Graphite Bushings & Bearings

About Us

Oilless Bearing – Great Price & Huge Selection – China Site, Graphite Bushes & Graphite Bearings – Solution for Bushing Problems, Find here Graphite Bronze Bushes, Graphite Filled Bronze Bushes manufacturers, suppliers & exporters in China. Get A free quote.

C86300 Alloy, C863 Manganese Brass Bushing

Real-life strategy to reach your goals.

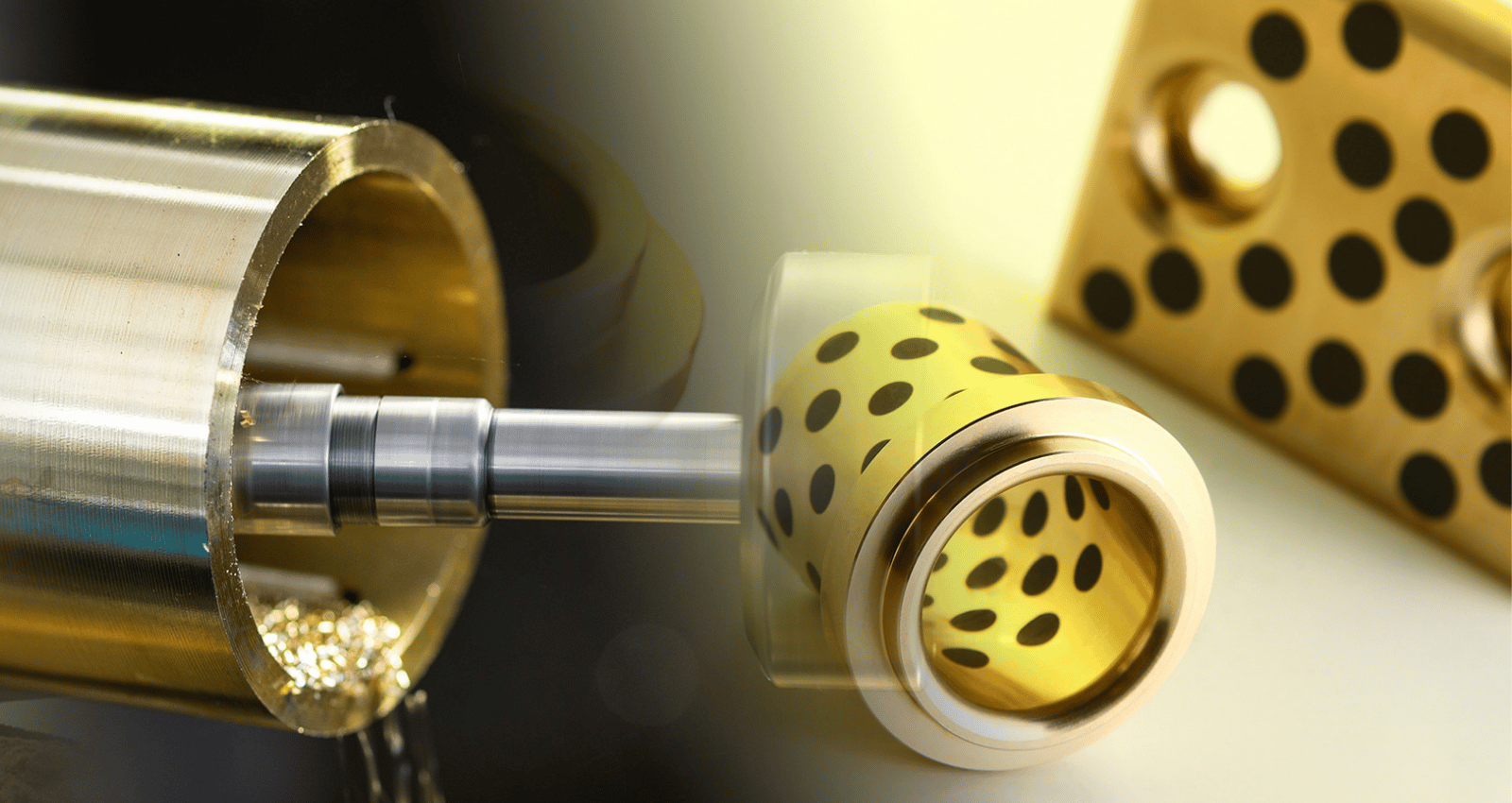

C86300 Alloy, C863 Manganese Brass, Global China company of self-lubricating bearings and vibration control technology. Quality design and supply of Bronze Bushings with Solid Lubricant Plugs Bushing and Engineering Materials, Get More Custom Oilless Bearings Part With Easy Online Sourcing From China. Our company manufactures a variety of self-lubricating graphite components, including precision straight bushings, engineering grade flange bearings, sliders, and gaskets, all designed to meet the challenges of our customers’ harsh operating environments. Our company’s manganese bronze bushings, and tin bronze graphite bushings, aluminum bronze bearings for optimum bushing self-lubrication life, plus special service options such as stainless steel bushings and tinning, will provide better harvest rates for your operation.

Our company manufactures a variety of self-lubricating graphite components, including precision straight bushings, engineering grade flange bearings, sliders, and gaskets, all designed to meet the challenges of our customers’ harsh operating environments. Our company’s manganese bronze bushings, and tin bronze graphite bushings, aluminum bronze bearings for optimum bushing self-lubrication life, plus special service options such as stainless steel bushings and tinning, will provide better harvest rates for your operation.

We strive for diversity across the globe

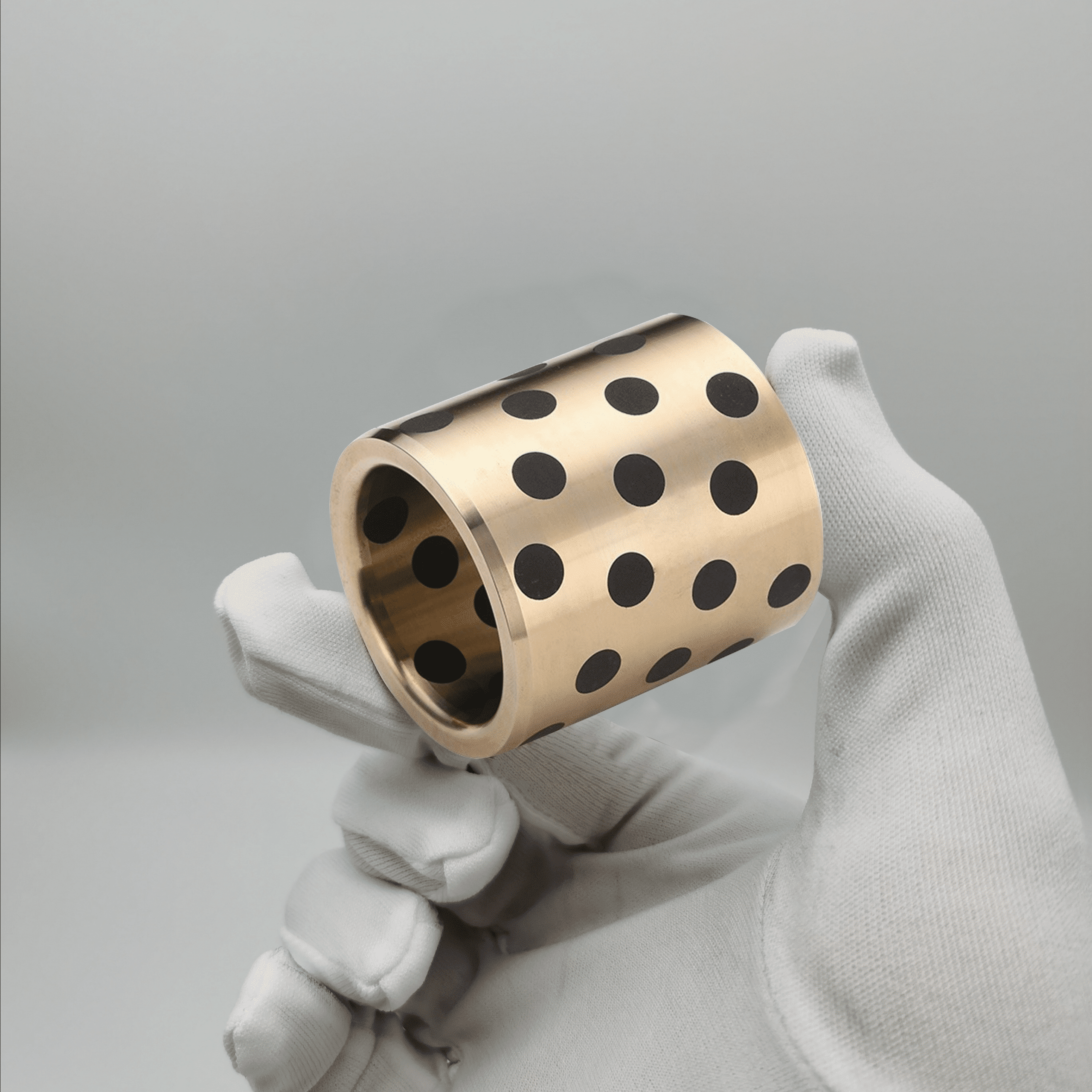

Graphite Impregnated Bronze Bushing

Metric.Imperial Bushes Plain Bronze Bushes: Official Site – Great Prices & Huge Oilless Bearing Material Selection, Self-Lubricating Bronze Bushing Catalogs And Brochures Available. Aluminum Bronze CDA-954, SAE660 Bronze, RG7 Bronze Bushing Double Loop Grease Groove, Problem Solve Manufacture Parts, Heavy Equipment Bushing & Bronze Alloy Selection,Get started with Us. Graphite Impregnated Bronze Parts: Custom Transport Solution: A full range of modern warehousing services for Plugged Graphite Bushings. Graphite Plugged Bronze Bushing Online Sales, In Stock, Ready To Ship &Customized Size, Fast Delivery. High-quality management of all your Plugged Graphite Bushings & Flange Bushing. Quick & Professional Plugged Graphite Bushings Custom Parts Services

30k

Converted users

85%

Sales increased

Move Forward With Graphite Bushing Bearing, Applicable Graphite Bushing, Optimized.

Our staff is extremely qualified to help your business grow

When it comes to self-lubricating graphite bronze bearings, Graphite Impregnated Bronze Bushes & Plates, our strength comes from our products and our knowledge of the application. With a wealth of experience, our engineers provide practical, real-world insight, working with you to find the right products to solve current problems in the industry and help avoid potential problems in the future.

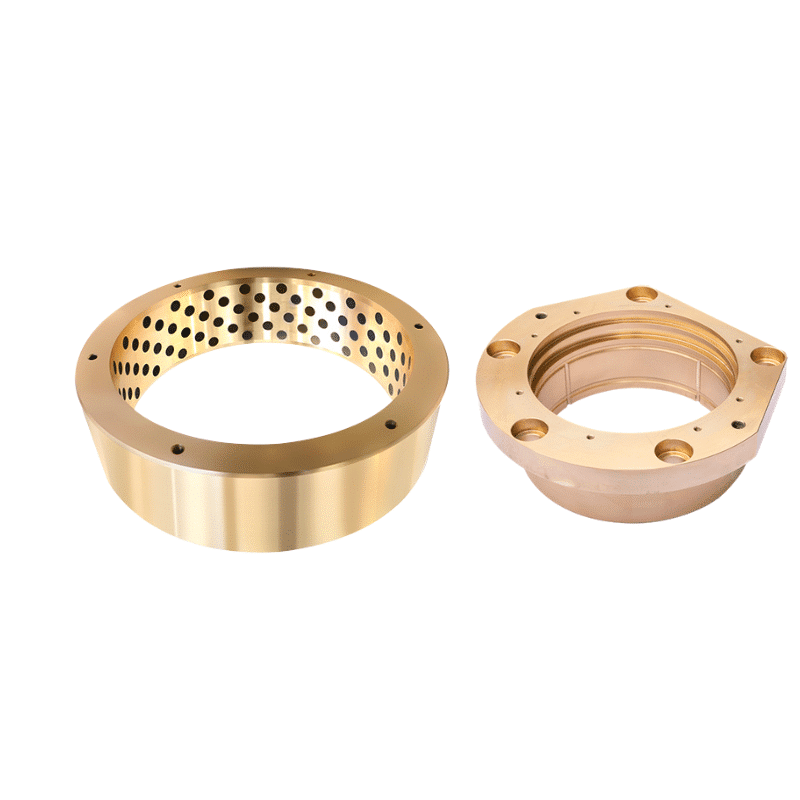

Graphite Impregnated Bronze Washer

Customized bronze bushing Material C86300 Good quality and fast delivery. Need Assistance? Call Or Email Us Engineering Support Available

Graphite Impregnated Bronze Plate

High-strength brass bearings with embedded solid lubricant wear plate, Offering Superior Performance In Hundreds Of Applications Replacing Plate. Slide Bronze Graphite is Suited for Submerged and High Temperature Applications.

Graphite Impregnated Bronze Flange Bush

Special high-strength brass bearings with embedded solid lubricant! Graphite Plugged Flange Bushings are a line of self-lubricating bushings that excel where standard lubrication is unwise, including heavy, high-temperature …

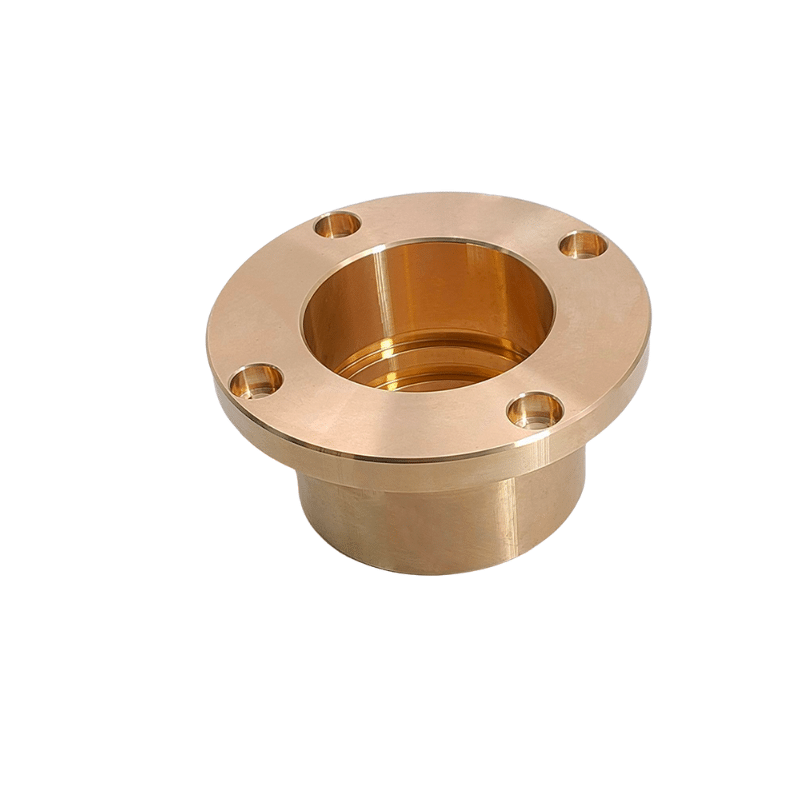

Plug Graphite Bearings

Hard special copper alloy bearings with embedded solid lubricant, CuZn25Al5Mn4Fe3, The self-lubricating graphite plugged bronze sleeve bushings are machined from continuous cast bronze bar stock. Plug graphite bushing are primarily used in applications that need continual lubrication in hard to reach areas.

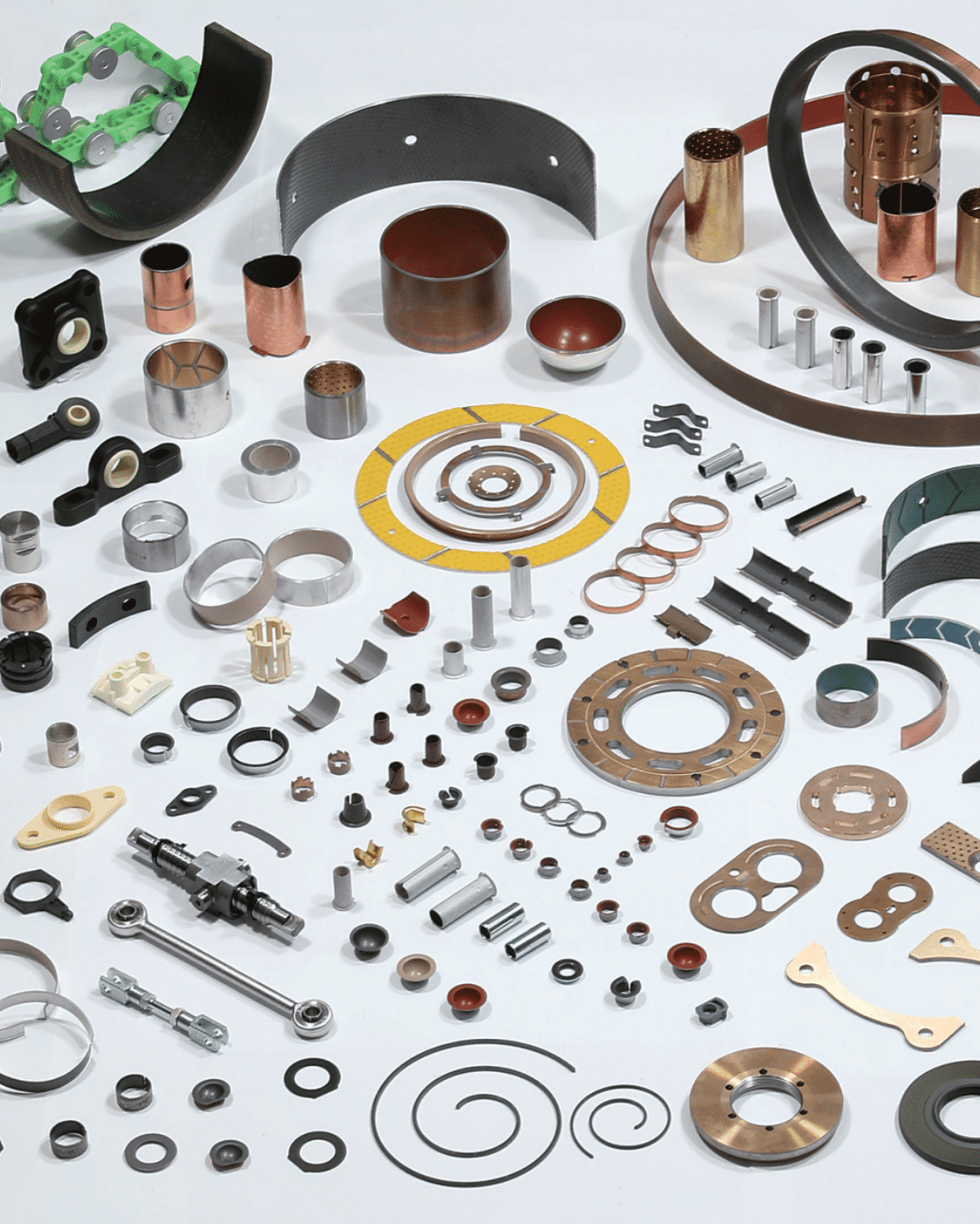

Standard Plate & Bushing Parts

Oilless Slide Plate Feature, Various standard wear plates and sliding bearings parts are available. Learn More Oil-Free Slide Plates Size & Dimensions Online.

Oilless Bearing High Temperature Applications. Reduced costs & downtime. Increased productivity. Services: Custom Design, Engineering Support, Short Lead Times. bronzelube.com offers a fresh innovative approach to design by collaborating with global oilless bronze bearing material technology leaders. With rich experience in engineered self-lubricating bearings we understand its the detail that makes the difference. Through our collaborative approach and global capabilities we bring the best for manufacturers and engineering.

Self Lubricated for Higher Temperatures and Heavier Loads. Bronze Bearings surface plugged graphite lubricant. The most common bronze alloy is CuSn7Zn4Pb7 (CC493K), also known as Rg7 or gunmetal. 2.1090 CuSn7Zn4Pb7,2.1096 material. Self-lubricating wear plates are manufactured from bronze with graphite plugs. The plugs cover 20-25% of the wear surface.

Graphite Impregnated Bronze Bushings Online Sourcing

Real-life strategy to reach your goals.

Manufactures A Complete Line Of Agricultural Graphite Bushes For Combines, Spreaders, Etc. Our Products Are Manufactured To The Oem Specifications For Maximum Strength And Wear Life. Custom Graphite Bearing – Prompt Delivery, Global Supply. Professional Graphite Bearings & Wear Plate Manufacturer. Flange Bushes Types & Competitive Price. Graphite Plate, Groove Parts, , China Thrust Washer Supplier, Special Self-Lubricating Bearings. Quote Now! Reasonable Price. Strict Quality Control. Professional Service. Deliver On Time…Oil-Free Bronze Bushings For High Temperature Use -Straight Type/Special Copper Alloy- Need Assistance? Call Or Email Us Engineering Support Available. Oil-Free Bronze Bearing (Embedded Lubricant:Mos2) From China I For Industrial Applications. We Offers Free Cad Downloads, Short Lead Times, Competitive Price.

Standard Plate & Bushing Parts

Oilless Slide Plate Feature, Various standard wear plates and sliding bearings parts are available. Learn More Oil-Free Slide Plates Size & Dimensions Online. Oilless Bearing High Temperature Applications. Reduced costs & downtime. Increased productivity. Services: Custom Design, Engineering Support, Short Lead Times. bronzelube.com offers a fresh innovative approach to design by collaborating with global oilless bronze bearing material technology leaders. With rich experience in engineered self-lubricating bearings we understand its the detail that makes the difference. Through our collaborative approach and global capabilities we bring the best for manufacturers and engineering.

Reliable & Safe, Self-lubricating Bronze Bushing Supplier for all branches of industry.

Real-life strategy to reach your goals.

Self-lubricating Bushing Features: Graphite plugged bronze bushing in stock, Graphite is mechanically forced into the holes/grooves under extreme pressure. Graphite Impregnated Bronze Bushing Groove Design. Graphite impregnated bronze bushing are a line of self-lubricating bushings that excel where standard lubrication is unwise, including heavy, high-temperature situations. Plugged Graphite Bushings, Safe Shipment. Plugged Graphite Bushings Cost Effective Solution, Get your graphite plugged bronze bushing price

We strive for diversity across the globe

Graphite Bronze Bushes, Get Latest Price! Factory Order Graphite Plugged Bronze Bearing.

Explore All the Oilless Bushing. The promise of Bronze Bushing Quality. Graphite Oilless Bearings & Bushings Designed for Any Type of Dry Running Environment. Custom Manufacturing Solutions Available To Match Your Application or Product Needs! Graphite impregnated bronze bushing Specifications: Custom-made graphite plugged bronze bearings: Depending on the application, we offer graphite impregnated bronze bushings for custom-made or devices in various designs. Oilless Bushing is Suited for Submerged and High-Temperature Applications. Reduced costs & downtime. Increased Productivity. Graphite plugged bronze bushing features:

- High Strength

- Bronze Casting Bushing

Increase efficiency decrease downtime

Real-life strategy to reach your goals.

High Tensile Plugged Graphite Bushings Premium: we take immense pride in driving the industry standards forward, focusing on efficiency, quality, and safety. Our expertise and continuous focus on self-lubricating bronze bushing designs, use of oilless bushing materials and process improvement has enabled our international expansion and saved our clients the cost. Oilless Bushing Exporter & Supplier for all Branches of Industry. Learn more self-lubricating bearings.

The Delivering Values- We’Re Continually Finding The Good Oilless Bearings Technology.

Our engineers problem solve and manufacture complex self-lubricating bearings parts, rebuilds and projects for the food, automotive and foundry industries. Find a solid bushing. standard-stocked sizes.ready for ship. Customized-items parts the need for fast delivery, increased competitive pressure, and ever-changing requirements all increase the importance of quality control processes in the design bushings.

Bushings made by Bronzelube.com – Graphite or Grease Grooves. Call us today! Quality bushings. Inch, metric, and custom sizes. Highlights: Quick Quote Available. High Tensile Brass Bearing & Graphite Impregnated Bronze Bushing Made Of Copper Material That Also Includes Small Percentages Of Other Metals To Improve Their Properties. Material: CuZn25Al5Mn4Fe3. Prevention & Quality Control In The Sliding Bearings Special Manufacturing & Precision Machining!

Most of the bearings used in various machinery industries are balls, needles, etc., only a small part has adopted self-lubricating Graphite Impregnated Bronze Bushings bearings. It is believed that in the near future, self-lubricating Graphite Impregnated Bronze Bearings will have indisputable advantages such as strong adaptability, wear resistance and economy. And become the leading product in the oilless bearing industry. The following are some of the application features and advantages of self-lubricating bearings: Oil-free Graphite Impregnated Bronze Bushings bearing series.

1. Oil-free or less oil-lubricated, suitable for places where refueling is impossible or difficult, and can be used without maintenance or with little maintenance.

2. Good wear resistance, small friction coefficient and long service life.

3. It has an appropriate amount of elasticity and plasticity, which can distribute the stress on a wider contact surface and improve the slide bearing capacity of the Graphite Impregnated Bronze Bushings bearing.

4. The static and dynamic friction coefficients are similar, which can eliminate crawling at low speed, thereby ensuring the working accuracy of the machine.

5. It can reduce vibration, reduce noise, prevent pollution and improve working conditions.

6. A transfer film can be formed during the operation, which protects the grinding shaft and does not bite the shaft.

7. The hardness of the grinding shaft is low, and the shaft without quenching and tempering treatment can be used, thereby reducing the processing difficulty of related parts.

8, thin-walled structure, light weight, can reduce the mechanical volume.

9. The back of steel can be electroplated with various metals and can be used in corrosive media; it has been widely used in sliding parts of various machinery, such as printing presses, textile machines, tobacco machinery, micro motors, automobiles, motorcycles and agricultural and forestry machinery etc.

Boundary lubrication self-lubricating Graphite Impregnated Bronze Bushings bearing series introduction

1. Good load bushing bearing and good wear resistance.

2. It is suitable for high-load and low-speed rotary motion, rocking motion and occasions where frequent opening and closing under load is not easy to form hydrodynamic lubrication.

3. Under the condition of boundary lubrication, it can be maintained without oil for a long time, and oil in the over-layer can make the Graphite Impregnated Bronze Bushings service life longer.

4. A certain margin can be left for the surface plastic layer during processing and molding, and it can be processed by itself after being assembled and pressed into the seat hole to achieve a better assembly size.

5. The products are mainly used in automobile chassis, metallurgical machinery, mining machinery, water conservancy machinery, construction machinery, agricultural machinery, steel rolling equipment, etc. Graphite Impregnated Bronze Bushings solid inlaid bearing series JDB solid inlaid bushes bearing series is a general basic product, no matter high pressure, low pressure, high temperature, low temperature, oil lubrication, oil-free lubrication or water lubrication, can be adapted. The base of the product is high-strength brass, which doubles the hardness and wear resistance of ordinary copper sleeves. Widely used in: light industry machinery, heavy industry machinery, construction machinery, metallurgical machinery, conveying machinery, etc., such as: continuous casting machines, rolling mills, injection molding machines, paper machines, mold guide posts, ships, machine tools, etc.

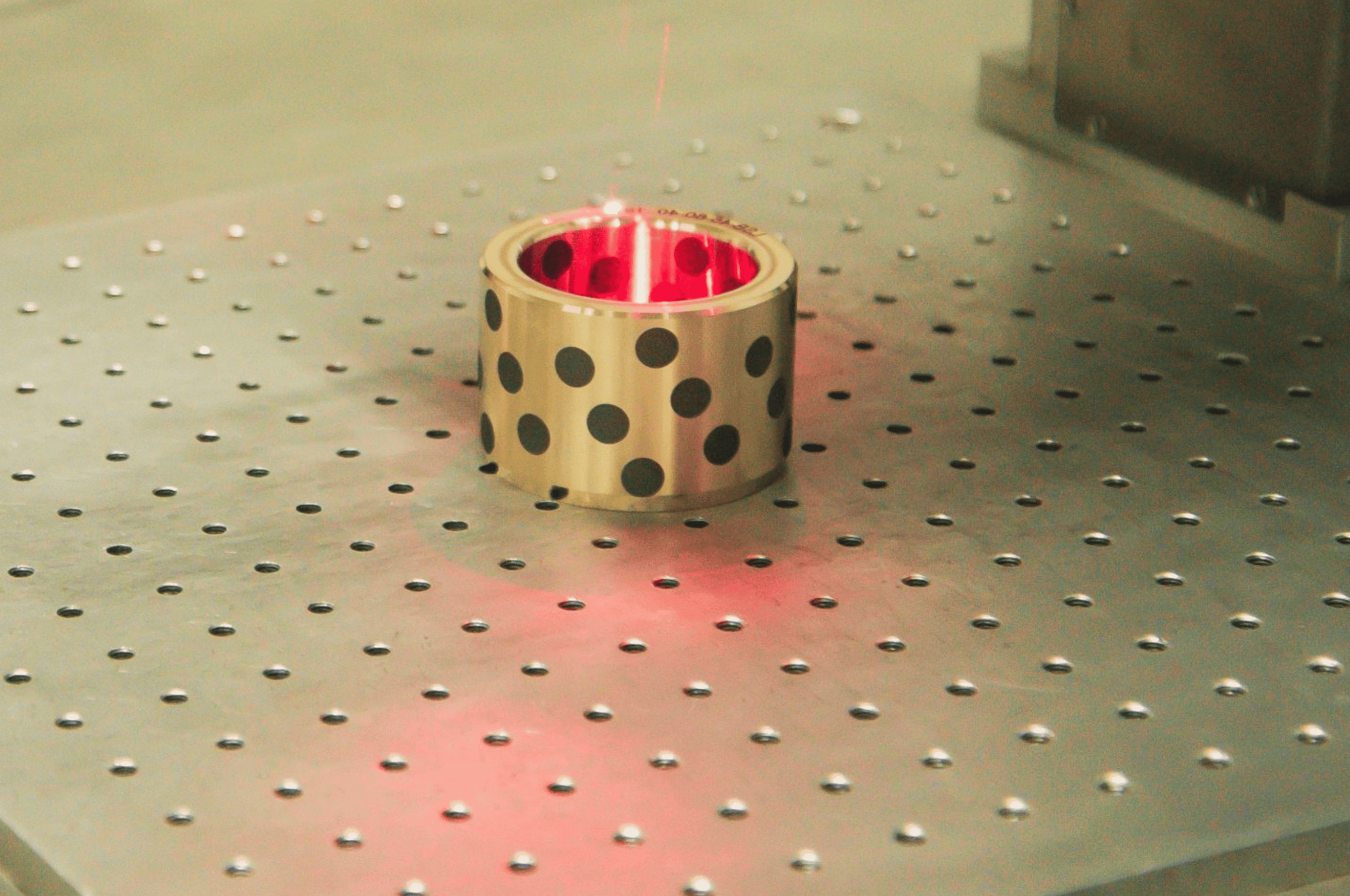

Manufacturing Solution

The test laboratory: rigorous testing for guaranteed oilless bushing quality. Always self-lubricating & grease-free! The best solutions come only when the problem is comprehensively understood.

- Flange bearings

- Sleeve bearings

- Thrust washers

- Sliding plate

Manufacturing Complex Graphite Bronze Bearing Parts

Replacement Plugged Graphite Parts

Complete Redesigns

Streamlined Productions

The Promise of Oilless Bush Quality, Bronze Graphite Bushings Factory Price

Get Innovative Solutions to Engineering Problems

Real-life strategy to reach your goals.

Providing Excellent, Reliable, And High-Quality Sleeve Bearing Solutions Is Important To Us. Heavy General Machining For Graphite Bronze Bushes, For Industrial, Metric Diameter & Inch Size: Our Small To Very Large CNC & Manual Machining Capacity Is What Sets Us Apart. Manufacturer Of Precision Mold And Die Components. Self-Lubricating Plugged Graphite Bushings Now Available Online! Bronze With Solid Lubricant, Oilless Lubricating: We Manufacture And Export A Huge Range Of Plugged Graphite Bronze Bushings, High Tensile Manganese Bronze Bearings From The Quality Material Of Bronze. Cast Bronze Bearing Supplier. These High Tensile Manganese Bronze Are Used In Various Industries.

We strive for diversity across the globe

Graphite Bushings & Bearings – Reduced Costs & Downtime

Custom-made graphite plugged bronze bearings: Depending on the application, we offer graphite impregnated bronze bushings for custom-made or devices in various designs. Oilless Bushing is Suited for Submerged and High-Temperature Applications. Reduced costs & downtime. Increased Productivity. Offering Superior Performance In Hundreds Of Applications Replacing Carbon Bearings. Increased productivity. Services: Custom Design, Engineering Support, Short Lead Times. Lubricated Graphite Impregnated Bearings Demand: We offer the highest quality tin bronze bearing, lead bronze bearings and bronze bushings and high tensile brass bearing with maximum performance in the most demanding sector.The power of predictability.Understanding the types of plain bearing & bushings and determine which one is best for your application. Bearing Solutions. High precision manufacturing can satisfy the need for the production of self-lubricating bearing intolerance and assembly.

Custom Engineering Solutions, Service, Maintenance and Graphite Impregnated Sleeve Bearing Design

Providing heavy machining, maintenance, service & design to a diverse range of industries across China and Maintenance-free bronze bearing & guide bushes, bronze with solid lubricant plugged graphite.

CAST BRONZE BEARING PRODUCTS: High Strength Brass Bronze Graphite part as attached drawing.

Overview: Any alloy consisting of more than two elements is called special brass. Such as aluminum, lead, tin, manganese, nickel, iron, silicon composed of copper alloy, high-strength brass is one of them. High strength brass has strong wear resistance, high strength brass, high hardness, strong chemical corrosion resistance. And machining mechanical properties are also very superior. High-strength brass is often made to manufacture sheet, bar, bar, pipe, casting parts, and so on.

Chemical composition: The chemical formula of high-strength brass is ZCuZn25AI6Fe3Mn3, containing about 65% copper and about 25% zinc. Aluminum improves the strength, hardness, and corrosion resistance of brass. There are three types of brass at room temperature: brass with less than 35% zinc content. The microstructure at room temperature is composed of a single-phase A solid solution and is called A brass.

Price and delivery time on request

- Bronze Brass Bushing Material:Special Brass (SO#50SP2)

- Self-lubricating:Yes

- Lubricant:Graphite Surface

- Pressure P:100 N/mm²

- Sliding speed v:30 m/minP*v-value:200 N/mm² x m/min

- Operating temperature:-50°C / +200°C (max. 300°C)

- Friction coefficient:0,07

Our company is specialized in manufacturing and selling oil-free bearing, composite bearing, self-lubricating bearing, oil-free axle sleeve, inlaid bearing, copper sleeve, dry axle sleeve, sliding bearing, axle bush, bushing, guide sleeve, sliding plate, and can be customized according to user requirements.

Maintenance-free bronze bearing size chart equivalent and guide bushes, bronze with solid lubricant plugged graphite, SOB bushing equivalent, Sankyo oilless Alternatives

SOB 8-12-8 |

8 |

12 |

8 |

0,5 |

0,5 |

||

SOB 6-10-12 |

6 |

10 |

12 |

0,5 |

0,5 |

||

SOB 8-12-10 |

8 |

12 |

10 |

0,5 |

0,5 |

||

SOB 8-12-12 |

8 |

12 |

12 |

0,5 |

0,5 |

||

SOB 8-12-15 |

8 |

12 |

15 |

0,5 |

0,5 |

||

SOB 10-14-8 |

10 |

14 |

8 |

0,5 |

0,5 |

||

SOB 10-14-10 |

10 |

14 |

10 |

0,5 |

0,5 |

||

SOB 10-14-12 |

10 |

14 |

12 |

0,5 |

0,5 |

||

SOB 10-14-15 |

10 |

14 |

15 |

0,5 |

0,5 |

||

SOB 10-14-20 |

10 |

14 |

20 |

0,5 |

0,5 |

||

SOB 10-15-10 |

10 |

15 |

10 |

0,5 |

0,5 |

||

SOB 12-18-8 |

12 |

18 |

8 |

0,5 |

0,5 |

||

SOB 12-18-10 |

12 |

18 |

10 |

0,5 |

0,5 |

||

SOB 12-18-12 |

12 |

18 |

12 |

0,5 |

0,5 |

||

SOB 12-18-15 |

12 |

18 |

15 |

0,5 |

0,5 |

||

SOB 12-18-16 |

12 |

18 |

16 |

0,5 |

0,5 |

||

SOB 12-18-19 |

12 |

18 |

19 |

0,5 |

0,5 |

||

SOB 12-18-20 |

12 |

18 |

20 |

0,5 |

0,5 |

||

SOB 12-18-25 |

12 |

18 |

25 |

0,5 |

0,5 |

||

SOB 12-18-30 |

12 |

18 |

30 |

0,5 |

0,5 |

||

SOB 13-19-10 |

13 |

19 |

10 |

0,5 |

0,5 |

||

SOB 13-19-12 |

13 |

19 |

12 |

0,5 |

0,5 |

||

SOB 13-19-15 |

13 |

19 |

15 |

0,5 |

0,5 |

||

SOB 13-19-16 |

13 |

19 |

16 |

0,5 |

0,5 |

||

SOB 13-19-20 |

13 |

19 |

20 |

0,5 |

0,5 |

||

SOB 13-19-25 |

13 |

19 |

25 |

0,5 |

0,5 |

||

SOB 14-20-10 |

14 |

20 |

10 |

0,5 |

0,5 |

||

SOB 14-20-12 |

14 |

20 |

12 |

0,5 |

0,5 |

||

SOB 14-20-15 |

14 |

20 |

15 |

0,5 |

0,5 |

||

SOB 14-20-20 |

14 |

20 |

20 |

0,5 |

0,5 |

||

SOB 14-20-25 |

14 |

20 |

25 |

0,5 |

0,5 |

||

SOB 14-20-30 |

14 |

20 |

30 |

0,5 |

0,5 |

||

SOB 15-21-10 |

15 |

21 |

10 |

0,5 |

0,5 |

||

SOB 15-21-12 |

15 |

21 |

12 |

0,5 |

0,5 |

||

SOB 15-21-15 |

15 |

21 |

15 |

0,5 |

0,5 |

||

SOB 15-21-16 |

15 |

21 |

16 |

0,5 |

0,5 |

||

SOB 15-21-20 |

15 |

21 |

20 |

0,5 |

0,5 |

||

SOB 15-21-25 |

15 |

21 |

25 |

0,5 |

0,5 |

||

SOB 15-21-30 |

15 |

21 |

30 |

0,5 |

0,5 |

||

SOB 16-22-10 |

16 |

22 |

10 |

0,5 |

0,5 |

||

SOB 16-22-12 |

16 |

22 |

12 |

0,5 |

0,5 |

||

SOB 16-22-15 |

16 |

22 |

15 |

0,5 |

0,5 |

||

SOB 16-22-16 |

16 |

22 |

16 |

0,5 |

0,5 |

||

SOB 16-22-19 |

16 |

22 |

19 |

0,5 |

0,5 |

||

SOB 16-22-20 |

16 |

22 |

20 |

0,5 |

0,5 |

||

SOB 16-22-25 |

16 |

22 |

25 |

0,5 |

0,5 |

||

SOB 16-22-30 |

16 |

22 |

30 |

0,5 |

0,5 |

||

SOB 16-22-35 |

16 |

22 |

35 |

0,5 |

0,5 |

||

SOB 16-22-40 |

16 |

22 |

40 |

0,5 |

0,5 |

||

SOB 17-23-15 |

17 |

23 |

15 |

0,5 |

0,5 |

||

SOB 18-24-10 |

18 |

24 |

10 |

0,5 |

0,5 |

||

SOB 18-24-12 |

18 |

24 |

12 |

0,5 |

0,5 |

||

SOB 18-24-15 |

18 |

24 |

15 |

0,5 |

0,5 |

||

SOB 18-24-16 |

18 |

24 |

16 |

0,5 |

0,5 |

||

SOB 18-24-20 |

18 |

24 |

20 |

0,5 |

0,5 |

||

SOB 18-24-25 |

18 |

24 |

25 |

0,5 |

0,5 |

||

SOB 18-24-30 |

18 |

24 |

30 |

0,5 |

0,5 |

||

SOB 18-24-35 |

18 |

24 |

35 |

0,5 |

0,5 |

||

SOB 18-24-40 |

18 |

24 |

40 |

0,5 |

0,5 |

||

SOB 19-26-15 |

19 |

26 |

15 |

0,5 |

0,5 |

||

SOB 19-26-20 |

19 |

26 |

20 |

0,5 |

0,5 |

||

SOB 20-28-10 |

20 |

28 |

10 |

0,5 |

0,5 |

||

SOB 20-28-12 |

20 |

28 |

12 |

0,5 |

0,5 |

||

SOB 20-28-15 |

20 |

28 |

15 |

0,5 |

0,5 |

||

SOB 20-28-16 |

20 |

28 |

16 |

0,5 |

0,5 |

||

SOB 20-28-19 |

20 |

28 |

19 |

0,5 |

0,5 |

||

SOB 20-28-20 |

20 |

28 |

20 |

0,5 |

0,5 |

||

SOB 20-28-25 |

20 |

28 |

25 |

0,5 |

0,5 |

||

SOB 20-28-30 |

20 |

28 |

30 |

0,5 |

0,5 |

||

SOB 20-28-35 |

20 |

28 |

35 |

0,5 |

0,5 |

||

SOB 20-28-40 |

20 |

28 |

40 |

0,5 |

0,5 |

||

SOB 20-28-50 |

20 |

28 |

50 |

0,5 |

0,5 |

||

SOB 20-30-10 |

20 |

30 |

10 |

0,5 |

0,5 |

||

SOB 20-30-12 |

20 |

30 |

12 |

0,5 |

0,5 |

||

SOB 20-30-15 |

20 |

30 |

15 |

0,5 |

0,5 |

||

SOB 20-30-16 |

20 |

30 |

16 |

0,5 |

0,5 |

||

SOB 20-30-20 |

20 |

30 |

20 |

0,5 |

0,5 |

||

SOB 20-30-25 |

20 |

30 |

25 |

0,5 |

0,5 |

||

SOB 20-30-30 |

20 |

30 |

30 |

0,5 |

0,5 |

||

SOB 20-30-35 |

20 |

30 |

35 |

0,5 |

0,5 |

||

SOB 20-30-40 |

20 |

30 |

40 |

0,5 |

0,5 |

||

SOB 20-30-70 |

20 |

30 |

70 |

0,5 |

0,5 |

||

SOB 22-32-12 |

22 |

32 |

12 |

0,5 |

0,5 |

||

SOB 22-32-15 |

22 |

32 |

15 |

0,5 |

0,5 |

||

SOB 22-32-20 |

22 |

32 |

20 |

0,5 |

0,5 |

||

SOB 22-32-25 |

22 |

32 |

25 |

0,5 |

0,5 |

||

SOB 25-33-12 |

25 |

33 |

12 |

0,5 |

0,5 |

||

SOB 25-33-15 |

25 |

33 |

15 |

0,5 |

0,5 |

||

SOB 25-33-16 |

25 |

33 |

16 |

0,5 |

0,5 |

||

SOB 25-33-20 |

25 |

33 |

20 |

0,5 |

0,5 |

||

SOB 25-33-25 |

25 |

33 |

25 |

0,5 |

0,5 |

||

SOB 25-33-30 |

25 |

33 |

30 |

0,5 |

0,5 |

||

SOB 25-33-35 |

25 |

33 |

35 |

0,5 |

0,5 |

||

SOB 25-33-40 |

25 |

33 |

40 |

0,5 |

0,5 |

||

SOB 25-33-50 |

25 |

33 |

50 |

0,5 |

0,5 |

||

SOB 25-33-60 |

25 |

33 |

60 |

0,5 |

0,5 |

||

SOB 25-35-12 |

25 |

35 |

12 |

0,5 |

0,5 |

||

SOB 25-35-15 |

25 |

35 |

15 |

0,5 |

0,5 |

||

SOB 25-35-16 |

25 |

35 |

16 |

0,5 |

0,5 |

||

SOB 25-35-20 |

25 |

35 |

20 |

0,5 |

0,5 |

SOB 25-35-25 |

25 |

35 |

25 |

0,5 |

0,5 |

||

SOB 25-35-30 |

25 |

35 |

30 |

0,5 |

0,5 |

||

SOB 25-35-35 |

25 |

35 |

35 |

0,5 |

0,5 |

||

SOB 25-35-40 |

25 |

35 |

40 |

0,5 |

0,5 |

||

SOB 25-35-50 |

25 |

35 |

50 |

0,5 |

0,5 |

||

SOB 28-38-20 |

28 |

38 |

20 |

0,5 |

0,5 |

||

SOB 28-38-25 |

28 |

38 |

25 |

0,5 |

0,5 |

||

SOB 28-38-30 |

28 |

38 |

30 |

0,5 |

0,5 |

||

SOB 28-38-40 |

28 |

38 |

40 |

0,5 |

0,5 |

||

SOB 30-38-12 |

30 |

38 |

12 |

1 |

1 |

||

SOB 30-38-15 |

30 |

38 |

15 |

1 |

1 |

||

SOB 30-38-20 |

30 |

38 |

20 |

1 |

1 |

||

SOB 30-38-25 |

30 |

38 |

25 |

1 |

1 |

||

SOB 30-38-30 |

30 |

38 |

30 |

1 |

1 |

||

SOB 30-38-35 |

30 |

38 |

35 |

1 |

1 |

||

SOB 30-38-40 |

30 |

38 |

40 |

1 |

1 |

||

SOB 30-38-50 |

30 |

38 |

50 |

1 |

1 |

||

SOB 30-38-60 |

30 |

38 |

60 |

1 |

1 |

||

SOB 30-40-12 |

30 |

40 |

12 |

1 |

1 |

||

SOB 30-40-15 |

30 |

40 |

15 |

1 |

1 |

||

SOB 30-40-20 |

30 |

40 |

20 |

1 |

1 |

||

SOB 30-40-25 |

30 |

40 |

25 |

1 |

1 |

||

SOB 30-40-30 |

30 |

40 |

30 |

1 |

1 |

||

SOB 30-40-35 |

30 |

40 |

35 |

1 |

1 |

||

SOB 30-40-40 |

30 |

40 |

40 |

1 |

1 |

||

SOB 30-40-50 |

30 |

40 |

50 |

1 |

1 |

||

SOB 30-40-60 |

30 |

40 |

60 |

1 |

1 |

||

SOB 31,5-40-30 |

31,5 |

40 |

30 |

1 |

1 |

||

SOB 31,5-40-40 |

31,5 |

40 |

40 |

1 |

1 |

||

SOB 32-42-15 |

32 |

42 |

15 |

1 |

1 |

||

SOB 32-42-20 |

32 |

42 |

20 |

1 |

1 |

||

SOB 32-42-30 |

32 |

42 |

30 |

1 |

1 |

||

SOB 32-42-40 |

32 |

42 |

40 |

1 |

1 |

||

SOB 35-44-20 |

35 |

44 |

20 |

1 |

1 |

||

SOB 35-44-25 |

35 |

44 |

25 |

1 |

1 |

||

SOB 35-44-30 |

35 |

44 |

30 |

1 |

1 |

||

SOB 35-44-35 |

35 |

44 |

35 |

1 |

1 |

||

SOB 35-44-40 |

35 |

44 |

40 |

1 |

1 |

||

SOB 35-44-50 |

35 |

44 |

50 |

1 |

1 |

||

SOB 35-44-60 |

35 |

44 |

60 |

1 |

1 |

||

SOB 35-45-15 |

35 |

45 |

15 |

1 |

1 |

||

SOB 35-45-20 |

35 |

45 |

20 |

1 |

1 |

||

SOB 35-45-25 |

35 |

45 |

25 |

1 |

1 |

||

SOB 35-45-30 |

35 |

45 |

30 |

1 |

1 |

||

SOB 35-45-35 |

35 |

45 |

35 |

1 |

1 |

||

SOB 35-45-40 |

35 |

45 |

40 |

1 |

1 |

||

SOB 35-45-50 |

35 |

45 |

50 |

1 |

1 |

||

SOB 35-45-60 |

35 |

45 |

60 |

1 |

1 |

||

SOB 38-48-30 |

38 |

48 |

30 |

1 |

1 |

||

SOB 38-48-40 |

38 |

48 |

40 |

1 |

1 |

||

SOB 40-50-15 |

40 |

50 |

15 |

1 |

1 |

||

SOB 40-50-20 |

40 |

50 |

20 |

1 |

1 |

||

SOB 40-50-25 |

40 |

50 |

25 |

1 |

1 |

||

SOB 40-50-30 |

40 |

50 |

30 |

1 |

1 |

||

SOB 40-50-35 |

40 |

50 |

35 |

1 |

1 |

||

SOB 40-50-40 |

40 |

50 |

40 |

1 |

1 |

||

SOB 40-50-50 |

40 |

50 |

50 |

1 |

1 |

||

SOB 40-50-60 |

40 |

50 |

60 |

1 |

1 |

||

SOB 40-50-70 |

40 |

50 |

70 |

1 |

1 |

||

SOB 40-50-80 |

40 |

50 |

80 |

1 |

1 |

||

SOB 40-55-15 |

40 |

55 |

15 |

1 |

1 |

||

SOB 40-55-25 |

40 |

55 |

25 |

1 |

1 |

||

SOB 40-55-30 |

40 |

55 |

30 |

1 |

1 |

||

SOB 40-55-35 |

40 |

55 |

35 |

1 |

1 |

||

SOB 40-55-40 |

40 |

55 |

40 |

1 |

1 |

||

SOB 40-55-50 |

40 |

55 |

50 |

1 |

1 |

||

SOB 40-55-60 |

40 |

55 |

60 |

1 |

1 |

||

SOB 45-55-30 |

45 |

55 |

30 |

1 |

1 |

||

SOB 45-55-35 |

45 |

55 |

35 |

1 |

1 |

||

SOB 45-55-40 |

45 |

55 |

40 |

1 |

1 |

||

SOB 45-55-50 |

45 |

55 |

50 |

1 |

1 |

||

SOB 45-55-60 |

45 |

55 |

60 |

1 |

1 |

||

SOB 45-56-30 |

45 |

56 |

30 |

1 |

1 |

