sliding bushings

sliding bushings

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

sliding bushings

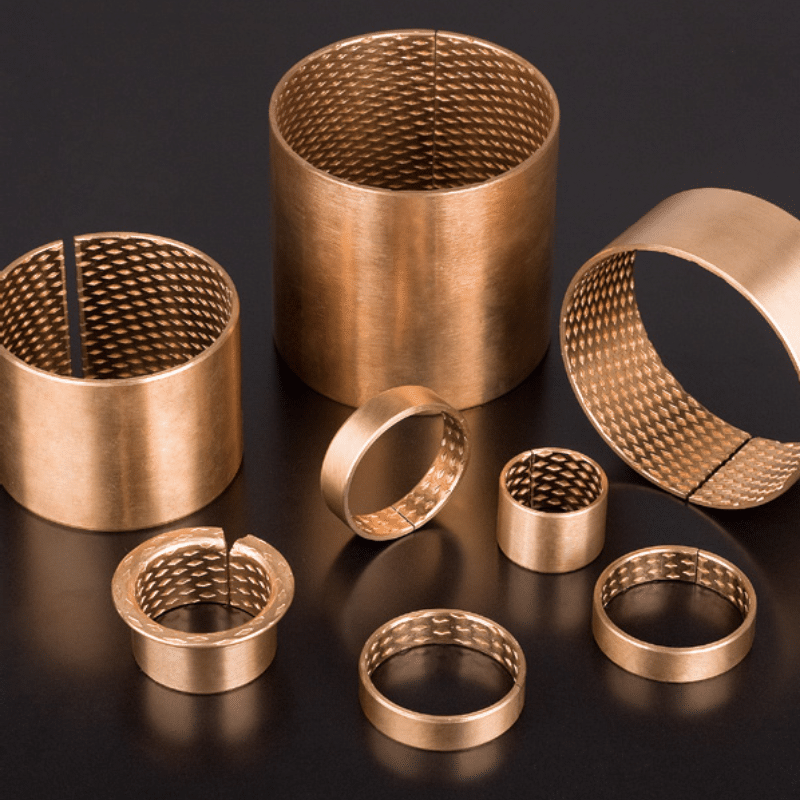

Sliding Bushings Wrapped bronze bearings, such as FB090 and FB092, are a specific type of plain bearing that utilizes a bronze material to provide a durable and self-lubricating surface.

Slide Bushings and Plain Bearings, Wrapped bronze bearings

Slide Bushings and Plain Bearings Overview

Slide bushings, also known as plain or journal bearings, operate on hydrodynamic or boundary lubrication principles. Within this category, wrapped bronze bearings like FB090 and FB092 use bronze to create a robust, self-lubricating bearing surface. Below is an overview of FB090 and FB092 wrapped bronze bearings:

FB090 Wrapped Bronze Bearings Characteristics:

Constructed from a high-density copper alloy strip. Can include diamond-shaped or spherical indents and grooves for lubrication, tailored to user needs. Benefits are their high load capacity, wear resistance, and extended lifespan. They offer an alternative to traditional cast bronze bushings, reducing size and cost in machinery. Common in heavy machinery, construction vehicles, tractors, machine tools, and mining equipment. Variants include bushings, flanged bushings, washers, and spherical segments. Technical Specifications:

Suited for high-load applications and capable of operating on rough surfaces. Designed to store grease in surface holes and indents, lengthening relubrication intervals. Available as straight bushings, washers, flanged versions, bearing bushes, slide plates, and steel sleeve combinations. Usage Cases:

Ideal for medium-load, low-speed roles such as in conveyors, lifts, hoists, and levelers. FB092 Wrapped Bronze Bearings Characteristics:

Bronze-based bearings with uniform, orderly lubrication holes. Thin-walled and rolled, they are greased post-assembly for convenience. Advantages include a large grease capacity, ease of installation, and compact size. A cost-effective alternative to bronze bushings. Technical Specifications:

Crafted with dense bronze alloy, potentially featuring roll forming or spherical indents for lubricant storage, enhancing wear resistance and lifespan. Resistant to corrosion. Usage Cases:

Fit for dirty environments where frequent relubrication is needed. Optimal for hydraulic systems, construction machinery, cranes, and agricultural machines, particularly under impact and variable loads. Material Composition and Structure

Both FB090 and FB092 utilize dense bronze alloys like CuSn6.5P or CuSn8P. Designed with lubricant pockets on their surfaces to minimize starting friction and maintain lubrication. Manufacturer Details

we offer customization and various packaging to meet client needs. These wrapped bronze bearings are designed to withstand challenging conditions, supporting heavy loads at low speeds and providing a self-lubricating solution in maintenance-intensive environments.

For precise specifications and usage guidance, consulting the manufacturers’ datasheets or direct communication with the companies is advisable.

Wrapped bronze slide bushing bearings, such as those made from CuSn8P and CuSn6.5 materials, are engineered to offer excellent performance in various industrial applications, particularly those that are subject to harsh operating conditions. Here’s a closer look at the characteristics and benefits of these bearings:

Material Composition

- CuSn8P: This is a high-grade phosphorous tin bronze alloy known for its excellent mechanical properties and resistance to wear. The phosphorus content enhances the material’s ability to hold a lubricating film, even under heavy loads and at high sliding speeds.

- CuSn6.5P: Similar to CuSn8P, this material also contains phosphorus, which provides self-lubricating properties. It is designed to offer good corrosion resistance and maintain a strong structure under load.

Design Features

- Lubrication Pockets: The bearing surface features diamond-shaped or patterned lubrication pockets or holes. These pockets are designed to hold and distribute lubricant, reducing friction and wear, especially in dirty or contaminated environments.

- Grease Filling: It is essential to fill these lubrication pockets with grease during installation to ensure the bearing’s self-lubricating properties are maximized.

Performance Benefits

- Long Service Intervals: Due to their self-lubricating nature and the ability to retain lubricant, wrapped bronze bearings can operate for extended periods without the need for maintenance or re-lubrication.

- Severe Operating Conditions: They are suitable for applications with high loads, high temperatures, or where there is significant contamination. The self-lubricating properties make them reliable even in conditions where regular lubrication is not feasible.

- Contamination Resistance: The design of wrapped bronze bearings makes them particularly effective in environments with high levels of dirt, dust, or other contaminants that could compromise the performance of traditional bearings.

Standards Compliance

- ISO 3547: Wrapped bronze bearings are manufactured in accordance with the ISO 3547 standard, which ensures a high level of quality and consistency in their production.

Applications

These bearings are widely used in various industries where their unique properties are advantageous, such as:

- Hydraulic Cylinders: For applications requiring high load capacity and resistance to wear.

- Construction Machinery: In equipment that operates in dusty or dirty environments.

- Crane Construction: For reliable operation under heavy loads and shock loads.

- Agricultural Machinery: Where the machinery is exposed to harsh environmental conditions and contamination.

In summary, wrapped bronze slide bushing bearings made from CuSn8P and CuSn6.5 materials are designed to provide long service intervals and reliable operation under severe conditions. Their self-lubricating properties and resistance to contamination make them a popular choice for industries that demand high performance and durability from their machinery components.

Our selection of acetal-lined POM wrapped bearings is designed for use in applications involving rotary and oscillatory motions.

Materials for Wrapped Bronze Slide Bushing Bearings Wrapped bronze bearings are crafted exclusively from phosphor bronze, specifically CuSn8 alloy. This material is renowned for its high purity and minimal impurity content. The production process involves using strips of this bronze, which are then wrapped and finely calibrated to form the bearings.

Lubrication Upon installation, wrapped bronze bearings require lubrication with either grease or oil. The use of high-quality lubricant is crucial as it reduces friction and wear by creating a protective film between the bearing and the shaft. For environments with heavy contamination, it is advisable to seal the bearings. This seal not only safeguards the bearing but also preserves the integrity of the lubricant.

Detailed Overview of Lubrication Pockets Lubrication pockets are strategically designed features on the surface of wrapped bronze bearings. These pockets serve as reservoirs for lubricants, ensuring consistent lubrication during operation and extending the bearing’s service life. They are particularly effective in maintaining lubrication under load and reducing wear, making them essential for the bearing’s efficiency and durability.

Specification overview of wrapped bronze bearings

| Specification overview | ||

|---|---|---|

| Properties | FB090 wrapped bronze bearings | FB092 wrapped bronze bearings |

| Max. load (Dyn/stat), N/mm2 | 40 / 120 | 40 / 120 |

| Max. sliding speed m/s | 2.0 | 2.5 |

| Max. PV value N/mm2 x m/s | 2.8 | 2.8 |

| Temperature range, oC | -100 / +200 | -100 / +200 |

| Shaft tolerance | e7 – f8 – h6 | e7 – f8 – h6 |

| Housing tolerance | H7 | H7 |

| Shaft roughness | Ra ≤ 0.8 | Ra ≤ 0.8 |

| Shaft hardness | > 200 HB | > 200 HB |

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally