Bronze Bushing Projects

Oil & Grease Groove Bronze Bushings Solution Supplier

“bronzelube.com” has since established itself as a leading distributor of Bronze, Copper & Brass, Iron, Sintered Products, Self lubricated bushings and Wear plate, in China. We Are Specialists In Cutting Lubrication Grooves In Virtually Any Pattern. Self-Lubricating, Fast, Reliable With Highest Quality Standards.Bronze bushings with oil grooves, grease grooves in bushings!

Oil & Grease Groove

Selecting Your Proper Oil Grooves For Bronze Bushings. Types of lubricant groove. Continuous Cast Bronze: The method of continuous casting of bronze involves the steady pour of molten bronze into a mold. This process results in a uniform, fine-grain structure without any porosity, ensuring the strength and consistency of the final product. Continuous cast bronze bushings offer superior quality compared to those made using other casting methods, and they provide excellent wear resistance and increased lifespan.

Bronze Bushings / Bearings with Groove

Groove bronze bushings are created from solid bronze, which offers excellent strength, durability, and corrosion resistance. Their surface features a pattern of grooves, which serve several important functions. Always tested. Always proven. Types of lubricant groove bearing. Global website www.bronzelube.com, Advantages: Some key benefits of using groove bronze bushings include the ability to withstand high loads, low maintenance due to self-lubrication, good resistance to shock and impact, high temperature tolerance, and long service life.

Cast Bronze Bearings, Types of Grooves

Large Inventory of Ready-to-Go Groove Bronze Bushing Products. Types of lubricant groove bronze bushing. Function of the Grooves: These grooves play a crucial role in the lubrication of the bearing. They act as lubricant reservoirs, maintaining a thin film of lubricant on the surface even under conditions of high load and slow speed. This feature allows for extended periods of operation without the need for additional lubrication, reducing maintenance requirements and improving the overall efficiency of the machinery in which they are used.

Premium Bronze Bushings – Made To The Highest Standards

Industrial groove bronze bushings, made from continuous cast bronze, provide a reliable, efficient, and long-lasting solution for various industrial applications. Their robust structure and self-lubricating properties make them an excellent choice for demanding environments.

Made-To-Order Cast Bronze Sleeve Bearings for an Oil/Grease

Applications: Industrial groove bronze bushings find wide application in various industries such as automotive, construction, mining, agriculture, and heavy machinery. They are used in any equipment that involves rotary or sliding motion and needs to endure high loads and harsh conditions.

Industrial Bronze Bushings – Continuous Cast Bronze

Industrial groove bronze bushings are an important part of various machinery and equipment, especially in high load and harsh conditions. These are manufactured using the process of continuous casting of bronze, which ensures their high quality and reliability.

Unveiling the Potential of Bronze Bush with Drilling Metric Size (Internal Groove): An Industrial Game-Changer

Efficiency, precision, and durability are the three pillars of successful industrial operations. When it comes to mechanical components, achieving these outcomes depends on the quality and design of the components in use. One such vital component in many industrial applications is the Bronze Bush with Drilling Metric Size (Internal Groove).

Understanding the Bronze Bush with Drilling Metric Size (Internal Groove)

Bronze Bushes with Drilling Metric Size (Internal Groove) are essentially bushings crafted from bronze and come with drilled holes of specific metric sizes. These holes often serve as reservoirs for lubricants, improving the self-lubrication capabilities of the bushing.

The internal groove is a design feature that further enhances the distribution of the lubricant across the entire bearing surface. This design ensures smoother operation and minimizes the risk of component failure due to insufficient lubrication.

Advantages of Bronze Bush with Drilling Metric Size (Internal Groove)

The utilization of this particular type of bronze bush brings several benefits to the table:

-

Extended Lifespan: Thanks to the continuous lubrication provided by the drilled holes and the internal groove, these bushes experience less wear and tear, thereby extending their lifespan and the lifespan of the surrounding components.

-

Reduced Maintenance: The self-lubricating property of these bushes significantly cuts down on maintenance time and costs. The need for regular manual lubrication is eliminated, freeing up resources and increasing overall efficiency.

-

Versatility: The use of metric measurements for drilling allows for customization to fit specific requirements. This versatility ensures that these bronze bushes can be used across a wide range of industrial applications.

-

Improved Efficiency: By reducing friction and ensuring smooth operation, these bushes help in maintaining the high-efficiency performance of the machinery they are part of.

Concluding Thoughts

In the ever-evolving landscape of industrial machinery, the Bronze Bush with Drilling Metric Size (Internal Groove) stands out as a remarkable innovation. By offering extended lifespan, reduced maintenance, improved efficiency, and adaptability, these components significantly enhance the performance and productivity of the machinery they are part of.

These components illustrate the continuous striving for improvement and optimization in industrial component design. They are yet another example of how seemingly small modifications can have a profound impact on overall machine performance, demonstrating the enormous potential of intelligent design in mechanical engineering.

Provides custom-made bronze bearings, tailored according to the specific designs provided by clients. Here’s a brief description of what you’ve stated:

Your primary material for bearing production is bronze, due to its superior friction resistance. The range of alloys and vast selection of lubricants allow these bearings to be utilized in a diverse array of operational conditions.

Your company offers four main groups of alloys for these bearings, including Tin Bronze, Lead Bronze, Aluminium Bronze, and High Tensile Brass. These were selected for their unique properties that make them particularly suitable for different applications. Through your collaboration with your parent company, which operates a continuous and centrifugal cast bronze foundry, you’re also able to manufacture bearings from other, less common alloys if needed.

Each bearing is machined based on the client’s specific designs. This means that all aspects of the bearing, from the type of bronze alloy used, to the dimensions of the bearing, to the inclusion of special features like grooves, are fully customizable to meet the client’s unique requirements. This level of personalization helps ensure that your bearings are perfectly suited to the specific applications they’re designed for.

-

Bushings: Bushings, also known as plain bearings, are used to reduce friction and wear between moving mechanical parts. They’re designed to support a rotating shaft, and are often found in systems where one part slides past another.

-

Bronze Bearings: These are a type of plain bearing specifically made from bronze, a metal alloy that’s especially durable and has excellent friction reduction properties. They’re used in a variety of applications, from small machinery to large industrial equipment.

-

Bronze Bush Bearing Liner: This is a type of liner made from bronze for bush bearings. It serves as an intermediary layer between the bearing and the shaft, reducing friction and wear and extending the life of the bearing.

-

Bronze Plates: These are broad, flat pieces of bronze, often used in machinery and equipment for a variety of purposes. Depending on the specific application, they may be used to distribute load, reduce friction, or provide a durable, wear-resistant surface.

-

Bronze Washers: These are thin, typically disk-shaped pieces of bronze that are used to distribute the load of a threaded fastener, such as a screw or nut. They can also be used as spacers, springs, and wear pads.

-

Other Customized CuSn8 and CuSn12 Tin Bronze Bearing Pieces: These are custom-made bearing components made from specific types of tin bronze (either CuSn8 or CuSn12). Tin bronze is known for its excellent resistance to wear, corrosion, and fatigue, making it a great material for bearings and similar components.

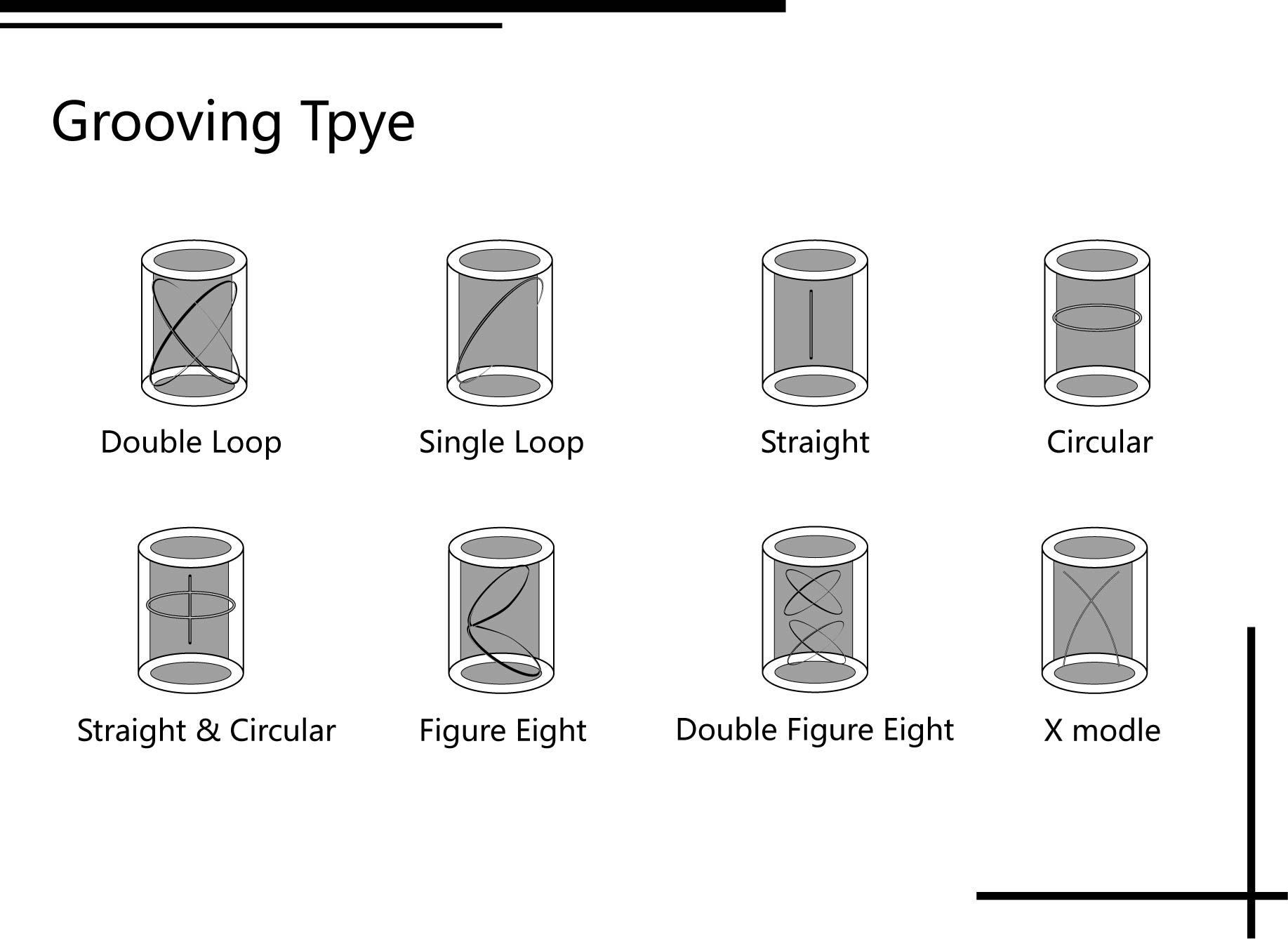

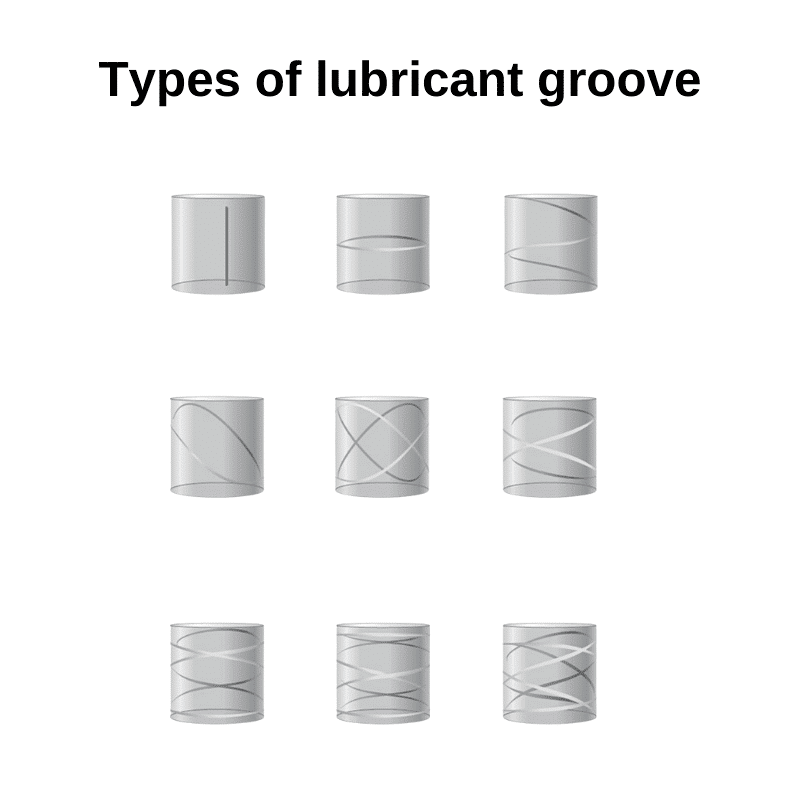

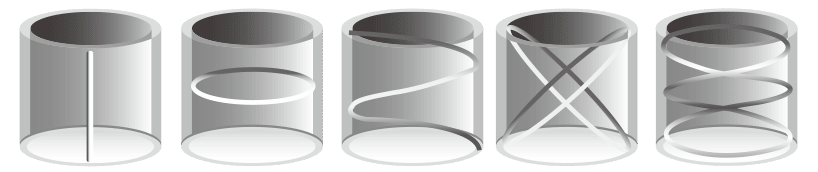

Bronze Bearing Types of Grooves

There are several types of lubricant grooves that can be used in bronze bushings, and the specific type chosen will depend on factors such as the type of lubricant being used, the application requirements, and the desired level of performance. Here’s a brief description of some of the most common types of lubricant grooves used in bronze bushings:

-

Axial grooves: These grooves run parallel to the axis of the bushing and are used to distribute lubricant evenly along the length of the bearing surface.

-

Circumferential grooves: These grooves run around the circumference of the bushing and are used to distribute lubricant evenly around the bearing surface.

-

Helical grooves: These grooves are spiraled around the circumference of the bushing and are used to create a pumping action that helps to circulate lubricant and prevent it from becoming trapped.

-

Oval grooves: These grooves have an oval shape and are used to promote better distribution of lubricant across the bearing surface.

-

Double oval grooves: These grooves have two oval shapes that are offset from each other and are used to promote better lubrication in high-load applications.

-

Figure of eight grooves: These grooves have a figure-eight shape and are used to promote better lubrication and reduce friction in high-speed applications.

-

One and a half figure of eight grooves: These grooves are similar to figure of eight grooves, but with one loop that is larger than the other. They are used to promote better lubrication in applications with high radial loads.

-

Double figure of eight grooves: These grooves have two interlocking figure-eight shapes and are used to promote better lubrication and reduce friction in high-speed, high-load applications.

-

Duplex figure of eight grooves: These grooves have two sets of interlocking figure-eight shapes and are used to promote better lubrication and reduce friction in very high-speed, high-load applications.

It’s important to note that the specific type of lubricant groove used in a bronze bushing will depend on a number of factors, and it’s often necessary to test and experiment with different groove designs in order to achieve optimal performance for a given application.

Types of lubricant groove

The type of groove used in a bronze bushing can have a significant impact on its performance, particularly in terms of lubrication and wear resistance. Here’s some additional information on the different types of grooves that can be used:

Closed grooves: These grooves are completely enclosed, meaning that lubricant is trapped within the groove and cannot escape. This can be useful in applications where there is limited lubrication available, as the closed groove helps to retain the lubricant and ensure that it is distributed evenly across the bearing surface.

Open grooves: These grooves are open on one or both sides, allowing lubricant to flow freely across the bearing surface. This can be beneficial in applications where there is a lot of lubrication available, as the open groove helps to prevent the lubricant from becoming trapped and causing excessive heat buildup.

The shape and geometry of the grooves can also vary depending on the specific application. For example, some grooves may be designed to promote better distribution of the lubricant, while others may be optimized for high-speed or high-load applications. Overall, the selection of the appropriate groove type and geometry is an important consideration when designing a bronze bushing for a particular application.

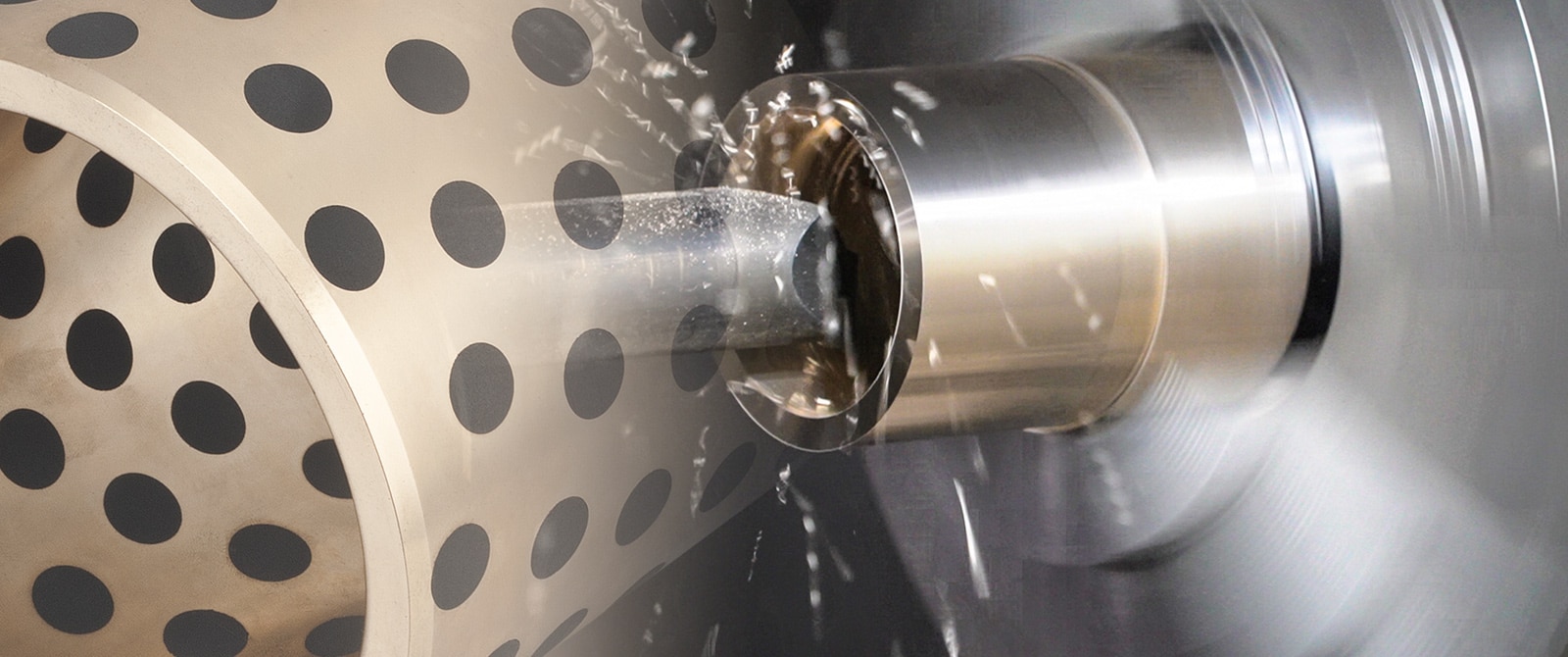

Bronze Bearing Design Cutting Lubrication Grooves

Cutting lubrication grooves in machine parts is a crucial process that ensures smooth and efficient operation while preventing damage to the equipment. At our company, we are experts in cutting lubrication grooves in almost any pattern to suit your specific application needs.

We offer a wide range of groove patterns to choose from, including l-spiral grooves, 11-letter shaped grooves, figure-of-eight, double figure-of-eight, ring, double ring, round, wick, or straight. Our skilled team can create any of these grooves within the length of the part or broken through from both ends.

We understand that selecting the right groove pattern for your application can be challenging, and that’s why we offer expert assistance to help you determine the best pattern for your needs. We have years of experience in cutting lubrication grooves for different industries and applications, and we can provide valuable insights to help you make an informed decision.

We also have industry-standard groove patterns available that have been tested and proven to be effective for specific applications. Our team can recommend these patterns if they are suitable for your needs.

At our company, we use advanced cutting technology and equipment to ensure precision and accuracy in every groove we create. We are committed to delivering high-quality results that meet or exceed our clients’ expectations.

In summary, if you need lubrication grooves cut into your machine parts, we have the expertise and technology to provide the best solution for your needs. Contact us today for assistance in selecting the best groove pattern for your application and for a quote on our services.

Bronze Bearing Design Groove Type Cross Reference Names:

Groove Style Cross Reference Names: |

|||||||

| Bunting Circular | Bunting Straight | Bunting 1 | Bunting 2 | Bunting 3 | Bunting 4 | Bunting 5 | Bunting 11 |

| Johnson H | Johnson G | Johnson A | Johnson D | Johnson C | Johnson B | Johnson E | Johnson F |

| Randall H | Randall G | Randall A | Randall D | Randall Straight & Circular | Randall B | Randall E | Randall F |

| Boston Gear II | Boston Gear I | Boston Gear III | Boston Gear VI | Boston Gear V | Boston Gear IV | Boston Gear VII | Boston Gear VIII |

| Buckeye Circular | Buckeye Straight | Buckeye A | Buckeye B | Buckeye C | Buckeye D | Buckeye E | Buckeye F |

Cast Bronze Bearings, Types of Grooves

Cast bronze bearings are a type of plain bearing made from a cast bronze material, typically composed of copper, tin, and small amounts of other metals. These bearings are commonly used in various industrial applications due to their high strength, durability, and corrosion resistance.

There are several types of grooves that can be machined into cast bronze bearings, including:

- Straight grooves: These grooves are machined into the surface of the bearing in a straight line. They are used to distribute lubricant evenly across the surface of the bearing, reducing friction and wear.

- Spiral grooves: These grooves are machined into the surface of the bearing in a spiral pattern. They are used to create a pumping action that helps to distribute lubricant across the bearing surface.

- Diamond grooves: These grooves are machined into the surface of the bearing in a diamond pattern. They are used to improve the retention of lubricant on the bearing surface, reducing the need for frequent lubrication.

- Dimples: These are small, shallow depressions that are machined into the surface of the bearing. They are used to retain lubricant and improve the distribution of lubricant across the bearing surface.

The choice of groove type depends on the specific application and operating conditions of the bearing, as well as the lubricant used. Proper lubrication is crucial for the proper operation and longevity of cast bronze bearings.

Made-To-Order Groove Bronze Bushing For Oil Application

-

Imperial Bronze Bush: These are bronze bushes (also known as bushings or plain bearings) that follow the Imperial measurement system, which uses inches.

-

They are designed to reduce friction between moving parts in a machine or system. They’re often used in applications where one part needs to slide over another.

-

Their durability and superior friction reduction properties make them an excellent choice for a wide range of industrial applications.

produces high-quality, oilless bronze bearing bushes that are self-lubricating. These include circular oil groove bronze bushings, which are designed to deliver superior performance and longevity.

Here are the details:

-

Oilless Bronze Bearing Bush Self-Lubricating: These bearings are designed to function without the need for additional lubrication. This makes them ideal for applications where regular maintenance is difficult or undesirable. The self-lubricating feature comes from the properties of the bronze itself or from a special coating or treatment applied to the bronze.