||

SOB 45-56-35 |

45 |

56 |

35 |

1 |

1 |

||

SOB 45-56-40 |

45 |

56 |

40 |

1 |

1 |

||

SOB 45-56-50 |

45 |

56 |

50 |

1 |

1 |

||

SOB 45-56-60 |

45 |

56 |

60 |

1 |

1 |

||

SOB 45-60-30 |

45 |

60 |

30 |

1 |

1 |

||

SOB 45-60-35 |

45 |

60 |

35 |

1 |

1 |

||

SOB 45-60-40 |

45 |

60 |

40 |

1 |

1 |

||

SOB 45-60-50 |

45 |

60 |

50 |

1 |

1 |

||

SOB 45-60-60 |

45 |

60 |

60 |

1 |

1 |

||

SOB 45-60-70 |

45 |

60 |

70 |

1 |

1 |

||

SOB 45-60-80 |

45 |

60 |

80 |

1 |

1 |

||

SOB 50-60-20 |

50 |

60 |

20 |

1 |

1 |

||

SOB 50-60-25 |

50 |

60 |

25 |

1 |

1 |

||

SOB 50-60-30 |

50 |

60 |

30 |

1 |

1 |

||

SOB 50-60-35 |

50 |

60 |

35 |

1 |

1 |

||

SOB 50-60-40 |

50 |

60 |

40 |

1 |

1 |

||

SOB 50-60-50 |

50 |

60 |

50 |

1 |

1 |

||

SOB 50-60-60 |

50 |

60 |

60 |

1 |

1 |

||

SOB 50-60-70 |

50 |

60 |

70 |

1 |

1 |

||

SOB 50-60-80 |

50 |

60 |

80 |

1 |

1 |

||

SOB 50-62-30 |

50 |

62 |

30 |

1 |

1 |

||

SOB 50-62-35 |

50 |

62 |

35 |

1 |

1 |

||

SOB 50-62-40 |

50 |

62 |

40 |

1 |

1 |

||

SOB 50-62-50 |

50 |

62 |

50 |

1 |

1 |

||

SOB 50-62-60 |

50 |

62 |

60 |

1 |

1 |

||

SOB 50-62-70 |

50 |

62 |

70 |

1 |

1 |

||

SOB 50-62-80 |

50 |

62 |

80 |

1 |

1 |

SOB 50-65-30 |

50 |

65 |

30 |

1 |

1 |

||

SOB 50-65-40 |

50 |

65 |

40 |

1 |

1 |

||

SOB 50-65-50 |

50 |

65 |

50 |

1 |

1 |

||

SOB 50-65-60 |

50 |

65 |

60 |

1 |

1 |

||

SOB 50-65-70 |

50 |

65 |

70 |

1 |

1 |

||

SOB 50-65-80 |

50 |

65 |

80 |

1 |

1 |

||

SOB 50-65-100 |

50 |

65 |

100 |

1 |

1 |

||

SOB 55-70-30 |

55 |

70 |

30 |

1 |

1 |

||

SOB 55-70-35 |

55 |

70 |

35 |

1 |

1 |

||

SOB 55-70-40 |

55 |

70 |

40 |

1 |

1 |

||

SOB 55-70-50 |

55 |

70 |

50 |

1 |

1 |

||

SOB 55-70-60 |

55 |

70 |

60 |

1 |

1 |

||

SOB 55-70-70 |

55 |

70 |

70 |

1 |

1 |

||

SOB 60-74-30 |

60 |

74 |

30 |

1 |

1 |

||

SOB 60-74-35 |

60 |

74 |

35 |

1 |

1 |

||

SOB 60-74-40 |

60 |

74 |

40 |

1 |

1 |

||

SOB 60-74-50 |

60 |

74 |

50 |

1 |

1 |

||

SOB 60-74-60 |

60 |

74 |

60 |

1 |

1 |

||

SOB 60-74-70 |

60 |

74 |

70 |

1 |

1 |

||

SOB 60-74-80 |

60 |

74 |

80 |

1 |

1 |

||

SOB 60-74-100 |

60 |

74 |

100 |

1 |

1 |

||

SOB 60-75-30 |

60 |

75 |

30 |

1 |

1 |

||

SOB 60-75-35 |

60 |

75 |

35 |

1 |

1 |

||

SOB 60-75-40 |

60 |

75 |

40 |

1 |

1 |

||

SOB 60-75-50 |

60 |

75 |

50 |

1 |

1 |

||

SOB 60-75-60 |

60 |

75 |

60 |

1 |

1 |

||

SOB 60-75-70 |

60 |

75 |

70 |

1 |

1 |

||

SOB 60-75-80 |

60 |

75 |

80 |

1 |

1 |

||

SOB 60-75-100 |

60 |

75 |

100 |

1 |

1 |

||

SOB 63-75-60 |

63 |

75 |

60 |

1 |

1 |

||

SOB 63-75-70 |

63 |

75 |

70 |

1 |

1 |

||

SOB 63-75-80 |

63 |

75 |

80 |

1 |

1 |

||

SOB 65-80-40 |

65 |

80 |

40 |

1 |

1 |

||

SOB 65-80-50 |

65 |

80 |

50 |

1 |

1 |

||

SOB 65-80-60 |

65 |

80 |

60 |

1 |

1 |

||

SOB 65-80-70 |

65 |

80 |

70 |

1 |

1 |

||

SOB 65-80-80 |

65 |

80 |

80 |

1 |

1 |

||

SOB 70-85-30 |

70 |

85 |

30 |

1 |

1 |

||

SOB 70-85-35 |

70 |

85 |

35 |

1 |

1 |

||

SOB 70-85-40 |

70 |

85 |

40 |

1 |

1 |

||

SOB 70-85-50 |

70 |

85 |

50 |

1 |

1 |

||

SOB 70-85-60 |

70 |

85 |

60 |

1 |

1 |

||

SOB 70-85-70 |

70 |

85 |

70 |

1 |

1 |

||

SOB 70-85-80 |

70 |

85 |

80 |

1 |

1 |

||

SOB 70-85-100 |

70 |

85 |

100 |

1 |

1 |

||

SOB 70-90-50 |

70 |

90 |

50 |

1 |

1 |

||

SOB 70-90-60 |

70 |

90 |

60 |

1 |

1 |

||

SOB 70-90-70 |

70 |

90 |

70 |

1 |

1 |

||

SOB 70-90-80 |

70 |

90 |

80 |

1 |

1 |

||

SOB 70-90-100 |

70 |

90 |

100 |

1 |

1 |

||

SOB 75-90-50 |

75 |

90 |

50 |

1 |

1 |

||

SOB 75-90-60 |

75 |

90 |

60 |

1 |

1 |

||

SOB 75-90-70 |

75 |

90 |

70 |

1 |

1 |

||

SOB 75-90-80 |

75 |

90 |

80 |

1 |

1 |

||

SOB 75-90-100 |

75 |

90 |

100 |

1 |

1 |

||

SOB 75-95-60 |

75 |

95 |

60 |

1 |

1 |

||

SOB 75-95-70 |

75 |

95 |

70 |

1 |

1 |

||

SOB 75-95-80 |

75 |

95 |

80 |

1 |

1 |

||

SOB 75-95-100 |

75 |

95 |

100 |

1 |

1 |

||

SOB 80-96-20 |

80 |

96 |

20 |

1 |

1 |

||

SOB 80-96-40 |

80 |

96 |

40 |

1 |

1 |

||

SOB 80-96-50 |

80 |

96 |

50 |

1 |

1 |

||

SOB 80-96-60 |

80 |

96 |

60 |

1 |

1 |

||

SOB 80-96-70 |

80 |

96 |

70 |

1 |

1 |

||

SOB 80-96-80 |

80 |

96 |

80 |

1 |

1 |

||

SOB 80-96-100 |

80 |

96 |

100 |

1 |

1 |

||

SOB 80-96-120 |

80 |

96 |

120 |

1 |

1 |

||

SOB 80-100-40 |

80 |

100 |

40 |

1 |

1 |

||

SOB 80-100-50 |

80 |

100 |

50 |

1 |

1 |

||

SOB 80-100-60 |

80 |

100 |

60 |

1 |

1 |

||

SOB 80-100-70 |

80 |

100 |

70 |

1 |

1 |

||

SOB 80-100-80 |

80 |

100 |

80 |

1 |

1 |

||

SOB 80-100-100 |

80 |

100 |

100 |

1 |

1 |

||

SOB 80-100-120 |

80 |

100 |

120 |

1 |

1 |

||

SOB 80-100-140 |

80 |

100 |

140 |

1 |

1 |

||

SOB 85-100-25 |

85 |

100 |

25 |

1 |

1 |

||

SOB 85-100-60 |

85 |

100 |

60 |

1 |

1 |

||

SOB 85-100-80 |

85 |

100 |

80 |

1 |

1 |

||

SOB 90-110-30 |

90 |

110 |

30 |

1 |

1 |

||

SOB 90-110-50 |

90 |

110 |

50 |

1 |

1 |

||

SOB 90-110-60 |

90 |

110 |

60 |

1 |

1 |

||

SOB 90-110-70 |

90 |

110 |

70 |

1 |

1 |

||

SOB 90-110-80 |

90 |

110 |

80 |

1 |

1 |

||

SOB 90-110-90 |

90 |

110 |

90 |

1 |

1 |

||

SOB 90-110-100 |

90 |

110 |

100 |

1 |

1 |

||

SOB 90-110-120 |

90 |

110 |

120 |

1 |

1 |

||

SOB 100-115-100 |

100 |

115 |

100 |

1,5 |

1,5 |

||

SOB 100-120-40 |

100 |

120 |

40 |

1,5 |

1,5 |

||

SOB 100-120-50 |

100 |

120 |

50 |

1,5 |

1,5 |

||

SOB 100-120-60 |

100 |

120 |

60 |

1,5 |

1,5 |

||

SOB 100-120-70 |

100 |

120 |

70 |

1,5 |

1,5 |

||

SOB 100-120-80 |

100 |

120 |

80 |

1,5 |

1,5 |

||

SOB 100-120-90 |

100 |

120 |

90 |

1,5 |

1,5 |

||

SOB 100-120-100 |

100 |

120 |

100 |

1,5 |

1,5 |

||

SOB 100-120-120 |

100 |

120 |

120 |

1,5 |

1,5 |

||

SOB 100-120-140 |

100 |

120 |

140 |

1,5 |

1,5 |

||

SOB 110-130-50 |

110 |

130 |

50 |

1,5 |

1,5 |

||

SOB 110-130-70 |

110 |

130 |

70 |

1,5 |

1,5 |

||

SOB 110-130-80 |

110 |

130 |

80 |

1,5 |

1,5 |

||

SOB 110-130-100 |

110 |

130 |

100 |

1,5 |

1,5 |

SOB 110-130-120 |

110 |

130 |

120 |

1,5 |

1,5 |

||

SOB 120-140-70 |

120 |

140 |

70 |

1,5 |

1,5 |

||

SOB 120-140-80 |

120 |

140 |

80 |

1,5 |

1,5 |

||

SOB 120-140-90 |

120 |

140 |

90 |

1,5 |

1,5 |

||

SOB 120-140-100 |

120 |

140 |

100 |

1,5 |

1,5 |

||

SOB 120-140-120 |

120 |

140 |

120 |

1,5 |

1,5 |

||

SOB 120-140-140 |

120 |

140 |

140 |

1,5 |

1,5 |

||

SOB 125-145-100 |

125 |

145 |

100 |

1,5 |

1,5 |

||

SOB 125-145-120 |

125 |

145 |

120 |

1,5 |

1,5 |

||

SOB 130-150-80 |

130 |

150 |

80 |

1,5 |

1,5 |

||

SOB 130-150-100 |

130 |

150 |

100 |

1,5 |

1,5 |

||

SOB 130-150-130 |

130 |

150 |

130 |

1,5 |

1,5 |

||

SOB 140-160-100 |

140 |

160 |

100 |

1,5 |

1,5 |

||

SOB 140-160-140 |

140 |

160 |

140 |

1,5 |

1,5 |

||

SOB 150-170-100 |

150 |

170 |

100 |

1,5 |

1,5 |

||

SOB 150-170-150 |

150 |

170 |

150 |

1,5 |

1,5 |

||

SOB 160-180-80 |

160 |

180 |

80 |

1,5 |

1,5 |

||

SOB 160-180-100 |

160 |

180 |

100 |

1,5 |

1,5 |

||

SOB 160-180-150 |

160 |

180 |

150 |

1,5 |

1,5 |

||

SOB 170-190-100 |

170 |

190 |

100 |

1,5 |

1,5 |

||

SOB 170-190-150 |

170 |

190 |

150 |

1,5 |

1,5 |

||

SOB 180-200-100 |

180 |

200 |

100 |

1,5 |

1,5 |

||

SOB 180-200-150 |

180 |

200 |

150 |

1,5 |

1,5 |

||

SOB 190-210-100 |

190 |

210 |

100 |

1,5 |

1,5 |

||

SOB 190-210-150 |

190 |

210 |

150 |

1,5 |

1,5 |

||

SOB 200-230-150 |

200 |

230 |

150 |

1,5 |

1,5 |

||

SOB 200-230-200 |

200 |

230 |

200 |

1,5 |

1,5 |

| Chemical constituents & mechanical properties of cast aluminum bronze(GB/T 1176-1987) | |||||

| material | casting process | Mechanical properties of ≧ | |||

| Tensile strength | The yield strength | elongationδ5 | (HBS) | ||

| σb | σ0.2 | /% | (HBS) | ||

| MPa | |||||

| ZCuAl8Mn13Fe3 | S | 600 | 270* | 15 | 1570 |

| J | 650 | 280* | 10 | 1665 | |

| ZCuAl8Mn13Fe3Ni2 | S | 645 | 280 | 20 | 1570 |

| J | 670 | 310* | 18 | 1665 | |

| ZCuAl9Mn2 | S | 390 | — | 20 | 835 |

| J | 440 | — | 20 | 930 | |

| ZCuAl9Fe4Ni4Mn2 | S | 630 | 250 | 16 | 1570 |

| ZCuAl10Fe3 | S | 490 | 180 | 13 | 980* |

| J | 540 | 200 | 15 | 1080* | |

| Li、La | 540 | 200 | 15 | 1080* | |

| ZCuAl10Fe3Mn2 | S | 490 | — | 15 | 1080 |

| J | 540 | — | 20 | 1175 | |

Choose your Inner diameter, Flanged bush, self-lubricating equivalent, Sankyo oilless Alternatives, Price and delivery time on request!

| SOBF 8-12-10 | 8 | 12 | 10 | 20 | 2 | 0,5 | |||

| SOBF 8-12-12 | 8 | 12 | 12 | 20 | 2 | 0,5 | |||

| SOBF 8-12-15 | 8 | 12 | 15 | 20 | 2 | 1 | |||

| SOBF 10-14-10 | 10 | 14 | 10 | 22 | 2 | 1 | |||

| SOBF 10-14-12 | 10 | 14 | 12 | 22 | 2 | 1 | |||

| SOBF 10-14-15 | 10 | 14 | 15 | 22 | 2 | 1 | |||

| SOBF 10-14-17 | 10 | 14 | 17 | 22 | 2 | 1 | |||

| SOBF 10-14-20 | 10 | 14 | 20 | 22 | 2 | 1 | |||

| SOBF 12-18-10 | 12 | 18 | 10 | 25 | 3 | 1 | |||

| SOBF 12-18-12 | 12 | 18 | 12 | 25 | 3 | 1 | |||

| SOBF 12-18-15 | 12 | 18 | 15 | 25 | 3 | 1 | |||

| SOBF 12-18-20 | 12 | 18 | 20 | 25 | 3 | 1 | |||

| SOBF 12-18-25 | 12 | 18 | 25 | 25 | 3 | 1 | |||

| SOBF 12-18-30 | 12 | 18 | 30 | 25 | 3 | 1 | |||

| SOBF 13-19-10 | 13 | 19 | 10 | 26 | 3 | 1 | |||

| SOBF 13-19-12 | 13 | 19 | 12 | 26 | 3 | 1 | |||

| SOBF 13-19-15 | 13 | 19 | 15 | 26 | 3 | 1 | |||

| SOBF 13-19-20 | 13 | 19 | 20 | 26 | 3 | 1 | |||

| SOBF 13-19-25 | 13 | 19 | 25 | 26 | 3 | 1 | |||

| SOBF 13-19-30 | 13 | 19 | 30 | 26 | 3 | 1 | |||

| SOBF 14-20-15 | 14 | 20 | 15 | 27 | 3 | 1 | |||

| SOBF 14-20-20 | 14 | 20 | 20 | 27 | 3 | 1 | |||

| SOBF 14-20-25 | 14 | 20 | 25 | 27 | 3 | 1 | |||

| SOBF 15-21-10 | 15 | 21 | 10 | 28 | 3 | 1 | |||

| SOBF 15-21-12 | 15 | 21 | 12 | 28 | 3 | 1 | |||

| SOBF 15-21-15 | 15 | 21 | 15 | 28 | 3 | 1 | |||

| SOBF 15-21-20 | 15 | 21 | 20 | 28 | 3 | 1 | |||

| SOBF 15-21-25 | 15 | 21 | 25 | 28 | 3 | 1 | |||

| SOBF 15-21-30 | 15 | 21 | 30 | 28 | 3 | 1 | |||

| SOBF 16-22-12 | 16 | 22 | 12 | 29 | 3 | 1 | |||

| SOBF 16-22-15 | 16 | 22 | 15 | 29 | 3 | 1 | |||

| SOBF 16-22-18 | 16 | 22 | 18 | 29 | 3 | 1 | |||

| SOBF 16-22-20 | 16 | 22 | 20 | 29 | 3 | 1 | |||

| SOBF 16-22-23 | 16 | 22 | 23 | 29 | 3 | 1 | |||

| SOBF 16-22-25 | 16 | 22 | 25 | 29 | 3 | 1 | |||

| SOBF 16-22-30 | 16 | 22 | 30 | 29 | 3 | 1 | |||

| SOBF 16-22-35 | 16 | 22 | 35 | 29 | 3 | 1 | |||

| SOBF 16-22-40 | 16 | 22 | 40 | 29 | 3 | 1 | |||

| SOBF 18-24-15 | 18 | 24 | 15 | 32 | 3 | 1 | |||

| SOBF 18-24-20 | 18 | 24 | 20 | 32 | 3 | 1 | |||

| SOBF 18-24-25 | 18 | 24 | 25 | 32 | 3 | 1 | |||

| SOBF 18-24-30 | 18 | 24 | 30 | 32 | 3 | 1 | |||

| SOBF 18-24-35 | 18 | 24 | 35 | 32 | 3 | 1 | |||

| SOBF 18-24-40 | 18 | 24 | 40 | 32 | 3 | 1 | |||

| SOBF 20-30-15 | 20 | 30 | 15 | 40 | 5 | 1 | |||

| SOBF 20-30-20 | 20 | 30 | 20 | 40 | 5 | 1 | |||

| SOBF 20-30-25 | 20 | 30 | 25 | 40 | 5 | 1 | |||

| SOBF 20-30-30 | 20 | 30 | 30 | 40 | 5 | 1 | |||

| SOBF 20-30-35 | 20 | 30 | 35 | 40 | 5 | 1 | |||

| SOBF 20-30-40 | 20 | 30 | 40 | 40 | 5 | 1 | |||

| SOBF 25-35-15 | 25 | 35 | 15 | 45 | 5 | 1 | |||

| SOBF 25-35-20 | 25 | 35 | 20 | 45 | 5 | 2 | |||

| SOBF 25-35-25 | 25 | 35 | 25 | 45 | 5 | 2 | |||

| SOBF 25-35-30 | 25 | 35 | 30 | 45 | 5 | 2 | |||

| SOBF 25-35-35 | 25 | 35 | 35 | 45 | 5 | 2 | |||

| SOBF 25-35-40 | 25 | 35 | 40 | 45 | 5 | 2 | |||

| SOBF 25-35-50 | 25 | 35 | 50 | 45 | 5 | 2 | |||

| SOBF 30-40-20 | 30 | 40 | 20 | 50 | 5 | 2 | |||

| SOBF 30-40-25 | 30 | 40 | 25 | 50 | 5 | 2 | |||

| SOBF 30-40-30 | 30 | 40 | 30 | 50 | 5 | 2 | |||

| SOBF 30-40-35 | 30 | 40 | 35 | 50 | 5 | 2 | |||

| SOBF 30-40-40 | 30 | 40 | 40 | 50 | 5 | 2 | |||

| SOBF 30-40-50 | 30 | 40 | 50 | 50 | 5 | 2 | |||

| SOBF 31,5-40-20 | 31,5 | 40 | 20 | 50 | 5 | 2 | |||

| SOBF 31,5-40-30 | 31,5 | 40 | 30 | 50 | 5 | 2 | |||

| SOBF 31,5-40-35 | 31,5 | 40 | 35 | 50 | 5 | 2 | |||

| SOBF 31,5-40-40 | 31,5 | 40 | 40 | 50 | 5 | 2 | |||

| SOBF 35-45-20 | 35 | 45 | 20 | 60 | 5 | 2 | |||

| SOBF 35-45-25 | 35 | 45 | 25 | 60 | 5 | 2 | |||

| SOBF 35-45-30 | 35 | 45 | 30 | 60 | 5 | 2 | |||

| SOBF 35-45-35 | 35 | 45 | 35 | 60 | 5 | 2 | |||

| SOBF 35-45-40 | 35 | 45 | 40 | 60 | 5 | 2 | |||

| SOBF 35-45-50 | 35 | 45 | 50 | 60 | 5 | 2 | |||

| SOBF 40-50-20 | 40 | 50 | 20 | 65 | 5 | 2 | |||

| SOBF 40-50-25 | 40 | 50 | 25 | 65 | 5 | 2 | |||

| SOBF 40-50-30 | 40 | 50 | 30 | 65 | 5 | 2 | |||

| SOBF 40-50-35 | 40 | 50 | 35 | 65 | 5 | 2 | |||

| SOBF 40-50-40 | 40 | 50 | 40 | 65 | 5 | 2 | |||

| SOBF 40-50-50 | 40 | 50 | 50 | 65 | 5 | 2 | |||

| SOBF 45-55-30 | 45 | 55 | 30 | 70 | 5 | 2 | |||

| SOBF 45-55-35 | 45 | 55 | 35 | 70 | 5 | 2 | |||

| SOBF 45-55-40 | 45 | 55 | 40 | 70 | 5 | 2 | |||

| SOBF 45-55-50 | 45 | 55 | 50 | 70 | 5 | 2 | |||

| SOBF 45-55-60 | 45 | 55 | 60 | 70 | 5 | 2 | |||

| SOBF 50-60-30 | 50 | 60 | 30 | 75 | 5 | 2 | |||

| SOBF 50-60-35 | 50 | 60 | 35 | 75 | 5 | 2 | |||

| SOBF 50-60-40 | 50 | 60 | 40 | 75 | 5 | 2 | |||

| SOBF 50-60-50 | 50 | 60 | 50 | 75 | 5 | 2 | |||

| SOBF 50-60-60 | 50 | 60 | 60 | 75 | 5 | 2 | |||

| SOBF 55-65-40 | 55 | 65 | 40 | 80 | 5 | 2 | |||

| SOBF 55-65-60 | 55 | 65 | 60 | 80 | 5 | 2 | |||

| SOBF 60-75-40 | 60 | 75 | 40 | 90 | 7,5 | 3 | |||

| SOBF 60-75-50 | 60 | 75 | 50 | 90 | 7,5 | 3 | |||

| SOBF 60-75-80 | 60 | 75 | 80 | 90 | 7,5 | 3 | |||

| SOBF 65-80-60 | 65 | 80 | 60 | 95 | 7,5 | 3 | |||

| SOBF 70-85-50 | 70 | 85 | 50 | 105 | 7,5 | 3 | |||

| SOBF 70-85-80 | 70 | 85 | 80 | 105 | 7,5 | 3 | 1 | ||

| SOBF 75-90-60 | 75 | 90 | 60 | 110 | 7,5 | 3 | 1 | ||

| SOBF 80-100-60 | 80 | 100 | 60 | 120 | 10 | 3 | 1 | ||

| SOBF 80-100-80 | 80 | 100 | 80 | 120 | 10 | 3 | 1 |

Oilless Bushing Specifications:

| Standard | Chemical Composition (%) | Mechanical Property | Uses | ||||||||||||

| KS | JIS | ASTM | Cu | Zn | Al | Fe | Mn | Sn | Ni | Pb | Si | TS(n/m²) | E(%) | HB | |

| HBsC1 | HBsC1 | 8A | 55.0-60.0 | R | 0.5-1.5 | 0.1-1.5 | 0.1-1.5 | 1.0 max | 1.0 max | 0.4 max | 0.1 max | 413 min | 20 min | 90 | Machinery part, Propellor, Hub |

| HBsC2 | HBsC2 | 8B | 55.0-60.0 | R | 0.5-2.0 | 0.1-3.5 | 0.1-3.5 | 1.0 max | 1.0 max | 0.4 max | 0.1 max | 490 min | 18 min | 100 | Marine Parts, gear, Bush, Bearings |

| HBsC3 | HBsC3 | 8C | 60.0-65.0 | R | 3.0-7.5 | 2.0-5.0 | 2.5-5.0 | 0.5 max | 0.5 max | 0.2 max | 0.1 max | 637 min | 15 min | 165 | Cyclinder Parts, Worm Gear, Cap |

| HBsC4 | HBsC4 | SAE430B | 60.0-65.0 | R | 3.0-7.5 | 2.0-5.0 | 2.5-5.0 | 0.2 max | 0.5 max | 0.2 max | 0.1 max | 755 min | 12 min | ||

GRAPHITE IMPREGNATED OILLESS BRONZE BUSHING WORKING PRINCIPLE & ADVANTAGES

The working principle of a graphite impregnated bronze bushing and copper sleeve :Generally solid lubricant accounts for 20-30% of friction surface, graphite and copper set of self-lubricating bearing lubrication principle is in the process of sliding friction of shaft and bearing, part of the graphite particles transferred to the shaft and the bearing friction on the surface, formed a relatively stable layer of solid lubricant membrane, prevent the shaft and bearing directly adhesive wear. This reasonable combination of metal alloy and non-metal wear reducing materials of their respective performance advantages, complementary, that is, with the metal’s high bearing capacity, but also get the wear reducing material lubrication performance. Therefore, it is especially suitable for no refueling, less refueling, high temperature, high load or water environment.

The application of graphite impregnated bronze bushing: Self-lubricating bearing, is the copper sleeve as a metal matrix friction surface to develop an orderly arrangement, the size of the appropriate holes, and embedded graphite or molybdenum disulfide as a solid lubricant, a self-lubricating product. At present, the graphite impregnated bronze bushing has been widely used in construction machinery, metallurgical machinery, mining machinery, locomotive support, steel rolling equipment, Marine machinery, die equipment, textile machinery, gas turbine and other low-speed heavy-duty, high-speed light load and other occasions.

- Graphite Impregnated Bronze Bushing Online Order; Graphite Impregnated Bronze Bushing Stock Size & Ready For Ship

Tailored Service.

Large Machining Capacity.

Infinite Possibilities.

Engineering Sleeve Bushing Solution and Design. The Graphite impregnated bush material has thermostable, inoxidizability, wear-resisting, self-lubrication merit.

It is based on high strength copper alloy of special techniques. The solid lubricant is by certain angle, density and special formula, and then is processed exactly. The bronze graphite bearings parts is widely applied to casting machine, mining machinery, shipping, steam turbine, Injection machinery and automobile mounding, etc.

Advantages of graphite plugged bronze bushings:

- Good bearing capacity and good wear resistance;

- Suitable for high load & low speed under the rotation movement, swing movement and often under the load open and close frequent and difficult to form hydrodynamic lubrication occasions;

- Under the condition of boundary lubrication, the bearing can be maintained without refueling for a long time, while the bearing can have a longer service life with refueling in the upper layer;

- The surface plastic layer can be left with a certain margin during the processing and forming, and can be processed by ourselves after the assembly is pressed into the seat hole, so as to achieve a better assembly s*Graphite Impregnated Oilless Bronze Bushing Supply Company. Customized Design Service: Metric Graphite Impregnated Oilless Bronze Bushing Customized Size!ize.

*Graphite Impregnated Oilless Bronze Bushing Supply Company. Customized Design Service: Metric Graphite Impregnated Oilless Bronze Bushing Customized Size!

Solid inlaid self-lubricating bearing is a product made of solid lubricant with certain shape and strength on the friction surface of ordinary sliding bearing (sleeve), bearing bush, slider, guide rail, and other parts with relative mechanical movement, through reasonable holes and grooves, and embedded in the hole grooves. Embedded lubricants include graphite, sulfide (molybdenum disulfide, tungsten disulfide, etc.), calcium fluoride, synthetic resin, polytetrafluoroethylene, etc. The thermal expansion coefficient of the embedded solid lubricant is greater than that of the embedded substrate, and the type of the embedded solid lubricant can be selected according to the working condition.

In view of the characteristics of oil (grease) lubrication, the relevant people at home and abroad continue to study lubrication technology, in the 1920s in the developed countries developed inlaid self-lubricating bearings, in the 1940s in the United States took the lead in the form of products, then Japan, Germany has also launched similar products.

What are the effects of aluminum, manganese, iron, tin, nickel, and lead content on cast copper alloys:

Alloying elements such as aluminum, manganese, iron, silicon, tin, nickel, and lead are usually added to improve the properties of common cast brass (copper-zinc binary alloy). Usually the aluminum, manganese, iron, silicon, tin, nickel and other 5 kinds of alloy elements of the sum of more than 2% of the cast brass is called high strength brass alloy (high force brass is high strength copper alloy). These elements affect the properties of cast brass.

(1) iron

The addition amount of ordinary brass is 0.3% ~ 0.5%, and the addition amount of multiple brass is 1% ~ 3%. The solid solubility of iron in copper is 0.1%-0.2%, and the high melting point of iron-rich phase compound is formed when iron exceeds this amount. Iron can refine the grain, improve the strength and hardness; When the content is too high, too many brittle compounds appear on the grain boundary, resulting in the decrease of strength, plasticity and corrosion resistance.

(2) manganese

When the amount of manganese is 2% ~ 4% in casting brass, the manganese can be dissolved in α brass in copper, and the brittle phase rich in manganese can be precipitated at room temperature. Its effect is: a small amount of manganese has a solid solution strengthening effect, improve the strength of the alloy but the plasticity is not significantly decreased; When zinc content in brass exceeds 35%, if manganese content exceeds 4%, brittle phase will appear, damaging plasticity and toughness.

(3) aluminum

The addition amount of cast brass is 2% ~ 7%. Stable β phase is formed in copper to prevent brittle γ phase from appearing. Its influence is: a small amount of aluminum can make α brass β phase, (α+β) brass β phase increase, is an important alloying element in high strength brass; When the aluminum content is high, the plasticity and toughness of the alloy decrease, and when the zinc content is high, the “cold and brittle” of the casting is caused.

(4) silicon

The addition amount in cast brass is 2% ~ 4.5%. The brittle phase Cu2Si is formed in brass. Its effect is: a small amount of silicon can make the alloy strength and hardness significantly increased, plasticity decreased; To reduce the solidification temperature range of the alloy and improve the casting properties of the alloy.

(5) lead

In casting brass, the amount is 1% ~ 3%, and fine free particles are formed in brass. Its effect is to improve the cutting performance and wear resistance of the alloy. The hardness and plasticity of the alloy are significantly reduced after 3%.

(6) tin

Less than 1% in cast brass, it is soluble in alpha solid solution. Its effect is to form a SnO2 protective film on the surface of the casting. Significantly improve the corrosion resistance of brass to sea water, so tin brass is suitable for shipbuilding industry, “naval brass” said.

(7) nickel

In the cast brass, the amount is about 1%. It can expand the alpha phase region. Its effects are as follows: refining grain size and improving corrosion resistance of alloy; It can improve the hardness of the alloy, but the effect is not significant.

Characteristics and function of graphite copper sleeve

Professional casting of all kinds of brass, bronze. Such as tin bronze, aluminum bronze, copper pipe, copper rod, copper tile, copper worm gear, copper slide plate and so on. Adopts the advanced centrifugal casting process, the quality is stable, the performance is excellent, conforms to the international standard

Graphite copper sleeve – is a kind of self-lubricating copper sleeve with high strength copper alloy as matrix and graphite as lubricant. Some customers also call it copper sleeve with black spot. This new product can completely replace the traditional copper sleeve with oil injection through the oil groove to achieve the lubrication effect.

The oil groove copper sleeve needs regular refueling and maintenance in the process of use to ensure its lubrication. If it is not refueling and maintained for a long time, the lubrication effect is lost, then the friction coefficient of the copper sleeve will increase, the wear amount is large, and it will soon be scrapped. Moreover, the oil groove copper sleeve is not easy to use in a high temperature environment, and improper treatment of the oil groove burr will cause damage to the shaft. The graphite copper sleeve produced by Chenhan Bearing has the following characteristics:

One, no need to add lubricating oil or grease as a lubricant.

Two, can operate normally at 300° high temperature, and there will be no burning tile, burning shaft phenomenon.

Three, graphite copper sleeve itself does not need to open the oil groove, through its matrix embedded graphite in the process of operation to form an oil film to play a role in self-lubrication, and can protect the shaft from being pulled.

Four, strong compressive capacity, high load, high hardness, low friction coefficient.

Five, high precision, good walking performance.

6. It is suitable for reciprocating, rotating, swinging and intermittent movement where oil film is difficult to form.

| CAST BRONZE BEARING MATERIAL | ||||||

| GB | ISO | DIN | BS | NF | JIS | ASTM |

| ZCuSn3Zn8Pb6Ni1 | G-CuSn2ZnPb | LG1 | CuSn3Zn9Pb7 | BC1 | C83800 | |

| ZCuSn3Zn11Pb4 | G-CuSn2ZnPb | LG1 | CuSn3Zn9Pb7 | BC1 | C83810 | |

| ZCuSn5Zn5Pb5 | CuSn5Zn5Pb5 | G-CuSn5ZnPb | LG2 | CuSn5Zn5Pb5 | BC6 | C83600 |

| ZCuSn10P1 | CuSn11P | PB1 | CuSn12P | PBC2 | C90710 | |

| ZCuSn10Pb5 | CuSn8Pb2 | G-CuSn7ZnPb | LB2 | CuSn8 | LBCLn2 | C92710 |

| ZCuSn10Zn2 | CuSn10Zn2 | G-CuSn10Zn | G1 | CuSn8 | BC3 | C90500 |

| ZCuPb10Sn10 | CuPb10Sn10 | G-CuPb10Sn | LB2 | CuPb10Sn10 | LBC3C | C93700 |

| ZCuPb15Sn8 | CuPb15Sn8 | G-CuPb15Sn | LB1 | LBC4 | C93800 | |

| ZCuPb17Sn4Zn4 | CuPb20Sn5 | G-CuPb20Sn | CuPb20Sn5 | C94100 | ||

| ZCuPb20Sn5 | CuPb20Sn5 | G-CuPb20Sn | LB5 | CuPb20Sn5 | LBC5 | C94500 |

| ZCuPb30 | C94310 | |||||

| ZCuAl8Mn13Fe3 | CMA1 | ALBC4 | C95700 | |||

| ZCuAl8Mn13Fe3Ni2 | CMA1 | ALBC4 | C95700 | |||

| ZCuAl9Mn2 | ALBC2 | C95520 | ||||

| ZCuAl9Fe4Ni4Mn2 | CuAl10Fe5Ni5 | G-CuAl9Ni | ALBC3C | C95810 | ||

| ZCuAl10Fe3 | CuAl10Fe3 | G-CuAl10Ni | AB1 | ALBC1 | C95200 | |

| ZCuAl10Fe3Mn2 | G-CuAl10Ni | C95510 | ||||

| ZCuZn38 | G-CuZn38Al | DCB1 | CuZn40 | HBsC1 | C85500 | |

| ZCuZn25Al6Fe3Mn3 | CuZn25Al6Fe3Mn3 | G-CuZn25Al5 | HTB3 | CuZn23Al4 | HBsC4C | C86300 |

| ZCuZn26Al4Fe3Mn3 | CuZn26Al4Fe3Mn3 | G-CuZn25Al5 | HTB3 | CuZn23Al4 | HBsC4C | C86300 |

| ZCuZn31Al2 | C86700 | |||||

| ZCuZn35Al2Mn2Fe1 | CuZn35AlFeMn | G-CuZn35Al2 | HTB1 | CuZn30AlFeMn | HBsC2 | C86500 |

| ZCuZn38Mn2Pb2 | CuZn40Pb | HBsC1C | C86700 | |||

| ZCuZn40Mn2 | HBsC2C | C86500 | ||||

| ZCuZn40Mn3Fe1 | CuZn35AlFeMn | HBsC2 | C86800 | |||

| ZCuZn33Pb2 | CuZn33Pb2 | SCB3 | HBsC1 | C85400 | ||

| ZCuZn40Pb2 | G-CuZn37Pb | PCB1 | CuZn40 | HBsC1 | C85700 | |

| ZCuZn16Si4 | G-CuZn15Si4 | HBsC3 | C87400 | |||

Graphite-Impregnated Bronze, Bronzelube.com Price and delivery time on request

Oilless Bronze Bushing, Plugged Graphite Bushings made in China. “Fast Delivery, Factory Price, High Quality”Choose from our selection of graphite-impregnated bronze, including metric size and inch size products in a wide range of material and type. Wear Plate, Thrust Washer, Flange Size. Graphite Bushings and Bronze Bearings – Made to order from China. *Graphite plugged bronze bushing in stock, Graphite is mechanically forced into the holes/grooves under extreme pressure.Graphite plugged bronze bushing bronze alloys material:

- C95400 Aluminum Bronze Bushing

- C93200 Bearing Bronze Bushing

- C86300 Manganese Bronze Bushing

- Cost-effective

- Easy to install

- Higher load capacity

- Oilless bushing long service life

Industry Solutions Save, Oil-free bushing are made from self-lubricating

About Us

Graphite Bushing and Slide Plate