Pom washer makes sealing easier

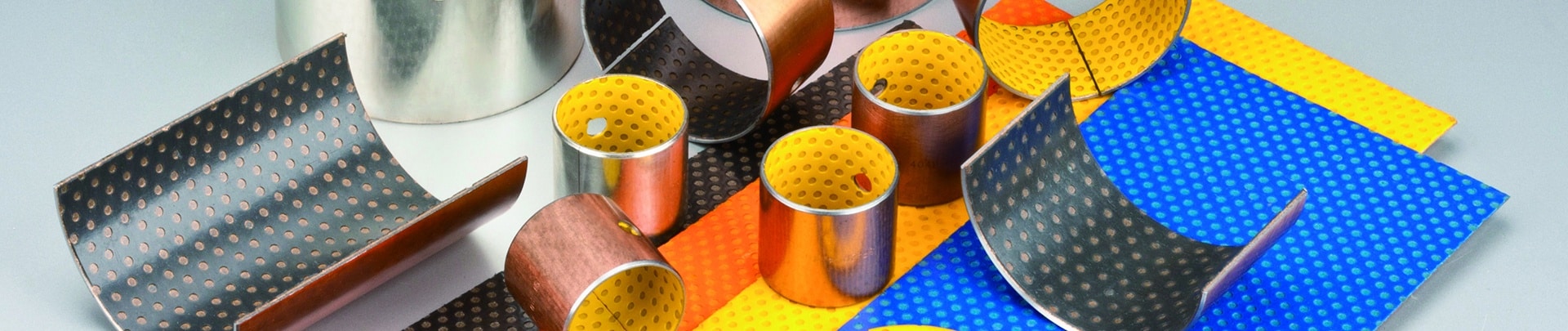

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Pom washer makes sealing easier

Pom washer makes sealing easier

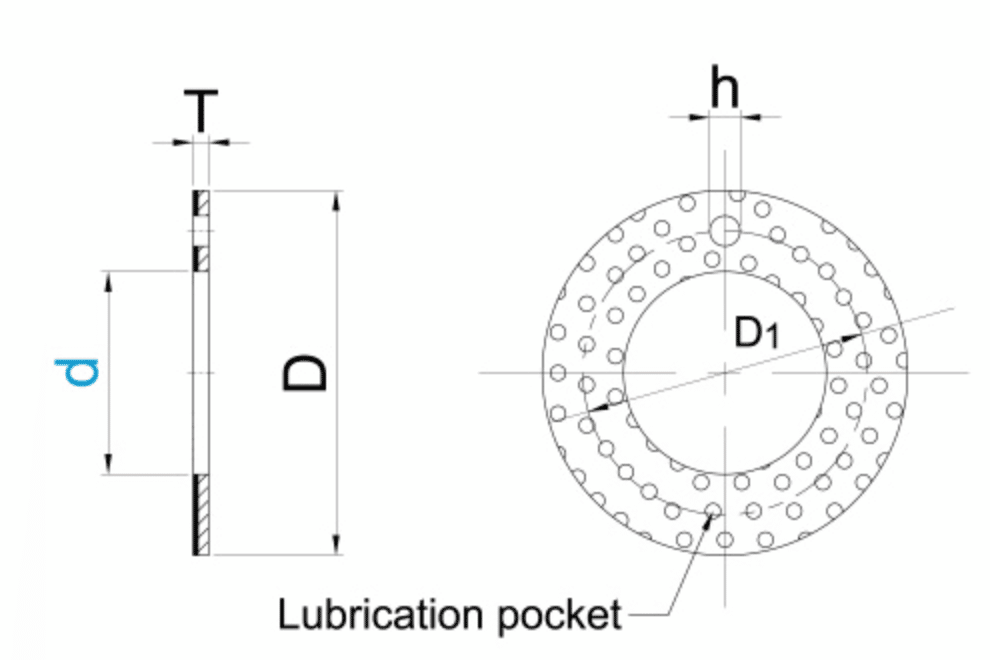

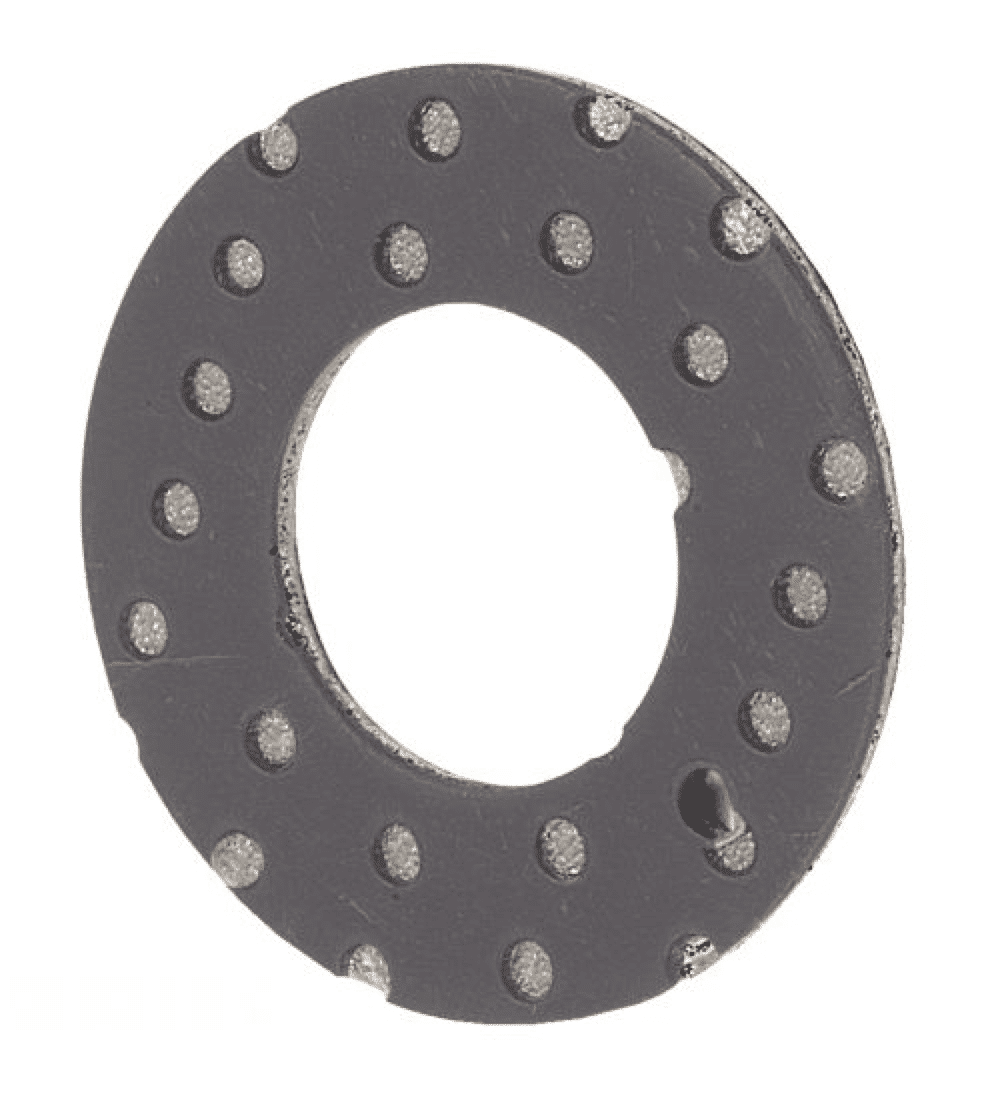

POM composite thrust washer

long-lasting, low-wear sliding

1. POM thickness 0.30 to 0.50 mm. It provides high wear resistance and low friction. Even if there is only a small amount of lubricant supplied, the bearing surface has a circular indentation pattern and the bearing assembly should be greased.

2. The thickness of sintered bronze powder is 0.20-0.35mm. A special powdered copper composition is heat fused to the steel backing. This contact layer acts as an anchor for the PTFE layer and performs heat accumulation away from the bearing surface.

3. Low carbon steel, the base of the bushing, steel back provides excellent stability, load bearing and heat dissipation characteristics.

Low-maintenance & maintenance-free bearings- Metal Polymer Composite Washer

Steel Back + Porous Bronze Sinter + POM with Lubrication Indents

POM based thrust washers is widely used in Vehicle chassis, forming machine tools, steel metallurgical machinery, mineral mountain machinery, hydraulic industry and rolling steel industry etc.

offers thrust washer components in custom and standard designs to meet your size, shape, and material requirements.

- Self-lubricating thrust washers coated with POM for lubrication or oil lubrication applications.

- Standard parts contain grease in the sliding layer, and the common

- Sliding layer must be supplied upon request.

- The best performance at high load and low speed.

- Suitable for straight, rotating and rotating movements.

- A wide variety, available for use on site.

Choose Plain Thrust Bearing Washer Pom Washers Makes Sealing Easier

Discover the future of TV with OLED technology

Choice – metal wound washer or metal toothed composite washer? Application Of Pom Washer In Hydrochloric Acid Plant!

Dry Lubricated Thrust WashersSound+

Dry lubricated thrust washers, specifically POM (Polyoxymethylene) washers, are extremely useful in various industries, including oil refineries and chemical plants. These are subjected to conditions involving thermal cycles, pressure changes, flange deflection, stress relaxation, and creep.

Flat WashersMode

These flat washers are available in both inch and metric sizes, making them versatile for various applications. They are ideal for use in systems where maintenance is difficult and where oil or grease lubrication is not ideal, hence the term “dry lubricated.” These types of bearings are also known for their excellent performance under high load and slow speed conditions.

Marginal lubricating washers

POM (Polyoxymethylene) Thrust Washers are part of a larger suite of Metal-Polymer maintenance-free bearing solutions. These washers are specifically engineered to reduce friction and wear in various applications, thus promoting longevity and reliability in the machinery where they’re used.

Available in both metric and imperial sizes, POM Thrust Washers cater to a wide range of industrial requirements across the globe. They are known for their durability, high resistance to wear and tear, and excellent load-bearing capabilities.

Metal-polymer composite materials, like POM, offer significant advantages in the engineering field due to their unique properties. They combine the high strength, elasticity, and durability of metal with the low friction characteristics of polymer materials. This blend of properties makes them ideal for applications in various industries, including automotive, aerospace, manufacturing, and more.

In short, if you need a high-performance, maintenance-free solution for reducing friction and improving the longevity of your machinery, POM Thrust Washers are a reliable option. They are built to withstand different environmental conditions and loads, ensuring their suitability for a wide range of applications. Always make sure to select the appropriate size (either metric or imperial) based on the specific requirements of your machinery or application.

Marginal lubricating washers are an essential component used in many industries, including in the production of silane and silicone products. In this specific case, the company in question produces a variety of silicone products across several production bases in China. Due to their extensive product lines and strict sealing requirements, the company required a sealing solution that offered superior comprehensive performance.

Challenges:

The company faced specific challenges in their hydrochloric acid unit. They used stainless steel flanges lined with PTFE (Polytetrafluoroethylene) due to the medium’s unique properties. Hydrogen chloride, when condensed, forms hydrochloric acid, which is highly corrosive. The typical sealing solution, rubber, can’t effectively seal in such conditions. Soft tetrafluoro doesn’t offer the necessary resilience and is not a suitable choice for long-term usage. Another challenge arose in sealing an FRP (Fibre-reinforced plastic) flange, which consistently leaked at high temperatures when used with rubber washers. The company needed a product that could address the sealing issues in both these scenarios.

Operating conditions:

Condition 1:

- Flange: Stainless steel lined with PTFE

- Temperature: 5°C

- Pressure: 6 bar

- Medium: Hydrogen chloride gas

- Dimensions: 2″ and 4″, conforming to ASME B16.21, Class 150, RF

Condition 2:

- Equipment: FRP flange

- Temperature: 80°C to 100°C

- Pressure: 6 bar – 8 bar

- Medium: 3% acidic wastewater

Solution:

To meet these demanding requirements, Viiplus recommended the POM Washer. This washer features a unique hexagonal surface projection that allows for a reliable, low-load seal as long as the compressive stress reaches 5MPa. The washer is made from PTFE with aluminum silicate microbeads, which can resist medium concentrations of acids, alkalis, solvents, low-temperature substances, and other chemicals. This material composition makes it highly suitable for the variety of different media required by the company.

After implementation, the POM Washers successfully resolved the sealing issues in both devices, with no leakage observed. The customer was satisfied with the products and the results they delivered, acknowledging their superior performance and compatibility with their demanding operating conditions.

POM (Polyoxymethylene) Thrust Washers

lubricating bushing

POM (Polyoxymethylene) Thrust Washers are part of a range of Metal-Polymer maintenance-free bearing solutions available in both metric and imperial sizes. These products, including composite bushings, strips, and thrust washers, are manufactured from PTFE (Polytetrafluoroethylene) and POM composite materials.

Thrust washers, specifically, are used where axial (along the axis) location is essential. They are typically utilized in conjunction with POM bushes to ensure stability, even when the axial loads are minimal.

POM washers are offered in three colors – black, yellow, and blue. Each color signifies a different filler material used in the washer, and as a result, the conditions in which they are applicable vary.

-

Black might signify the standard POM material which is known for its high stiffness, low friction, and excellent dimensional stability.

-

Yellow and Blue could represent modified versions of POM with additives that enhance certain properties such as heat resistance, improved friction characteristics, or increased chemical resistance.

Customers are able to choose the color based on the specific needs of their application.

POM Washers are known for their low-load and low-leak characteristics, making them suitable for a wide range of applications. This versatility allows them to be used in various industries, simplifying the process of sealing and making it more efficient.

Remember to consult with an engineering or material expert to understand the specific properties of each color variant and ensure you’re choosing the correct washer for your application.

Metal Polymer Composite Washer Size

Self-lubricating bearings like POM Thrust Washers offer several key advantages:

-

Reduced Maintenance: As the name suggests, self-lubricating bearings require less maintenance compared to other types of bearings. This is because they automatically provide their own lubrication, reducing the need for frequent manual lubrication.

-

Improved Performance: By continuously providing their own lubrication, these bearings help maintain optimal performance levels of the machinery they’re used in. They help reduce friction and wear, thereby prolonging the lifespan of the machinery.

-

Versatility: POM Thrust Washers, in particular, are available in a variety of sizes, both metric and imperial, making them suitable for a wide range of applications.

-

Durability: POM is a highly durable material that is resistant to wear and tear, making these bearings highly durable.

In conclusion, POM Thrust Washers are a type of self-lubricating bearing that offers reduced maintenance, improved performance, versatility, and durability. They are used in a variety of applications, ranging from automotive to manufacturing, where they provide essential friction reduction and load handling.

If you’re looking to purchase POM (Polyoxymethylene) Washers directly from factories in China, www.bronzelube.com is your go-to source. They offer a wide range of washer solutions, and you can request a quote for your specific requirements directly on their website.

Remember, when purchasing these components, consider factors like the nature of your project, the expected load, the working conditions, and any specific characteristics of the washers you need. This will help ensure you get the most suitable product for your application. To request a quote, follow these steps:

- Go to www.bronzelube.com

- Navigate to the specific product category you’re interested in.

- Select the type of POM Washer that suits your needs.

- Click on the “Request a Quote” button and fill in your details, including contact information and specific requirements.

- Submit the form, and a representative from the company will get back to you with a quote.

With direct factory sourcing, you have the opportunity to get high-quality products at potentially lower prices due to the absence of a middleman. Plus, with direct communication with the manufacturer, you can ensure your specific needs are met, whether you need standard sizes or custom solutions.

Always remember to verify the authenticity of the supplier and to review their quality certifications to ensure you’re getting a product that meets industry standards and safety regulations.

| Order Code | D | D1 | T | h | |

| Code | d | ||||

| WASHER | 10 | 20 | 15 | 1.5 | 1.5 |

| 12 | 24 | 18 | |||

| 14 | 26 | 20 | 2 | ||

| 16 | 30 | 23 | |||

| 18 | 32 | 25 | |||

| 20 | 36 | 28 | 3 | ||

| 22 | 38 | 30 | |||

| 24 | 42 | 33 | |||

| 26 | 44 | 35 | |||

| 28 | 48 | 38 | 4 | ||

| 32 | 54 | 43 | |||

| 38 | 62 | 50 | |||

| 42 | 66 | 54 | |||

| 48 | 74 | 61 | 2 | ||

| 52 | 78 | 65 | |||

| 62 | 90 | 76 |

POM (Polyoxymethylene) Washers

POM (Polyoxymethylene) Washers represent the next generation of metal-polymer composite washers, integrating advanced material engineering and innovative design concepts. The use of a protruded surface structure improves the washer’s friction properties, ensuring optimal sealing and reducing wear.

POM washers rely on the excellent properties associated with colors black, yellow, and blue. While the specific properties associated with these colors may vary, it’s common for colors to denote different composite materials or coatings that provide unique benefits. For example, black may signify a standard POM coating, while yellow and blue may represent modified POM materials with added durability, heat resistance, or other qualities.

These washers are designed to meet the needs of the fluid sealing industry, providing practical and reliable solutions for a wide range of applications. Whether it’s used in high-pressure pumps, industrial machinery, or hydraulic systems, a POM washer can provide superior sealing and longevity, reducing maintenance needs and improving overall system performance.

In the future, real-world cases of POM washers used in different industries and working conditions will be shared. These case studies will help potential users understand how POM washers can be implemented in various contexts and how they can address unique challenges in the field. By continuously innovating and responding to the needs of different industries, POM washers can remain a cutting-edge solution in the fluid sealing industry.

Metal-Polymer Maintenance-free Bearing Solutions Pom Thrust Washer Metric and Imperial Sizes

POM (Polyoxymethylene) Thrust Washers are a type of self-lubricating bearing. These specialized components are designed to handle axial loads and reduce friction in a variety of mechanical applications.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.