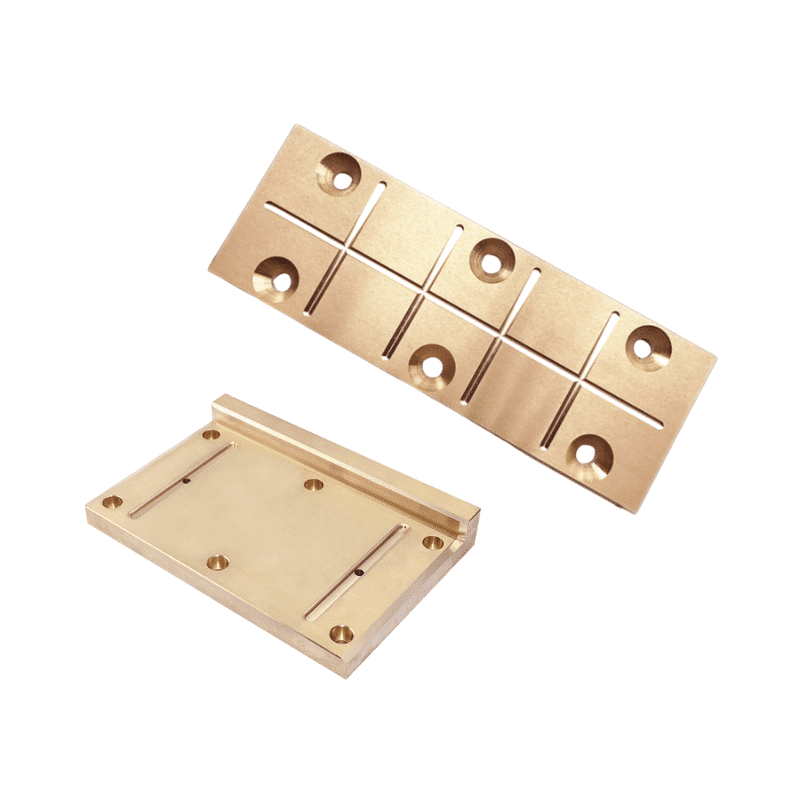

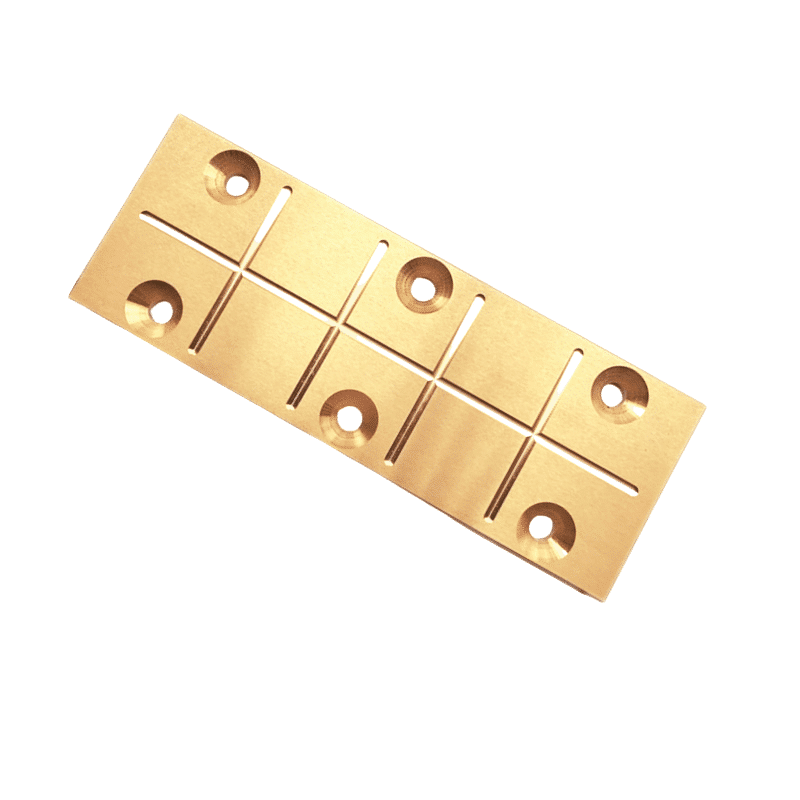

CuAl10Fe5Ni5 Bronze Slide Plate

CuAl10Fe5Ni5 Bronze Slide Plate

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

CuAl10Fe5Ni5 Bronze Slide Plate

Exploring the CC333G: The CuAl10Fe5Ni5 Bronze Plate

In the vast universe of metal alloys, there are a few that stand out for their unique properties and applications. One such alloy is the CuAl10Fe5Ni5 Bronze, commonly known by its product code CC333G. This bronze alloy, specifically in plate form, offers a plethora of advantages that cater to a range of industrial applications.

