Unveiling the Superiority of Bronze Bush for Worm Gear: A Deep Dive into CuAl11Fe6Ni6 Material

The world of mechanical components is vast and diverse, filled with a plethora of materials and designs that facilitate optimal functioning of various machines and equipment. One such essential component, often overlooked yet undeniably significant, is the humble bronze bush, specifically designed for worm gears. In this context, a bronze alloy that’s been making waves due to its remarkable properties is the CuAl11Fe6Ni6. It is highly valued for its exceptional load carrying capacity, resistance to wear and corrosion, and excellent machinability. We Can Machine All Brass, Bronze & Copper Alloys To Meet Your Most Demanding Requirements. Our Experienced Staff Member Available To Discuss Your Needs!

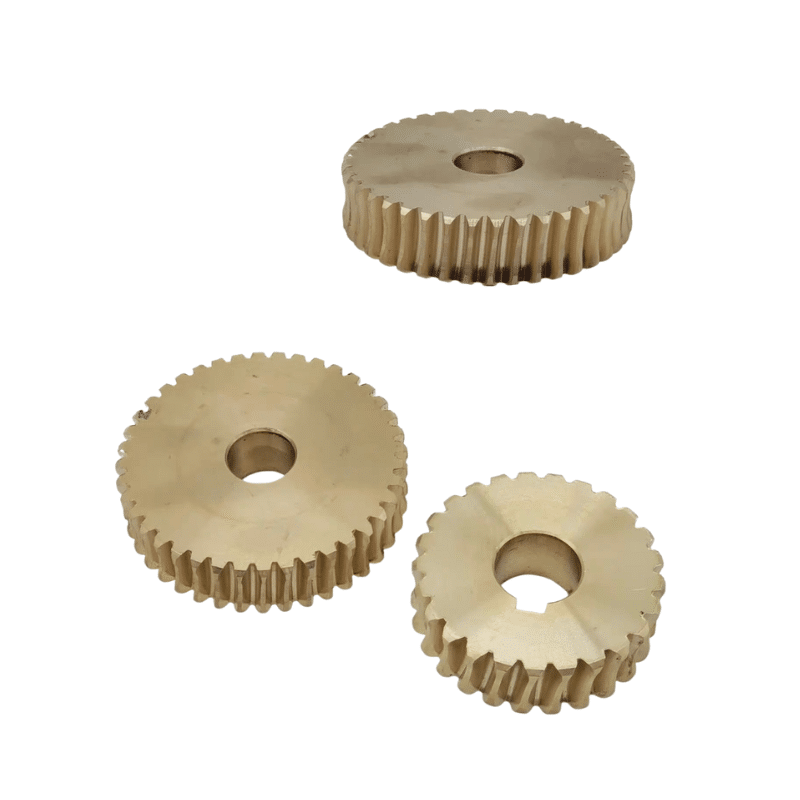

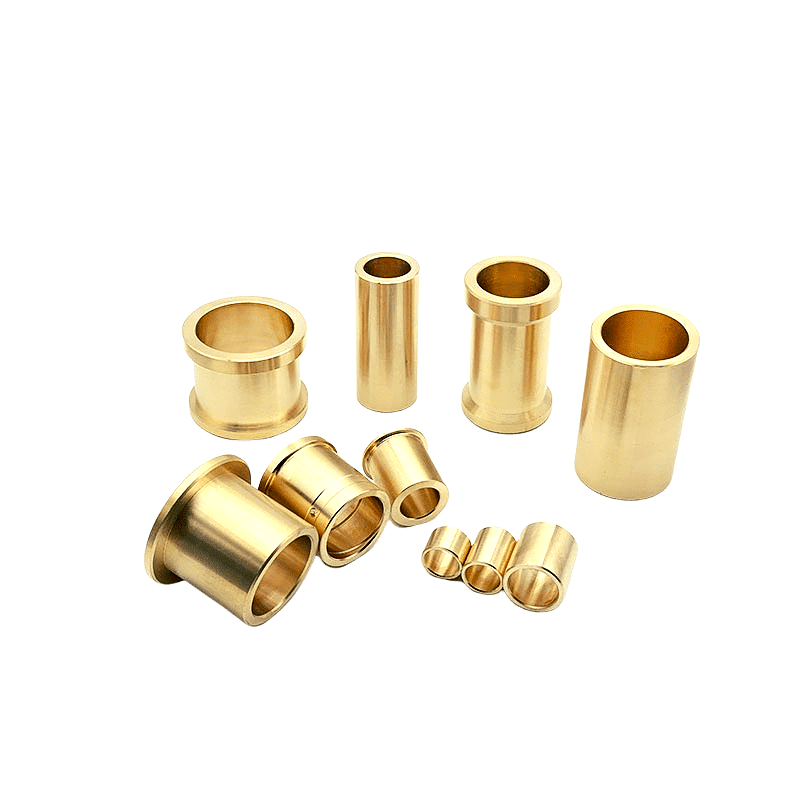

Customization of Quality Worm Gears: Industrial Precision Gear Reducer Parts and Non-Standard Processing

specializing in CuAl11Ni Bronze Bushing

What Makes CuAl11Fe6Ni6 Stand Out? As the name suggests, the CuAl11Fe6Ni6 alloy is a unique mix of Copper (Cu), Aluminium (Al), Iron (Fe), and Nickel (Ni). This specific composition exhibits high strength and hardness, increased load capacity, and impressive wear resistance – all attributes that are vital for worm gear applications.

Copper serves as the primary element, providing excellent thermal conductivity and corrosion resistance. Aluminium enhances the strength and hardness, while Iron and Nickel boost the overall wear resistance and toughness. This balanced mixture makes CuAl11Fe6Ni6 a preferred choice for producing bronze bushes for worm gears. Bronze bushing Manufacturers – Bronze bushing Passed The Inspection And Certification To Ensure Reliable Product Quality. Quality bushings. Inch, metric and custom sizes. Made in China. Bronze Plates Made。

Bronze bushing Manufacturers – The Superiority of Custom Bronze Bearings in Worm Gear Mechanisms

We specialize in crafting top-quality, custom bronze bearing parts for worm gear mechanisms. Whether you require flanged bearings, thrust washers, wear plates, or cam stroke plates, we offer precision-made parts, designed and manufactured to meet your specific needs. Our portfolio encompasses a wide range of bronze alloys such as CuSn5Pb5Zn5, BS1400 LG2, CC491K, Rg5, Rg7, C83600, SS5204, NS16530, and many more. As industries evolve and the demands on mechanical components continue to rise, selecting the right materials is more critical than ever. The CuAl11Fe6Ni6 alloy, with its superior properties and proven performance, offers an outstanding solution for worm gear applications. By adopting this high-performing bronze bush, businesses can improve their operational efficiency, extend equipment lifespan, and ultimately, achieve greater ROI. The future of mechanical components shines bright, and CuAl11Fe6Ni6 is poised to play a significant role in it. If you’re seeking to enhance the performance and lifespan of your worm gear assembly, consider integrating custom bronze bearings into your design. The superior durability, performance, and cost-effectiveness of these bearings offer tangible benefits that contribute to the overall efficiency and effectiveness of your operation.

Customized Bronze Bearings For All Your Industrial Needs

Bronze bushing Company – Reliable Supplier, Custom Size and Material: Casting Solid Bronze Bearings

Custom Size and Material: Casting Solid Bronze Bearings

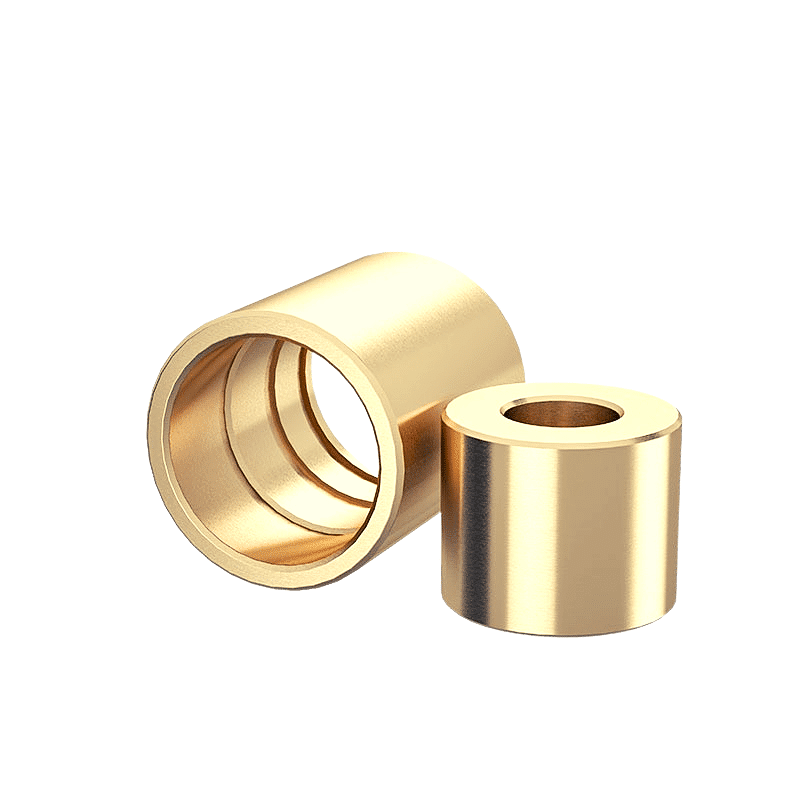

In the world of precision machinery, high-performing bearings are indispensable. Among the many materials available, solid bronze bearings occupy a unique place due to their durability, resistance to wear, and excellent thermal conductivity. In this blog post, we will explore the process of casting solid bronze bearings in custom sizes and materials.

Casting Bronze Bearings – The Materials

Bronze bearings are cast using different types of bronze alloys based on the specific application’s requirements. Some of the commonly used materials include CuSn5Pb5Zn5, BS1400 LG2, CC491K, Rg5, Rg7, C83600, SS5204, NS16530, and many more. Each material type offers different properties and benefits. For instance, C83600, also known as leaded red brass, is recognized for its excellent machinability and corrosion resistance.

Other popular choices are CuAl10Ni5Fe4, CW307G, CuAl10Ni, BS1400 AB2, C63000, SS5716-15, NS16570-15, which are used for casting bronze flanged bearings. These materials are renowned for their strength and corrosion resistance, making them ideal for heavy-duty applications.

The Casting Process

In the casting process, molten bronze is poured into a mold matching the desired bearing size and shape. The mold is then cooled, allowing the bronze to solidify into the finished bearing. This casting process can produce bearings in various forms such as flanged bearings, thrust washers, wear plates, cam stroke plates, split bearings, and more.

It’s no secret that bronze bearings have been extensively used across various industries due to their exceptional load-carrying capacity, resistance to impact and wear, as well as their excellent corrosion resistance. As the industry progresses, the demand for custom bronze bearings is on the rise, calling for specialized, unique solutions tailored to meet specific needs.

That’s where our expertise comes in. We specialize in casting solid bronze bearings, employing a wide range of bronze materials and providing custom sizes to perfectly suit your project.

Cast Bronze Bearings Made From a Variety of Bronze Alloys

When it comes to casting bronze bearings, it’s vital to choose the right bronze alloy for your needs. Each bronze alloy offers unique properties, making them more suitable for specific applications. Here’s a brief look at some of the bronze alloys we employ:

-

CuSn5Pb5Zn5: Also known as BS1400 LG2, CC491K, Rg5, Rg7, C83600, SS5204, NS16530, this alloy is a popular choice for casting solid bronze bearings due to its high strength, toughness, and excellent machinability.

-

CuAl10Ni5Fe4: Recognized as CW307G, CuAl10Ni, BS1400 AB2, C63000, SS5716-15, NS16570-15, this alloy boasts superior resistance to wear, corrosion, and cavitation.

-

C86300 Manganese Bronze: An alloy with excellent load-carrying capacity, this material also features high hardness and strength, making it suitable for heavy-duty applications.

-

C93200 Leaded Tin Bronze: Known for its superb machinability, this alloy is often used in manufacturing bearings and bushings due to its high wear resistance.

The list goes on, with alloys such as C85700 Leaded Red Brass, C95400 Aluminum Bronze, C95800 Nickel Aluminum Bronze, and many more utilized according to project requirements.

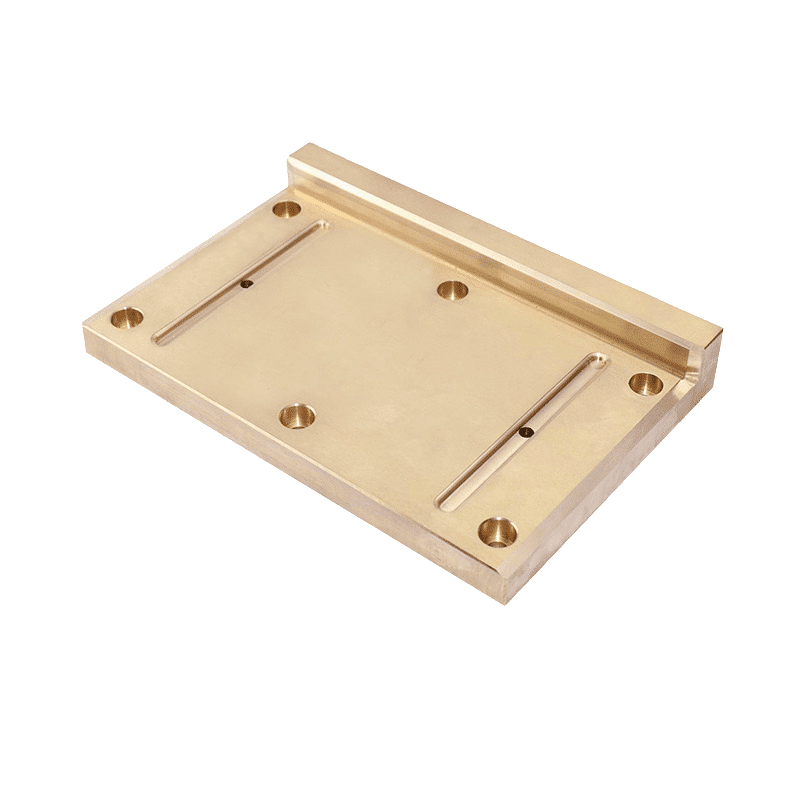

Variety of Bronze Bearing Products

We offer an extensive range of products, including flanged bearings, thrust washers, wear plates, cam stroke plates, and more. Our manufacturing process allows us to provide you with bearings that perfectly match your specifications, whether that be a specific shape, size, or alloy. We also offer machined-to-drawing services to ensure your bearings are crafted to precise dimensions.

Specialized Bronze Products

Beyond standard bearings, we offer unique solutions, including:

-

Casting Bronze Split Bearing & Solid Bronze Split Bushing, featuring the utilization of alloys such as C83600, LG2, CuSn5Zn5Pb5, for greater load distribution.

-

Casting Bronze Slippers, Sliding Blocks & Die Blocks, crafted from materials like BS1400 LG2, CuSn5Zn5Pb5, for use in a variety of industries.

-

Solid Casting Bronze Bearing C93700, CuPb10Sn, CuSn10Pb10, CC495K, LB2, G-SnPbBz10, G-CuPb10Sn, offering superior strength and longevity.

Quality Assurance

All our products are subjected to rigorous quality control measures to ensure they meet our high standards. Each bronze bearing is inspected for quality and durability, ensuring it’s free of defects and can perform under extreme conditions.

In conclusion, when it comes to customized bronze bearings, we offer a one-stop solution for all your needs. We understand that every project is unique, and our team is dedicated to helping you choose the right bronze material, size, and design for your application. Trust us to deliver high-quality, reliable, and efficient bronze bearings for your project.

In many industrial and mechanical systems, the choice of materials for specific components can significantly impact performance, durability, and maintenance requirements. Bronze, specifically types like Pb2/Aluminum Bronze, has long been a favored choice for the manufacturing of components such as worm wheels, worm gears, nuts, and bearing bushes due to its excellent physical and mechanical properties.

Bronze Worm Wheels and Gears:

Worm wheels and gears are crucial components in worm drives, which are used in various applications ranging from conveyor systems to tuning instruments. When these components are made from bronze, they offer advantages like good wear resistance, low friction, and excellent load-carrying capacity.

Bronze worm wheels and gears are particularly effective in applications that require slow rotational speeds and high torque. The combination of a bronze worm wheel with a steel worm can provide a very high efficiency, and bronze’s natural lubricity can lead to reduced wear over time.

Pb2/Aluminum Bronze Nuts:

Pb2/Aluminum Bronze is an alloy that combines copper, aluminum, and a small amount of lead. This composition gives the alloy excellent machinability, high strength, and superior wear resistance.

Nuts made from this alloy are capable of handling heavy loads and high-stress environments. They also have excellent resistance to corrosion and wear, making them suitable for applications in marine environments, heavy machinery, and other challenging conditions.

Worm Shaft Bearing Bush:

Worm shaft bearing bushes serve as the interface between the shaft and the gear housing in a worm gear mechanism. Made from Pb2/Aluminum Bronze, these bearing bushes are not only strong and wear-resistant, but they also have excellent resistance to heat and corrosion.

These properties make them an ideal choice for applications where high load capacity and durability are required. They can function effectively even under high-stress and high-temperature conditions, contributing to the overall reliability and efficiency of the worm gear mechanism.

In conclusion, whether it’s for worm wheels, gears, nuts, or bearing bushes, the use of bronze, specifically Pb2/Aluminum Bronze, can significantly enhance the performance and longevity of mechanical systems. By offering high strength, excellent wear resistance, and superior machinability, this material helps ensure that these components can handle even the most demanding applications.

Aluminium Bronze: Copper-Aluminium Alloys

Aluminium bronze, also known as copper-aluminium alloys, can be categorized according to DIN 17 665, DIN EN 12 163/12 167/12 420/12 451/1652/1653. Below, we’ll detail various alloy types, their composition, and their uses.

CuAl10Ni5Fe4

Recognized under the EN number CW307G, this alloy has a density of approximately 7.6. Its composition includes Aluminium (8.5 – 11.0%), Nickel (4.0 – 6.0%), Iron (3.0 – 5.0%), and Copper. It stands out for its high strength and fatigue resistance, even in high-temperature conditions up to 400°C. It’s highly resistant to corrosion and acidic or watery environments. The alloy is utilized in a broad range of applications such as heat exchanger sheets, hydraulic control parts, shipbuilding, and mining.

CuAl10Fe3Mn2

This alloy, with EN number CW306G, has a similar density of about 7.6. It consists of Aluminium (9 – 11.0%), Iron (2.0 – 4.0%), Manganese (1.5 – 3.5%), and Copper. Like CuAl10Ni5Fe4, it maintains high strength at higher temperatures, offering good corrosion resistance. It is often used in engine and gear construction and for components subject to wear or vibrations.

CuAl11Fe6Ni6

The CuAl11Fe6Ni6 alloy, also known as CW308G, shares the properties of CuAl10Ni5Fe4 but with notably high strength, corrosion resistance, and wear resistance. It’s ideal for highly stressed bearing parts and worm wheels.

CuAl8Fe3

Also known as CW303G, CuAl8Fe3 offers high strength even at temperatures up to around 300°C. This alloy is notably resistant to corrosion, salt water, sulphite alkalis, and mineral acids. It’s perfect for heat exchanger sheets and sheets for chemical apparatus engineering.

CuAl9Ni3Fe2

This alloy, recognized under the EN number CW304G, has a low friction coefficient and is both cold and hot formable. It is commonly used in the construction of desalination plants, oil coolers, and pickling plants.

CuAl9Mn2

With a density of about 7.5, CuAl9Mn2 offers high strength and is especially useful for shock loads due to its excellent thermal conductivity. It’s typically used in highly stressed bearing parts, gears and worm wheels, and spark-proof tools.

CuAl7Si2

Known as CW302G, this alloy is praised for its high strength, wear resistance, and good machinability. It’s ideal for slide bearings with high shock loads, valves, screws, and gear parts.

We also supply other copper-aluminium alloys in bars, hollow bars, plates/strips, welding consumables, and forgings to meet international standards and aviation standards.

Cast Aluminium Bronze (Copper-Aluminium-cast-alloys)

Following DIN EN 1982, we offer several cast aluminium bronze options, including CuAl10Ni3Fe2-C, CuAl10Fe5Ni5-C, CuAl11Fe6Ni6-C, and CuAl10Fe2-C. Each of these alloys possesses unique compositions and properties, catering to various applications ranging from shipbuilding to chemical industries.

Whether you require a construction material with high strength or an alloy resistant to cold and warm seawater, our range of cast aluminium bronze has you covered.

Aluminium Bronze (Copper-Aluminium Alloys) Bushing Bearing

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl10Ni5Fe4 | DIN EN 12163, 12167, 12420, 1653 | 7.6 | Al 8.5 – 11.0, Ni 4.0 – 6.0, Fe 3.0 – 5.0, Cu Balance | High strength even at higher temperatures up to approximately 400°C. High fatigue strength even in corrosive environments. Resistant to neutral and acidic watery media as well as seawater. Good resistance to scaling, erosion, and cavitation. Very high wear resistance. Suitable for condenser and heat exchanger sheets, shafts, screws, wear parts, control parts for hydraulics, and high-pressure steam fittings in mechanical engineering, shipbuilding, and mining. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | |

| Bars M | ≥ 680 | ≥ 320 | ≥ 10 | |

| Plates M | ≥ 620 | ≥ 250 | ≥ 14 |

Comparable Specifications: CuAl10Ni5Fe4, 2.0966, DIN 17665, C63200, C63000 UNS, CA 104, BS 2872, 2874, 2875

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl10Fe3Mn2 | DIN EN 12163, 12167, 12420 | 7.6 | Al 9.0 – 11.0, Fe 2.0 – 4.0, Mn 1.5 – 3.5, Cu Balance | High strength even at higher temperatures. Good corrosion resistance. Good resistance to scaling, erosion, and cavitation. Suitable for impacting, vibrating, or wear parts in engine and gear construction, bolts, high-strength bolts and nuts, shafts, spindles, worm and gear wheels, wheel rims, bearings, and sliding components. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | |

| Bars M | ≥ 590 | (ca. 330) | ≥ 12 | |

| Plates M | ≥ 490 | ≥ 180 | ≥ 20 |

Comparable Specifications: CuAl10Fe3Mn2, 2.0936, DIN 17665, C62300, C62500 UNS, CA 103, BS 2872, 2874

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl11Fe6Ni6 | DIN EN 12163, 12167, 12420 | 7.4 | Al 10.5 – 12.5, Ni 5.0 – 7.0, Fe 5.0 – 7.0, Cu Balance | Similar to CuAl10Ni5Fe4 with especially high strength, corrosion resistance, and wear resistance. Suitable for extremely highly stressed bearing parts and worm wheels, valves, valve seats, cover plates, sliding components, wear parts, matrices for chipless forming technology, and high-pressure steam fittings. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | |

| Bars M | ≥ 740 | ≥ 420 | ≥ 5 | |

| * | ≥ 830 | ≥ 550 | k.A. |

Comparable Specifications: CuAl11Ni6Fe5, 2.0978, DIN 17665

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl8Fe3 | DIN EN 12420, 1652, 1653 | 7.7 | Al 6.5 – 8.5, Fe 1.5 – 3.5, Cu Balance | High strength even at higher temperatures up to approximately 300°C. Good corrosion resistance, including saltwater, sulfite alkalis, and mineral acids (excluding nitric acid). Good resistance to scaling, erosion, and cavitation. High wear resistance. Suitable for plates in condenser and heat exchanger sheets and sheets for chemical apparatus engineering. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | |

| Plates M | ≥ 480 | ≥ 210 | ≥ 30 |

Comparable Specifications: CuAl8Fe3, 2.0932, DIN 17665, C61400 UNS, CA 106, BS 2874, 2875

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl9Ni3Fe2 | DIN EN 12420, 1653 | 7.4 | Al 8.0 – 9.5, Ni 2.0 – 4.0, Fe 1.0 – 3.0, Cu Balance | Low friction coefficient. Cold and hot formable, easy to weld. Suitable for welded constructions in desalination plants, oil coolers, pickling plants, and potash industry. Also used for bearing parts subjected to intermittent loads, plates in condenser and heat exchanger sheets. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | |

| Plates M | ≥ 490 | ≥ 180 | ≥ 20 |

Comparable Specifications: CuAl9Ni3Fe2, 2.0971, DIN 17665

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl9Mn2 | DIN 17665, 2.0960 | 7.5 | Al 8.0 – 10.0, Mn 1.5 – 3.0, Cu Balance | Wear-resistant sliding material, otherwise similar to CuAl10Fe3Mn2. High strength. Suitable for highly stressed bearing parts, gears and worm wheels, wear bars and wedge bars, spark-proof tools, and plastic molds. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | |

| Bars P | ≥ 490 | ≥ 200 | ≥ 25 |

Comparable Specifications: CuAl9Mn2, 2.0960, DIN 17665

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl7Si2 | DIN EN 12163, 12167, 12420 | 7.7 | Al 6.3 – 7.6, Si 1.5 – 2.2, Cu Balance | Offers high strength and excellent wear resistance. It has good machinability and corrosion resistance, including resistance to seawater. Ideal for slide bearings subjected to high shock loads, valves, screws, and gear parts. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | |

| Bars M | R500-R600 (≥ 500-600) | (≥ 250-350) | ≥ 20 | |

| * | ≥ 500-600 | (≥ 250-350) | ≥ 12 |

Comparable Specifications: C64200 UNS

Other copper-aluminum alloys, conforming to international standards and aviation standards, are available upon request.

We supply: Bars, Hollow bars, Plates/Strips, Welding consumables, Forgings according to DIN 17 672, DIN 17 671/1785, DIN 17 670, DIN 1733, DIN EN 12 420 respectively DIN EN 12 163/12 167, DIN EN 1652/1653.

Cast Aluminum Bronze (Copper-Aluminium Cast Alloys) Bushing Bearing

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl10Ni3Fe2-C | DIN EN 1982 | 7.5 | Cu 80.0 – 86.0, Al 8.5 – 10.5, Ni 1.5 – 4.0, Fe 1.0 – 3.0 | A construction material with good strength properties, resistant to both cold and warm seawater. It exhibits excellent weldability and is used for corrosion-stressed parts, fittings in aggressive waters, and flanges for shipbuilding. It shares similarities with CuAl10Fe5Ni5-C but with better properties in various aspects. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | Hardness HB |

| GC | ≥ 550 | ≥ 220 | ≥ 20 | ≥ 120 |

| GZ | ≥ 550 | ≥ 220 | ≥ 20 | ≥ 120 |

Comparable Specifications: CuAl9Ni, 2.0970, DIN 1714

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl10Fe5Ni5-C | DIN EN 1982 | 7.6 | Cu 76.0 – 83.0, Al 8.5 – 10.5, Ni 4.0 – 6.0, Fe 4.0 – 5.6 | A construction material with high strength, resistant to cold and hot seawater. It exhibits very good thermal stability and fatigue strength in both air and seawater. Highly resistant to cavitation and corrosion, it can handle high stress and offers good wear resistance. Sliding stress requires good lubrication. It exhibits very good pressure tightness and weldability. Ideal for highly stressed slide bearings, worm rims, worm and helical wheels at high gear tooth pressures, high-pressure steam fittings, fittings for aggressive waters, and pump housings. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | Hardness HB |

| GC | ≥ 650 | ≥ 280 | ≥ 13 | ≥ 150 |

| GZ | ≥ 650 | ≥ 280 | ≥ 13 | ≥ 150 |

Comparable Specifications: CuAl9Ni, 2.0975, DIN 1714, Cu 95 800, C 95 500 UNS, AB 2, BS 1400

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl11Fe6Ni6-C | DIN EN 1982 | 7.6 | Cu 72.0 – 82.5, Al 10.0 – 12.0, Ni 4.0 – 7.5, Fe 4.0 – 7.0 | Similar to CuAl10Fe5Ni5-C but with higher demands on cavitation and/or wear resistance. Suitable for chemical industry and shipbuilding. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | Hardness HB |

| GC | ≥ 750 | ≥ 380 | ≥ 5 | ≥ 185 |

| GZ | ≥ 750 | ≥ 380 | ≥ 5 | ≥ 185 |

| GM | ≥ 750 | ≥ 380 | ≥ 5 | ≥ 185 |

Comparable Specifications: CuAl11Ni, 2.0980, DIN 1714

| Alloy | EN Number | Density ca. | Composition in % of weight | Properties and Use |

|---|---|---|---|---|

| CuAl10Fe2-C | DIN EN 1982 | 7.5 | Cu 83.0 – 89.5, Al 8.5 – 10.5, Fe 1.5 – 3.5 | An aluminum bronze with high strength and elongation. It offers good wear resistance, seawater and corrosion resistance. Ideal for mechanically stressed parts, pinions, and bevel gears. |

| Important Tempers | Tensile Strength Rm N/mm² | Yield Stress Rp0,2 N/mm² | Elongation A % | Hardness HB |

| GC | ≥ 550 | ≥ 200 | ≥ 18 | ≥ 130 |

| GZ | ≥ 550 | ≥ 200 | ≥ 15 | ≥ 130 |

Comparable Specifications: CuAl10Fe, 2.0940, DIN 1714, C 95 200 UNS, AB 1, BS 1400

Other cast aluminum bronze bushing bearing products are available upon request.

We supply cast bronze bushing: GC = Continuous casting bronze bushing, GZ = Centrifugal casting bronze bushing, GM = Gravity die casting.

Aluminium Bronze: The Versatile Copper-Aluminium Alloys

Aluminium bronze, also known as copper-aluminium alloys, refers to a group of materials that exhibit excellent properties and versatile applications. In this article, we’ll explore some key variations of aluminium bronze and their compositions, properties, and uses.

CuAl10Ni5Fe4: High-Strength Performer

Composition:

- Aluminium (Al): 8.5% – 11.0%

- Nickel (Ni): 4.0% – 6.0%

- Iron (Fe): 3.0% – 5.0%

- Copper (Cu): Balance

Properties and Use: CuAl10Ni5Fe4, also known as CW307G, showcases high strength, even at elevated temperatures up to approximately 400°C. It exhibits exceptional fatigue strength even when exposed to corrosion. This alloy is resistant to neutral and acid, watery media, including seawater. It possesses good resistance to scaling, erosion, and cavitation. Moreover, it offers very high wear resistance and excellent sliding properties when used with mating materials having hard surfaces and proper lubrication. Due to its outstanding properties, CuAl10Ni5Fe4 finds applications in various industries, including:

- Plates for condenser and heat exchanger sheets.

- Shafts, screws, wear parts, and control parts for hydraulics.

- High-pressure steam fittings.

- Mechanically and chemically stressed parts in mechanical engineering, shipbuilding, and mining.

Important Tempers:

- Tensile Strength (Rm) ≥ 680 N/mm²

- Yield Stress (Rp0.2) ≥ 320 N/mm²

- Elongation (A) ≥ 10%

Comparable Specifications:

- CuAl10Ni5Fe4, 2.0966, DIN 17665

- C63200, C63000 UNS

- CA 104, BS 2872, 2874, 2875

CuAl10Fe3Mn2: Strength with Corrosion Resistance

Composition:

- Aluminium (Al): 9.0% – 11.0%

- Iron (Fe): 2.0% – 4.0%

- Manganese (Mn): 1.5% – 3.5%

- Copper (Cu): Balance

Properties and Use: CuAl10Fe3Mn2, also known as CW306G, possesses high strength, even at elevated temperatures. It offers good corrosion resistance and exhibits resistance to scaling, erosion, and cavitation. This alloy is primarily used for impacting, vibrating, or wear-exposed parts in engine and gear construction. Its applications include:

- Bolts, high-strength bolts, and nuts.

- Shafts and spindles.

- Worm and gear wheels.

- Wheel rims, bearings, and sliding components.

Important Tempers:

- Tensile Strength (Rm) ≥ 590 N/mm²

- Yield Stress (Rp0.2) ≥ 250 N/mm²

- Elongation (A) ≥ 12%

Comparable Specifications:

- CuAl10Fe3Mn2, 2.0936, DIN 17665

- C62300, C62500 UNS

- CA 103, BS 2872, 2874

CuAl11Fe6Ni6: The Ultimate in Strength and Wear Resistance

Composition:

- Aluminium (Al): 10.5% – 12.5%

- Nickel (Ni): 5.0% – 7.0%

- Iron (Fe): 5.0% – 7.0%

- Copper (Cu): Balance

Properties and Use: CuAl11Fe6Ni6, also known as CW308G, is akin to CuAl10Ni5Fe4 but boasts exceptional strength, corrosion resistance, and wear resistance. It is specifically designed for extremely high-stressed bearing parts and worm wheels. The applications of CuAl11Fe6Ni6 include:

- Valves, valve seats, and cover plates.

- Sliding components and wear parts.

- Matrices for chipless forming technology.

- High-pressure steam fittings.

Important Tempers:

- Tensile Strength (Rm) ≥ 740 N/mm²

- Yield Stress (Rp0.2) ≥ 420 N/mm²

- Elongation (A) ≥ 5%

Comparable Specifications:

- CuAl11Ni6Fe5, 2.0978, DIN 17665

CuAl8Fe3: Strength at Elevated Temperatures

Composition:

- Aluminium (Al): 6.5% – 8.5%

- Iron (Fe): 1.5% – 3.5%

- Copper (Cu): Balance

Properties and Use: CuAl8Fe3, also known as CW303G, exhibits high strength even at higher temperatures, approximately up to 300°C. It offers good corrosion resistance, including saltwater, sulphite alkalis, and mineral acids (except nitric acid). Moreover, it is resistant to scaling, erosion, and cavitation, making it highly suitable for applications requiring wear resistance. Its uses include:

- Plates for condenser and heat exchanger sheets.

- Sheets for chemical apparatus engineering.

Important Tempers:

- Tensile Strength (Rm) ≥ 480 N/mm²

- Yield Stress (Rp0.2) ≥ 210 N/mm²

- Elongation (A) ≥ 30%

Comparable Specifications:

- CuAl8Fe3, 2.0932, DIN 17665

- C61400 UNS

- CA 106, BS 2874, 2875

CuAl9Ni3Fe2: Low Friction, High Formability

Composition:

- Aluminium (Al): 8.0% – 9.5%

- Nickel (Ni): 2.0% – 4.0%

- Iron (Fe): 1.0% – 3.0%

- Copper (Cu): Balance

Properties and Use: CuAl9Ni3Fe2, also known as CW304G, offers a low friction coefficient and exhibits excellent formability in both cold and hot conditions. It is easy to weld and finds applications in welded constructions for desalination plants, oil coolers, pickling plants, and the potash industry. It is particularly suitable for bearing parts subject to intermittent loads, as well as plates for condenser and heat exchanger sheets.

Important Tempers:

- Tensile Strength (Rm) ≥ 490 N/mm²

- Yield Stress (Rp0.2) ≥ 180 N/mm²

- Elongation (A) ≥ 20%

Comparable Specifications:

- CuAl9Ni3Fe2, 2.0971, DIN 17665

CuAl9Mn2: Wear-Resistant Sliding Material

When it comes to transmission devices, worm gears are indispensable due to their unique ability to decrease speed while concurrently increasing torque. Composed of a worm (a screw-shaped gear) and a worm wheel (akin to a spur gear), the worm gear assembly finds extensive application across a plethora of sectors. However, the efficiency and longevity of a worm gear assembly are dependent not only on its design but also on the quality and specification of its components, particularly the bearings. The importance and advantages of using custom bronze bearings for your worm gear mechanisms.

The Essence of Bronze Bearings in Worm Gears

Bronze bushings or bearings play a crucial role in any gear assembly, worm gears included. As the gear components rotate, the bearings provide a smooth, low-friction surface for these parts, facilitating a seamless motion. The material composition of these bearings is crucial as it needs to withstand the continuous stress and potential wear and tear that accompanies the motion. This is where bronze, with its impressive durability and superior friction-reducing characteristics, comes into the picture.

Customization: The Way Forward

Given the diversity in the applications of worm gears, a one-size-fits-all approach for bearings simply does not work. The varying demands regarding speed, torque, and operational environment necessitate customized solutions. With custom bronze bearing parts, it’s possible to cater to the specific needs of each application, ensuring optimal performance, longevity, and overall cost-effectiveness.

Advantages of Custom Bronze Bearings

1. Improved Durability: Custom bronze bearings are manufactured to suit specific applications, thereby offering improved durability. They can withstand high loads and are exceptionally resistant to wear and tear, resulting in a longer lifespan.

2. Superior Performance: Tailored to match the specific requirements of the gear assembly, custom bronze bearings ensure smoother operation, reduced friction, and, consequently, superior performance.

3. Cost-Effective: Despite the upfront costs associated with customization, the overall lifecycle cost of custom bronze bearings is lower. This is primarily due to their longer operational life and reduced maintenance requirements.

4. Versatility: Custom bronze bearings can be designed and manufactured to fit any worm gear assembly, irrespective of the complexity or uniqueness of the design.

The Silent Heroes of Machinery: Turbine Bronze Bushings and Worm Wheel Bronze Parts

Introduction

In the world of machinery, countless components work in harmony to ensure smooth and efficient operation. While some components, like gears and motors, often steal the limelight, there are unsung heroes that quietly contribute to the overall performance and longevity of machines. Among these unsung heroes are the turbine bronze bushings and worm wheel bronze parts. In this blog post, we will shed light on these crucial components, understanding their roles, significance, and the value they bring to the realm of engineering.

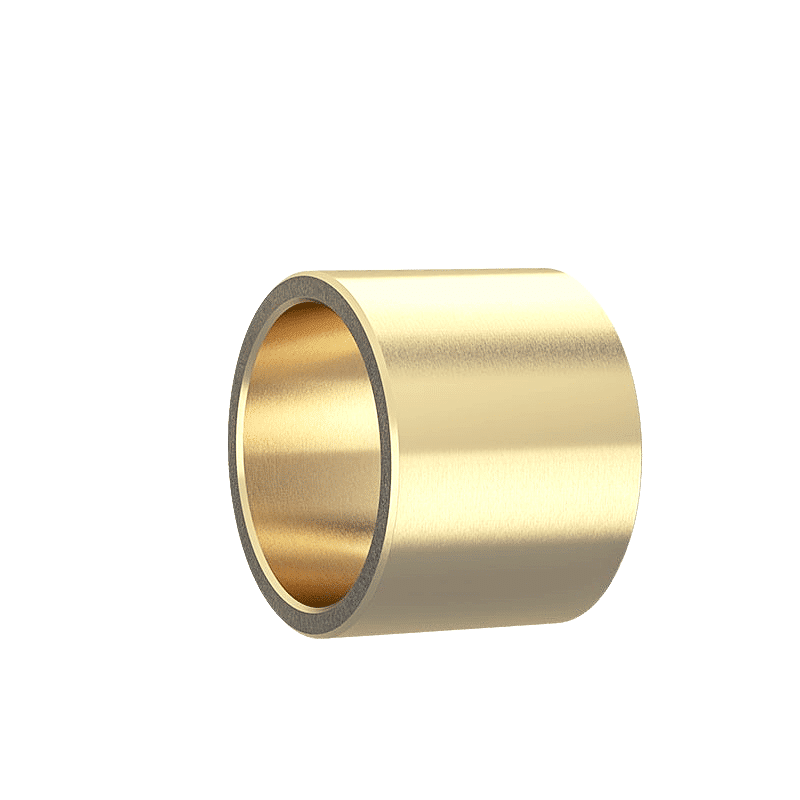

1. Turbine Bronze Bushings: The Bearings of Power

Bronze bushings are vital components in various machines and mechanical systems, providing support and reducing friction between moving parts. Turbine bronze bushings, in particular, play an indispensable role in power generation systems and turbines. These bushings act as bearings, allowing smooth rotation of shafts within their housings, ensuring minimal wear and tear even under high-speed and heavy-load conditions.

Key Features of Turbine Bronze Bushings:

a. Exceptional Durability: Turbine bronze bushings are engineered to withstand extreme temperatures, high pressures, and harsh environments, making them ideal for critical applications in power plants.

b. Self-Lubricating Properties: One of the remarkable characteristics of these bushings is their self-lubricating ability. This reduces the need for constant maintenance and ensures continuous operation without frequent lubrication intervals.

c. Corrosion Resistance: Bronze, the primary material used in these bushings, exhibits excellent resistance to corrosion, ensuring long-term reliability and stability.

d. Shock Absorption: Turbine bronze bushings effectively dampen vibrations, reducing stress on the entire system and preventing potential failures.

2. Worm Wheel Bronze Parts: Precision in Motion

In many industries, worm gears play a critical role in power transmission and precision motion control. The worm wheel, an essential part of this gear system, is often made from bronze due to its exceptional mechanical properties and wear resistance. Worm wheel bronze parts are employed in various applications, including automotive, industrial machinery, and even in the aerospace sector.

Key Advantages of Worm Wheel Bronze Parts:

a. Low Noise and Vibration: Bronze’s inherent characteristics contribute to quiet and smooth operation, which is especially valuable in machinery where noise reduction is crucial.

b. High Efficiency: The worm gear system, when paired with bronze components, exhibits excellent efficiency, making it an energy-saving solution in many applications.

c. Dimensional Stability: Bronze parts maintain their shape and structural integrity over time, ensuring accurate and reliable motion control.

d. High Load Capacity: Despite their relatively small size, worm wheel bronze parts can handle significant loads, making them suitable for heavy-duty applications.

Conclusion

As we delve into the intricate world of machinery, we uncover the significance of seemingly unassuming components like turbine bronze bushings and worm wheel bronze parts. These unsung heroes work tirelessly to maintain the integrity and efficiency of various systems, facilitating smooth motion, reducing friction, and ensuring long-lasting performance. By appreciating and understanding the roles of these essential components, we gain a deeper appreciation for the marvels of engineering and the silent heroes that power our world.

Peering through the lens of metallurgical proficiency, aluminium bronze’s significance manifests as a cornerstone within the sphere of semi-finished goods. This alloy amalgamation, teeming with copper and aluminum’s inherent capacities, forges an unshakeable kinship in the vast, vibrant, and relentless industrial sphere.

A tableau of intrinsic strengths – commendable resistance to wear, anti-corrosion properties, and an underlying tenacity – are meticulously woven into the fabric of this alloy. These compelling characteristics propel aluminium bronze into the revered realms of high-demand applications, ones that mercilessly test the mettle of materials under their dominion.

Seizing a moment of contemplation to appreciate the transformative process of aluminium bronze metamorphoses from a raw, unrefined substance to a sophisticated and complex entity, we unearth the dexterity of modern manufacturing. This perennial journey of transformation, unyielding in its commitment, epitomizes the essence of perpetual innovation and industrial evolution.

Exhibiting an unparalleled resilience when grappled by the cold hand of thermal conductivity, aluminium bronze’s demeanor remains unfazed. The alloy’s endurance is, perhaps, its most salient feature, extending its territory across a wide array of operational thresholds. Whether at the helm of machinery components, scribed within the notes of orchestral compositions, or nestled amidst ship propellers, aluminium bronze leaves an indelible imprint.

Admirably straddling a fine line between mechanical robustness and aesthetic appeal, aluminium bronze graces the world with a rich, golden hue, endearing it to artists and industrialists alike. This duality of purpose, standing at the crossroads of form and function, hails a new age for industrial design where aesthetic elements are no longer shrouded by the shadows of mechanical prowess.

The continual refining of aluminium bronze, honed by the relentless grindstone of human ingenuity, remains a testament to the power of progressive metallurgical pursuits. The alloy’s ability to bridge the chasm between industrial utility and aesthetic versatility paints a poignant portrait of its ever-increasing relevance within our rapidly evolving world.

Thus, aluminium bronze prevails as a stalwart ally amidst the volatile seas of industry, standing as a testament to the eternal dance of metallurgical innovation and human ambition. Embodied in this alloy amalgamation is an unspoken ode to the relentless quest for enhanced performance, durability, and aesthetic appeal. Aluminium bronze, in its embodiment of these lofty ideals, holds steadfast in the face of industry’s ceaseless demands, embodying the spirit of evolution and innovation.