lined bearings

lined bearings

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

lined bearings

Sleeve Bearings PTFE lined⚙️

Reliable ptfe lined bearing sleeve bearings built for seamless, low-friction operation in any environment. Exceptional quality, cost-effective solutions.

🛠️ Explore More and get the right bearing for your application!

Sleeve Bearings: The Power of PTFE-Lined Steel Bearings

When it comes to choosing the best bearing for your engineering projects, it’s crucial to consider a solution that is not only high-performing but also cost-effective and versatile. One such powerful solution is the PTFE-lined steel bearing, a product that offers outstanding durability, low friction, and a wide range of applications.

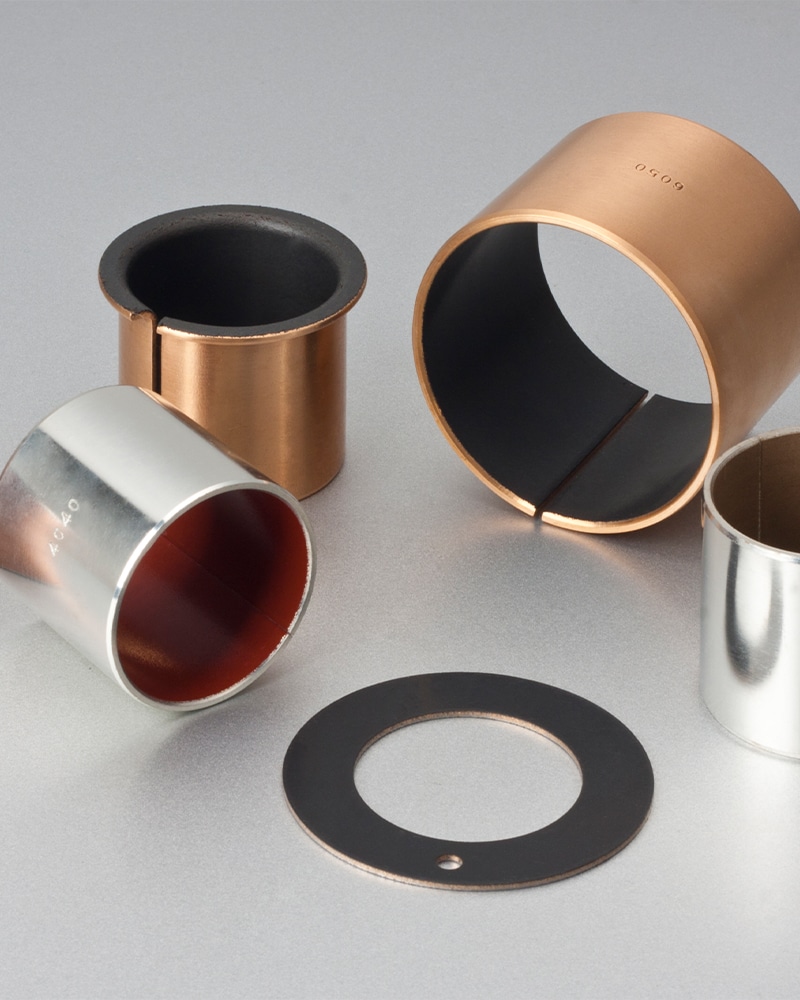

The Structure: What Makes PTFE-Lined Steel Bearings So Effective?

These bearings feature a steel backing strip layered with sintered bronze and PTFE (Polytetrafluoroethylene). This unique structure is carefully designed to deliver maximum performance:

- Lead-Free Polymer Fiber Mixture: Forms a protective initial transfer film that coats the mating surface of the bearing assembly. This oxide-type solid lubricant film ensures low friction and reduces wear on mating surfaces.

- Sintered Bronze Powder Layer: Maximizes thermal conductivity, efficiently drawing heat away from the bearing surface while also acting as a reservoir for the PTFE mixture.

- Steel Backing: Offers high load-carrying capacity and exceptional heat dissipation, ensuring the bearings can withstand demanding applications.

- Copper/Tin Plating: Provides the entire structure with excellent corrosion resistance, extending the bearing’s lifespan even in challenging environments.

Versatile Applications

These PTFE-lined bearings are tailored for high-duty applications, including:

- Automotive Suspension Struts: Enhance vehicle stability by providing smooth, low-friction movement.

- Shock Absorbers: Reduce the impact of road irregularities, improving comfort and handling.