The material CuAl10Fe5Ni5 refers to a type of aluminum bronze. It is used in various applications, such as in the manufacturing of slide wear plates, hollow bars, and bushings. The composition of CuAl10Fe5Ni5 is approximately 10% aluminum, 5% iron, 5% nickel, and the rest copper. It is known for its performance in demanding applications and is available in different forms such as plates and bushings

CuAl10Fe5Ni5 Bronze Slide Plate

The CuAl10Fe5Ni5 Bronze Slide Plate is a specialized material that has been designed for a range of applications, given its unique combination of chemical and mechanical properties. Known by its product code CC333G, this bronze alloy showcases a distinct chemical composition and mechanical attributes that make it stand out.

Chemical Composition

The chemical composition of the CuAl10Fe5Ni5 Bronze Slide Plate is as follows (all values are given in weight percentage, %):

| Element | Cu | Sn | Al | Fe | Mn | Ni | Pb | Si | P | Zn |

|---|---|---|---|---|---|---|---|---|---|---|

| % | 76.0-83.0 | 0.1 | 8.5-10.5 | 4.0-5.5 | 3 | 4.0-6.0 | 0.03 | 0.1 | – | 0.5 |

Note: The individual values in the table represent the maximum percentage of that specific element present in the alloy.

Mechanical Properties

Apart from its chemical attributes, the CuAl10Fe5Ni5 Bronze Slide Plate offers impressive mechanical properties. Here’s a quick glance:

| Property | Value |

|---|---|

| Tensile Strength (Mpa) | 650 |

| Yield Strength (Mpa) | 280 |

| Elongation (%) | 13 |

| Hardness (HB) | 150 |

Points to Remember:

- The individual values in the chemical composition table signify the highest value of that particular element in the alloy.

- The hardness value provided under mechanical properties is solely for reference and should be considered with discretion in application scenarios.

The CuAl10Fe5Ni5 Bronze Slide Plate or CC333G is a robust and versatile material. Its unique chemical and mechanical attributes make it suitable for a plethora of applications. Whether you are in the automotive industry, construction, or any other domain requiring strong, corrosion-resistant materials, this bronze alloy can be an ideal choice. Always ensure that you consult with a materials expert to ascertain its suitability for your specific application.

Custom-Made CuAl10Fe5Ni5 Bronze Bushing Bearings: A Deep Dive

In the world of machinery and equipment, the significance of using the right materials cannot be emphasized enough. With a wide range of metals and alloys available, it’s crucial to select the one that perfectly aligns with the demands of your application. One such standout material is the CuAl10Fe5Ni5 Bronze, which has been increasingly sought after for crafting high-quality bushing bearings.

Introduction to CuAl10Fe5Ni5 Bronze

The CuAl10Fe5Ni5 Bronze, also known by its product code CC333G, is a specialized bronze alloy that boasts of a unique chemical composition and mechanical properties. With a blend of copper, aluminum, iron, and nickel, among others, this alloy ensures durability, strength, and resistance to wear and tear.

Why Choose CuAl10Fe5Ni5 for Custom-Made Bushing Bearings?

1. Outstanding Mechanical Properties:

- Tensile Strength (Mpa): 650

- Yield Strength (Mpa): 280

- Elongation (%): 13

- Hardness (HB): 150

These figures aren’t just numbers; they translate to exceptional strength and durability in real-world applications.

2. Excellent Wear Resistance:

The composition of CuAl10Fe5Ni5 ensures reduced friction and a longer lifespan for parts, making it ideal for bushing bearings that are subjected to high loads and frequent movements.

3. Corrosion Resistance:

Thanks to its unique alloying elements, especially the presence of aluminum and nickel, this bronze alloy showcases impressive resistance to corrosion, especially in marine or high-humidity environments.

4. Customizability:

Being a versatile material, CuAl10Fe5Ni5 Bronze can be molded, machined, or cast into intricate shapes and sizes, making it perfect for custom-made bushing bearings tailored to specific requirements.

Application Scenarios

Given its properties, CuAl10Fe5Ni5 Bronze bushing bearings find their use in:

- Heavy machinery

- Automotive industry

- Marine applications

- Construction equipment

- Aerospace components

…and anywhere else where the combination of strength, wear resistance, and durability is paramount.

Custom-made bushing bearings crafted from CuAl10Fe5Ni5 Bronze are not just a luxury; they’re a necessity in industries that demand precision, durability, and longevity. Whether you’re in the design phase or looking to upgrade existing machinery, consider CuAl10Fe5Ni5 Bronze for your bushing bearing needs. The advantages it offers are hard to match, ensuring that your equipment runs smoothly and efficiently for years to come.

Unpacking the CC333G: Chemical Composition

The CuAl10Fe5Ni5 Bronze Plate, represented by its code CC333G, boasts a particular chemical composition that defines its characteristics:

| Element | Cu | Sn | Al | Fe | Mn | Ni | Pb | Si | P | Zn |

|---|---|---|---|---|---|---|---|---|---|---|

| % | 76.0-83.0 | 0.1 | 8.5-10.5 | 4.0-5.5 | 3 | 4.0-6.0 | 0.03 | 0.1 | – | 0.5 |

The distinctive blend of copper with elements like aluminum, iron, and nickel provides the CC333G with its distinct properties.

Why the Hype Around the CuAl10Fe5Ni5 Bronze Plate?

- Strength & Durability: With a tensile strength of 650 Mpa and a yield strength of 280 Mpa, this bronze plate promises durability and resilience against external forces.

- Wear Resistance: Thanks to its unique composition, the CC333G plate offers remarkable wear resistance, making it perfect for applications involving friction or movement.

- Corrosion Resistance: The alloy’s elemental mixture, especially the presence of aluminum and nickel, gives it strong resistance against corrosion. This makes it especially valuable in environments prone to moisture or marine conditions.

- Machinability: The CuAl10Fe5Ni5 Bronze Plate can be easily machined, allowing for customizations and tailored applications.

- Aesthetic Appeal: Beyond its functional advantages, bronze plates often have a distinct visual appeal, which can be beneficial in architectural or decorative applications.

Potential Applications of the CC333G Bronze Plate

Given its unique properties, the CuAl10Fe5Ni5 Bronze Plate finds its place in:

- Heavy Machinery: As components that require strength and wear resistance.

- Shipbuilding: For parts that need to withstand saline and humid environments.

- Architectural Features: Leveraging both its aesthetic and functional properties.

- Automotive Components: In areas where wear resistance is vital.

- Art & Sculpture: Owing to its visual appeal and malleability.

The CC333G, CuAl10Fe5Ni5 Bronze Plate, is more than just a metal alloy. It’s a blend of durability, aesthetics, and versatility. Whether you’re in the industrial sector, architecture, or arts, this bronze plate promises value and performance. If you’re looking to invest in a material that offers a balance of beauty and brawn, the CuAl10Fe5Ni5 Bronze Plate is worth considering.

Cual10fe5ni5 Equivalent

The alloy CuAl10Fe5Ni5, often referred to by the designation CC333G, is a high-strength, corrosion-resistant aluminum bronze. It contains a specific blend of copper, aluminum, iron, and nickel to give it its unique properties.

When it comes to finding an equivalent for this alloy, it’s essential to understand that while there might be other alloys with similar compositions, the exact blend of elements might differ, leading to different properties. Therefore, “equivalent” alloys might have similar applications or characteristics but won’t necessarily be identical in composition or performance.

However, the CuAl10Fe5Ni5 (CC333G) alloy falls into the category of aluminum bronzes. Some common aluminum bronzes include:

- C63000 (AMS 4640, SAE J463, QQ-C-465B, ASME SB150): This is a nickel-aluminum bronze. It is not identical to CC333G but shares some characteristics due to the presence of aluminum and nickel.

- C95400 (AMS 4870, SAE J461, QQ-C-390B): This is an aluminum bronze without nickel but is known for its strength and wear resistance.

- C95500 (AMS 4880, SAE J461): Another nickel-aluminum bronze similar in some respects to C63000.

It’s worth noting that while these alloys may share certain characteristics with CuAl10Fe5Ni5, the exact properties can vary based on the specific composition. If you’re looking for an equivalent for a particular application, it’s vital to evaluate the desired properties and consult with metallurgists or materials experts to find the best match.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally