Bearing vs Bushing: Understanding the Differences

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Bearing vs Bushing: Understanding the Differences

Bearing vs Bushing: Understanding the Differences

bearings and bushings are two distinct components that serve different purposes in machinery and equipment. Bearings are versatile components that can handle high loads and high speeds, making them a good choice for many applications. Bushings, on the other hand, are simple and cost-effective components that are best suited for low-load and low-speed applications. By understanding the differences between these two components and considering the specific needs of your application, you can choose the right component for optimal performance and longevity.

80%

Sales Growth

90+

Projects Delivered

custom bearing bushing

Solution

Whether you need a replacement or are starting a new project, we have the right fit for your needs.

professional

bearing bushing supplier

Get all the information you need about bronze flanged and plain bushings. Find out how they compare to other materials and why they may be the right choice for your application.

high quality bushing

Focus

Get a comprehensive guide to bronze bushings. Learn how they are made, their benefits, and how they compare to other types of bronze bushings.

sales

Growth

Browse our selection of high-quality bronze bushings for sale. Whether you need a replacement or are starting a new project, we have the right fit for your needs.

What is a Bearing?

A bearing is a precision component that is designed to support radial and/or axial loads and reduce friction between moving parts. It typically consists of an inner race, an outer race, rolling elements (such as balls or rollers), and a cage or retainer that holds the rolling elements in place. The rolling elements roll between the races, which reduces friction and enables smooth rotation or oscillation of the shaft.

Bearings come in various shapes, sizes, and materials to suit different applications and operating conditions. Some common types of bearings include ball bearings, roller bearings, needle bearings, and spherical bearings. Ball bearings are the most widely used type of bearing and are commonly found in machines such as motors, pumps, and conveyors.

Advantages & Disadvantages of Bearings

- Lower friction: Bearings are designed to reduce friction between moving parts, which can improve efficiency, reduce wear, and extend the life of the components.

- High speed capability: Bearings can operate at high speeds without overheating or wearing out prematurely.

- Precision: Bearings are typically manufactured to tight tolerances and can provide precise positioning and alignment of rotating or oscillating shafts.

- Easy to replace: Bearings can be easily replaced when they wear out or fail, which can save time and money compared to repairing or replacing the entire system.

Disadvantages of Bearings

- Cost: Bearings can be more expensive than bushings, especially if high precision or specialized types are required.

- Noise and vibration: Bearings can generate noise and vibration, especially at high speeds, which may be undesirable in some applications.

- Maintenance: Bearings require regular lubrication and maintenance to ensure proper operation and prevent premature failure.

- Limited load capacity: Bearings have a limited load capacity and may not be suitable for applications that require high load carrying capacity.

taxation planning

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

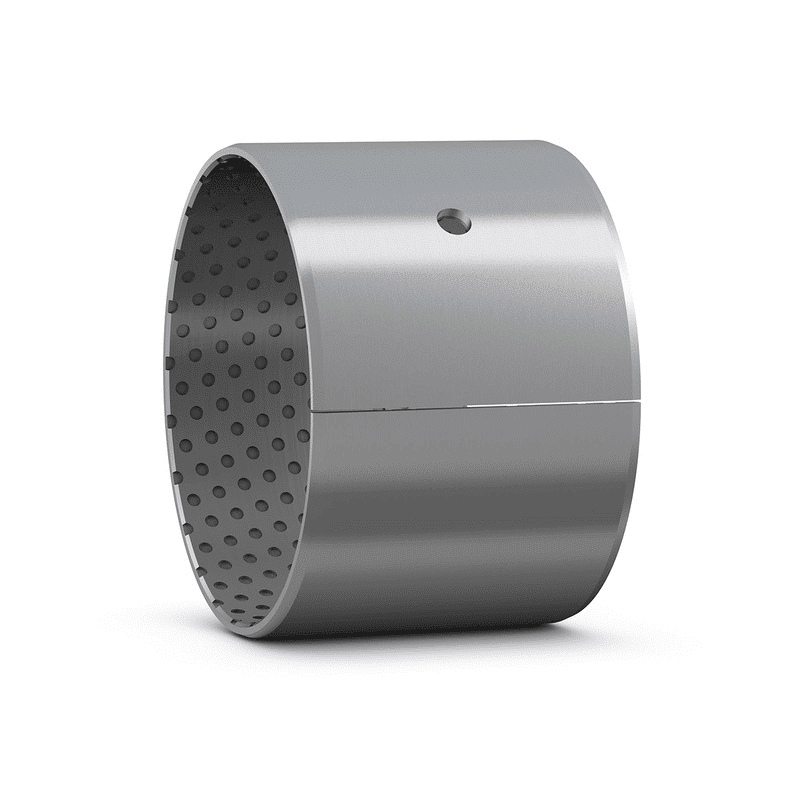

what is a bushing

A bushing, also known as a sleeve bearing or plain bearing, is a cylindrical component that is designed to support radial loads and reduce friction between moving parts. It typically consists of an inner and outer cylindrical surface, with a layer of lubricant (such as oil or grease) between them to reduce friction.

Bushings come in various materials, including bronze, brass, steel, and plastic, to suit different applications and operating conditions. They are commonly used in applications such as electric motors, automotive suspension systems, and hydraulic cylinders.

Advantages and Disadvantages of Bushings

- Cost-effective: Bushings are generally less expensive than bearings, especially for low-precision or low-load applications.

- Quiet operation: Bushings are typically quieter than bearings and can reduce noise and vibration in the system.

- Self-lubricating: Some types of bushings are self-lubricating and do not require external lubrication, which can simplify maintenance and reduce operating costs.

- High load capacity: Bushings can support higher loads than bearings, especially if they are made of strong and durable materials such as bronze or steel.

Disadvantages of Bushings

- Higher friction: Bushings typically have higher friction than bearings, which can reduce efficiency and cause more wear and tear on the components.

- Limited speed capability: Bushings may not be suitable for high-speed applications, as the friction and heat generated by the sliding motion can cause premature wear and failure.

- Difficult to replace: Bushings

Bearing vs Bushing: What’s the Difference and Which One Should You Use?

Custom bearing & bushing

If you’re involved in machinery or equipment manufacturing, you’ve likely come across the terms “bearing” and “bushing” at some point. While these two components may seem interchangeable, they actually have distinct differences that can affect the performance and longevity of your machinery. In this blog post, we’ll take a closer look at the differences between bearings and bushings, their respective advantages and disadvantages, and which one you should use in different scenarios.

Bearing Bushings Maintenance: Keep Your Equipment Running Smoothly

We manufacture bearing bushing tailored to your individual needs.

Discover all you need to know about bearing bushings, from its definition to its functions, types, and maintenance.

If you’re involved in machinery or equipment manufacturing, you’ve likely come across the terms “bearing” and “bushing” at some point. While these two components may seem interchangeable, they actually have distinct differences that can affect the performance and longevity of your machinery. In this blog post, we’ll take a closer look at the differences between bearings and bushings, their respective advantages and disadvantages, and which one you should use in different scenarios.

What is a Bearing?

A bearing is a machine element that reduces friction between moving parts, allowing for smooth and efficient motion. Bearings come in a variety of shapes and sizes, including ball bearings, roller bearings, and plain bearings. Ball bearings are the most common type of bearing and consist of a series of small metal balls held in a raceway. Roller bearings, on the other hand, use cylindrical rollers to reduce friction. Plain bearings, also known as sleeve bearings or journal bearings, have a simple design consisting of a cylindrical sleeve or bushing that rotates around a shaft.

What is a Bushing?

A bushing, also known as a sleeve bearing, is a cylindrical component that is used to reduce friction between two moving parts. Unlike bearings, bushings do not have rolling elements and instead rely on a sliding motion to reduce friction. Bushings are often made from materials such as bronze, brass, or plastic and are commonly used in applications such as hinges, pivots, and pulleys.

Advantages and Disadvantages of Bushings

One of the main advantages of bushings is their simplicity, which makes them easy to install and replace. Bushings are also less expensive than bearings, making them a cost-effective choice for many applications. However, bushings are typically less durable than bearings and can wear out more quickly. They also have a lower load capacity than bearings, which can limit their use in certain applications.

Bearing Bushing: Everything You Need to Know

Beautifully crafted leather products.

In addition to load capacity and speed, it’s also important to consider the environmental conditions that your machinery will be operating in. Bearings are typically better suited for high-temperature or high-vibration environments, while bushings are better suited for low-temperature or low-vibration environments.

bearings and bushings are two distinct components that serve different purposes in machinery and equipment. Bearings are versatile components that can handle high loads and high speeds, making them a good choice for many applications. Bushings, on the other hand, are simple and cost-effective components that are best suited for low-load and low-speed applications. By understanding the differences between these two components and considering the specific needs of your application, you can choose the right component for optimal performance and longevity.

Beautifully crafted leather products.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.