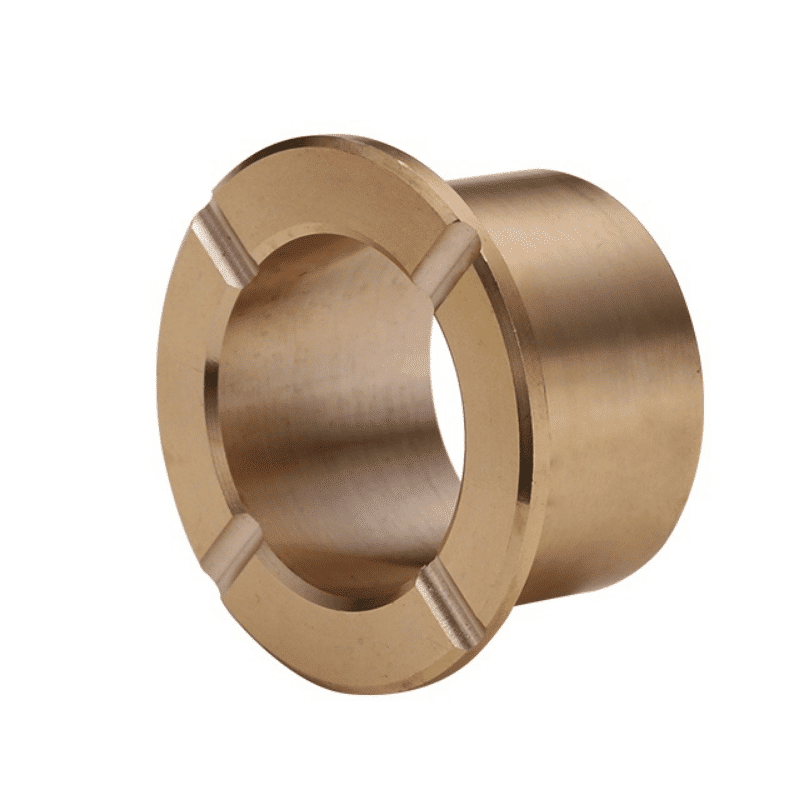

CuAl10Fe3 bronze bushing

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

CuAl10Fe3 bronze bushing

Finished Parts Custom Bronze Bushings, CuAl10Fe3

About Us

Finished Parts Custom Bronze Bushings ; Type: Flanged or Sleeve ; Material: Bronze Alloy ; Size: Customized ;

Metric Bronze Bushing- Inch Size Bushing

Real-life strategy to reach your goals.

CuAl10Fe3 C95500 bronze bushing with plugged graphite is a type of bearing material used in various applications, including machinery, automotive, and marine industries. It is a composite material that is made up of copper, aluminum, iron, and other elements, which make it highly resistant to wear and corrosion.

We strive for diversity across the globe

Advantages of the CuAl10Fe3 C95500 bronze bushing with plugged graphite

One of the key advantages of the CuAl10Fe3 C95500 bronze bushing with plugged graphite is its ability to operate without the need for external lubrication. This means that it can be used in environments where lubrication is difficult or impossible to maintain, reducing maintenance costs and increasing equipment uptime.

Another advantage of this material is its low coefficient of friction, which minimizes wear and tear on the equipment. This, in turn, reduces the need for frequent replacement of the bushings, saving time and money in the long run.

We manufactured bronze bushings, wear plates, and other bronze groove-bearing parts according to drawings, offering our services to clients worldwide.

CAST BRONZE FINISHED PARTS

C95400 Aluminum Bronze Bushing Bearing- Wholesale Supplier

Choose from our selection of bronze bushings in a wide range of materials and sizes. C95400 Alloy, C954 Aluminum Bronze – Metal Bronze Bushing Products

CuSn6Zn6Pb3 Bronze Bushing

Tin Bronze Bushing

CuSn5Zn5Pb5 Bronze Bushing

C83600 Bronze Bearings

CuSn5Zn5Pb5 Bronze Bearing

Standard Bronze Bushing Material

CuZn25Al6Fe3Mn3

CuZn25Al6Fe3Mn3 Cast Bronze Bushings , Brass Bushing Material

Bronze Bushings & Bearings: CuAl10Fe3 is a high-quality cast bronze material

CuAl10Fe3 can be easily machined and is readily available in various shapes and sizes, making it an excellent choice for manufacturing bushings and other bearing components. Its machinability also allows for the creation of custom designs that can be tailored to specific applications.

CuAl10Fe3 is a high-quality cast bronze material that offers excellent strength, wear resistance, and corrosion resistance. Its versatility and reliability make it an ideal choice for various industrial applications where high-load and slow-speed operations are required.

Our bronze bushings, bearings, and thrust washers in various sizes. These products satisfy most applications and may be resized, oil grooved, or plugged graphite!

CuAl10Fe3 C95500 bronze bushing with plugged graphite

Real-life strategy to reach your goals.

The CuAl10Fe3 C95500 bronze bushing with plugged graphite is a highly reliable and durable material that is ideal for use in heavy-duty equipment. Its exceptional wear resistance, self-lubricating properties, and ability to operate without external lubrication make it an ideal choice for high-load and low-speed applications. Its excellent thermal conductivity and low coefficient of friction also make it highly efficient and cost-effective. If you need a material that can withstand the toughest operating conditions, the CuAl10Fe3 C95500 bronze bushing with plugged graphite is an excellent choice.

Custom Parts: CuAl10Fe3 bronze bushing

correct design of the technology of the castings.

In addition to its mechanical properties, CuAl10Fe3 also offers excellent corrosion resistance, making it suitable for use in marine and other harsh environments. Its resistance to corrosion is due to the formation of a protective oxide layer on its surface, which prevents further oxidation and degradation of the material. specialist in the manufacture of bronze parts and self-lubricating bronze based on clients’ drawings. Machined products

CuAl10Fe3 Closest International Standards

| Region | Standard | Alloy |

|---|---|---|

| Europe | BS 1400 | AB1 |

| Europe | DIN 1714 | CuAl10Fe |

| Europe | NFA-53709 | CuAl10Fe3 |

| USA | ASTM B505 | C95200 |

| USA | ASTM B271 | C95200 |

| Australia | AS 1565 | C95210 |

| Japan | JIS H5121 | CAC701C |

| Japan | JIS H5120 | CAC701 |

| ISO | 1338 | CuAl10Fe3 |

CuAl10Fe3 Chemical Composition Chart

| Element | Composition (%) |

|---|---|

| Copper (Cu) | Balance (Typically around 76-79%) |

| Aluminium (Al) | 8.5 – 9.5% |

| Iron (Fe) | 2.0 – 4.0% |

| Nickel (Ni) | Up to 5% (Often around 4-5%) |

| Manganese (Mn) | Up to 1.5% |

| Other elements | May include small amounts of Zinc (Zn), Lead (Pb), Silicon (Si), etc., usually totaling less than 0.5% |

CuAl10Fe3 Mechanical Properties (Minimum Values)

| Property | Minimum Value |

|---|---|

| Tensile Strength | 550 MPa |

| Yield Strength (0.2% Offset) | 250 MPa |

| Elongation (5.65√A) | 13% |

| Brinell Hardness | 130-150 HB |

We generate results for our customers

Self-Lubrication Options for Bronze Bearings

Manufacture of Bronze CuAl10Fe3 and Self-lubricated Bushing

CuAl10Fe3 bronze bushing- correct design of the technology of the castings. – correct preparation of the manufacturing process technology: – a severe technological discipline; interoperability control. – methodical analysis of the defects of the castings to obtain high-quality castings. without casting defects (segregations, blows, recesses, micro-residues and porosities, formation mixture inclusions, slag inclusions, metal inclusions, etc.).

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.