- Hydraulic Cylinders: Deliver consistent and efficient movement under high pressure.

- Gear Pumps and Motors: Support smooth fluid transfer in various industrial processes.

- Axial and Radial Piston Pumps and Motors: Maintain precision and reliability under varying loads.

Comprehensive Range

We offer PTFE-lined bearings in a wide variety of formats, including:

- Metric & Imperial Plain Bearings

- Metric Flanged Bearings

- Metric & Imperial Washers

- Metric & Imperial Strip Bearings

Custom sizes can also be manufactured according to your unique project requirements.

Alternative Brands

If you’re considering alternative brands, our PTFE-lined bearings are equivalent to Glacier Garlock’s DU, P10, and P14 models, providing a seamless transition if you’re accustomed to those brands.

Beyond Steel: Bronze and Stainless Steel Backing Options

For applications where standard steel may not be suitable, we also offer bronze-backed and stainless steel-backed PTFE-lined bearings. These variants offer the same dimensions and tolerances but provide enhanced resistance to specific environmental challenges.

Need a PTFE- lined Bearings, Connect with Us

Our PTFE-lined wrapped bearings are versatile and durable, making them suitable for a wide array of applications. Contact us today to discuss how these bearings can be tailored to meet your project’s demands and provide a reliable, efficient solution for your engineering needs.

High-performance lined bearings with PTFE-lined, metal-backed bushings consist of a metal shell with a polytetrafluoroethylene (PTFE) coating applied to the inside surface as the wear surface of the bearing. For applications involving water or chemicals, the metal shell of PTFE-lined bearings can be made from a stainless steel base. Thanks to the very low coefficient of friction of PTFE, the friction level of PTFE-lined bearings typically remains excellent throughout the bearing’s lifespan.

Plain Lined Bearings: Exploring Advanced Bearing Technologies

High-Performance Bearings Available, Looking for reliable bearings? Our PTFE Coated Bearings are designed for supreme performance and longevity. See our range!

Specification Overview for PTFE Lined Bearings:

| Property | (Steel PTFE Lined Bearings) | (Bronze PTFE Lined Bearings) | (Stainless Steel PTFE Lined Bearings) |

|---|---|---|---|

| Maximum Load (Dyn/Stat), N/mm² | 140 / 250 | 140 / 140 | 140 / 250 |

| Maximum Sliding Speed, m/s | 2.5 | 2.5 | 2.5 |

| Maximum PV Value, N/mm² x m/s | 1.8 | 1.8 | 1.8 |

| Temperature Range, °C | -200 to +280 | -200 to +280 | -200 to +280 |

| Shaft Tolerance | f7 – h8 | f7 – h8 | f7 – h8 |

| Housing Tolerance | H7 | H7 | H7 |

| Shaft Roughness, Ra | < 0.4 | < 0.4 | < 0.4 |

| Shaft Hardness, HB | > 200 | > 200 | > 200 |

Exploring Wrapped Acetal (POM) Lined Bearings: A Comprehensive Guide

In the world of engineering and industrial machinery, high-quality bearings are indispensable. One bearing solution that’s gaining popularity is the wrapped Acetal (POM) lined bearing. Known for its excellent performance and versatility, it’s an essential component for many demanding applications. Let’s dive deeper into what makes these bearings unique and why they could be the perfect fit for your next project.

POM Linded bearings Our range of wrapped acetal-lined bearings is suitable for rotary and oscillating movement applications.