-

Circular Oil Grooves Bronze Bushing: These bearings feature circular grooves that are designed to distribute lubricant evenly across the bearing surface. This helps reduce friction and wear over time.

-

Superior Quality from Continuous Casting: Your company uses a continuous casting process to produce these bearings, which ensures a uniform bronze structure throughout. This makes the bearings free from porosity and hard particle inclusions, which can be found in other casting processes.

-

Material-Alloys: The bearings are made from a variety of bronze alloys, including CuSn12, CuZn37Mn3Al2PbSi, CuAl10Ni5Fe4, and RG7 (CuSn7ZnPb). These different alloys offer a range of properties to meet different application requirements.

Cast Bronze Bearing Materiel-Alloys

- CuSn12

- CuZn37Mn3Al2PbSi

- CuAl10Ni5Fe4

- RG7 (CuSn7ZnPb)

High-quality & Choose your correct bronze bushing

“Standard Groove Bronze Bushing Dimensions – The Cost-effective Alternative.”

Bushing Grease Groove Design, Grease Grooves in Bushings!

Bronze Plain Bearing, Groove Bronze Bushing

RG7 (CuSn7ZnPb) circular oil grooves RG7 Bearing Bronze made to order from china.

Grooves are often machined in plain bushes to improve the lubricant flow and therefore the sliding properties of the bush. Grooves also aim at carrying of the wear wastes from the sliding surface.

Mechanical Characteristics, High quality at cost-effective prices.

The groove bronze bushing with a single oil hole can have approximately three times the load bearing capacity then a bearing with an annular or circumferential groove in the same length bearing.

The oil groove of the oil groove of the copper sleeve is some inside the copper sleeve, and some outside the copper sleeve. Its oil groove is generally processed directly by lathe milling machine or NUMERICAL control lathe. Different processing techniques can be selected according to different forms of oil groove.

*In order to form a more perfect oil film between the bearing & shaft, we recommend a V-shaped groove whenever the design permits, as it allows full flow of the lubricant across the bearing surface.

“Standard Groove Bronze Bushing Dimensions – The Cost-effective Alternative.”

| Properties | Type | Groove bronze bushing | Unit |

| Tensile strength | Rm | 230-600 | N/mm2 |

| Load | Oscillation | 90-150 | N/mm2 |

| Speed | Greased | 1,5 – 2 | m/s |

| Temperature | -40 ; +225 | °C | |

| Thermal conductivity | 58 | W(m.K)-1 | |

| Coef. of thermal expansion | 18.10-6 | K-1 |

Oil Grooved Bronze Bushing at bronzelube.com, Bronze Bushes

GROOVE BRONZE BUSHING CUSTOMIZED ITEMS – BRONZE BEARING:Plain & Self-Lubricating Bearings Type:Straight ,Shouldered,Flanged Bearings,Pillow Block and Open Type.We manufacture bronze bushings & parts according to your specifications and drawings.Special manufacturing,Our specialty is customized parts in all kinds of bronze and brass alloy bearings.

SOLID-LUBRICANT-INLAID BEARING MANUFACTURING

BULID BRANDS, TRANSFORMING MOMENTS

When self-lubrication is needed in high-temperature or messy environments, we machine custom parts with many different

material types including; bronze, steel, aluminum, composite, ptfe, sliding layer metal,Bi-metal and brass.

GROOVE BRONZE BUSHING CHARACTERISTICS

Bronze Graphite Bushings Fullfills the highest operational demands and is suitable for shock loads. Depending on the alloy, it is corrosion-resistant and also highly wear-resistant with a long life span.

MATERIAL AND COMPOSITION

Support material: CuZn25AI5Mn4Fe3 + graphite

Sliding layer Solid lubricant graphite surface: app. 25-30%

Other commonly used bronze alloys: CuAl10Ni, CuSn12Pb, CuSn7ZnPb

GROOVE BRONZE BUSHING DIMENSIONS

Metric (mm) Imperial (inch) Bushing

Shaft and housing tolerances (Design of bushing arrangements)

Housing ØH7 Bushing inner-Ø after mounting

Please consult our sales engineers, standard delivered tolerance: r6 or E7 Shaft tolerance f7 or h6

AVAILABILITY: Bearing forms available in standard dimensions

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping or deep drawing, customized bushing designs

SHAPES & FORMS: Straight Bronze Type Flange Type & Washer

ASSEMBLY ADVISE: Lubrication Bearings

Graphite Bronze Bearing is maintenance-free but lubricating the sliding surfaces during assembly is recommended for initial start-up period. Common lubricants such as greases or oils can be used. For optimal performance and longevity, it is important that mating surfaces are properly cleaned when assemblying.

RANGE OF APPLICATION

Hardware and steel fabrication, stamping dies, tooling components for the automotive industry, sheet pressing etc.

SPECIAL MANUFACTURING

* For higher requirements – e.g. higher temperature ranges – different materials are available in this category.Special dimensions are available on request

