POM metal polymer orange bushes

POM metal polymer orange bushes

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

POM metal polymer orange bushes

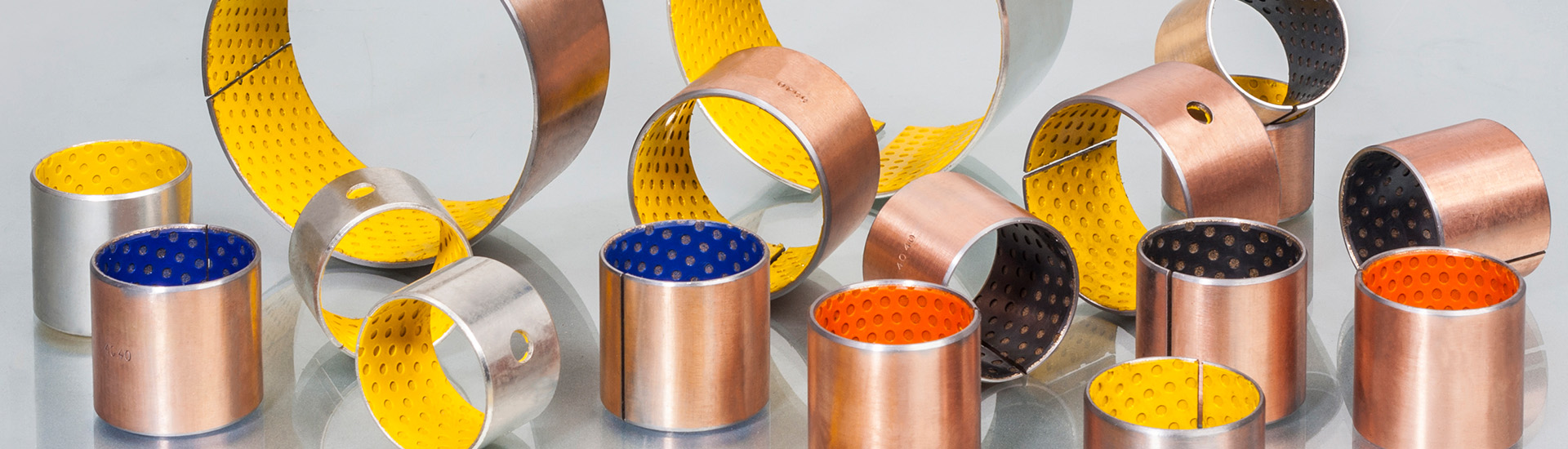

Metal-Polymer POM Bearings, Orange Blackish/Grayish teflon coated pom bushing

POM (Polyoxymethylene) composite bushings, also recognized under the names acetal or Delrin bushings, are crafted to deliver outstanding performance across a diverse array of applications, thanks to their robust strength, minimal friction, and exceptional resistance to wear. These bushings are crafted from a semi-crystalline engineering thermoplastic noted for its formidable strength, reduced friction, superior dimensional stability, and resilience against a broad spectrum of chemicals and solvents.

OTHER PRODUCTS

Slide bearings, bushings, washers, wear plates, oil seals, hydraulic seals and O-rings are basic machinery parts in general industries.

Metal-Polymer Composite Oilless Bush Bearing Bush Bronze Bushing Oilless Bearing, low Friction, anti-corrosion and is of long life.

online bushing bearing supplier!

Key Attributes of POM Composite Bushings:

- Minimal Friction: POM bushings boast a low coefficient of friction, which serves to enhance the efficiency of machinery by minimizing losses attributable to friction.

- Enhanced Durability and Stiffness: Owing to their remarkable strength and stiffness, these bushings are adept at resisting deformation under pressure, ensuring durability.

- Superior Wear Resistance: The notable wear resistance of POM bushings extends the operational life of machinery components and reduces the need for maintenance.

- Robust Chemical Resistance: Their ability to withstand various solvents, oils, and chemicals renders them ideal for deployment in demanding conditions.

- Broad Temperature Range Compatibility: POM retains its characteristics across a wide temperature spectrum, making it adaptable to diverse environments and applications.

Orange Blackish/Grayish teflon coated pom bushing

Applications: POM composite bushings find utility in an array of mechanical and industrial settings, such as:

- Gearbox assemblies

- Pivot points

- Linkage systems

- Steering mechanisms

- Suspension setups

These uses benefit from the bushings’ high stiffness, reduced friction, outstanding wear characteristics, and excellent dimensional stability.

Availability: POM composite bushings are accessible in standard sizes and various forms, including cylindrical and split bushings, to accommodate the needs of industrial and mechanical applications. They are employed across sectors like automotive, aerospace, electronics, and machinery manufacturing.

Metal-Polymer Composite Bearings: Metal-polymer composite bearings, incorporating POM bushings, signify a breakthrough in bearing technology. They provide a lubrication-free, high-efficiency solution particularly suited to challenging applications and are increasingly popular in industries such as textiles.

Usage Considerations: For metal/polymer composite plain bushes, it’s crucial to account for factors like allowable misalignment, edge loading, and mounting tolerances to maximize performance and lifespan.

In conclusion, POM composite bushings stand as a high-performance option for needs demanding durable, low-friction, and wear-resistant bearings. Their adaptability and dependability earmark them as a favored selection in a wide range of industrial contexts.

Polyoxymethylene (POM) stands out as a highly crystalline engineering thermoplastic with impressive mechanical characteristics, including robust strength, stiffness, and superior resistance to wear. This material is produced through the polymerization of formaldehyde, earning it alternative names like polyacetal or acetal. POM is distinguished by its metallic-like qualities, such as durability, elasticity, and fatigue resistance, making it exceptionally suitable for manufacturing components like gears, bearings, and snap-fit assemblies. It comes in two primary variants: homopolymer and copolymer, each offering slightly distinct features. However, both types exhibit low glass transition temperatures (around -80°C) and high levels of crystallinity, which accounts for their stiffness, likening POM to a very rigid type of rubber at ambient temperatures.

For specific uses that demand orange-colored POM components, like bushes or mechanical parts, the material can be dyed to meet precise color specifications. This process may involve the use of dyes or pigments that are compatible with POM to attain the desired orange hue. The practicality of achieving such a color will depend on the POM’s characteristics and the application it’s intended for, considering the color’s stability under conditions like UV light exposure and heat.

In conclusion, POM serves as a highly adaptable engineering thermoplastic, ideal for metal substitution in numerous applications owing to its exceptional mechanical properties and longevity. When the application necessitates specific colors, such as orange, achieving the desired shade is possible by incorporating suitable dyes or pigments during production!

Metal-Polymer POM Bearings, also recognized as DX/SF-2 bushings, are crafted from copper-plated steel enveloped in a layer of POM (Polyoxymethylene). These standard bearings come equipped with lubrication indents on their surface to facilitate smooth operation.

Application & Details: These bearings are ideal for scenarios involving medium loads and slow, rotating, or oscillating movements, thanks to their boundary lubrication design.

Features & Advantages: Prior to assembly, it’s advisable to pre-lubricate these components with grease, which the indents effectively retain in an optimized configuration. Regular lubrication during use extends the lifespan of the bearings. With low friction coefficients, excellent wear resistance, and dependable load capacity, these bearings are perfectly suited for low-speed rotation and oscillating movements.

Structure & Application of Metal-Polymer POM Bearings: The POM material is known for its superior wear resistance, making it applicable for medium to high load conditions, especially in environments with impact loads and dust. Pre-lubrication before assembly is essential. These bearings are commonly used in commercial vehicle axles, brake systems, suspension systems, agricultural and forestry machinery, as well as in material handling equipment, serving as a potential replacement for traditional steel or bronze sleeves.

- Layer 1 consists of POM with a thickness ranging from 0.30 to 0.50mm, featuring a pattern of circular indents on the bearing surface intended to be filled with grease during assembly.

- Layer 2 is made up of sintered bronze, with a thickness of 0.20 to 0.35mm, ensuring a robust mechanical bond and exceptional thermal conductivity.

- Layer 3 comprises low-carbon steel, providing the necessary mechanical strength and thermal conductivity for the bearing’s functionality

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a widely used material known for its distinctive features, including low friction, resistance to chemicals, and ability to endure high temperatures. These qualities make Teflon a preferred material for industrial and consumer product coatings and bushings.

Orange PTFE Coating:

The Orange PTFE Coating is a variant of Teflon coating that retains the hallmark low friction and chemical resistance of PTFE but is distinguished by its bright orange hue. This specific coating can be applied to different surfaces to boost their functionality in challenging environments, with the added benefit of the orange color aiding in the identification and organization in industrial contexts.Blackish/Grayish Teflon Coated Bushings:

Bushings made from PTFE, available in blackish or grayish shades, are renowned for their low friction and high endurance against extreme temperatures. These bushings are versatile, finding applications in diverse industries such as chemical, pharmaceutical, electrical, and thermal power sectors. The integration of fillers like glass, graphite, bronze, and stainless steel into pure PTFE not only enhances its mechanical and thermal characteristics but also contributes to the bushings’ color variation, resulting in blackish or grayish tones.Usage of Teflon Coatings and Bushings:

The exceptional attributes of Teflon coatings and bushings make them indispensable in various sectors. Their applications include improving food production machinery in compliance with FDA standards, preventing metal surface galling in the oil and gas industry, boosting corrosion resistance and reducing friction in chemicals, diminishing automotive part friction, offering thermal stability and radiation resistance in aerospace, and enhancing the chemical and friction resistance of medical devices.In conclusion, the multifaceted utility of Teflon, marked by its low friction, chemical resistance, and high-temperature resilience, renders it an essential material for a multitude of applications. From the identifiable Orange PTFE Coating to the robust blackish/grayish Teflon coated bushings, the applications of Teflon are extensive and diverse across various industries.

Surface requirements – Painted surfaces for:

- Premium loaders

- Compact loaders

- Utility loaders

- Backhoes

- Implements

- Subframes

- Cylinders

- Hydraulic kit items

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally