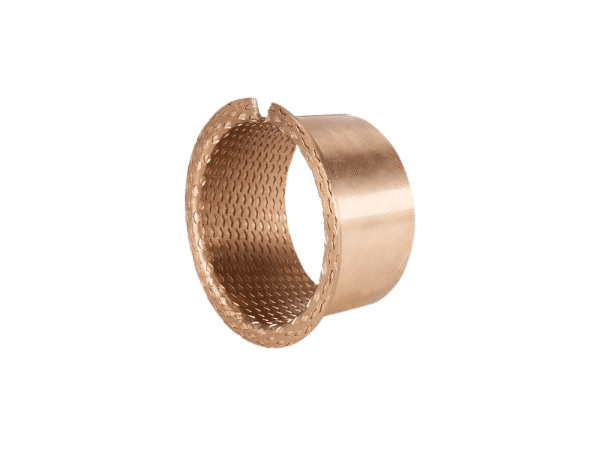

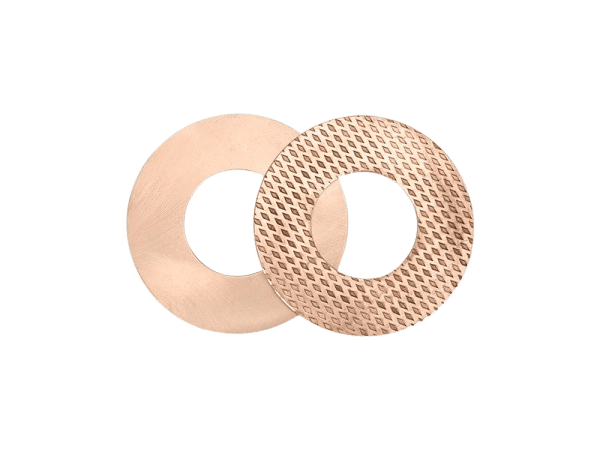

Homogeneous Bronze Bushes and Washers

Homogeneous Bronze Bushes and Washers

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

Homogeneous Bronze Bushes and Washers

Flange Bronze Bush with Through Hole, CuSn8 Bronze, similar BK-090, BRM10, COB-090, MBZ-B09, PRM, PRMF, SERIE SBA, SERIE SBB, WB700, WF-WB 700

Material – Characteristics, Cu – 91.3% Sn – 8.5% P – 0.2% CuSn8. DIN 17662. CW453K

These flanged bronze bushes are crafted from solid CuSn8 tin bronze and feature lubrication holes that act as reservoirs for the lubricant. The presence of hole depots allows for the storage of larger quantities of lubricant, thereby extending the intervals between maintenance. It’s important to note that these Wrapped flanged bushings are specifically designed for use with grease lubrication only.

For Wrapped Bronze Bushes, feel free to request a complimentary quote.

The Essentials of Homogeneous Bronze Bushes and Washers: Delving into Cu 91.3%, Sn 8.5%, P 0.2%

WB702, WB700,WB800,WB802, CuSn8 Bronze Bushing

In the realm of mechanical components, the selection of materials plays a pivotal role in determining performance, longevity, and efficiency. Homogeneous bronze, particularly the alloy comprising Cu 91.3%, Sn 8.5%, and P 0.2%, is a prominent choice for manufacturing bushes and washers. This blog post aims to provide a comprehensive technical overview of this specific bronze alloy, highlighting its properties, applications, and benefits.

Composition and Characteristics

The homogeneous bronze alloy in discussion has a composition of 91.3% copper (Cu), 8.5% tin (Sn), and 0.2% phosphorus (P). This combination offers a balance of mechanical properties and corrosion resistance, making it suitable for various applications.

Technical Data of Cu 91.3%, Sn 8.5%, P 0.2% Alloy

- Density: Approximately 8.8 g/cm³, contributing to its substantial weight and strength.

- Tensile Strength: Ranges between 200 to 250 MPa, making it strong enough to withstand significant mechanical stress.

- Yield Strength: Approximately 90 to 120 MPa, indicating the stress at which it begins to deform permanently.

- Elongation: Around 15%, showing its ability to undergo plastic deformation before fracturing.

- Hardness: Typically around 60 to 70 Brinell, denoting a good level of resistance to wear and indentation.

- Corrosion Resistance: Excellent resistance to corrosion, particularly in marine and acidic environments.

- Thermal Conductivity: Good thermal conductivity, making it suitable for applications involving heat transfer.

Applications of Homogeneous Bronze Bushes and Washers

- Marine Industry: Ideal for components exposed to seawater, such as in ships and docks.

- Automotive Sector: Used in bearings, washers, and components where wear resistance is critical.

- General Engineering: For machinery and equipment requiring robust and durable components.

- Electrical Applications: Utilized in connectors and switches due to its good conductivity.

Homogeneous bronze is a type of bronze alloy characterized by a uniform composition throughout the material. The term “homogeneous” refers to the consistency in the distribution of the constituent elements within the alloy, providing uniform properties across the entire piece of metal. This uniformity is crucial for applications where consistent strength, wear resistance, and corrosion resistance are needed across the entire component.

Composition:

- Copper (Cu): The primary component, copper gives bronze its fundamental characteristics such as ductility and conductivity.

- Tin (Sn): The addition of tin improves the alloy’s strength and wear resistance. The tin content typically ranges from a few percent up to around 12% in some alloys.

- Other Elements: Depending on the specific requirements of the bronze, other elements like phosphorus (P), aluminum (Al), or nickel (Ni) may be added. For example, phosphorus is often added to increase wear resistance and improve machinability.

Properties:

- Strength and Hardness: Homogeneous bronze is stronger and harder than pure copper.

- Corrosion Resistance: It has good resistance to corrosion, particularly in marine environments.

- Wear Resistance: The alloy is known for its excellent wear resistance, which is important for components like bearings and gears.

- Conductivity: While not as conductive as pure copper, it still has good thermal and electrical conductivity.

Applications:

Homogeneous bronze is used in a variety of applications where its strength, corrosion resistance, and wear resistance are beneficial. Common uses include:

- Bearings and Bushings: Due to its low friction and wear resistance.

- Gears and Components: In machinery for its strength and durability.

- Marine Hardware: Its corrosion resistance makes it suitable for marine applications.

- Sculpture and Artwork: For its aesthetic appeal and workability.

In summary, homogeneous bronze is a versatile and reliable alloy, widely used across various industries for its balanced mechanical properties and durability.

Homogeneous Bronze Bushes and Washers: An Essential Component for Mechanical Systems

Homogeneous bronze, a solid and reliable material, is widely used in the manufacturing of bushes and washers. This material, known for its excellent mechanical properties and resistance to wear and corrosion, is particularly favored in applications where durability and longevity are paramount. In this article, we delve into the specifics of homogeneous bronze bushes and washers, focusing on their composition, properties, and applications.

Composition of Homogeneous Bronze

Typically, homogeneous bronze used for bushes and washers contains a blend of copper (Cu), tin (Sn), and phosphorus (P). A common composition is Cu 91.3%, Sn 8.5%, and P 0.2%. This blend offers an ideal balance of mechanical properties, making it suitable for a wide range of applications.

Properties of Homogeneous Bronze (Cu 91.3%, Sn 8.5%, P 0.2%)

- Strength and Durability: This alloy is known for its excellent strength and durability, making it ideal for high-stress applications.

- Corrosion Resistance: The presence of phosphorus in the alloy enhances its corrosion resistance, especially in marine environments.

- Wear Resistance: The tin content in the alloy provides exceptional wear resistance, prolonging the life of the components.

- Machinability: Despite its strength, this bronze alloy is relatively easy to machine, allowing for precision in manufacturing.

Applications of Homogeneous Bronze Bushes and Washers

- Industrial Machinery: In heavy machinery, these components are used for their strength and ability to withstand high loads.

- Marine Equipment: Their corrosion resistance makes them suitable for use in ships and underwater equipment.

- Automotive Industry: Used in various car parts for their durability and resistance to wear.

- Aerospace: In aircraft, these components are valued for their strength-to-weight ratio and reliability.

Manufacturing and Customization

The manufacturing of homogeneous bronze bushes and washers involves several key steps:

- Casting or Forging: The bronze alloy is either cast or forged into the desired shape.

- Machining: Precision machining ensures that the bushes and washers meet the exact specifications required.

- Heat Treatment: This process can be used to enhance certain properties of the bronze, such as its hardness or ductility.

- Finishing: Surface treatments may be applied to improve wear resistance or to meet specific application needs.

Conclusion

Homogeneous bronze bushes and washers, with their combination of strength, durability, and resistance to wear and corrosion, are indispensable in many mechanical systems. Whether used in industrial machines, automotive components, marine equipment, or aerospace technology, these bronze components ensure reliability and efficiency in operation. Their customizable nature also makes them a versatile choice for a wide range of applications.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally