C86200 and C86300 Manganese Bronze Bushings

C86200 and C86300 Manganese Bronze Bushings

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

C86200 and C86300 Manganese Bronze Bushings

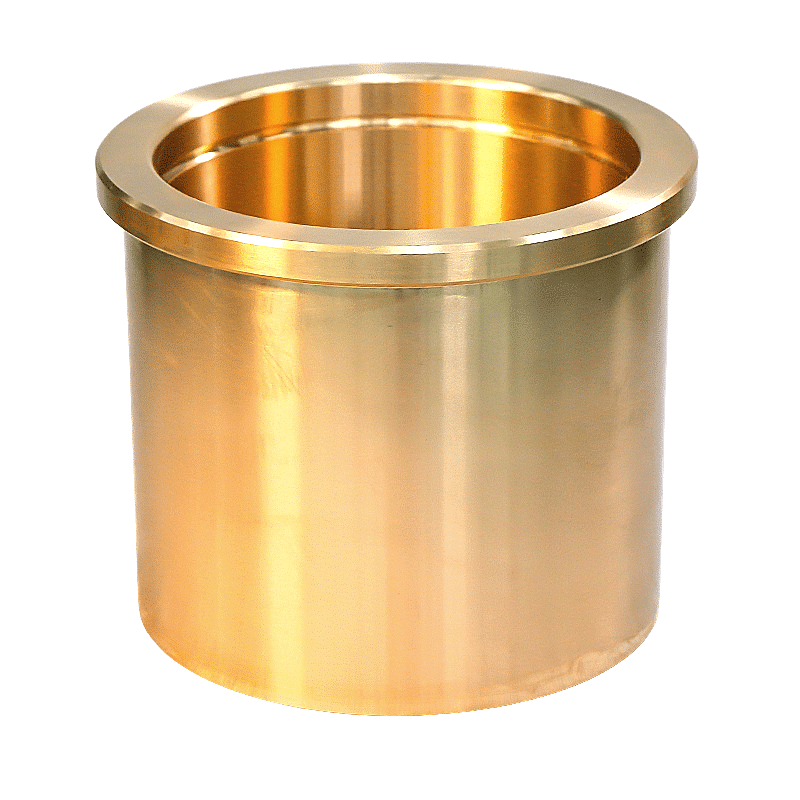

Flanged C86200 and C86300 Manganese Bronze Bushings Plain Bearings – Metallic, Graphite Impregnated Brass, Metric

Graphite-impregnated bronze bushings combine the best of both worlds – the strength and resilience of bronze and the superior lubricating properties of graphite. They offer outstanding durability, reliability, and performance in a wide range of applications. Whether you’re dealing with high-load, high-temperature, or corrosion-prone environments, these bushings can be a valuable addition to your mechanical assembly.

Harness the Strength of C86200 and C86300 Manganese Bronze Bushings

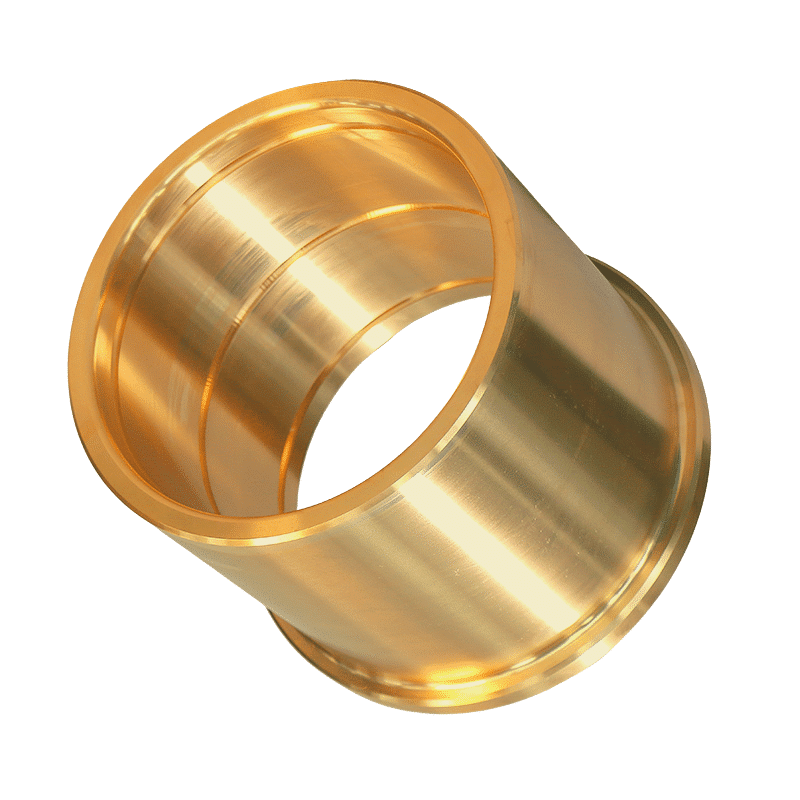

Straight Linear Plain Bearings – Metallic, Graphite Impregnated Brass C86200 and C86300 Manganese Bronze Bushings, I.D. F7, Standard/Thin Wall, Metric

Bushings play a crucial role in reducing friction and wear in various machinery and equipment, contributing significantly to their smooth and efficient operation. One of the preferred materials for crafting high-performance bushings is manganese bronze, specifically the C86200 and C86300 alloys. Let’s delve into their features, benefits, and why they make a great choice for bushings.

Understanding C86200 and C86300 Manganese Bronze

C86200 and C86300, both part of the high-strength manganese bronze family, are copper-based alloys known for their superior strength, durability, and resistance to wear. Their excellent mechanical properties result from the high content of manganese and aluminum, combined with iron, zinc, and a small percentage of lead.

C86200 Manganese Bronze – Also known as “High-Strength Yellow Bronze,” this alloy is composed of approximately 64% copper, 24% zinc, 5% manganese, 3% aluminum, 1% iron, and a small amount of lead. It is known for its superior load-bearing properties and wear resistance.

C86300 Manganese Bronze – Also known as “High-Strength Manganese Bronze,” this alloy consists of approximately 63% copper, 25% zinc, 6% aluminum, 3% manganese, and 3% iron. It has even higher strength and hardness than C86200, making it ideal for applications involving heavy loads and rough operating conditions.

C86200 and C86300 Manganese Bronze Bushings

The inherent properties of C86200 and C86300 manganese bronze make them ideal for crafting bushings. Their robustness and resistance to wear provide durability, while their impressive load-bearing capacity and high coefficient of friction ensure effective operation even under heavy-duty applications.

C86200 Bronze Bushings – These bushings offer excellent mechanical properties, good machinability, and corrosion resistance. They are ideally suited for applications with medium loads and speeds.

C86300 Bronze Bushings – These bushings, with their higher strength and hardness, are suited for more demanding applications. They can handle high loads and difficult operating conditions while providing excellent resistance to wear.

Key Benefits of C86200 and C86300 Manganese Bronze Bushings

1. High Strength and Durability: These bushings are designed to withstand tough conditions and heavy loads, providing long service life.

2. Excellent Wear Resistance: The high hardness of these manganese bronze alloys translates to exceptional resistance to wear and tear.

3. Good Corrosion Resistance: Both C86200 and C86300 show good resistance to corrosion, further enhancing their durability.

4. Reduced Friction: Thanks to their high coefficient of friction, these bushings help to minimize friction between moving parts, ensuring smooth and efficient operation.

C86200 and C86300 are high-strength manganese bronze alloys widely used for bushings and bearings due to their excellent strength, durability, and wear resistance.

Chemical Composition

C86200 Manganese Bronze

| Element | Percentage (%) |

|---|---|

| Copper (Cu) | 60 – 66 |

| Zinc (Zn) | 22 – 28 |

| Aluminum (Al) | 5.0 – 7.0 |

| Iron (Fe) | 2.0 – 4.0 |

| Manganese (Mn) | 2.5 – 5.0 |

| Lead (Pb) | 0.20 (Max) |

| Nickel (Ni) | 1.0 (Max) |

C86300 Manganese Bronze

| Element | Percentage (%) |

|---|---|

| Copper (Cu) | 60 – 66 |

| Zinc (Zn) | 22 – 28 |

| Aluminum (Al) | 5.0 – 7.0 |

| Iron (Fe) | 2.0 – 4.0 |

| Manganese (Mn) | 2.5 – 5.0 |

(Note: All values are approximate and can vary based on the specific requirements of the application.)

Technical Data

C86200 Manganese Bronze

| Property | Value |

|---|---|

| Tensile Strength | 620 MPa (Min) |

| Yield Strength (0.5% extension under load) | 290 MPa (Min) |

| Elongation (in 50mm) | 14% (Min) |

| Brinell Hardness | 170-210 HB |

| Machinability Rating | 20% |

C86300 Manganese Bronze

| Property | Value |

|---|---|

| Tensile Strength | 758 MPa (Min) |

| Yield Strength (0.5% extension under load) | 427 MPa (Min) |

| Elongation (in 50mm) | 14% (Min) |

| Brinell Hardness | 225 HB (Min) |

| Machinability Rating | 20% |

(Note: All values are approximate and can vary based on the specific requirements of the application.)

These alloys are ideally suited for applications that demand high strength and heavy load-bearing capacity, such as heavy-duty machinery and industrial components. Their excellent wear resistance also makes them suitable for high-impact and abrasive conditions.

Wrapping Up

Whether you’re dealing with heavy machinery, automotive parts, or hydraulic equipment, the strength and resilience of C86200 and C86300 manganese bronze bushings make them a great choice. These bushings not only enhance the performance of your equipment but also increase its lifespan, leading to improved productivity and reduced maintenance costs. Always consider the specific needs of your application when selecting the right bushing material.

C93200 Tin Bronze Bushings SAE 430B

SAE 430B, also known as C93200 or bearing bronze, is a popular alloy used in the manufacturing of bushings and bearings due to its excellent properties such as superior wear resistance, good hardness, and strength. Here is the standard chemical composition of SAE 430B (C93200) and some key technical data:

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Copper (Cu) | 81 – 85 |

| Tin (Sn) | 6.3 – 7.5 |

| Lead (Pb) | 6.0 – 8.0 |

| Zinc (Zn) | 2.0 – 4.0 |

| Phosphorus (P) | 0.15 (Max) |

| Iron (Fe) | 0.20 (Max) |

| Nickel (Ni) | 1.0 (Max) |

| Antimony (Sb) | 0.35 (Max) |

| Aluminum (Al) | 0.005 (Max) |

| Silicon (Si) | 0.005 (Max) |

| Sulfur (S) | 0.08 (Max) |

(Note: All values are approximate and can vary based on the specific requirements of the application.)

Technical Data

| Property | Value |

|---|---|

| Tensile Strength | 220 MPa (Min) |

| Yield Strength (0.5% extension under load) | 110 MPa (Min) |

| Elongation (in 50mm) | 10% (Min) |

| Brinell Hardness | 60-85 HB |

| Machinability Rating | 80% |

| Soldering | Excellent |

| Brazing | Good |

| Oxyacetylene Welding | Not Recommended |

| Gas Shielded Arc Welding | Not Recommended |

| Coated Metal Arc Welding | Not Recommended |

| Resistance Welding | Not Recommended |

(Note: All values are approximate and can vary based on the specific requirements of the application.)

SAE 430B (C93200) is a high leaded tin bronze that is suitable for applications requiring moderate load and speed. Its properties make it highly versatile and it can be used for various purposes from bushings and bearings to hydraulic cylinder parts and machine tool components. The addition of lead makes it easy to machine, while the tin increases the toughness of the alloy and assists in resisting corrosion.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally