idler bushing design

Idler Pulley Bushing Bearing Manufacturer & Supplier

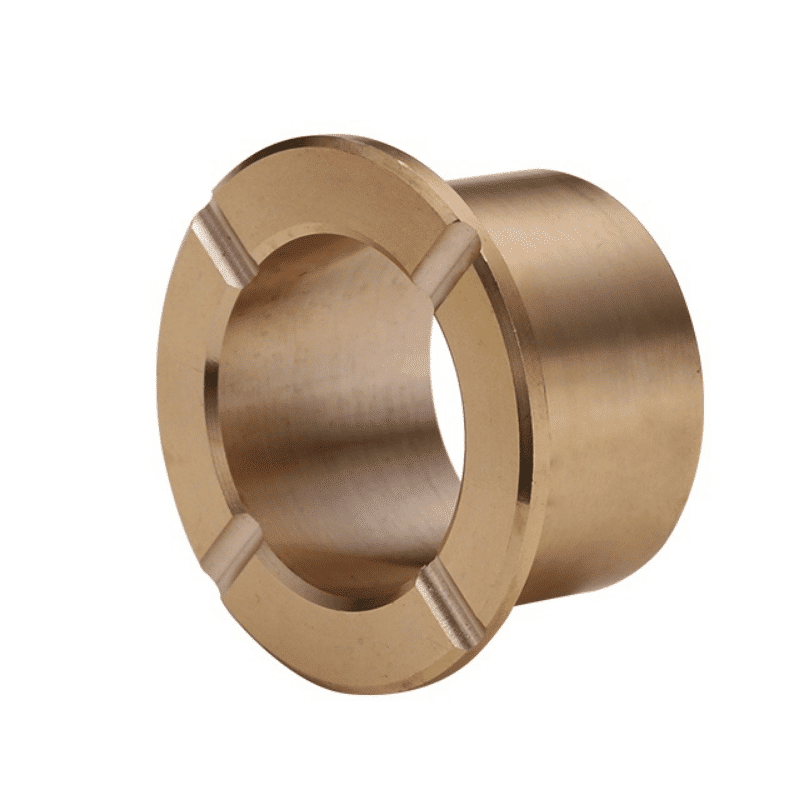

Bulldozer Front Idler Bushing

Bronze Idler Arm Bushings, For Industrial, The main production and sales of bulldozer excavator four wheels and one belt and other machinery parts, supporting wheel, guide wheel and other chassis assembly, production and processing and sales of self-lubricating bearing parts, production and export of other construction machinery parts.

The company has independent import and export rights of self-lubricating copper bushings, idler bushing, bimetal bearing, sleeve bushing. The company’s business scope covers the whole world, and the bushing bearings products cover the international markets of Eastern Europe, East Asia and South America.

Committed to build a professional supplier and exporter of construction machinery bearings. Bulldozer and excavator bushings, bogie assembly bushing, supporting wheel bushings, guide wheel bushings, brass bushings and other products. High Performance Bushing Bearings For Automotive Applications … main shaft bushing and idler bushing, …

Track roller bushing bearing, Your Bearing Solutions Provider

Beautifully crafted leather products.

Track rollers bushing. Bronze bearing for track rollers are self-lubricating metallic thick-walled bushing. In addition to high radial forces, the roller bushing can also support axial forces in both directions. The bushing have a flange or cylindrical bushing type. Tackling OEM bushing challenges with innovative solutions and high-quality bushing bearing products for many years. Idler bushings supplier, The bushings may be small, but without them, your product won’t work. We know how critical it is for you to have the right bushing parts at the right time, all the time. That’s why we specialize in providing solutions for bearings and related bushing components. From the supply of self-lubricating bearings to engineering and design, we’ve got your back.

What is track roller

Beautifully crafted leather products.

Track roller bushing and bronze bearing supplier, idler bearing.

The track roller is used to support the weight of the tractor while rolling on the track rails (rail links) or track plates, and it is also used to restrain the track to prevent lateral slippage. It is also used to restrain the tracks and prevent them from slipping sideways. The supporting wheel is often in mud, water and dust, and is subject to strong impact, so it requires a reliable seal and wear-resistant rims.

Cast Bronze Bushings with Solid Lubricant Inserts, idler bearing,cast bronze bearings & idler bearing bushings are ideal for maintenance-free & heavy duty applications. Available as cylindrical bushing, flange bearings, and groove type.

We supply bronze bushing & idler bushings tailored to your needs.

High performance auto parts bearing products for self-lubricating bearings, metal bearing solutions, auto spare parts

Any feature that contributes to the safety and comfort of modern automobiles relies on selecting the ideal automotive bearing parts to meet stringent standards of design, function and application performance. We offer a wide range of self-lubricating bearing solutions for automotive accessory market applications.

Even in the most demanding environments, customers benefit from the low friction, high wear resistance and superior reliability of bearings for industry applications.

- Steering system: steering column bushings, gear pump bearing bushings

- Transmission: rear output shaft bushings, main shaft and reverse idler bearings, clutch bearings, pump bushings, gear bushings…

- Seats: Bearing replacements for seat recliners and height adjuster devices

- Brake system

- Hinges: door, trunk and hood hinges, door checkers

- Engine management: water and oil pump bearings, belt tensioner bushings, pulley dampers

- Bracket and shock absorber bushings

We provide excellent customer service and technical support for customer-specific automotive self-lubricating bearing designs at the global and local levels. Globally, we provide self-lubricating bearings for virtually all of the automotive and trucking industries. Our wide range of self-lubricating bearing materials ensure the functionality and performance of bushing assemblies. Our customers benefit from the reliability of our bearing bushing products due to our secure supply chain that provides ready-to-use local supplies.

Our strengths offer. A wide range of high performance self-lubricating bearing and idler bushing materials and solutions to meet the most demanding applications. Our compact and lightweight solutions reduce fuel consumption and thus emissions. Continuous innovation of technically superior products, systems and tools puts us at the forefront of high performance self-lubricating bearing technology. Comprehensive customer support benefits from our application specialists who provide technical support and customer-specific bearing designs.

Idler bushings

Idler bushings are a type of bearing used to support idler rollers in various types of machinery and equipment. These bushings are designed to provide a low-friction surface for the idler roller, reducing wear and extending the life of the equipment.

Idler bushings are typically made from high-strength materials, such as steel or bronze, to withstand heavy loads and operate in a wide range of temperatures and environments. They may also be coated or treated to improve their corrosion resistance and reduce wear.

One of the key benefits of idler bushings is their ability to reduce friction and wear on the idler roller, which can help to extend the life of the equipment and reduce maintenance requirements. This is especially important in applications where the idler roller is subject to heavy loads and frequent use.

Idler bushings are commonly used in a variety of industries, including manufacturing, construction, mining, and agriculture. They are used in equipment such as conveyors, cranes, excavators, and other heavy machinery.

When selecting idler bushings, it’s important to consider factors such as the load capacity of the equipment, the temperature and environmental conditions of the application, and the desired level of corrosion resistance. Proper installation and maintenance are also important to ensure the optimal performance and longevity of the idler bushings.

In summary, idler bushings are a critical component in many types of machinery and equipment, providing a low-friction surface for idler rollers and reducing wear and maintenance requirements. They are available in a range of materials and coatings to meet the specific needs of different applications, and proper selection and installation are important to ensure optimal performance and longevity.

Providing self-lubricating bushing bearing solutions and supplies.

In recent years, the operational requirements of automotive equipment have placed greater demands on bearing performance. Our range of lead-free bearing materials offers enhanced performance to meet the most stringent performance requirements, offering significant advantages over rolling element bearings where space and weight are limited, or where high loads and oscillating movements can cause damage.

- Self-lubricating bearings offer many advantages

- Long life, reliability and smooth operation

- High wear resistance

- Self-lubricating properties

- Low coefficient of friction and breakaway torque with no stick-slip effect

- Compatible with most standard oils and lubricants

- High precision and dimensional stability

- High standards of quality and environment

- Our environmentally friendly lead-free bearings reduce installation, operation and maintenance costs

- We are committed to product design, development, and production.

- Outperforming the competition

We are able to offer our customers viable alternatives to OEM custom self-lubricating bearings. Our experts can help develop designs and provide samples.

To meet the specific application needs of our customers, we offer a large selection of standard or custom bearings. Our self-lubricating bearings offer excellent wear and friction performance over a wide range of loads, speeds and temperatures, and self-lubricating materials offer good resistance to chemicals, cavitation, flow erosion and fatigue. Our bimetallic bearings give customers an optimized bearing design that simplifies assembly and reduces development time.

Providing Bulldozer Front Idler Bimetal Bushing

Bimetal bearing bushes are a type of bearing commonly used in bulldozers for applications such as the front idler bushing. These bearings are made from two different materials, typically a steel backing and a layer of low-friction material such as bronze or PTFE.

The steel backing provides strength and support for the bearing, while the low-friction layer provides a smooth surface for the idler to rotate on, reducing wear and extending the life of the component.

Bimetal bearing bushes are designed to withstand heavy loads and operate in a wide range of temperatures and environments, making them ideal for use in bulldozers and other heavy machinery. They offer excellent wear resistance, low friction, and long service life, which is essential for components such as the front idler bushing that are subject to heavy use and exposure to harsh conditions.

In addition, bimetal bearing bushes offer a cost-effective solution compared to other types of bearings, while still providing excellent performance and durability.

Proper selection and installation of bimetal bearing bushes are important to ensure optimal performance and longevity. It’s essential to consider factors such as the load capacity of the equipment, the temperature and environmental conditions of the application, and the desired level of corrosion resistance when selecting bimetal bearing bushes for use in bulldozers.

In summary, bimetal bearing bushes are a reliable and cost-effective solution for front idler bushings in bulldozers. They provide excellent wear resistance, low friction, and long service life, and are designed to withstand heavy loads and operate in a wide range of temperatures and environments. Proper selection and installation are essential to ensure optimal performance and longevity for this critical component.

Bimetal Bushing Material

The material alloy chart table for bimetal bushings used in bulldozer front idler bushings is an important reference tool for selecting the right material for the specific application. Here is a general overview of some of the commonly used materials and their properties:

Steel backing: The steel backing provides strength and support for the bearing. It is typically made from high-quality carbon steel, which provides good corrosion resistance and high strength.

Bronze layer: The bronze layer provides a low-friction surface for the idler to rotate on, reducing wear and extending the life of the component. It is typically made from a high-quality copper alloy, such as C93200 or C93700, which provides good wear resistance, high load capacity, and excellent corrosion resistance.

PTFE layer: Some bimetal bushings may also include a layer of PTFE, which provides a self-lubricating surface that eliminates the need for external lubrication. PTFE is a high-performance polymer that offers excellent wear resistance, low friction, and resistance to high temperatures and corrosive environments.

When selecting the right material for a specific application, it’s important to consider factors such as the load capacity, operating temperature, and environmental conditions of the application. The material alloy chart table provides a reference point for selecting the best material for the specific needs of the application.

In summary, bimetal bushings used in bulldozer front idler bushings typically consist of a steel backing and a layer of bronze or PTFE. These materials provide excellent wear resistance, low friction, and long service life, making them ideal for use in heavy machinery such as bulldozers. The material alloy chart table is an important reference tool for selecting the right material for the specific needs of the application.

OEM custom self-lubricating bearings & roller bushing

Self-lubricating bearings are an important component in many types of machinery and equipment, including bulldozers. One critical application for self-lubricating bearings in bulldozers is the front idler bushing.

The front idler bushing is responsible for supporting the weight of the track chain and helping to maintain tension in the track system. This component is subject to heavy loads, frequent use, and exposure to harsh environmental conditions, making it essential that it is made from high-quality materials and designed for long-lasting durability.

Self-lubricating bearings are an ideal solution for front idler bushings in bulldozers. These bearings are designed to reduce friction and wear, while also providing a low-maintenance solution that can withstand heavy loads and operate in a wide range of temperatures and environments.

Self-lubricating bearings are typically made from a composite material that includes a combination of polymers, such as PTFE, and other materials that provide strength and durability. This composite material eliminates the need for external lubrication, reducing maintenance requirements and extending the life of the component.

In addition, self-lubricating bearings offer excellent resistance to wear and corrosion, which is important for components that are subject to heavy loads and exposure to harsh environmental conditions. This helps to ensure long-lasting performance and reliability, reducing downtime and maintenance costs.

Self-lubricating bearings are an excellent solution for front idler bushings in bulldozers. They provide a low-maintenance, durable, and reliable solution that can withstand heavy loads and operate in a wide range of temperatures and environments. Proper selection and installation of self-lubricating bearings are essential to ensure optimal performance and longevity for front idler bushings in bulldozers.

We are able to offer our customers viable alternatives to OEM custom self-lubricating bearings. Our experts can help develop designs and provide samples.

To meet the specific application needs of our customers, we offer a large selection of standard or custom bearings. Our self-lubricating bearings offer excellent wear and friction performance over a wide range of loads, speeds and temperatures, and self-lubricating materials offer good resistance to chemicals, cavitation, flow erosion and fatigue. Our bimetallic bearings give customers an optimized bearing design that simplifies assembly and reduces development time.

self-lubricating bearing customization services

It’s time to standardize for success. With our self-lubricating bearing customization services, we’ll help you address the basics of standardized bearings, such as self-lubricating bearing, idler bushings, or bushing product rationalization and bushing brand substitution, so you can start running a leaner, more functional workplace. From bushing basics to metal finishing, our engineering will analysis your bushing requirement for manufacturing industry. But, don’t worry. We’ll teach you exactly what you need to get work done accurately and efficiently. Custom size bushing are available in both size and material. Self-lubricating bearing development tooling and assembly applies. Design and manufacture self-lubricating bearings. Our team of experts will work side-by-side with you to help optimize your bearing assembly process for success, as well as recommend styles and materials for self-lubricating bearings.

ENGINEERING & QUALITY BUSHING

We are a team of experienced, cross-functional engineers in bearing manufacturing and idler bushings design, backed by a development department for self-lubricating bearings and a quality lab. Whether you have a new bushing part to design, efficiency to improve, or a problem area to solve, we offer a range of engineered self-lubricating bearing and idler bushings customized services to help put your business at the forefront of your industry.

Bushing Technology

We take pride in our work. That’s why we offer the high quality Bushings solutions and services for our customers.