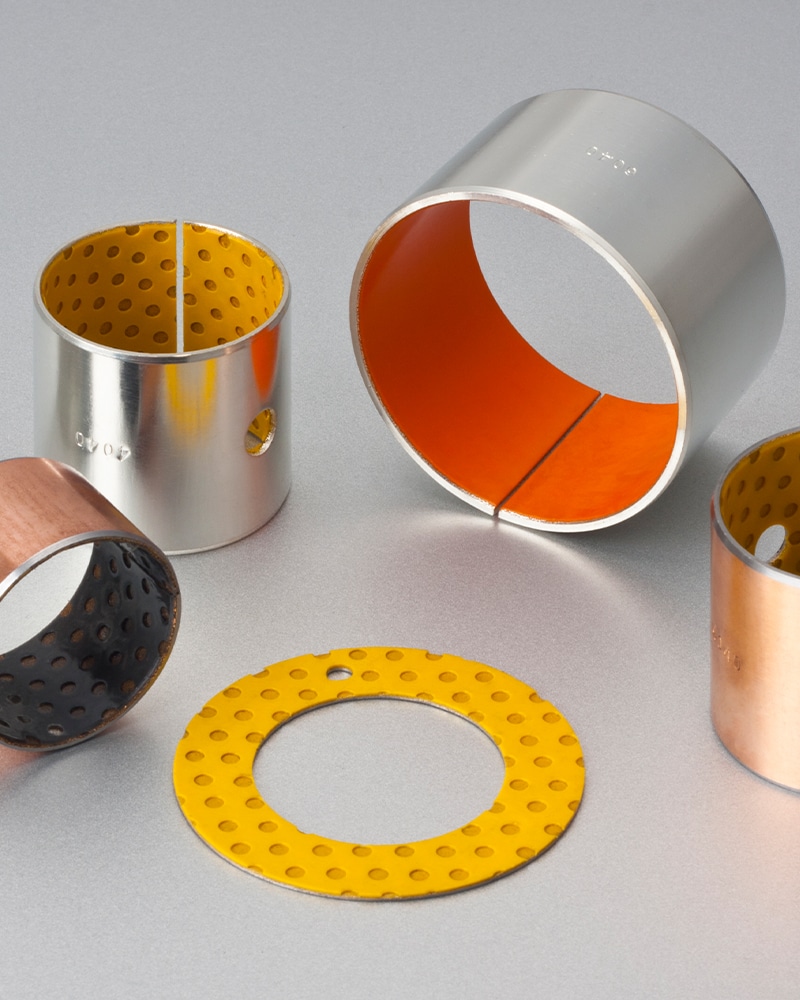

What Are Wrapped Acetal (POM) Lined Bearings?

Wrapped Acetal bearings are constructed with a high-strength steel backing and an inner lining made of Acetal, also known as Polyoxymethylene (POM). This polymer material offers exceptional mechanical properties, including low friction and high wear resistance.

Specification overview of POM lined bearings

| Specification Overview | |

|---|---|

| Properties | POM: steel backing strip with sintered bronze and Acetal polymer layers |

| Max. load (Dyn/stat), N/mm2 | 140 / 250 |

| Max. sliding speed m/s | 2.5 |

| Max. PV value N/mm2 x m/s | 2.8 |

| Temperature range, oC | -400 / +130 |

| Shaft tolerance | f7 – h8 |

| Housing tolerance | H7 |

| Shaft roughness | Ra ≤ 0.4 |

| Shaft hardness | > 200 HB |

Key Features and Benefits

- High Load Capacity

The steel backing ensures that these bearings can handle significant loads, making them suitable for heavy-duty applications. - Low Friction

The Acetal (POM) liner provides a low coefficient of friction, enabling smooth movement and reducing wear on mating surfaces. - Corrosion Resistance

POM is resistant to moisture and various chemicals, which helps maintain bearing integrity even in harsh environments. - Dimensional Stability

Acetal maintains its shape and functionality under different temperatures, ensuring consistent performance. - Maintenance-Free Operation

With self-lubricating properties, POM-lined bearings don’t require additional lubrication, reducing downtime and maintenance costs.

Applications of Wrapped Acetal Lined Bearings

These bearings find utility in various sectors due to their versatility and reliability, including:

- Agricultural Equipment: Ideal for machinery exposed to moisture and chemicals.

- Construction Machinery: Handles heavy loads and resists corrosion on construction sites.

- Automotive Industry: Supports components that require low friction and high durability.

- Packaging Equipment: Ensures smooth operation in machinery that frequently changes direction or speed.

- Marine Applications: Resists the corrosive effects of seawater and chemicals.

Why Choose Wrapped Acetal Lined Bearings?

- Durability: The combination of steel and POM provides a strong, long-lasting bearing solution.

- Cost-Efficiency: Their low maintenance requirements make them cost-effective over the long term.

- Versatility: Available in various sizes and formats to suit different applications.

Find the Perfect Lined Bearing for Your Project

Whether you need a reliable bearing solution for your heavy-duty machinery or a versatile option for various environments, wrapped Acetal (POM) lined bearings are a solid choice. Contact us to explore our comprehensive range and discuss how these bearings can be tailored to meet the unique requirements of your application. We’re here to help you find the best solution for optimal performance and durability.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally