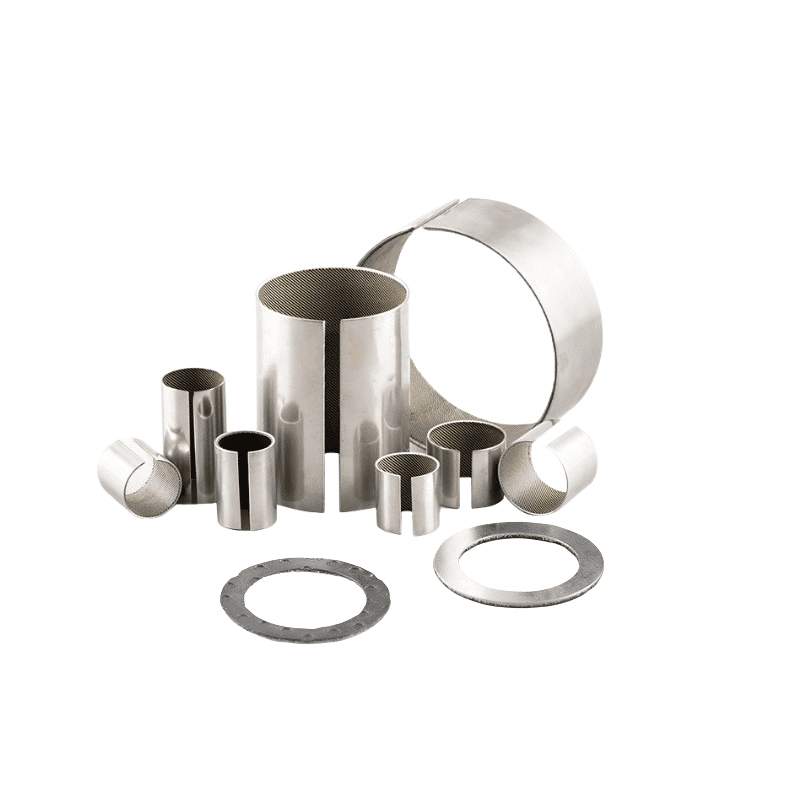

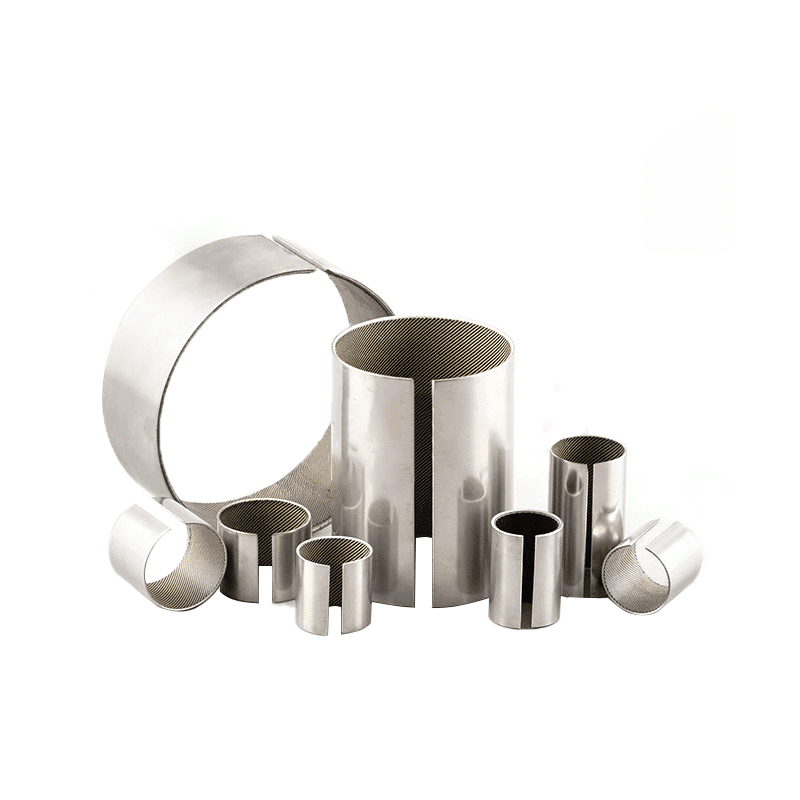

collar bush

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

collar bush

The Revolutionary Impact of Self-Lubricating Steel Bronze PTFE Bearings on Industry

The advent of self-lubricating bearings has revolutionized various industries due to their remarkable properties and efficient performance. Collar bush self-lubricating steel bronze PTFE bearings, in particular, have emerged as a game-changer in the world of bearings, offering superior functionality and durability. This article delves into the composition, benefits, and applications of these innovative bearings, underscoring their contribution to the ongoing industrial evolution.

Standard Bush bearings

Flange Bushes

As industries evolve and equipment designs become more complex, there is an increasing demand for specialized components that cater to specific requirements.

professional

Bearing Bush

Custom size self-lubricating collar bush slide bearings provide a tailored solution that addresses unique needs while maintaining the advantages of standard self-lubricating bearings.

Metal collar Bush Bearing

Focus

Custom bearings can be designed to accommodate a wide range of applications across various industries, making them a versatile solution for unique bearing needs.

Custom Size

Self-lubricating Bearing washer

Custom Size Self-Lubricating Collar Bush Slide Bearings: Meeting Unique Requirements with Precision and Efficiency

Collar bush Composition and Functionality

Reduced Downtime: Custom size self-lubricating collar bush slide bearings offer the same low-maintenance benefits as standard self-lubricating bearings, resulting in reduced downtime and maintenance costs. Collar bush self-lubricating steel bronze PTFE bearings are composite bearings made from three key components:

Self-Lubricating pTFE Collar Buh Enhanced Performance

By tailoring the bearing design to the specific requirements of the application, custom bearings can provide optimized performance in terms of load capacity, operating temperature, and other factors.

These three components work together to create a self-lubricating bearing that can withstand high loads and harsh operating conditions while requiring minimal maintenance.

Self-Lubricating PTFE Fabric TEX Collar Bush: A Reliable Solution for Challenging Applications. Self-lubricating PTFE fabric TEX collar bushes offer a unique combination of properties that make them ideal for a wide range of applications where durability, low friction, and high load capacity are required. These bearings incorporate a flange-like extension, or collar, which provides additional support and stability, making them suitable for applications that demand axial guidance or axial load support.

taxation planning

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

Benefits of Self-Lubricating Steel Bronze PTFE Bearings

- Maintenance-Free Operation: The self-lubricating properties of these bearings eliminate the need for constant lubrication, reducing maintenance costs and downtime.

- Extended Service Life: Due to their low friction coefficient and wear-resistant properties, these bearings have an extended service life compared to traditional bearings, which translates to reduced replacement costs and increased efficiency.

- Environmentally Friendly: The absence of external lubrication reduces the risk of environmental contamination caused by leaking lubricants. Furthermore, PTFE is a chemically inert material that does not react with other substances, further enhancing its eco-friendly nature.

- Versatility: Collar bush self-lubricating steel bronze PTFE bearings can be utilized in various applications across different industries, owing to their ability to perform under a wide range of temperatures, loads, and speeds.

- Resistance to Corrosion: The PTFE layer provides excellent corrosion resistance, making these bearings suitable for use in environments where corrosion is a concern.

PTFE Collar Bush: An Overview of Its Applications and Benefits

PTFE collar bushes consist of a collar that provides a flange-like extension at one end of the bearing. This collar offers additional support and stability, making it suitable for applications requiring axial guidance or axial load support. The bearing structure is a composite of a steel backing, a sintered bronze intermediate layer, and a PTFE sliding layer.

Perfect Fit: Custom bearings are designed to meet the exact dimensions and tolerances required by the customer, ensuring a seamless fit in their equipment or machinery.

polytetrafluoroethylene (PTFE), also known as Teflon, is a versatile material known for its low friction coefficient, excellent chemical resistance, and high-temperature stability. PTFE collar bushes are specialized self-lubricating bearings that incorporate these properties to deliver superior performance and reliability in various applications.

Collar bush self-lubricating steel bronze PTFE bearings have emerged as a revolutionary solution in the world of bearings.

Their unique composition, combined with their low

We Deliver Sleeve and Collar Bush At Your Address

Exploring the Options for Maintenance-Free Performance Collar Bush Bearing:

Dry bearings, also known as solid or self-lubricating bearings, are designed to operate without the need for external lubrication. These bearings offer maintenance-free performance, making them ideal for applications where lubrication is difficult or undesirable. Collar bush bearings with a flange-like extension provide additional support and stability, making them suitable for applications requiring axial guidance or axial load support. Various materials can be used to manufacture dry bearing collar bushes, each with its unique properties and advantages.

PTFE (Polytetrafluoroethylene) Composite

PTFE composites are among the most popular dry bearing collar bush materials. These composites consist of a steel backing, a sintered bronze intermediate layer, and a PTFE sliding layer. The PTFE layer offers excellent self-lubricating properties, low friction, and high chemical resistance. Some of the advantages of PTFE composite collar bushes include:

- Self-lubricating and maintenance-free

- High load capacity

- Wide operating temperature range

- Excellent corrosion resistance

- Metal-Polymer Composites

Metal-polymer composites are another common option for dry bearing collar bushes. These composites consist of a metal backing (usually steel or bronze) and a polymer sliding layer. The polymer layer may be impregnated with solid lubricants, such as graphite or MoS2, to enhance its self-lubricating properties. Advantages of metal-polymer composite collar bushes include:

- Good load capacity

- Low friction

- Suitable for a wide range of applications

- Maintenance-free operation

- Solid Lubricant-Embedded Metals

Solid lubricant-embedded metals, such as graphite-plugged bronze or leaded bronze, are also used for dry bearing collar bushes. In these materials, solid lubricants are embedded within the metal matrix, providing self-lubricating properties. Some advantages of solid lubricant-embedded metal collar bushes include:

- High load capacity

- Suitable for high-temperature applications

- Good wear resistance

- Maintenance-free operation

- High-Performance Plastics

High-performance plastics, such as UHMWPE (ultra-high-molecular-weight polyethylene), PEEK (polyether ether ketone), or nylon, can be used to manufacture dry bearing collar bushes. These materials offer inherent self-lubricating properties and have several advantages:

- Lightweight and corrosion-resistant

- Low friction and good wear resistance

- Suitable for a wide range of applications

- Maintenance-free operation

- Ceramic Materials

Ceramic materials, such as silicon nitride or zirconia, can be used for dry bearing collar bushes in specialized applications. These materials offer excellent wear resistance, high-temperature stability, and corrosion resistance. Advantages of ceramic collar bushes include:

- Suitable for high-temperature and corrosive environments

- Excellent wear resistance

- Low friction

- Maintenance-free operation

- Conclusion

When selecting a dry bearing collar bush material, it is essential to consider factors such as load capacity, operating temperature, wear resistance, and corrosion resistance. The choice of material will depend on the specific requirements of the application and the desired performance characteristics. By selecting the appropriate dry bearing collar bush material, maintenance-free performance and increased efficiency can be achieved in a wide range of industrial applications.

Self-lubricating Maintenance-Free bearing supplier

Benefits of PTFE Collar Bush Bearing:

Benefits of PTFE Collar Bushes

Self-Lubricating: The PTFE sliding layer ensures smooth, low-friction operation without the need for external lubrication. This reduces maintenance costs and downtime, and provides an extended service life.

High Load Capacity: PTFE collar bushes can support high radial and axial loads due to the robust steel backing and the unique composite structure.

Wide Operating Temperature Range: PTFE is capable of withstanding temperatures ranging from -328°F (-200°C) to 500°F (260°C), making these bushes suitable for use in various environments and applications.

Corrosion Resistance: The PTFE sliding layer offers excellent corrosion resistance, protecting the bearing from harsh chemicals or environments where corrosion may be a concern.

Versatility: PTFE collar bushes can be employed in various industries and applications due to their unique properties and performance characteristics.

Self-lubricating slide bearing supplier

Custom size self-lubricating Bearing and Collar Bush:

Custom size self-lubricating collar bush slide bearings can be used in a variety of industries and applications, including:

Aerospace: Tailored bearings can be designed for use in aircraft components, such as landing gear systems and flight control mechanisms, where precise dimensions and performance specifications are critical.

Medical Equipment: Custom bearings can be incorporated into medical devices and equipment, such as surgical robots and diagnostic machines, to ensure smooth operation and accurate performance.

Robotics and Automation: Precision bearings are essential in robotics and automation systems, where they provide smooth and efficient motion control.

Renewable Energy: Custom size self-lubricating collar bush slide bearings can be used in wind turbines and solar panel tracking systems, where they offer low maintenance requirements and increased reliability.

Custom size self-lubricating collar bush slide bearings offer a tailored solution to meet unique bearing requirements across various industries. By working closely with bearing manufacturers, customers can ensure that their custom bearings are designed and manufactured to meet their precise specifications and provide optimal performance in their specific applications. This collaboration leads to increased efficiency, reduced downtime, and enhanced performance in diverse industrial settings.

Self-lubricating flange bearing and collar bushes supplier

Self-Lubricating PTFE Fabric TEX Collar Bush: A Reliable Solution for Challenging Applications Collar Bush:

Composition and Functionality

Self-lubricating PTFE fabric TEX collar bushes consist of a composite structure that features:

Steel or Bronze Backing: A robust metal backing provides structural support and enhances the bearing’s overall strength.

PTFE Fabric Layer: A woven PTFE fabric is applied to the metal backing. The fabric is typically reinforced with high-strength fibers, such as glass, aramid, or carbon, to increase its load capacity and wear resistance. This PTFE fabric layer offers excellent self-lubricating properties and low friction.

Benefits of Self-Lubricating PTFE Fabric TEX Collar Bushes

Maintenance-Free Operation: The self-lubricating properties of PTFE fabric TEX collar bushes eliminate the need for external lubrication, reducing maintenance costs and downtime.

High Load Capacity: The reinforced PTFE fabric layer provides excellent load capacity, making these bearings suitable for heavy-duty applications.

Wide Operating Temperature Range: PTFE fabric TEX collar bushes can operate over a wide range of temperatures, making them suitable for various environments and applications.

Excellent Wear Resistance: The PTFE fabric layer, reinforced with high-strength fibers, offers outstanding wear resistance, resulting in extended service life and reduced replacement costs.

Chemical and Corrosion Resistance: The PTFE fabric layer is chemically inert and resistant to most chemicals, making these bearings suitable for use in corrosive environments or applications where chemical resistance is required.

Applications of Self-Lubricating PTFE Fabric TEX Collar Bushes

Due to their unique properties and superior performance, self-lubricating PTFE fabric TEX collar bushes are utilized across a wide range of industries and applications, including:

Automotive Industry: These bearings can be found in automotive components such as suspension systems, steering systems, and other parts where low friction, high load capacity, and resistance to harsh environments are crucial.

Construction and Heavy Machinery: PTFE fabric TEX collar bushes are used in construction equipment and heavy machinery, including excavators, loaders, and cranes, where they offer reduced maintenance requirements and increased reliability.

Food Processing Industry: The chemically inert and non-toxic properties of PTFE make these bearings suitable for use in food processing equipment, where hygiene and cleanliness are of utmost importance.

Marine and Offshore Industry: PTFE fabric TEX collar bushes are ideal for marine and offshore applications, as they offer excellent corrosion resistance and can withstand harsh operating conditions.

Pumps and Valves: The low-friction, self-lubricating properties of PTFE fabric TEX collar bushes make them an excellent choice for pump and valve applications, ensuring smooth operation and reduced wear.

Conclusion

Self-lubricating PTFE fabric TEX collar bushes offer a reliable and efficient bearing solution for a wide range of applications. Their unique composition and benefits, such as low friction, high load capacity, and excellent wear resistance, make them a valuable asset in various industries, contributing to increased productivity and reduced maintenance costs.

Self-lubricating flange bearing and collar bushes supplier

Customization Process Self-lubricating Bearing Collar Bush:

Customization Process

The process of creating custom size self-lubricating collar bush slide bearings typically involves the following steps:

Design Consultation: Customers work closely with bearing manufacturers to discuss their specific needs and requirements. This includes providing details on the operating environment, load capacity, temperature range, and desired dimensions for the custom collar bush bearings.

Engineering and Design: Bearing manufacturers analyze the customer’s requirements and develop a custom design that meets their specifications. This design incorporates the self-lubricating features and the collar bush structure for the best possible performance.

Manufacturing and Quality Control: The custom bearings are produced using advanced manufacturing techniques, such as CNC machining, to ensure precise dimensions and tolerances. Quality control processes, including dimensional inspections and performance tests, are implemented to guarantee that the custom bearings meet the desired specifications and quality standards.

Delivery and Installation: The custom size self-lubricating collar bush slide bearings are shipped to the customer, who then installs them in their equipment or machinery, ensuring a perfect fit and optimal performance.

Self-lubricating sleeve bearing manufacturer

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.