NON-FERROUS ALLOYS FOUNDRY

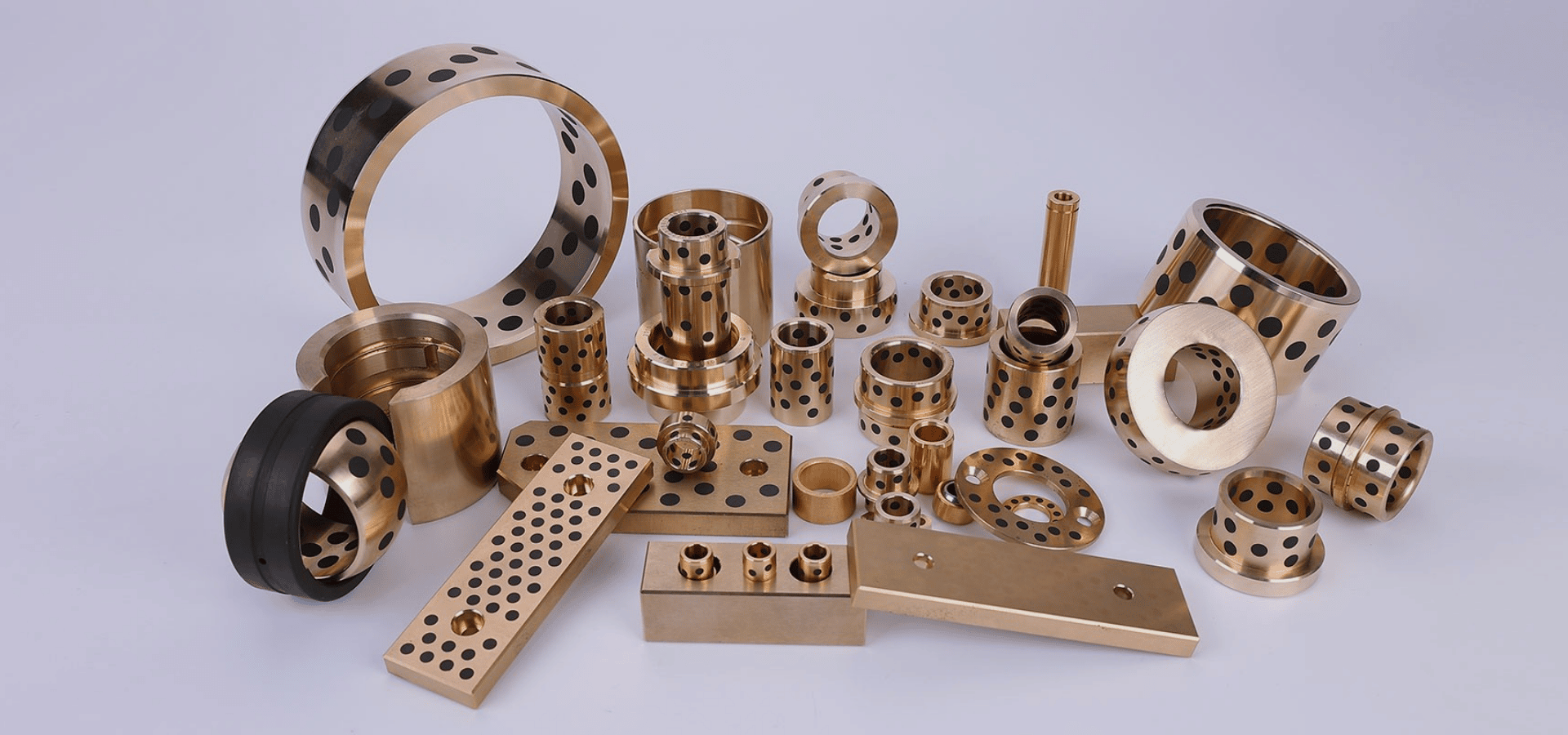

Heavy Duty, High Speed, Bronze Casting Bushing Bearings, Machine Parts, Flange Bushing, Non-Ferrous Alloys Foundry – Good Offer!

We will support prioritizing customer orders from essential businesses like yours.

We hope to help your business continue to grow.

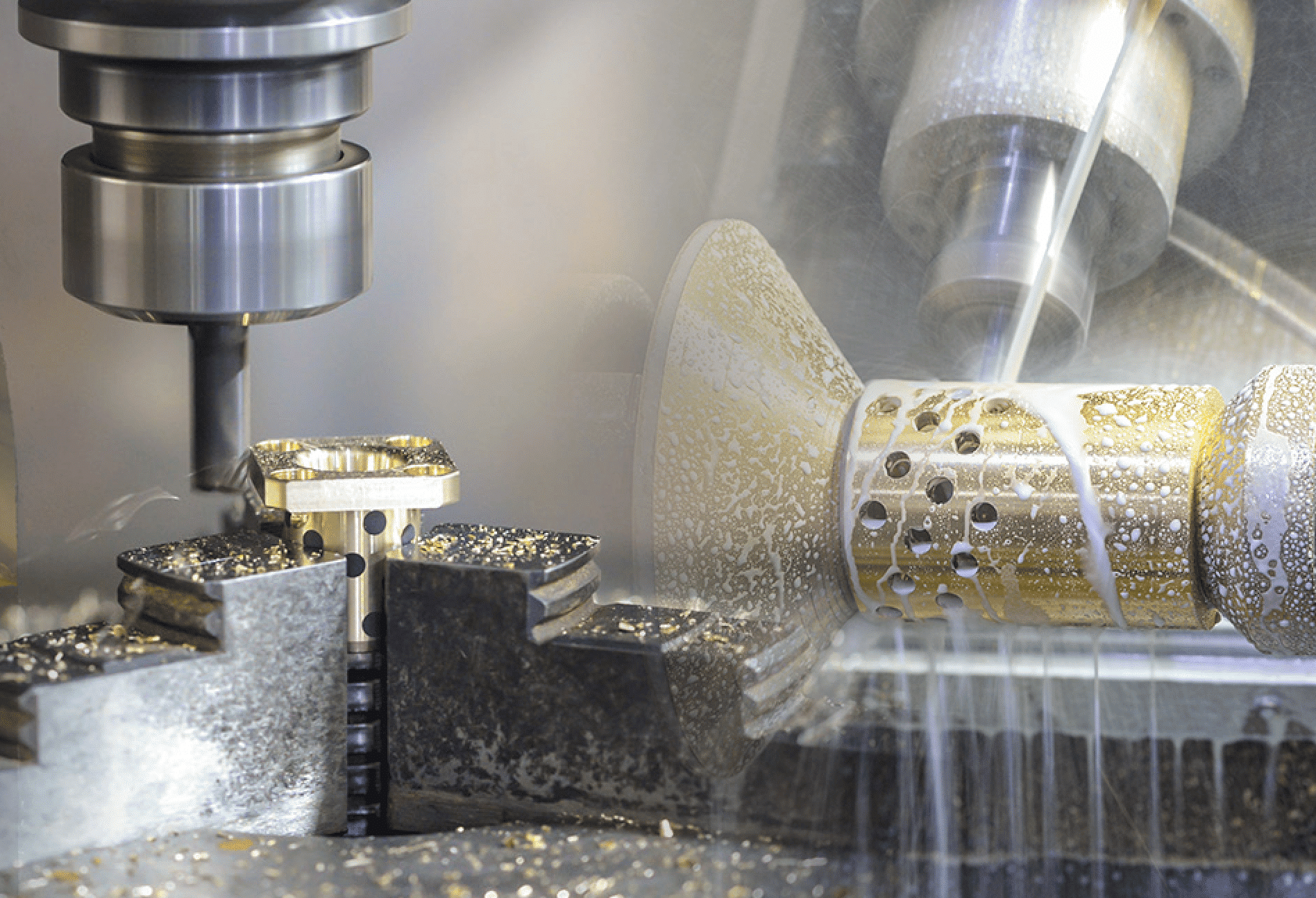

Process of self-lubricating bearings.

Production process of self-lubricating bearings

Self-lubricating bearings are divided into composite self-lubricating bearings, solid inlay self-lubricating bearings, bimetallic material self-lubricating bearings, special material self-lubricating bearings, according to different applications and working conditions, the use of different self-lubricating bearings.

The self-lubricating bearing has high bearing capacity, impact resistance, high temperature resistance, self-lubricating ability and other characteristics, especially for heavy load, low speed, reciprocating or oscillating and other difficult to lubricate and form oil film occasions, also not afraid of water and other acid corrosion and erosion. The products have been widely used in metallurgical continuous casting machine, steel rolling equipment, mining machinery, molds, lifting machinery, textile machinery, wind power generation, ships, steam turbines, hydraulic turbines, injection molding machines and equipment production lines. The wear resistance is double that of ordinary bushings.

Product Quality Index

Energy Generation

Continuous casting

Bronze metal alloy castings continuous & centrifugal cast. Sizes range from metric size to inch size.

Continuous casting is an advanced casting method, its principle is to molten metal, constantly pouring into a special metal type called crystallizer, solidified (crust) castings, continuous pull out from the other end of the crystallizer, it can get arbitrarily long or specific length of the casting. The development of continuous casting is China’s metallurgical industry for structural optimization of an important means, will make China’s metal material production of low efficiency, high consumption status quo to get a fundamental change, and promote the product structure to the direction of specialization. Near the end of the shape of continuous casting, single crystal continuous casting, high-efficiency continuous casting, continuous casting billet hot feed hot installation and other advanced continuous casting technology development will be very active, and will drive a series of new materials development.

The casting method used for oversized bronze bearings depends on many factors related to the finished part.

Advantages of Continuous Casting

Continuous casting has been widely adopted both at home and abroad, such as continuous casting of ingots (steel or non-ferrous metal ingots), continuous casting of pipes, etc. Continuous casting has the following advantages compared with ordinary casting.

1, because the metal is rapidly cooled, crystallization is dense, uniform organization, mechanical properties are better.

2, continuous casting, no casting system on the riser, so continuous casting ingots in the rolling without cutting the head to remove the tail, saving metal, improve the yield.

3、Simplify the process, eliminating molding and other processes, thus reducing labor intensity; the required production area is also greatly reduced.

4, continuous casting production is easy to achieve mechanization and automation, ingot casting can also achieve continuous casting and rolling, greatly improving production efficiency

Bronze Bearing Design

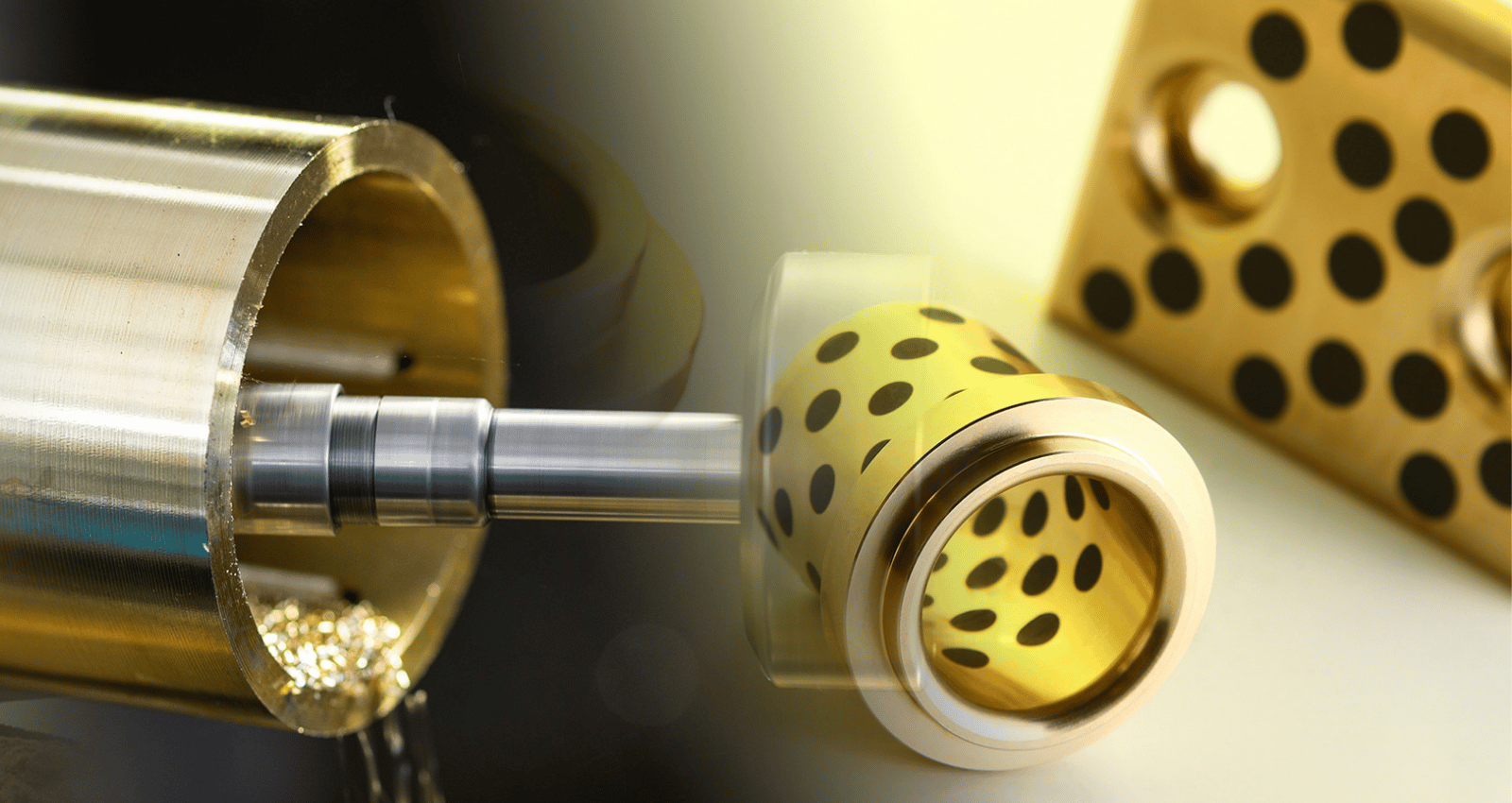

Bronze Bushing Manufacturing

Bronze Casting Order

Bronze Foundry Tin Bronzes Bearing

Heavily loaded machine parts bronze bearings, bushings, water resistant bronze parts.

Centrifugal Casting

Centrifugal casting is a technique and method of injecting liquid metal into a high-speed rotating mold so that the liquid metal fills the mold and forms a casting under the action of centrifugal force. Centrifugal force enables the liquid metal to fill the mold and form the free surface of the casting in the radial direction; it can obtain a cylindrical bore without the core; it helps to exclude the gas and inclusions in the liquid metal; it affects the crystallization process of the metal, thus improving the mechanical and physical properties of the casting.

Manufacturing Cast Bronze Bushings ; Plain cast bronze sleeve bushings ; Grooved bronze bearing. grooved cast bronze sleeve bushings ; Flanged. flanged cast bronze bushings ; Thrust washer self-lubricating bronze parts.

Advantages of centrifugal casting.

① almost no metal consumption of the pouring system and the riser system, improving the process yield.

②Production of hollow castings without core, so in the production of long tube-shaped castings can significantly improve the metal filling capacity, reduce the ratio of casting wall thickness to length or diameter, simplify the production process of sleeve and tube castings.

③ high density of castings, fewer defects such as pores and slag, high mechanical properties.

④Easy to manufacture barrel and sleeve composite metal castings, such as steel-backed copper sleeve, bimetallic rolls, etc.; when forming castings, the centrifugal movement can be used to improve the metal filling capacity, so it can produce thin-walled castings.

Provides professional casting services bronze casting parts.

We provide self-lubricating copper bearing bushings technical solutions, products with high technical standards of quality and precise performance at competitive prices while ensuring safety.

Bronze Casting Parts, Precision Bronze Casting Bushing & Bearings

Bronze is copper-tin and alloy copper containing elements such as Al, Pb, Tin and Mn. In addition to the double alloys, multi-component alloys are also applied. The name of each bronze comes from the main component or alloying element, such as tin bronze, aluminum bronze, manganese bronze, tin-lead bronze, and manganese bronze.

Bronze Bearing Manufacturer: We offer bronze castings for sale in the form of straight and flanged bushings, bushings, rings, shaped castings of graphite bronze bushings such as self-lubricating bushings inlaid with graphite, slides, gaskets, and other bronze bushing parts for machinery and equipment. We also make large size castings from manganese bronze. The weight range of our castings is from 0.5 kg to 200 kg. We also offer casting of bushing bore from copper alloys. The following are the alloys we use to make our castings.

about the company

Self-lubricating bronze Casting Bushing bearing

Our self-lubricating bronze bushings and bearings for transport systems in the mining industry are its main area of activity. The next step in our strategy is to expand our business in non-ferrous metal alloy castings, which include bronze bearings, brass bearings and aluminum bronze bearings. Thanks to our experience, we can offer our customers self-lubricating bronze bearing casting components that meet their expectations in terms of quality and price. We specialize in the production of castings in tin bronze, manganese bronze; aluminum bronze, and especially high force brass. We can also produce castings for shafts, bushings, rings, flats, and complex shapes.

In addition to the production of castings, we are also active in the field of industrial technology. Contacts and cooperation with many domestic and foreign companies, knowledge and experience enable us to provide our customers with appropriate technical solutions for materials, castings, parts and machinery for various industries. Our products are delivered to the following recipients. We respond flexibly to the needs of our customers in order to adapt to the specificities of the current market. The range of services, prices and terms are determined with each customer on individual terms. The main profile of our activities is unit production, but small batches are also possible on request.

Product Quality Index

Energy Generation

Selection of self-lubricating bronze bearings in the casting and its characteristics tailored to your individual needs.

The selection of self-lubricating bearings in the casting and its characteristics

In order to solve the mechanical equipment in the high temperature, low speed, heavy load, dusty, water washout and have shock vibration lubrication problems, the choice of oil-free self-lubricating bearings.

1, bearing construction self-lubricating bearing is the metal friction surface of the bearing matrix bimetal bearing on the development of an orderly arrangement of the appropriate size of the hole, and embedded in molybdenum disulfide, graphite and other linear bearings made of composite self-lubricating block inlaid on the metal sleeve, made of composite bearings, solid lubricant friction area of 25-65%.

Solid self-lubricating block can work normally at 280℃. But because of its low mechanical strength, bearing copper bushing ability is weak, easy to produce deformation, set it in the metal hole slot will be able to suppress this shortcoming, the formation of the metal part of the bearing role, self-lubricating block to play a lubricating role.

This self-lubricating bearing lubrication mechanism is in the process of sliding friction between the shaft and the set, part of the self-lubricating material molecules transferred to the metal surface of the shaft, filling the tiny not plane, and formed a more stable layer of solid lubricating film, resulting in solid lubricating film between the pair of grinding, to prevent the shaft and set of adhesive wear.

This rational combination of a combination of copper alloy and non-metallic wear reducing materials of their complementary advantages, especially suitable for oil-free, high temperature, high load, low speed, anti-fouling, anti-corrosion, strong radiation in the environment of the movement of the amplitude, as well as in the water or other solutions infiltration and simply can not add lubricating grease under special working conditions.

2, self-lubricating block accounted for area than self-lubricating block accounted for the amount of surface area and running speed, bearing strength, running speed is low; bearing strength is large, the area occupied by the metal should be larger.

Such as grabbing the ingot trolley walking wheel bearing self-lubricating block accounted for about 25% of the area, pulling the ingot mechanism rotating shaft bearing lubrication to be adequate, the pressure strength is not large, self-lubricating block accounted for about 65% of the area.

3, the technical requirements of the bushing material bushings should be made of alloy copper, bushings to have a high hardness, generally subject to heat treatment, its hardness is not less than HRC45.

4, self-lubricating block geometry and inlay requirements. The shape of self-lubricating block has two kinds of columnar and rectangular, self-lubrication according to the size of the occupied area can be used columnar, and vice versa can be used rectangular. Whatever the shape must be set firmly, to prevent in operation off.

5, the bushing and shaft clearance value of the self-lubricating block of the coefficient of linear expansion is about 10 times that of steel.

In order to adapt to bearing temperature changes, shaft and bushing clearance from the original metal parts four dynamic fit (D4/DC4) 0.032 ~ 0.15MM, increased to 0.45 ~ 0.5MM.

Self-lubricating block in the friction side of the protruding bushing metal 0.2 ~ 0.4MM. this will be in the bearing operation of the initial break-in period to get sufficient lubrication, reduce the power to drag the power consumption.

The advantages of oil-free self-lubricating bearings

A, oil-free lubrication or less oil lubrication, suitable for the place that can not be refueled or very difficult to refuel, can be used in the use of no maintenance or less maintenance.

B, good wear resistance, small friction coefficient, long service life.

C, there is a moderate amount of elasticity, can distribute the stress in a wider contact surface, to improve the bearing capacity.

D. The static and dynamic friction coefficients are similar, which can eliminate crawling at low speeds, thus ensuring the working accuracy of the machinery.

E, can make machinery to reduce vibration, reduce noise, prevent pollution and improve labor conditions.

F、It can form a transfer film during operation, which can play a role in protecting the shaft of the grinding, without the phenomenon of biting the shaft.

G. Low hardness requirement for grinding shaft, unconditioned shaft can be used, thus reducing the processing difficulty of related parts;.

H. Thin-walled structure, light weight, can reduce the volume of machinery.

I. The material of bushing is brass, which can be used in corrosive medium.