JF800 bimetallic bearings

JF800 bimetallic bearings

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

JF800 bimetallic bearings

Metal & Bimetal – Bronze Bearings – Steel Bushings, bimetallic bearings

The JF800 bimetal bushing is a type of bearing that consists of a steel backing with a sintered lead bronze sliding layer, specifically CuPb10Sn10 or CuSn6Zn6Pb3. This material is designed to provide high resistance to fatigue strength, load capacity, and good corrosion resistance, making it suitable for applications with middle to high loads and low to high speeds. The JF800 bimetal bushing is particularly recommended for use in internal combustion engines, connecting rod bushings, and other mechanical applications where heavy loads and challenging conditions are present.

Bimetallic Bearings and Bushings High-Performance Bearings and Bushings Featuring Bimetallic Bearings and Bushings Composed of SAE 49 – CuPb24Sn Composed of SAE 792 – CuSn10Pb10

Bimetallic Bearings and Bushings Overview: Bimetallic bearings and bushings serve as self-lubricating components ideal for applications requiring medium to high loads and speeds. Through advanced manufacturing techniques, these bearings and bushings are engineered to operate efficiently under various lubrication conditions, making them versatile for a wide range of uses. They are commonly employed in automotive engines, gear pumps, and lifting machinery, showcasing their adaptability and reliability in demanding environments.

Our manufacturing capabilities include an extensive selection of high-precision bimetallic bushings. These bushings are available with ball indents and surfaces in both semi-finished and finished dimensions, catering to specific customer requirements. The diameters range from metric size and inch size, tailored to fit precise specifications. Additionally, we offer bushings with optimized geometries on the sliding surfaces, enhancing lubrication circulation for superior performance.

Bimetal Bushing Material JF800 bimetallic bearings Lining: CuPb10Sn10 , China Bimetal Bearing – High-Quality Price Ratio, Bimetal Plain Bearings to Standard SAE 792

Engine Bearings, Bushing and Thusrt Washers

We specialize in producing bimetallic bearings, specifically offering the JF-800 bimetallic strip with a CuPb10Sn10 lining, as well as plain shaft bushings tailored for the tractor industry. Our bimetallic bearings, made from various alloys, are essential components in plain bearing surfaces, typically serving as self-lubricating materials. However, we can provide alternative alloys upon request. These materials are available in different forms, including ingots for centrifugal or static casting, or as welding rods for repair and joining applications. Notably, our tin-based alloys are environmentally friendly, being lead-free and boasting superior technical characteristics.

Our product range includes:

- Bimetallic Bearing Plain Shaft Bushings

- Centrifugal Casting Services

Centrifugal casting is renowned for its premium quality, especially suited for bearings that don’t require thick liners. For those with thicker liner needs, other methods like static casting may be more advantageous.

Static Casting Expertise: Our team is proficient in static casting, a method where alloys solidify from the bottom upwards, ensuring a strong bond from the inside out.

Welded Linings: Our welding expertise ensures top-quality linings, comparable to those achieved through centrifugal casting, with no restrictions on the alloy, whether tin- or lead-based.

We understand that wear and damage to rotors, crankshafts, and pistons can lead to significant operational losses. By offering expert repair and fabrication services, including the manufacturing of bushings and bearings, we aim to reduce your downtime and save you money.

Bimetallic Bushings copper Lead Alloy,

- Material SAE 792 – CuSn10Pb10

- Copper Lead Alloy

- SAE 792 / SAE 783

COMPOSITION

Steel Backing and Leaded Bronze Overlay

Steel + CuPb10Sn10 with indents

| Material: | Copper-plated steel backing, lead bronze layer (CuPb10Sn10) |

JF800 bimetallic bearings are composite bearings that combine a steel base with a sintered copper alloy layer, tailored for various applications through different material compositions such as CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, and CuSn8Ni. This copper layer can be customized with oil grooves, holes, and other features to meet specific lubrication requirements, ideal for situations where maintenance is challenging or operating conditions are harsh.

These bearings excel in heavy-duty environments like vehicles, construction machinery, and agricultural equipment due to their high load-bearing capability and superior fatigue resistance at elevated temperatures. They are versatile, functioning well under a wide spectrum of speeds and loads.

The various copper alloy compositions offer distinct advantages:

- CuPb10Sn10 is optimal for high-speed, high-load scenarios with its excellent fatigue strength and load capacity.

- CuPb6Sn6Zn3 strikes a balance between strength and corrosion resistance for medium-load situations.

- CuPb24Sn4 suits medium-speed, medium-load environments with its robust fatigue strength and load capacity.

- CuPb30, with high lead content, excels in applications experiencing intermittent or oscillating movements due to its outstanding conformability and embeddability.

- AlSn20Cu is preferred for its anti-fatigue performance, load capacity, and corrosion resistance, making it ideal for hydraumatic applications and internal combustion engine bearings.

- CuSn8Ni, known for its high wear resistance, is commonly used in high-speed engine bearings, connecting rod bushings, and rocker arm bush.

These Bushing bearings are designed for lubricated use to boost their efficacy and durability. The steel backing ensures stability, supports loads, and aids in heat dissipation. Available in various forms like cylindrical bushes, flanged bushes, thrust washers, and sliding plates, JF800 bearings can be customized to meet specific needs.

When choosing a JF800 bimetallic bearing, it’s crucial to account for the application’s specific load, speed, temperature, and lubrication requirements. Consulting with experts in bimetallic bearings can guide selecting the most suitable material and design for optimal performance.

Bimetallic bearings, often referred to as bimetal bushes, are specialized composite bearings composed of two distinct metal layers fused together. The exterior layer is usually crafted from a bronze material known for its low-friction characteristics, while the interior layer is constructed from steel, providing enhanced strength and durability. These bearings are designed to outperform traditional single-metal bearings in applications that demand high load-bearing capacity and are subject to intense stress.

The structure of bimetal bushes Bushing typically features a steel base that delivers structural strength and stability, coupled with a lead bronze alloy surface that excels in reducing friction and wear. This dual-layer construction not only supports substantial loads and absorbs shocks effectively but also offers remarkable resistance to wear and corrosion. Bimetal bushes find widespread application in various sectors, including automotive engines, gearboxes, agricultural machinery, and other areas where heavy-duty performance is essential

Manufacturers provide an array of bimetal bushing compositions, including CuPb10Sn10, CuPb24Sn4, CuPb30, and AlSn20Cu, to cater to diverse operational needs. Each material variant is selected for its unique advantages, such as enhanced fatigue strength, load-bearing capability, shock resistance, and lubrication efficiency, making them adaptable to a range of environmental conditions and operational demands.

Overall, bimetallic bearings Bushing represent a robust and adaptable solution, marrying the structural integrity of steel with the advantageous sliding properties of bronze. This combination ensures dependable performance in challenging applications, where a high tolerance for load and resistance to wear and corrosion are paramount.

JF-800 Bimetallic Composite Bearings JF-800 bimetallic composite bearings are crafted with a high-quality low-carbon steel base, topped with a sintered copper alloy layer known for its low friction properties (options include CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) to serve as the wear-resistant surface. The copper alloy layer can be customized through the addition of sump holes, oil holes, and other modifications to meet specific operational needs, making these bearings ideal for applications where regular lubrication is challenging or not feasible.

JF800 bimetallic bearings,Bimetallic Bushings copper Lead Alloy

Bimetallic Bushing Material Characteristic

| Material Trademark | Alloy Composition | Alloy Hardness | International Standard |

| JF-800 Bi-metallic Bushing type JF-800 (Lining: CuPb10Sn10 Thickness) | CuPb10Sn10 | 70~100 HB | SAE-797/GLYCO 66/JIS-LBC3 |

| JF-720 | CuPb24Sn4 | 45`70 HB | SAE-797/GLYCO 68/JIS-LBC6 |

| JF-700 | CuPb30 | 40~60 HB | US SAE-48/JIS-KJ3 |

| JF-20 Bi-metallic strip type JF-20(lining AlSn20cu Lining) | AlSn20Cu Lining | 30~45 HB | SAE-783/GLYCO 74/JIS-AJL |

| JF-930 | CuPb6.5P0.1 | 69~90 HB |

Bimetallic Bushing Technical Data

| Data | JF-800 CuPb10Sn10 | JF-720 | JF-700 | JF-20 AlSn20Cu Lining | JF-930 | |

| Max Load Capacity P N/mm² | 150 | 130 | 120 | 100 | 150 | |

| Tensile Strength N/mm² | 185 | 150 | 200 | 200 | 185 | |

| Max Sliding Speed m/s | 5 | 10 | 10 | 25 | 5 | |

| Friction Coefficient μ | 0.06~0.14 | 0.06~0.16 | 0.08~0.16 | 0.08~0.17 | 0.06~0.16 | |

| Max PV Value N/mm²·m/s | Grease Lubrication | 2.8 | 2.8 | 2.5 | – | 2.8 |

| Oil Lubrication | 20 | 10 | 8 | 6 | – | |

Bimetallic Bushings Application Characteristics

| Material Trademark | Applicable Conditions | Applications |

| JF-800 | Very good resistance to fatigue strenth, with high shock resistance and good corrosion resisitance. | Fit for middle load, high speed, bushes,washer and connecting rod bearing in internal combustion engine used in machinical equipment and high shock bushing. |

| JF-720 | Good resistance to fatigue strength and high load capacity,good performance of sliding, liable to be corrupted by lubricationg oil. | middle load middle speed, principle axis of internal combustion engine. |

| JF-700 | Good resistance to fatigue strength,load capacity, shock resistance and corrosion. | Principle axis of internal combustion engine, connecting rod bushing. |

| JF-20 | Good performance of anti-seizing, covering eyewinker, soft alloy be plated on working surface. | High speed, middle or low load, principle axis internal combustion engine |

| JF-930 | Moderate fatigue strength, and load capacity, good performance of bearing sliding. | High speed, low load, internal combustion engine half bearing, bushing used in compressing and refrigerating machine. |

Bimetallic Bearing Bushings Tolerances Of Machined and – machined Thickness

| Nominal Thickness | Tolerances+ of Series B (non-machinable) | Tolerances of Series C (non-machinable) |

| 0.1 | -0.025 | +0.25 +0.15 |

| 1.5 | -0.030 | +0.25 +0.15 |

| 2.0 | -0.035 | +0.25 +0.15 |

| 2.5 | -0.040 | +0.30 +0.15 |

| 3.0 | -0.045 | +0.30 +0.15 |

| 3.5 | -0.050 | +0.30 +0.15 |

Bimetallic Bearing JF-800 Series

The JF-800 series of bimetallic self-lubricating bearings utilize a high-quality low-carbon steel plate as the base material, with a sintered porous bronze layer on its surface. These bearings are designed for applications involving rotary oscillating, reciprocating movements under high loads, low speeds, low friction, excellent wear resistance, long service life, and effective prevention of seizing. The bronze layer surface can be customized with various grooves to suit specific requirements.Overview

The JF bimetallic bearings feature a combination of a high-quality low-carbon steel base and a sintered copper alloy surface with low-friction properties. Various copper alloy compositions such as CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, and CuSn8Ni are used as the wear layer to cater to different operating conditions. The bearing’s copper alloy surface can be tailored with grooves, oil holes, or other features to accommodate specific lubrication needs or challenging environments. By employing secondary extrusion and secondary sintering processes, these bearings achieve strong bonding strength and optimal load-carrying capacity for reliable performance.

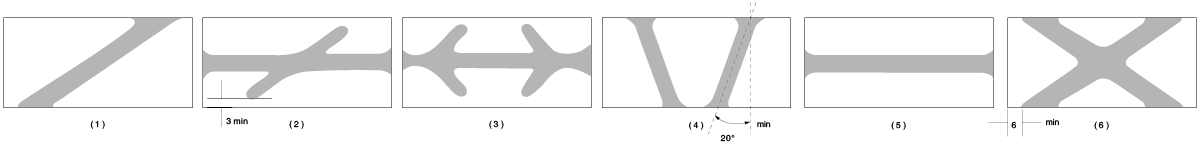

Type for Bi-Metaltic Bushing Grooves

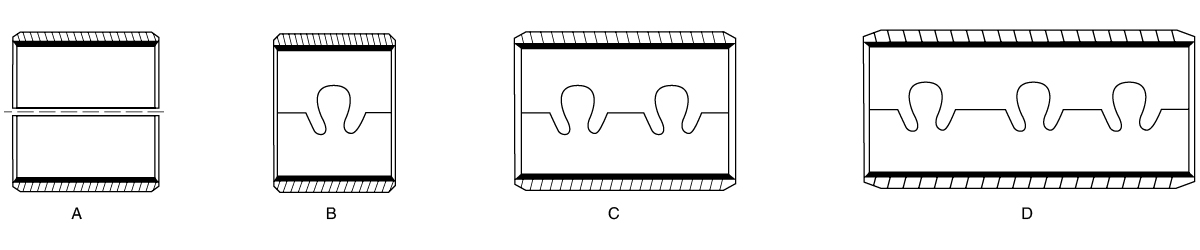

Lock Types for Bi-metal Bushing Bearing

Bimetallic bearing applications include:

For construction equipment: Utilized in the track chassis for the running gear wheel set, towing wheelset, and tension wheel set.

In the automotive industry: Employed for various components such as balance shaft bush, steel pin bushing, kingpin shaw bushings, rod bushings, valve rocker bushings, camshaft bushings, differential bushings, gearbox bushings, engine main bearings, thrust washers, as well as in piston side panels, and gear pump side panels.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally