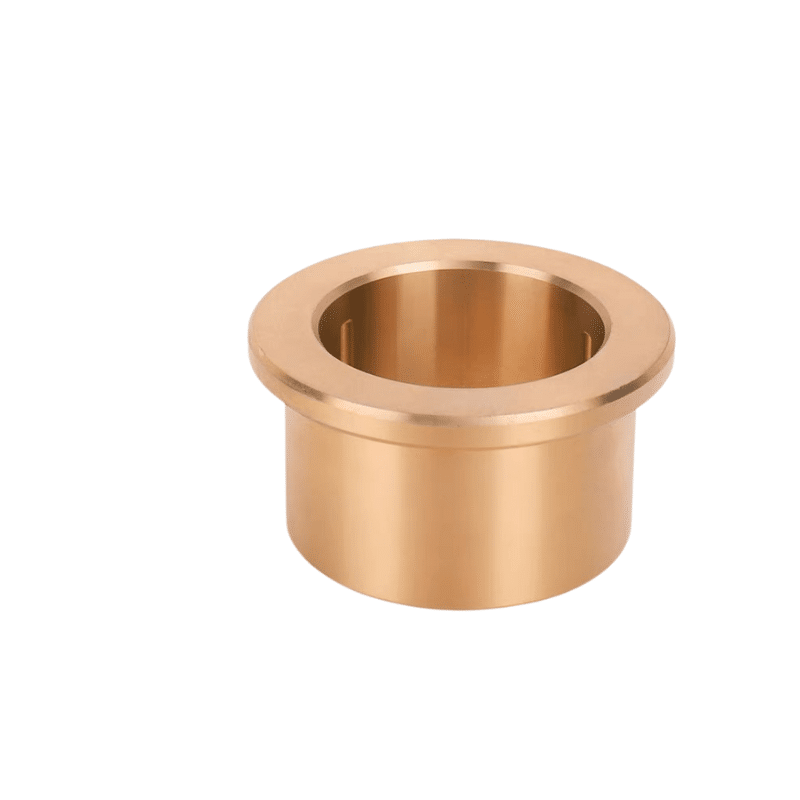

C93700 Bronze Bearing

C93700 Bronze Bearing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

C93700 Bronze Bearing

C93700 Alloy, C937 High-Leaded Tin Bronze Bushes

The C93700 Alloy, also known as C937 High-Leaded Tin Bronze or C93700 High-Leaded Tin Bronze Alloy, is exceptionally well-suited for bearing uses in situations where the lubrication boundary might be compromised.

The Solid Bronze Bearing C93700, known by various names such as CuPb10Sn, CuSn10Pb10, CC495K, LB2, G-SnPbBz10, and G-CuPb10Sn, is a type of bronze bushing. It is made from C93700 High Leaded Tin Bronze, a material provided by SINOBRONZE. C93700 is the specific alloy used in this product.

C93700 bronze bearing, also known as SAE 64 bearing bronze, is a high-leaded tin bronze alloy used for various bearing applications.

Centrifugal Cast Bronze Bearing

The C93700 bronze bearing, often referred to as High-Leaded Tin Bronze or 80-10-10 Bronze, is a popular bronze alloy used in the manufacturing of bearings. This alloy stands out for its superior machinability, effective anti-friction characteristics, and decent resistance to corrosion from seawater and brine. Composed of 78.00% to 82.00% copper, 8.00% to 11.00% lead, and 9.00% to 11.00% tin, the C93700 alloy contains a lead percentage ranging from 7% to 30%. The lead serves as a lubricant, enhancing the alloy’s machinability and anti-friction properties.

C93700 bronze bearings are particularly suitable for scenarios where lubrication might be lost. They excel in environments contaminated with dirt and other foreign substances. Thanks to the high lead content, the alloy can mold around foreign particles, thereby safeguarding the wear surface of mating components, like shafts.

These bearings are noted for their exceptional wear resistance, especially in conditions involving high speed, significant pressure, and vibration. They exhibit low friction and are useful in situations with inadequate lubrication or minor misalignments.

C93700 bronze is versatile, finding applications in bearing plates, bearings, bushings for high-speed and high-pressure situations, corrosion-resistant castings, crankshafts, high-speed/heavy-load bearings, impellers, machine parts, maintenance parts for steel mills, pressure-tight castings, pumps, slide guides for steel mills, and large bearings for ships.

However, it is important to mention that C93200 SAE 660 Bearing Bronze is often chosen as an alternative to C93700. This is due to its improved mechanical properties, lower cost, and shorter production lead times.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally