Bushings for the Mining

For many years, our company has been a steadfast partner to the mining industry. We have provided comprehensive solutions, from design to manufacturing, catering to various application scenarios in mining enterprises. Our self-lubricating bearing sleeves and industrial transmission products are crafted specifically for the harsh operating environments typical of mining. They effectively tackle the challenges posed by open-pit operations, underground mining, and other engineering tasks. Through our durable, efficient, safe, and reliable sliding bearing sleeves, we aim to help mining operators achieve their objectives of safety and efficiency. By doing so, we’re transforming the stubborn rocks deep beneath the Earth’s surface into the driving force behind our civilization’s progress.

In the current wave of green development, our company is committed to helping humanity mine more of the Earth’s treasures, paving the way for a sustainable future.

Bushings and Bearings for Heavy Construction and Mining: A Steadfast Partner in the Mining Industry

Mining Resources: The Indispensable Element of Civilizational Progress

From ancient times to the modern era, mineral resources have been an essential element in the development of civilizations. As humanity entered the modern age, the demand for mineral resources surged. The mining industry now requires reliable, efficient, and long-lasting bearings and industrial transmission products. Having partnered with the mining industry for so long, how has our company contributed to humanity’s quest to unearth the Earth’s treasures? Why Choose Our Supplier?

- Scale Flexibility: From the tiniest bushings in handheld tools to the large ones in heavy machinery, the supplier crafts them with precision.

- Durability: The combination of high-grade materials and the added feature of oil grooves means that these bushings are built to last.

- Customization: Recognizing that one size doesn’t fit all, especially in the diverse world of mining, the supplier offers tailored solutions to meet specific needs.

- Industry Reputation: Years of serving the mining sector with consistent quality has established the supplier as a trusted name.

Bushings For Mining Industry

Bushing Bearings for Mining: Engineered for Excellence in the Harshest Conditions

In the relentless and rugged world of mining, where machinery is subjected to extreme conditions and the potential for wear and tear is omnipresent, the importance of reliable components cannot be overstated. Among these components, the humble bushing bearing stands out as a silent hero, playing an indispensable role in ensuring seamless operations.

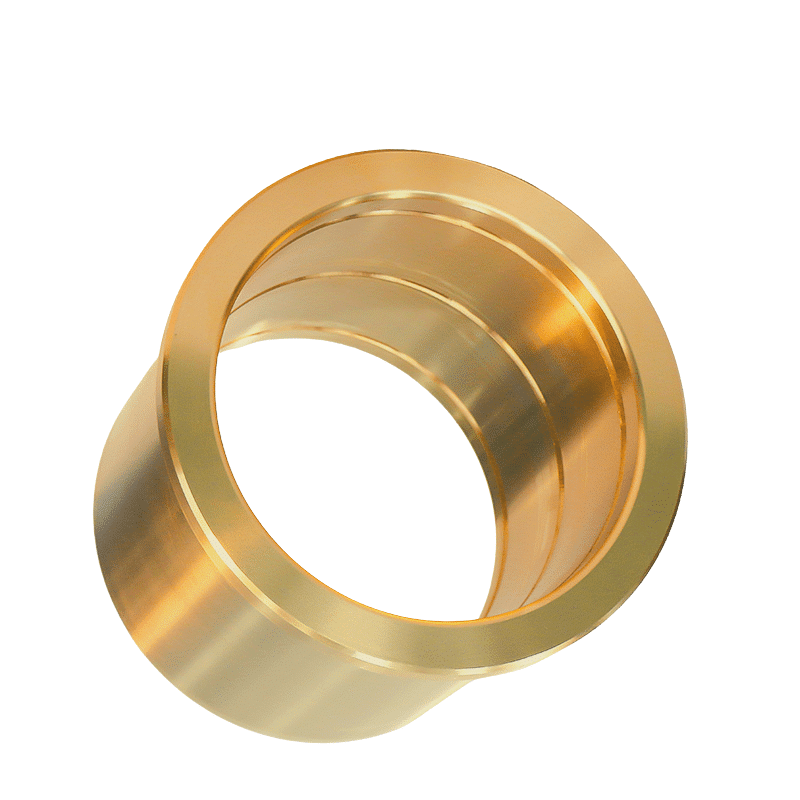

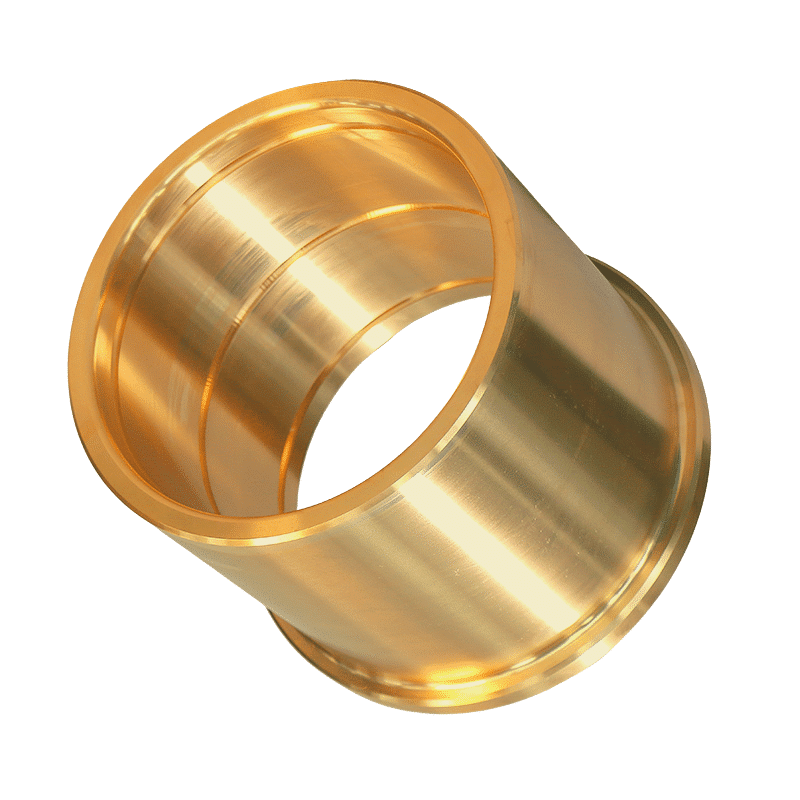

High-Performance Sliding Bushing Bearings:

Designed with precision and crafted for durability, high-performance sliding bushing bearings are the go-to choice for mining machinery. These bearings:

- Offer minimal friction, ensuring that machinery operates smoothly.

- Are made of materials that can withstand the abrasive environment of mining, from dust-laden atmospheres to chemically aggressive scenarios.

- Provide superior load-bearing capabilities, perfect for heavy-duty mining operations.

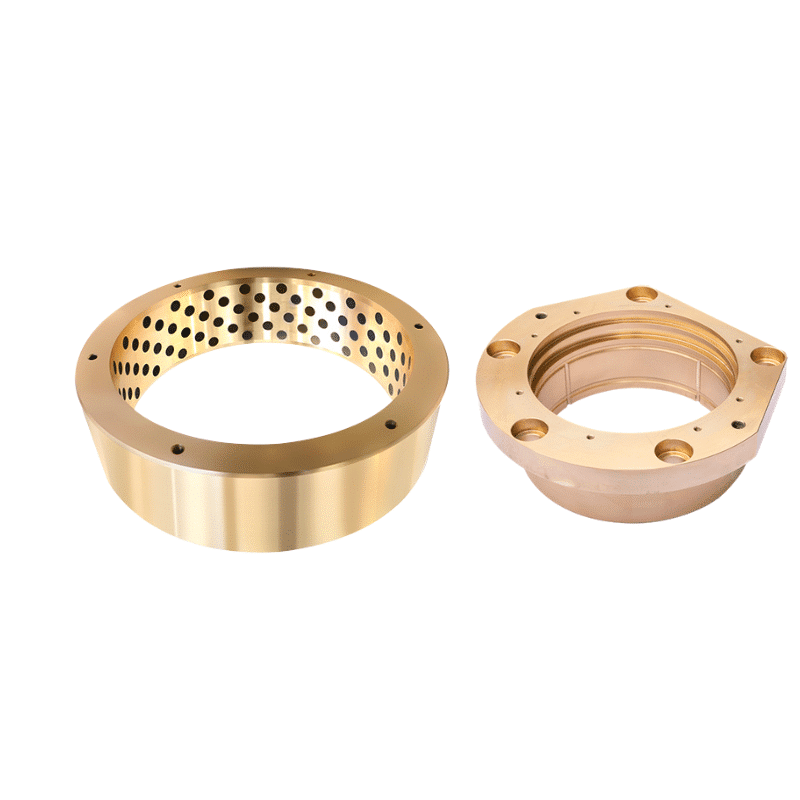

Greased Bronze Bushings: A Cut Above the Rest

Bronze, known for its excellent wear resistance and anti-friction properties, is an ideal material for bushings in the mining sector. But when these bronze bushings are greased, their performance is elevated to the next level:

- Lubrication: The grease in the bushings ensures a consistent lubrication layer, reducing wear and prolonging the bushing’s life.

- Temperature Resistance: Greased bronze bushings can operate effectively in a range of temperatures, from the cold depths of underground mines to the heat of open-pit operations.

- Contaminant Shielding: The greased layer acts as a barrier, preventing contaminants like dust and grit from affecting the bearing’s performance.

Engineered for Harsh Environments:

What sets these bushing bearings apart is their design, tailored specifically for the challenges of the mining world:

- Corrosion Resistance: Materials and lubricants are chosen to resist the corrosive agents often found in mining environments.

- High Load Capacity: Recognizing the heavy-duty nature of mining operations, these bushings are crafted to handle substantial loads without faltering.

- Longevity: In an industry where downtime can be costly, these bushing bearings are designed for extended service life, reducing the need for frequent replacements.

In Conclusion:

The mining industry, with its unique challenges and demanding environments, requires components that are both robust and reliable. High-performance sliding bushing bearings, especially the greased bronze variants, have proven to be invaluable assets in this context. Engineered specifically for the harshest conditions, these bushings ensure that mining operations continue unabated, driving productivity and ensuring safety. For mining professionals, these aren’t just components; they’re the bedrock of efficient operations.

Bushings and Bearings for Heavy Construction and Mining: A Deep Dive into Tribological Solutions

The mining sector, an intricate web of machinery and human effort, is the backbone of our modern world, supplying raw materials that fuel our daily lives. Whether it’s the roads we travel, the vehicles we drive, or the medical equipment that saves lives, the trace of mining’s output is evident. However, in the backdrop of this colossal industry, there’s a component that often goes unnoticed, yet is critical: the bushing bearing.

Mining’s Deepening Challenges

As global demand for resources surges, mining operations have been forced to dig deeper, searching for higher-grade ores. This deeper excavation leads to increased energy costs, owing to:

- The need for enhanced ventilation and air conditioning due to deeper mines.

- Rising health risks from pollution and emissions, necessitating stricter regulations.

- The environmental hazards presented by mine waste.

The Four Pillars of Mining Techniques

- Underground Mining: Often costlier, this is essential for reaching deep-seated deposits.

- Surface Mining: Suitable for shallower, less valuable deposits.

- Placer Mining: A method to extract valuable metals from river sediments.

- In-situ Mining: Used mainly for copper and uranium extraction, this involves dissolving naturally solid-state minerals.

The Role of Bushings and Bearings

These mining techniques, each with its set of challenges, demand equipment that’s robust, durable, and efficient. Enter the realm of tribological solutions, where bushing bearings crafted from a variety of materials, from composite to metal-polymer, play a pivotal role.

Composite Bushing Bearings: These high-precision bearings, reinforced with fiber, can be machined for superior application accuracy. They offer a maintenance-free alternative to traditional greased bronze, with excellent resistance to shock, misalignment, and substantial load capacity.

Metal & Bimetal Bearings: Ranging from thick-walled monometal bearings with embedded solid lubricants like graphite to case-hardened steel bearings suited for lubricated applications, these are the heavy lifters of the mining world.

Metal-Polymer Bearings: These bearings, such as the Metal-Polymer hydrodynamic composite variant, provide marginal lubrication for optimal wear and chemical resistance. Another version, the POM composite layer, is grease-lubricated and offers exceptional wear performance under high loads and temperatures.

Collaborative Engineering for Superior Solutions

Our commitment goes beyond just providing products. By partnering with us early in the design phase, you unlock reliable, cost-effective solutions with faster lead times. With our wide array of bearing solutions, all ROHS compliant and eco-friendly, innovation is at your fingertips.

The Unwavering Promise of Performance

Our bearings are tailor-made for the adversities of mining:

- Maintenance-Free Operation: Especially vital in environments where routine maintenance is challenging.

- Resistance to Harsh Environments: From corrosive atmospheres to abrasive surroundings.

- Eco-Friendly Solutions: Lead-free bearings that not only ensure seamless operation but also align with global environmental regulations.

Final Thoughts

The mining industry, with its challenges and demands, requires partners that understand its depth and breadth. Our tribological solutions, from bushing bearings to innovative materials, are geared towards ensuring that mining, the very heart of our civilization’s progress, beats strong and uninterrupted.

The Premier Supplier of Bushings and Bearings for Heavy Construction and Mining

In the massive world of heavy construction and mining, machinery is expected to perform at peak levels regardless of the punishing environments they are placed in. This makes the choice of components, particularly bushings and bearings, absolutely crucial. For those in the know,

viiplus.com stands out as the gold standard for supplying these pivotal parts.

Why Choose viiplus?

-

Industry Expertise: With years of experience under our belt, we understand the unique challenges faced by the heavy construction and mining sectors. This expertise allows us to offer solutions that are tailored to meet the specific demands of these industries.

-

Quality Assurance: Our bushings and bearings are manufactured under strict quality control guidelines. We source the highest-grade materials, ensuring longevity and optimal performance even in the most challenging conditions.

-

Wide Range of Products: From tribological sliding bushings suitable for high-load applications to self-lubricating bearings designed for maintenance-free operation, our catalog covers a vast array of products tailored for every need.

-

Innovative Solutions: We don’t just supply; we innovate. Our R&D team is continually pushing the boundaries, developing new materials and designs that set the benchmark in the industry.

-

Global Reach with a Local Touch: With our global distribution network, we can supply products anywhere in the world. Yet, our local representatives ensure personalized service, understanding the unique needs of each region.

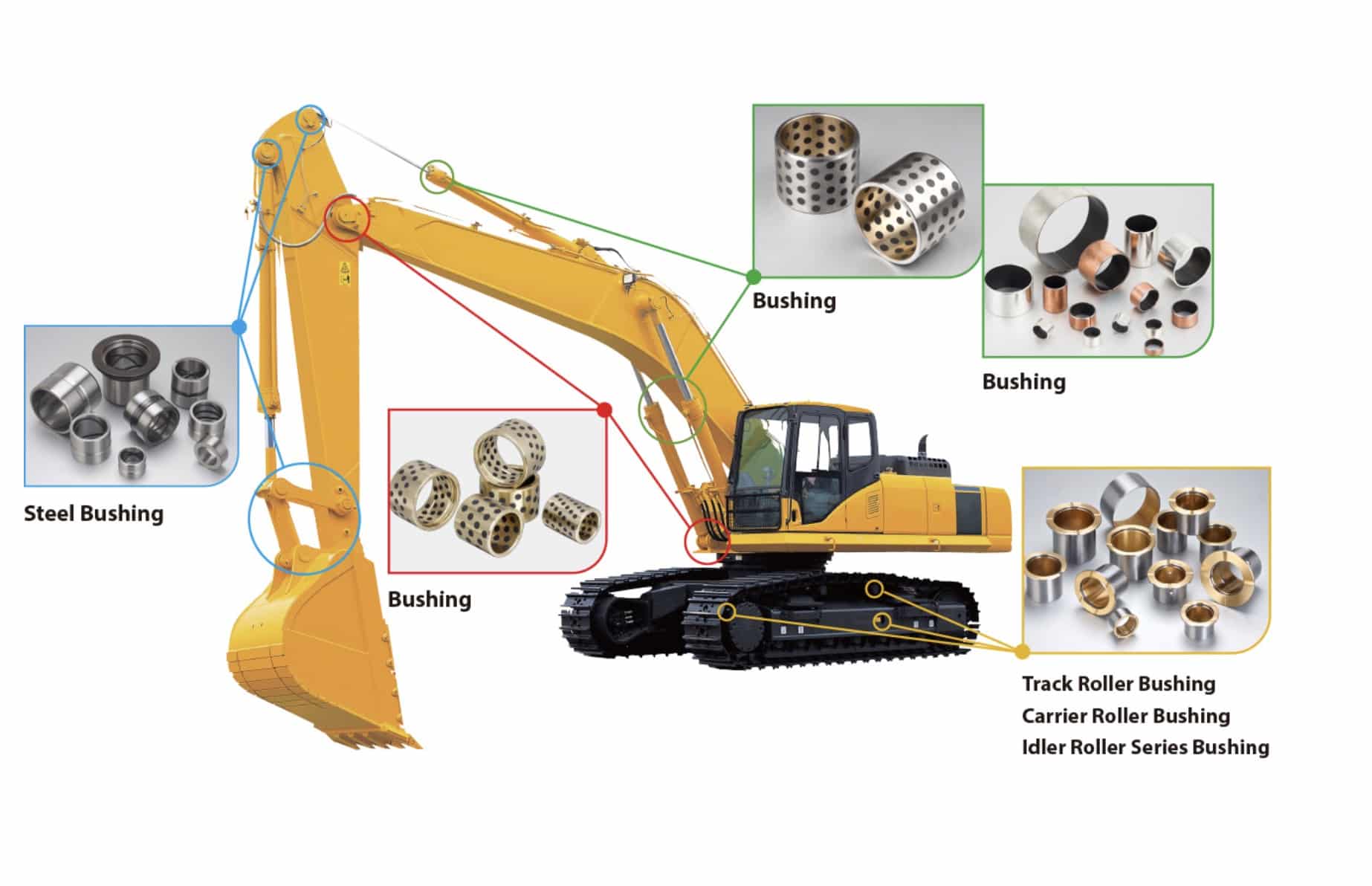

Applications in Heavy Construction and Mining

Our products are trusted by industry leaders for various applications, including:

-

Excavators and Earthmovers: Our bushings provide smooth articulation for the boom, arm, and bucket joints, ensuring efficient digging and material handling.

-

Loaders and Dozers: The load-bearing capacities of our bearings make them ideal for these heavy machines, ensuring they operate seamlessly even under immense stress.

-

Drilling Rigs and Mining Trucks: In the punishing environment of mines, our bearings ensure that these machines can operate without frequent maintenance, reducing downtime.

Environmentally Conscious

In an era of heightened environmental awareness, we are proud to offer products that are not only lead-free and RoHS compliant but also designed for reduced energy consumption. By choosing our products, you’re making an eco-friendly choice without compromising on performance.

Collaboration and Custom Solutions

We believe in working closely with our clients. By understanding your unique challenges and requirements, we can provide custom solutions, ensuring optimal performance and cost-effectiveness.

Final Thoughts

When it comes to the demanding world of heavy construction and mining, you need components you can rely on. With viiplus.com as your partner, you’re not just choosing a supplier; you’re choosing a partner dedicated to ensuring your machinery operates at its best, project after project.