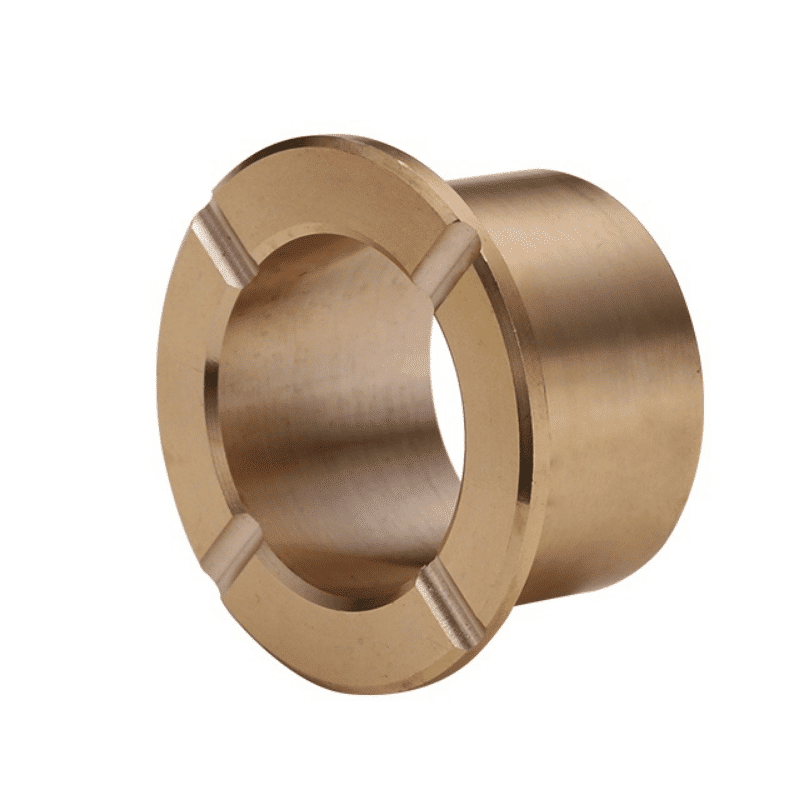

Oil Grooved Flange Bronze Bushing at bronzelube.com, Flange Bronze Bushes

A grease groove flange bronze bushing is a type of bronze bushing that has one or more grooves machined into its surface to improve the distribution of lubricating grease or oil. The grooves can be machined into the bearing’s ID, OD, or both, depending on the specific application requirements.

A flange bronze bushing is a type of bushing that has a flange or a lip on one end to prevent it from sliding out of place during operation. The flange can also act as a seat or a stop for the bearing or other components.

The combination of the grease grooves and flange in a bronze bushing offers several advantages:

- Improved lubrication: The grooves help to distribute lubricating grease or oil more evenly across the bearing’s surface, reducing friction and wear.

- Reduced maintenance: With better lubrication, the bushing requires less frequent maintenance, which can result in cost savings and improved efficiency.

- Increased load capacity: The combination of grooves and flange can help to increase the bearing’s load capacity, making it suitable for heavy-duty applications.

- Secure positioning: The flange helps to secure the bearing in place and prevent it from moving during operation, reducing the risk of damage or failure.

Grease groove flange bronze bushings are commonly used in a wide range of applications, including automotive, construction, and industrial equipment. They are available in various sizes and configurations to suit specific application requirements.

Oil & Grease Groove Bronze Bushings / Bearings

Oil Grooved Bronze Bushing at bronzelube.com, Bronze Bushes

Cutting grease grooves in bushing, Oil & Grease Groove Bronze Bushings. Our Cast Bronze Bushings are machined from continuous cast C93200 (SAE 660) bronze for superior quality and performance. Bushing Spiral Grease Groove, Precision Bronze Bushings, Straight, Oil Groove, Grooved Cast Bronze Bushings! Oil Groove Bushing Supplier!

Chemical Composition

| Steel Layer(45 Steel) | Copper Layer(And Japan CAC304 Considerable) | ||||||||

| Fe | C | Si | Mn | S.P | Cu | Fe | Mn | Ai | Zn |

| Margin | 0.45~0.50 | 0.17~0.37 | 0.50~0.80 | ≤0.040 | 60~66 | 3~8 | 2.25~5 | 5~7.5 | Margin |

Mechanical Behavior

| Bond Strength Of Steel And Copper(N/mm²) | Copper Layer Hardness HB | Steel Layer Hardness | |

| Not heat-treated state | Surface high-frequency quenching after the cylindrical surface | ||

| ≥300MPa | >210 | 0≤241HBS | ≥45HRC |

Solid Lubricants

| Solid Lubricants | Features | |

| Graphite+add | Good wear performance and chemical stability,temperature limit 400℃ | Suit for general machines and under atmosphere |

| PTFE+add | Lowest friction coefficient and good water lubrication, temperature limit 300℃ | Suit for water and seawater lubricant, such as ship |

Technical Parameters

| Grade | JDB-1 | JDB-2 | JDB-22 | JDB-23 | JDB-24 | JDB-25 | JDB-1S |

|---|---|---|---|---|---|---|---|

| International Brands GB1776-87 | ZCuZn25 Al6Fe3Mn3 |

ZCuSn6Zn6Pb3 | ZCuAl10Fe3 | ZCuSu10P1 | Steel+ ZCuSn6Zn6Pb3 | HT250 | GCr15 |

| International ISO1338 | GCuZn25 Al6Fe3Mn3 |

GCuSn6Zn6Pb3 | GCuAl10Fe3 | – | Steel+ CuSn6Zn6Pb3 Fe3Ni5 |

– | B1 |

| Germany DIN | G-CuZn25 Al5 |

GB-CuSn5Zn5Pb5 | GB-CuAl10Ni | GB-CuSn10 | Steel+ CuSn6Zn6Pb3Ni | – | 100Cr6 |

| Japan JIS | HBsC4 | BC6 | AIBC3 | BC3 | BC6 | FC250 | SUJ2 |

| American ASTM/UNS | C86300 | C83600 | C95500 | C90500 | C83600 | Class40 | 52100 |

| British Standard(BS) | HTB2 | LG2 | AB1 | PB4 | LG2 | – | – |

Material Composition And Performance

| Grade | JDB-1 | JDB-2 | JDB-22 | JDB-23 | JDB-24 | JDB-25 | JDB-1S |

|---|---|---|---|---|---|---|---|

| Chemical Composition | CuZn25Al5Mn4Fe3 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn10Pb1 | CuSn7ZnPb | CuSn12Pb1 | CuZn25Al5Mn4Fe3 |

| Density g/cm³ | 8 | 8.9 | 7.8 | 8.9 | 8.8 | 8.9 | 8 |

| Hardness HB | >210 | >70 | >140 | >80 | >75 | >95 | >250 |

| Tensile Strength N/mm² | >750 | >200 | >600 | BC3 | >270 | >260 | >800 |

| Yield Strength N/mm² | >450 | >90 | >260 | C90500 | >130 | >150 | >450 |

| Elongation % | >12 | >15 | >10 | PB4 | >16 | >8 | >8 |

| Linear Expansion Coefficient | 1.9X10-5/℃ | 1.8X10-5/℃ | 1.6X10-5/℃ | 1.8X10-5/℃ | 1.8X10-5/℃ | 1.8X10-5/℃ | 1.9X10-5/℃ |

| Working Temperature ℃ | -40~+400 | -40~+400 | -40~+400 | -40~+400 | -40~+400 | -40~+400 | -40~+150 |

| Max Load Capacity | 100 | 60 | 50 | 70 | 70 | 70 | 120 |

| Max Line Speed V | 15 | 10 | 20 | 10 | 10 | 10 | 15 |

| Max. PV value (lubrication) N/mm²*m/min | 200 | 60 | 60 | 80 | 60 | 80 | 200 |

| Permanent Compression Deformation 300N/mm² | <0.01mm | <0.05mm | <0.04mm | <0.05mm | <0.05mm | <0.05mm | <0.05mm |

Custom Machined Parts CNC Machining– You Design It, We’ll Make It.

Custom machined parts CNC machining

Custom machined parts CNC machining refers to the process of manufacturing precision parts to exact specifications using computer-controlled machines. CNC machines can create complex shapes and patterns with high precision, accuracy, and repeatability, making them an ideal choice for producing custom parts that are difficult or impossible to produce using traditional machining techniques.

The process starts with a design or CAD file that specifies the dimensions and features of the part. The file is then loaded into a CNC machine, which uses a cutting tool to remove material from a solid block of material, such as metal or plastic, to create the desired shape. The machine is programmed to follow the design precisely, and the cutting tool moves along multiple axes to create the necessary features and contours.

The advantage of custom machined parts CNC machining is that it can produce high-quality parts quickly and with minimal human intervention. Once the machine is set up, it can run continuously until the parts are complete, ensuring consistency and accuracy. It can also be used to produce large quantities of parts with ease, making it a cost-effective option for mass production.

If you need a custom machined part, you can provide your design or specifications to a CNC machining service, and they will produce the part to your exact requirements. This service is especially useful for industries such as aerospace, automotive, and medical, which require precision parts with complex geometries.

Overall, custom machined parts CNC machining is a highly versatile and efficient manufacturing process that can produce complex parts to exact specifications quickly and cost-effectively.

Shop bronze bushings with oil grooves, bronze bearings with lubrication groove

When your application requires lubrication of the bearing housing or shaft, an oil or grease groove is essential. At bronzelube.com, we can groove to customer specifications, including single ring, figure-eight, double ring, double figure-eight, half figure-eight, linear and circular groove patterns.

Bronze bearings with lubrication grooves are a type of plain bearing that is commonly used in various industrial applications. The lubrication grooves are machined on the bearing surface to provide a path for lubricant flow, which helps to reduce friction and wear.

Bronze is a common material for bearings due to its good wear resistance, high strength, and ability to withstand high temperatures. It also has good corrosion resistance and can be easily machined to tight tolerances.

The lubrication grooves on a bronze bearing can take various shapes, such as circular, spiral, or straight. The grooves allow lubricant to penetrate into the bearing surface and create a film of lubrication between the bearing and the shaft, reducing friction and wear.

Bronze bearings with lubrication grooves are commonly used in applications such as pumps, motors, and industrial machinery, where high loads and speeds are present. They are also used in marine applications, where their corrosion resistance is advantageous.

It is important to note that the effectiveness of the lubrication grooves depends on the quality of the lubricant used and the operating conditions of the bearing. Regular maintenance and lubrication are essential to ensure optimal performance and long service life of the bearing.

Cutting grease grooves in bushings, Groove Bronze Bushing material

Cutting grease grooves in bushings is a process that involves machining small channels or grooves into the surface of the bushing to improve its lubrication and performance. The process can be done using a lathe or other machining tool, and the grooves can be cut in a variety of patterns, such as spiral, helical, or circular, depending on the specific application requirements.

The following steps can be taken to cut grease grooves in bushings:

Determine the pattern and dimensions of the grooves: The groove pattern and dimensions will depend on the specific application requirements, load, speed, and operating environment. It is important to select the correct pattern and dimensions to ensure optimal lubrication and performance.

Secure the bushing in a lathe or other machining tool: The bushing should be securely clamped or mounted in the machining tool to prevent it from moving during the grooving process.

Cut the grooves: Using a cutting tool, the grooves can be machined into the surface of the bushing. The depth, width, and spacing of the grooves should be carefully controlled to achieve the desired lubrication performance.

Remove any burrs or debris: After cutting the grooves, it is important to remove any burrs or debris from the surface of the bushing to ensure smooth operation.

Inspect the bushing: After cutting the grooves, the bushing should be inspected for any signs of damage or irregularities.

Cutting grease grooves in bushings can help to improve the distribution of lubricant, reduce friction and wear, and prolong the life of the bushing. It is important to ensure that the grooves are cut to the correct specifications for a specific application. Consulting with a bearing manufacturer or supplier can help to ensure that the grooves are cut to the correct specifications for a specific application.

Custom Bronze Parts Made Fast – Custom Parts Machined Fast, High-quality rapid custom prototyping and manufacturing services for product development. Bronze bushings with oil grooves!

Bronze is a commonly used material for making bushings due to its high strength, durability, and resistance to wear and corrosion. When it comes to groove bronze bushings, the most common material used is phosphor bronze.

Phosphor bronze is a type of bronze that is alloyed with phosphorus, which gives it several beneficial properties for use in bushings. Some of the advantages of using phosphor bronze for groove bushings include:

High strength: Phosphor bronze has a high tensile strength, which means it can withstand heavy loads and high stress without deforming or breaking.

Good wear resistance: Phosphor bronze has a low coefficient of friction, which means it resists wear and can help to prolong the life of the bushing.

Corrosion resistance: Phosphor bronze is resistant to corrosion, which means it can be used in harsh environments without deteriorating or rusting.

Machinability: Phosphor bronze is easy to machine, which means it can be customized to fit specific applications.

In addition to phosphor bronze, other types of bronze may also be used for groove bushings, such as aluminum bronze or manganese bronze. The choice of material depends on factors such as the application requirements, load, speed, and operating environment.

Oil grooves, Grooved Cast Bronze Bushings, Grooving

We can cutting grease grooves in bushings, bearing or related part to your specification. double figure eight, double loop, loop, circular, straight bushing.

Oil grooves, grooved cast bronze bushings, and grooving all refer to the same process of adding grooves to the surface of a bronze bushing to improve its lubrication and performance.

Oil grooves are small channels or depressions that are cut into the surface of the bushing in a specific pattern to help distribute lubricant evenly throughout the bearing surface. The grooves can be cut in a variety of patterns, such as spiral, helical, or circular, depending on the specific application requirements.

Grooved cast bronze bushings are manufactured with the grooves already incorporated into the design of the bushing. This means that the grooves are cast directly into the surface of the bushing during the manufacturing process, rather than being cut into the surface afterward.

Grooving is the process of cutting grooves into the surface of a bronze bushing using a lathe or other machining tool. This can be done to improve the lubrication of an existing bushing or to create a custom bushing with specific grooves to suit a particular application.

Adding grooves to a bronze bushing can help to improve the distribution of lubricant, reduce friction and wear, and prolong the life of the bushing. It is important to ensure that the grooves are cut to the correct depth, width, and spacing to achieve optimal lubrication and performance. Consulting with a bearing manufacturer or supplier can help to ensure that the grooves are cut to the correct specifications for a specific application.

Alternatives to bearings with lubrication groove

Bearings with lubrication grooves are designed to improve lubricant distribution within the bearing, which can help to reduce friction and wear, and increase bearing life. However, there are a few alternatives to bearings with lubrication grooves, depending on the specific application and performance requirements.

Here are some alternatives to bearings with lubrication grooves:

Sealed bearings: Sealed bearings are designed with built-in seals to keep contaminants out and retain lubricant within the bearing. This can help to reduce the need for additional lubrication, and may also help to prolong bearing life by preventing the ingress of dirt and moisture.

Dry bearings: Some types of bearings, such as self-lubricating or solid lubricant bearings, are designed to operate without additional lubrication. These bearings may be particularly useful in applications where traditional lubricants cannot be used, or where lubrication is difficult or impractical.

Lubrication systems: In some cases, it may be possible to improve lubricant distribution by using a lubrication system, such as a centralized lubrication system, to deliver lubricant directly to the bearing. This can help to ensure that the bearing is always properly lubricated, and may be particularly useful in high-speed or high-load applications.

Surface treatments: Surface treatments, such as plating or coatings, can help to reduce friction and wear in bearings. These treatments may also help to improve the distribution of lubricant within the bearing, without the need for lubrication grooves.

Alternative bearing materials: Some alternative bearing materials, such as ceramics, may be able to operate without lubrication or may require less lubrication than traditional bearing materials. These materials may also be able to operate at higher temperatures or in harsher environments than traditional bearings.

It is important to select the appropriate bearing solution for each application, based on factors such as load, speed, temperature, and environment. Consulting with a bearing manufacturer or supplier can help to ensure that the most suitable bearing is selected for a specific application.

American bronze bearing material code

The American bronze-bearing material code is a standardized system used to identify different types of bronze bearing materials based on their chemical composition. The code uses a letter-number system to represent the major elements present in the alloy, as well as the percentage of each element. The letter represents the major elements present in the alloy, while the numbers represent the percentage of each element.

The following are some examples of the American bronze-bearing material code and their respective composition:

- C93200: This is a type of bronze-bearing material that contains approximately 83% copper, 7% tin, and 7% lead.

- C95400: This is a type of bronze-bearing material that contains approximately 85% copper, 5% tin, and 5% aluminum.

- C95500: This is a type of bronze-bearing material that contains approximately 81% copper, 10% tin, and 5% aluminum.

- C83600: This is a type of bronze-bearing material that contains approximately 84% copper and 4% each of lead, tin, and zinc.

The American bronze-bearing material code is used to identify different types of bronze-bearing materials and is helpful for manufacturers and customers to ensure that they are using the correct material for a specific application.

Standard Bronze is a commonly used bearing material in the United States. It is a type of bronze alloy that is composed of copper, tin, and zinc. The exact composition of ASB can vary depending on the specific application and manufacturer, but typically it contains between 84% and 90% copper, 6% to 12% tin, and 2% to 4% zinc.

ASB is known for its high strength, wear resistance, and durability, which make it a popular choice for a wide range of bearing applications. Some of the key benefits of using ASB for bearings include:

High load capacity: bronze bearing has a high load capacity, which means it can withstand heavy loads and high stress without deforming or breaking.

Good wear resistance: bronze bearing has a low coefficient of friction, which means it resists wear and can help to prolong the life of the bearing.

Corrosion resistance: bronze bearing is resistant to corrosion, which means it can be used in harsh environments without deteriorating or rusting.

Machinability: bronze bearing is easy to machine, which means it can be customized to fit specific applications.

Bronze bushing is available in a variety of forms, including solid bars, tubes, and sheets. It can be used to manufacture a range of bearing types, including sleeve bearings, thrust bearings, and flange bearings. The specific application requirements, load, speed, and operating environment should be taken into consideration when selecting the appropriate bronze bearing material for a bearing application.

Are you looking for the bronze bearing with lubrication groove

Breathtaking design for home living.

Bronze bearings with lubrication grooves are available in a range of sizes and configurations to suit different applications. They can be used in a variety of industries, including automotive, aerospace, marine, and industrial equipment. If you are looking for a specific bronze bearing with a lubrication groove, contact us to help you find the right product for your needs.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.