PTFE Flange Bushes

PTFE Flange Bushes

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

PTFE Flange Bushes

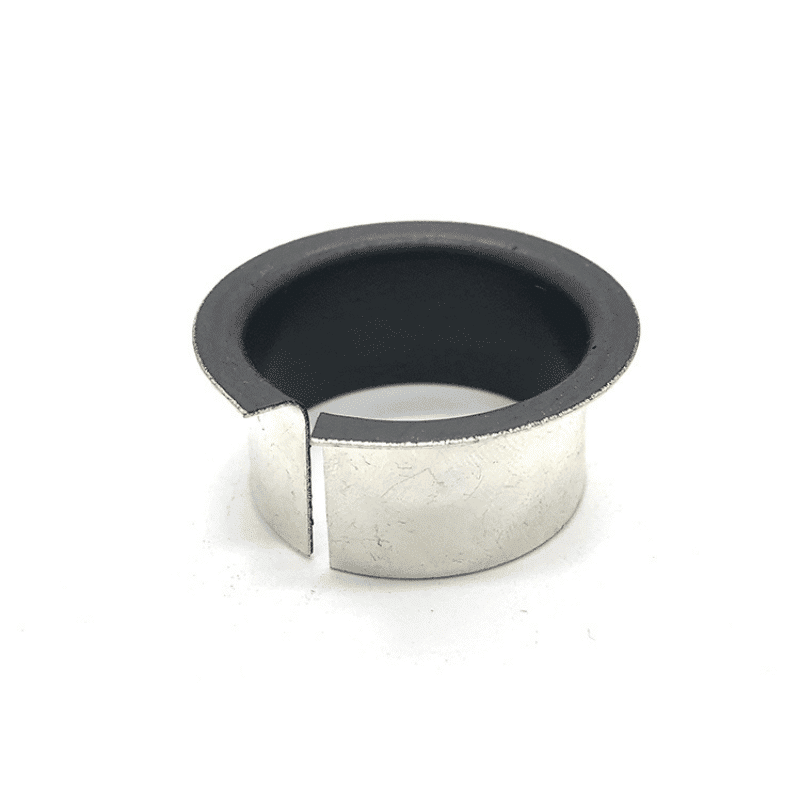

Self Lubricating Plain Split Flanged Bearing Bush Bearing,

Blackish/Grayish teflon-coated

Imperial Line Bushings. Dimensions

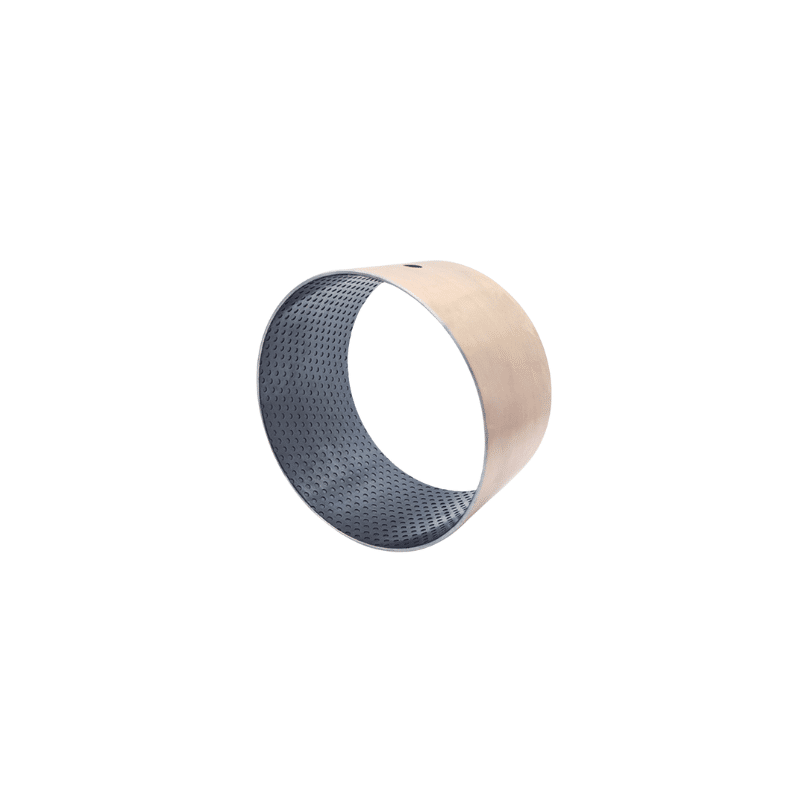

PTFE Flange Bushes, steel-backed, sintered-bronze PTFE-lined bushings are used in a wide range of industries and applications due to their superior shock and impact load resistance, low friction, high wear resistance, and wide applicable temperature range. They are self-lubricating and can be used without additional lubrication at high load and low-speed operations.

Flanged Bearing, PTFE Lined, Steel, 1 mm thickness, Steel-Backed PTFE Flange Bearing

The PTFE-lined flanged bushings are made of a triple-layer composite material consisting of a bronze plate as the base material, with a film of heat-resistant powder-filled PTFE calendered onto a sintered spherical bronze interlayer. This design provides excellent wear resistance, low friction, and high temperature resistance, making them suitable for various industrial applications. These bushings are used in various industries and applications, such as automobiles, railroad cars, ships, aircraft, hydraulic systems, printing, food processing, and the textile industry. They are designed to provide superior shock and impact load resistance, low friction, and high wear resistance. The steel-backed PTFE-lined bushings are self-lubricating and can be used without additional lubrication at high load and low-speed operations.

MULTILAYER BUSHINGS IMPERIAL LINE SIZE BUSHING

Material: Steel + bronze sinter + PTFE with lubrication indents. Specific marking, Cylinders Bushing, Shaft h8 Housing H7, Greasing Hole

Plain Bush, BUSHINGS available in metric size and specifications.

Plain and Self-Lubricating Bushings Flange Bushes, Straight Linear Plain Bearings – Multi-Layered, Steel-Backed Bronze Sinter with PTFE Layer, Metric

PTFE Glacier bushes, also known as plain wrapped bearings, feature a PTFE lining and are designed for applications where low friction, low wear, and dry running are essential. These bearings excel in their sliding capabilities, creating a protective transfer film on the adjacent metal surface. Developed primarily for high-duty applications that require lubrication, PTFE Glacier bushes are utilized in a variety of mechanical components such as automotive suspension struts, shock absorbers, hydraulic cylinders, and various types of pumps and motors. These bushes are available in a range of styles and sizes, including metric and imperial, plain, flanged, washers, and strips. Additionally, custom sizes can be manufactured to meet specific requirements.

Bearings are typically subject to significant frictional resistance, which generates heat. To counter this, lubricants like oil or grease are traditionally applied to prevent the seizing or unusual wear caused by this heat. However, self-lubricating bushings are designed to eliminate the need for such lubricants. This is achieved either through a lubricating feature within the bearing material itself or by incorporating solid lubricants into the bearing. As a result, these bushings are particularly valuable in applications where adding lubricating oil is challenging, such as in precision machinery, or in devices that are incompatible with oil.

The absence of a requirement for lubricating oil means that self-lubricating bushings are a preferred choice for reducing maintenance demands, cutting costs associated with regular lubrication, and ensuring consistent, long-term performance. These bushings are available in various forms to suit diverse applications, including straight, collar, flange, and housing bushings, providing flexibility and adaptability for different mechanical needs.

Flanged Linear Plain Bearings – PTFE Polymer, Steel Grade, Metric

Mounting Hole Fits H7, Type Flange Bushing Material PTFE

Materials: PTFE flange bushing

Blackish/grayish Teflon-coated PTFE (Polytetrafluoroethylene) flange bushes are specialized components designed for various industrial uses. These bushings stand out due to their low friction, superior heat resistance, chemical resilience, and self-lubricating features, making them ideal for scenarios where lubrication is challenging or unwanted.

Attributes of PTFE Flange Bushes:

- Material Composition: Mainly made from PTFE polymer, these bushes may incorporate graphite or other fillers to boost specific characteristics.

- Color: The presence of graphite or similar fillers imparts a dark gray hue to the bushings.

- Hardness: These bushings exhibit a hardness level of 60 shore D.

- Temperature Resistance: Capable of enduring temperatures up to 500 degrees Fahrenheit.

- Chemical Resistance: The chemically inert nature of PTFE makes these bushes apt for corrosive settings.

- Self-Lubricating: With a low friction coefficient, they function efficiently without extra lubrication.

- PV Value Range: They have an acceptable PV (pressure-velocity) range of 0.3 to 1.0 N/mm²•m/s.

Utilization in Various Industries:

- Chemical and Pharmaceutical: Their resistance to chemicals renders them suitable for these fields.

- Electrical and Thermal: Beneficial for their outstanding insulating properties.

- Agricultural and Construction Equipment: Their robustness and tolerance to different environments make them fit for heavy-duty machinery.

- Food Production: Their non-toxicity allows for usage in food-related processes.

Blackish/grayish Teflon-coated PTFE flange bushes are versatile, high-performance components offering numerous advantages like minimal friction, heightened temperature and chemical resistance, and self-lubrication. These qualities render them apt for a broad spectrum of industry applications. When choosing a PTFE flange bush, it’s crucial to assess the specific demands of the application, including required hardness, temperature tolerance, and chemical exposure, to guarantee optimal functionality and durability.

Flange Bush Bearings are readily available as standard inventory items, featuring a self-lubricating, dry-sliding design. These bearings consist of a multi-layer composite material that includes:

- A low carbon steel backing to support extremely high loads, with a thickness ranging from .50 to 2.7 mm.

