textile machinery bearing

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

textile machinery bearing

Durable self-lubricating bearings for textile machines.

Durable self-lubricating bearings, such as wall-wrapped bearings, are ideal for use in textile machines as they offer several advantages over traditional lubricated bearings. These bearings are designed to provide long-lasting performance and reduce maintenance requirements by eliminating the need for frequent lubrication. Wall-wrapped bearings are a type of self-lubricating bearing that features a layer of solid lubricant wrapped around the bearing surface. As the bearing rotates, the lubricant is gradually released, providing continuous lubrication and reducing friction and wear.

In textile machines, wall-wrapped bearings are particularly useful in applications where frequent lubrication is difficult or impossible. They are durable and resistant to wear, making them ideal for use in high-speed and high-load applications.

Some common applications for wall-wrapped bearings in textile machines include spinning frames, weaving machines, and knitting machines. They are also used in other types of machinery, such as conveyor systems, printing presses, and packaging machines.

Overall, wall-wrapped bearings offer a reliable and efficient solution for textile machinery applications, providing long service life, low maintenance requirements, and excellent performance in harsh operating conditions. Whether you are designing a new machine or looking for replacement parts for existing equipment, wall-wrapped bearings can help to improve the efficiency and reliability of your textile machinery.

Bearing for Textile Manufacturing Applications

Bearings for textile machinery have excellent performance and have been adopted by textile machinery manufacturers around the world.

A solution for self-lubrication of textile machinery

Textile machinery bearings are specialized bearings designed for use in textile manufacturing equipment. These bearings must be able to withstand high speeds and high temperatures, while also providing reliable performance and long service life.

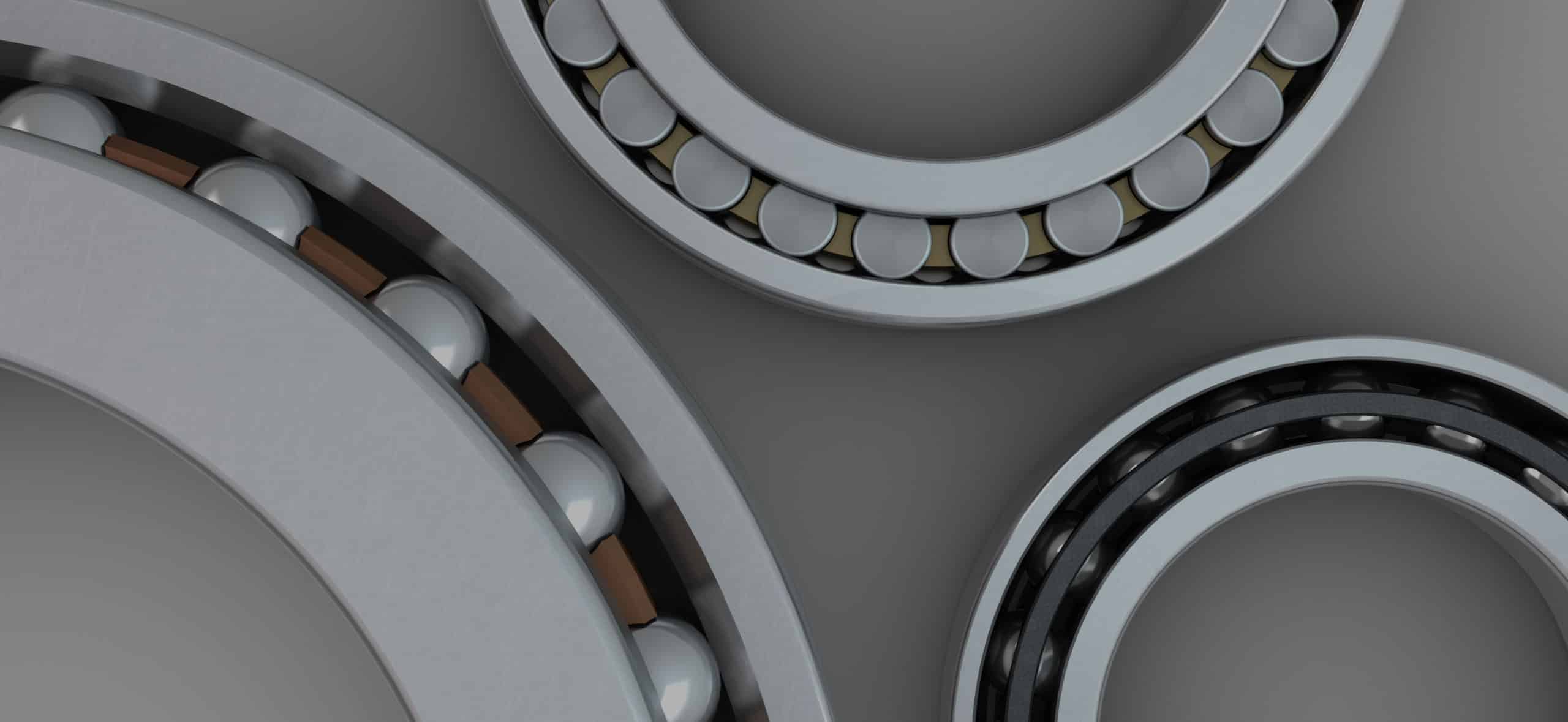

Common types of textile machinery bearings include deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, and needle roller bearings. These bearings may be used in a range of textile machinery applications, including spinning, weaving, knitting, and finishing processes.

To ensure optimal performance and long service life, it is important to choose the right type of bearing for the specific application and operating conditions. Proper lubrication and maintenance are also key factors in extending the life of textile machinery bearings.

Textile Bearing at Best Price in China

Self-lubrication is a great solution for textile machinery, as it eliminates the need for additional lubrication and reduces maintenance requirements. Self-lubricating bearings are designed to provide long-lasting performance and reduce friction, noise, and vibration.

Textile bearings are an essential component of textile machinery, and they must be able to withstand heavy loads, high speeds, and harsh operating conditions. In China, there are many reliable and high-quality textile bearing manufacturers that offer a wide range of products at competitive prices.

These bearings are engineered to deliver low noise, long service life, and excellent sealing performance. They are designed to withstand heavy loads and high speeds, while also reducing friction and minimizing downtime. Whether you are looking for deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, or needle roller bearings, there are many quality machinery bearing suppliers in China that can meet your needs.

If you are looking for a reliable and affordable supplier of textile bearings in China, be sure to do your research and choose a reputable manufacturer that can provide high-quality products and excellent customer service.

Quality Machinery Bearings Supplier & Manufacture in China, Contact Now!

We Manufacture Parts For Textile Machinery!

Types of bearings used in textile machinery

There are several types of bearings used in textile machinery to meet the diverse needs of different applications. Some common types of textile machinery bearings include:

- Deep groove ball bearings: These bearings are commonly used in textile machinery due to their high load capacity and suitability for high-speed rotation. They are non-separable bearings with deep grooves in their inner and outer races that can bear radial and combined loads.

- Angular contact ball bearings: These bearings can accommodate both radial and axial loads, making them suitable for applications that require high precision and accuracy. They are commonly used in textile machinery such as spinning frames and knitting machines.

- Cylindrical roller bearings: These bearings are designed to withstand heavy radial loads and are commonly used in textile machinery applications such as spinning frames and winding machines.

- Needle roller bearings: These bearings have a high load capacity and are suitable for applications that require high-speed rotation and a compact design. They are commonly used in textile machinery such as embroidery machines and knitting machines.

In addition to these types, there are other specialized bearings used in textile machinery such as thrust bearings, spherical roller bearings, and tapered roller bearings. The specific type of bearing used in a textile machine depends on the application and operating conditions.

As a manufacturer of parts for textile machinery, we understand the critical importance of bearings in ensuring optimal performance and reliability. Bearings are among the most vital components in most machines, and their load capacity and durability are crucial for the smooth and efficient operation of textile machinery.

Rolling bearings have become an indispensable part of textile machinery due to their high load capacity, reliability, and long service life. We specialize in manufacturing a wide range of bearings for textile machinery, including deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, and needle roller bearings.

Our bearings are designed to withstand heavy loads, high speeds, and harsh operating conditions, and they are engineered to deliver optimal performance and reliability. We use only high-quality materials and advanced manufacturing techniques to ensure that our bearings meet the most stringent quality standards.

If you are looking for a reliable and experienced manufacturer of parts for textile machinery, we are here to help. We have a team of experts who can work with you to design and manufacture custom bearings to meet your specific needs and requirements. Contact us today to learn more about our products and services.

Textile Machinery Parts and Service High Quality Textile Machine Part with Competitive Price – Texile Machinery Bushing Online Sales

A large range of bearing bushing products to meet your needs

We offer a large range of products to meet your bearing needs, including deep groove ball bearings such as the 6000, 6200, and 6300 series. These bearings are versatile and widely used in a variety of industries, including construction machinery, machine tools, automobiles, metallurgy, mining, petroleum, machinery, electricity, and railways.

Deep groove ball bearings are easy to install and do not require special sealing, making them a popular choice for a wide range of applications. They are non-separable bearings with deep grooves in their inner and outer races that can bear radial and combined loads, making them suitable for high-speed rotation.

Our deep groove ball bearings feature high-quality materials and advanced manufacturing techniques to ensure reliable performance and long service life. We offer a range of sizes and configurations to meet the specific needs of our customers.

Whether you are looking for deep groove ball bearings for a new application or replacement parts for existing equipment, we have the products and expertise to help you find the right solution for your needs. Contact us today to learn more about our deep groove ball bearings and other products.

Self-lubricating bearing for textile machinery

Self-lubricating bearings are becoming increasingly popular in textile machinery due to their ability to reduce maintenance requirements and eliminate the need for additional lubrication. These bearings are designed to provide reliable and efficient performance in harsh operating conditions, and they can offer several advantages over traditional lubricated bearings.

Self-lubricating bearings use a solid lubricant such as graphite, PTFE, or molybdenum disulfide, which is embedded in the bearing material or coating. The lubricant is released gradually as the bearing rotates, providing continuous lubrication and reducing friction and wear.

In textile machinery, self-lubricating bearings can help to reduce downtime and maintenance costs by eliminating the need for frequent lubrication and reducing the risk of lubrication-related failures. They can also help to improve the efficiency and performance of the machine by reducing friction and minimizing energy consumption.

Common types of self-lubricating bearings used in textile machinery include plain bearings, spherical bearings, and rod end bearings. These bearings can be made of a variety of materials, including bronze, steel, and thermoplastics, depending on the specific application requirements.

Overall, self-lubricating bearings are a reliable and efficient solution for textile machinery applications, offering long service life, low maintenance requirements, and excellent performance in harsh operating conditions.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.