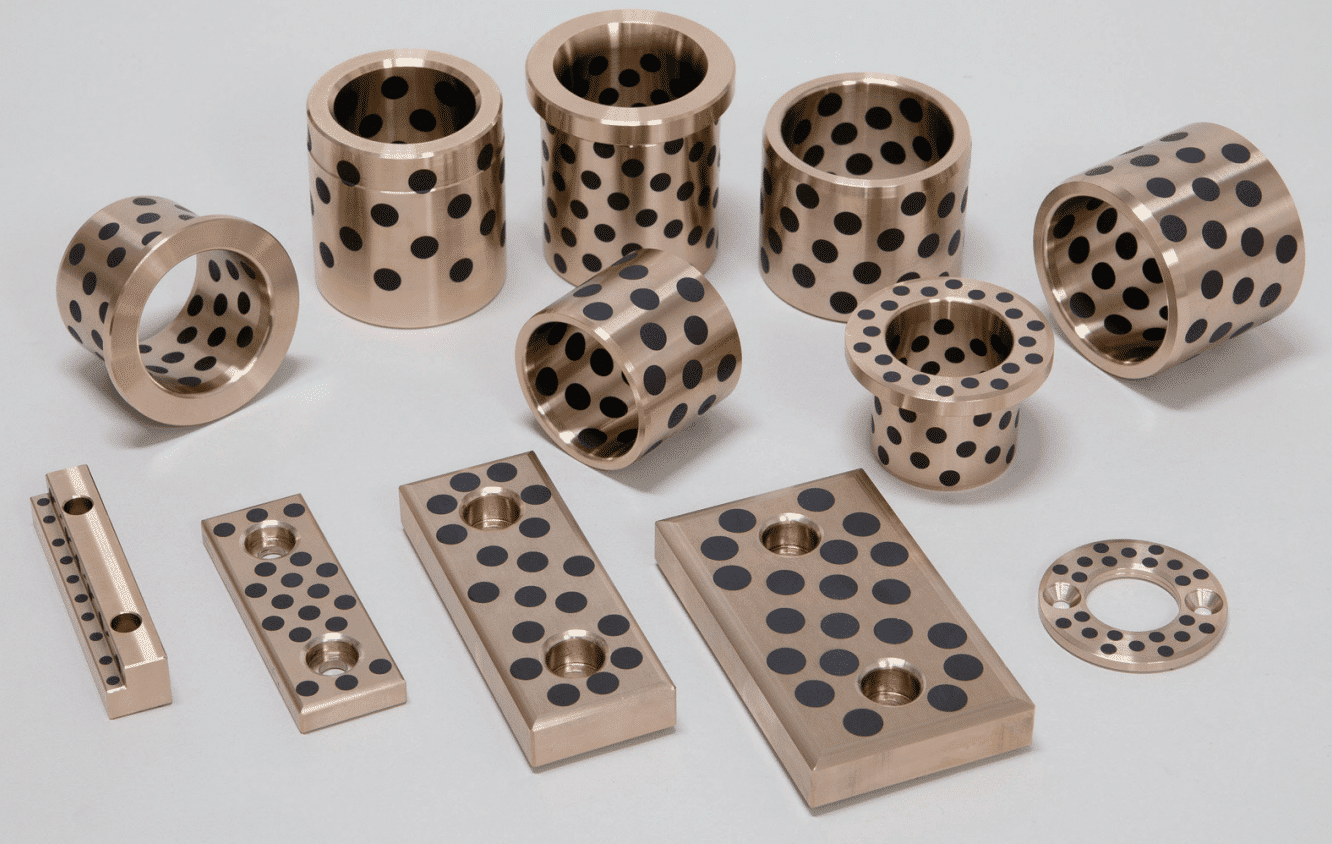

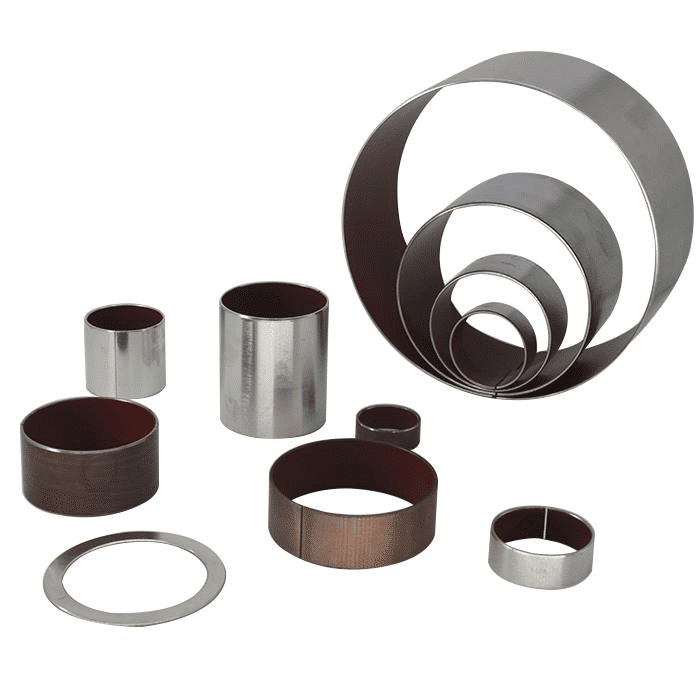

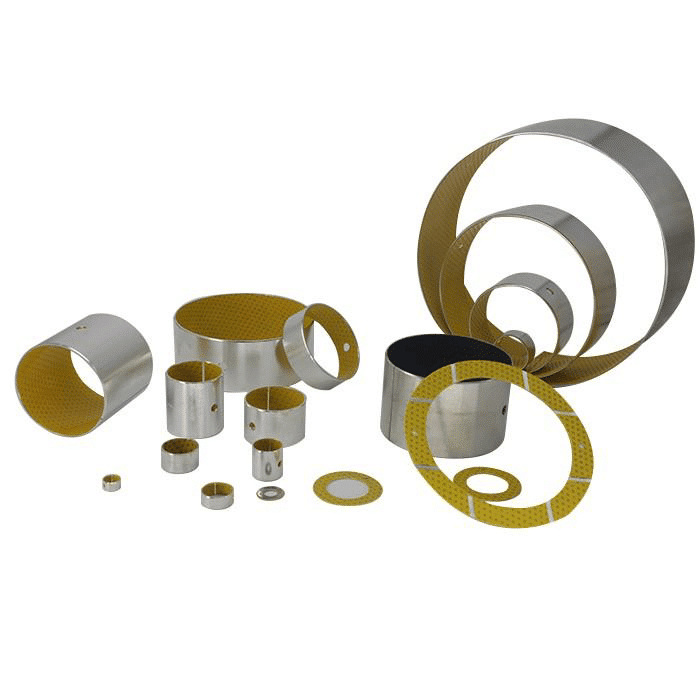

Oil Free Bushings products from China

Oil Free Bushings made to order from China for industrial applications. We offers free CAD downloads, prompt lead times, competitive pricing, and small minimum order … available metric size and inch size. Wide Variety of custom bushing products and free CAD data.

Made to Order

Bushing Standards. Iso 3547 And Other International Standards, Sliding Bearings For Agricultural Machinery, View the Available Products. Request A Quote Enter the Required Details, Request a Quote Now.

Discover our diverse brass bushing products and exclusive additions to our range.

On this page you will find a short overview of the bronze bearings and can access further bushing bearings descriptions directly via the links. Have fun browsing!

High-Quality factory bushing To Your Specifications

We have the best instructors

Sliding Bearings Technology, Factory Direct Sales, Enjoy Direct Purchasing from China.Order Now!

Where now meets next

Customer can made to order order their special bushing part made of tribological optimized metal-polymers bushing from china online.

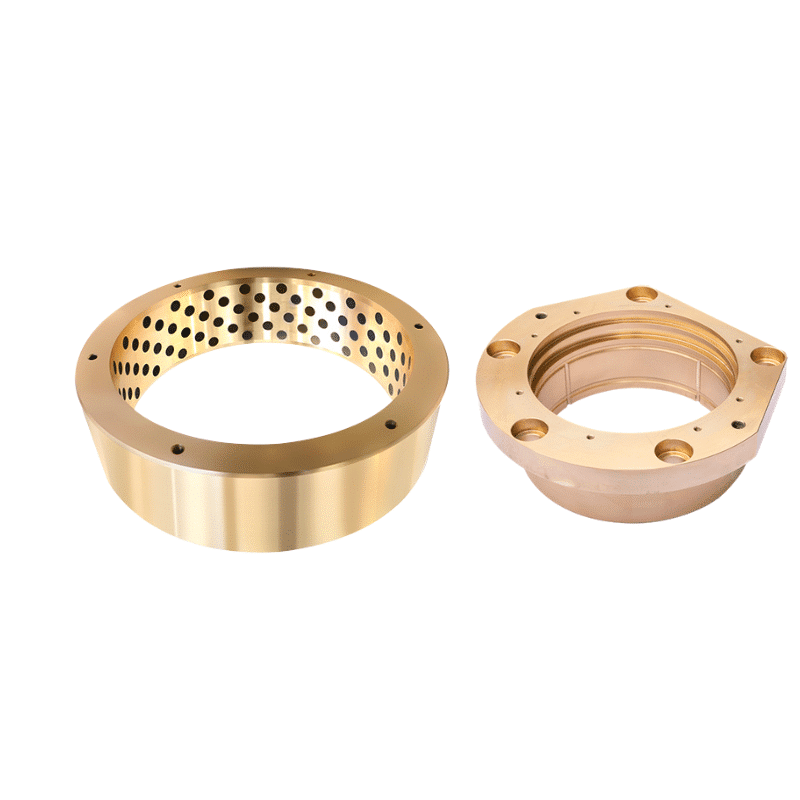

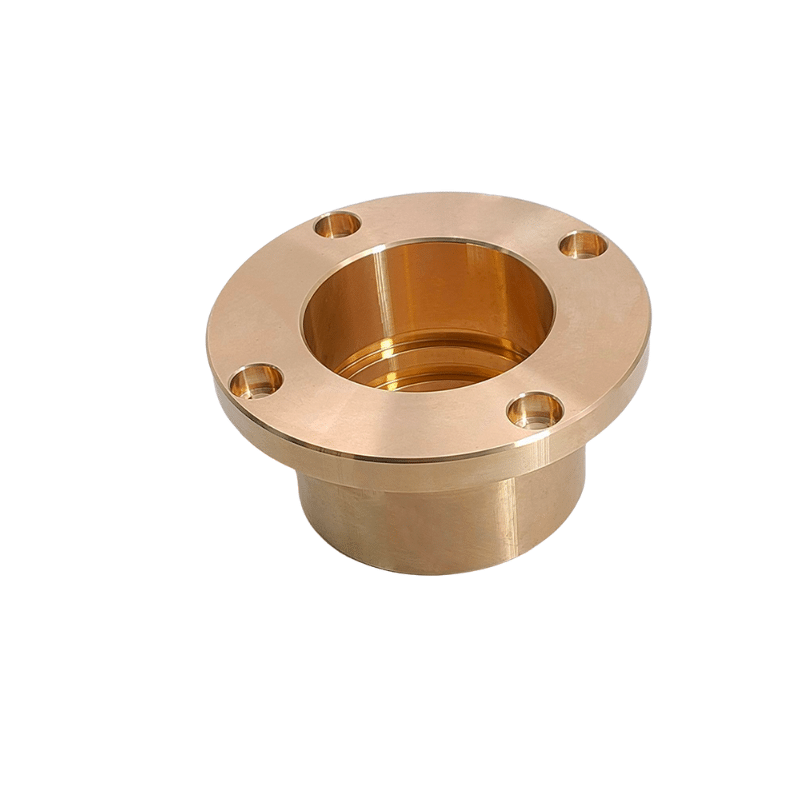

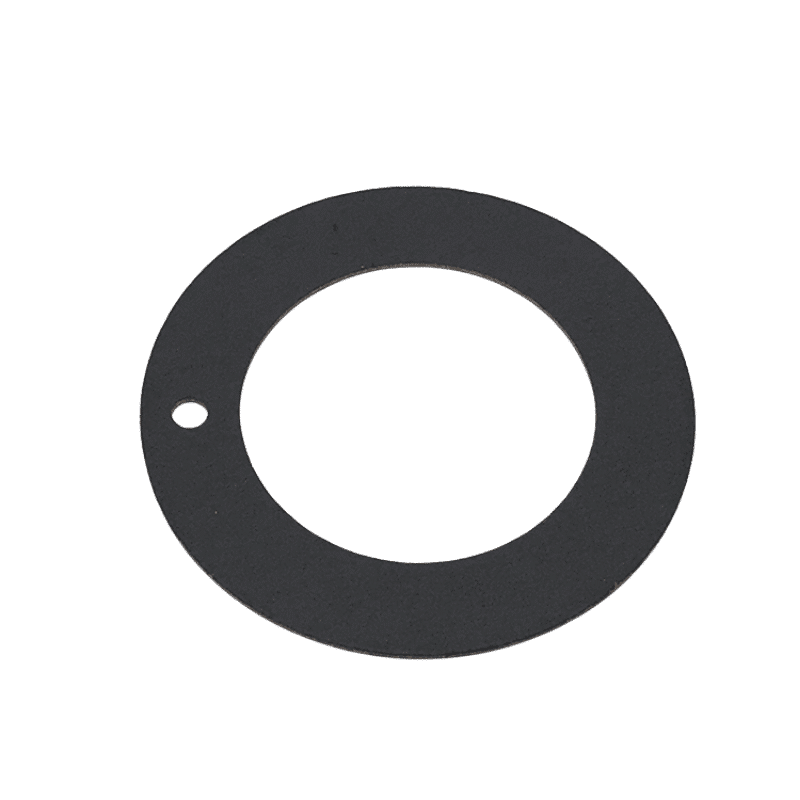

“Custom Bushing Bearing Manufacture – Special Dimension….” Just select a bushing type and tell us your desired sleeve or flange dimensions, Custom Made-To-Order Experts. Choose any item anywhere & tell us how you wanted it, Specializing in custom bushing bearings. Bronze Bearings. Oilless Bearings. Steel Backed Bushing Bearings. Sliding Bearings.

Bushing Catalog Online Available, Select Your Preferred Index To View the Available Sliding Bearings Products.

We Have Been Supplying All Kinds of Self-lubricating Bearing, Special Dimension Bronze Bushing and Custom Flange Size.

25%

“Food is symbolic of love when words are inadequate.”

MADE TO ORDERcustom

Bushing Bearings Shipping & Delivery Service, quality bearings are manufactured from high-performance material.

Custom Parts Tailor-Made Especially for You -www.bronzelube.com, Manufacturing service for customized parts made of … We make your prototype. Bushing Design, Made to order From China, You will see the price immediately, allowing you to then order the component online or make a request.

Self-lubricating & Maintenance-free

Bronze Lube offers customized bearing & bushings, metric size & inched sized in different type plain bearing specifications through self-lubricating tribology technology. Quality Bushings Bearings Online – Precision Bronze Parts, Purchase Your Bushing Here – bronzelube.com, Fast, Convenient & Easy. Self-lubricating polymer bushing from China. Save 40% over metal bearings! Fast Delivery. Small MOQ. Various Types Available. Fast Delivery. Get Quote Now For Wholesales Price.

Start Your Project With An Application Engineer

Custom Bushings & Sliding Bearings Manufacturing Capability. Find A Self -Lubricating Bronze Bushing. Request A Quote! Source Online For Latest & High Quality Products From Verified Wholesale Suppliers!Custom Parts, Made-to-Order self-lubricating bronze bearing Products from china.

- Custom Bearing Size

- Custom Alloy Material

- Custom CAD Drawing

- Custom Specification

- Custom Packaging