- A layer of sintered bronze for superior heat dissipation, measuring between .20 and .35 mm in thickness.

- A PTFE-lead sliding layer that ensures a low friction coefficient and supports a broad temperature spectrum, with a thickness of .2 mm.

These bearings excel in environments where many liquid lubricants would fail, yet they also perform impressively with lubrication. They are perfectly suited for handling heavy loads at moderate speeds or light loads at high speeds, boasting a maximum Pv of 102,000, a P-Load of 36,250, and a V-SFM of 1,900. They operate effectively within a temperature range of -328° F to +536° F. Standard tolerances for these bearings vary by size, and specific tolerances can be found listed with each item.

Material |

Steel-Backed PTFE Lined |

Material Standard |

Steel-Backed PTFE Lined |

- Steel-Backed PTFE Lined Self Lubricating

- Lead-Free Steel-Backed PTFE Lined Self Lubricating

Are you aware of the part number you need? We offer a variety of standard-bearing solutions, including:

- Sleeve Bushings & Bearings

- Flange Bushings

- Thrust Washers / Flange Bearings

- Bars, Discs, & Plates

Additionally, we provide custom-bearing solutions tailored to your specific requirements.

The term “dış çap bushes” specifically refers to the external diameter of bushings, emphasizing a key dimensional attribute critical for their application in mechanical systems. Bushings, integral to reducing friction and wear between moving parts, are designed in various forms such as solid, split, flanged, and sleeve types to suit different mechanical and engineering needs. The external diameter is pivotal for ensuring a precise fit within a housing or bore in machinery, affecting the bushing’s performance and the system’s overall efficiency.

Material selection for bushings, including metal, plastic, and composite materials, is tailored to meet application-specific demands like load capacity, operating speed, and resistance to environmental conditions. This customization extends to bushings designed for high-load, high-speed, or corrosive environments, showcasing the adaptability of these components across a wide range of industrial applications.

The significance of bushings in mechanical systems is underscored by their varied applications, from limiting opening sizes and supporting loads to providing protective surfaces for mating components and serving as guides. The distinction between different bushing types—such as straight (cylindrical) bushings for radial loads and flanged bushings for both radial and axial loads—illustrates their versatility and functionality in facilitating smooth and efficient machine operations.

In essence, “dış çap bushes” highlights a fundamental aspect of bushing design critical for their effective integration and performance in mechanical and engineering systems. The external diameter not only influences the fit and alignment of the bushing within a system but also plays a crucial role in the bushing’s ability to meet the operational demands of various applications, from industrial machinery to automotive components.

Plain flanged bearings, designed for durability, are capable of bearing loads both perpendicular and parallel to the shaft. These bearings are equipped with a PTFE lining and a steel backing.

Teflon-coated bushings, particularly those with a blackish/grayish appearance, are a specialized type of bushing designed to offer low friction, high durability, and resistance to various environmental factors. These bushings are made from PTFE (Polytetrafluoroethylene), and can be filled or coated with various materials to enhance their properties.

Key Characteristics of Teflon-Coated Bushings

- Low Friction: PTFE bushings inherently have a very low coefficient of friction, which is further reduced by the addition of fillers such as graphite

.

- High Temperature Resistance: PTFE can withstand continuous operation in temperatures up to 500°F, and with certain additives, this can increase to up to 550°F.

- Chemical Resistance: PTFE is highly resistant to chemicals, making it suitable for use in harsh environments.

- Self-Lubricating: Due to their low friction, PTFE bushings can operate without lubrication, which is beneficial in environments where lubrication is not possible or desired.

- Versatility: The addition of fillers to PTFE can enhance its mechanical strength, thermal conductivity, and heat dissipation properties. Common fillers include glass, graphite, bronze, stainless steel, and molybdenum disulfide.

- Color and Appearance: The addition of certain fillers, such as graphite, can give the bushings a dark gray color.

Applications

Teflon-coated bushings are used in a wide range of industries due to their versatile properties. Some of the applications include:

- Aerospace and Automotive: Their high temperature and chemical resistance make them suitable for various components in aerospace and automotive applications.

- Electrical and Thermal: The excellent electrical insulating properties of PTFE make these bushings ideal for electrical and thermal applications.

- Pharmaceutical and Food Production: The non-toxic nature of PTFE, along with its resistance to aggressive cleaning, makes it suitable for pharmaceutical and food production environments.

- Agricultural Machinery: Their durability and resistance to environmental factors make them suitable for use in agricultural machinery.

Conclusion

Blackish/grayish Teflon-coated bushings offer a combination of low friction, high-temperature resistance, chemical resistance, and self-lubricating properties, making them an excellent choice for a wide range of industrial applications. The addition of fillers can further enhance their properties, tailoring them to specific needs. Whether for use in aerospace, automotive, electrical, or food production industries, these bushings provide reliable performance under challenging conditions.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally