Online Air Compressor Lubricating Bushings Solutions- High Quality Bushing

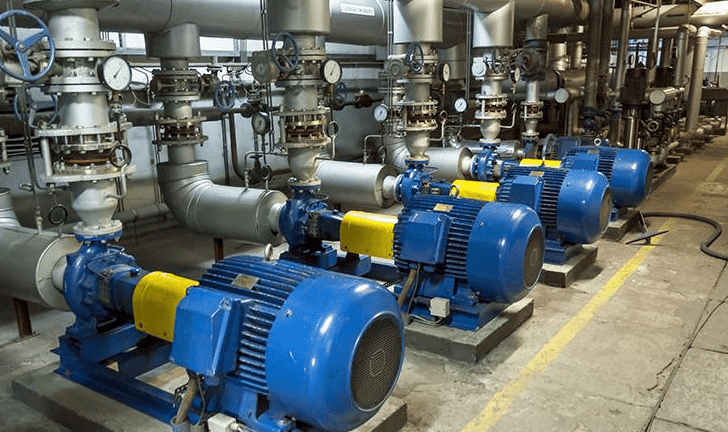

Our custom lubricating bushings are designed to meet the diverse needs of our customers while also reducing the cost of bearings. These bushings can be used in various applications, including air compressors. An air compressor is a device used for compressing gas, and its structure is similar to that of a water pump. Most air compressors use either reciprocating pistons, rotating vanes, or rotating screws. In larger applications, centrifugal compressors are commonly used. Our lubricating bushings are designed to withstand the rigorous demands of air compressor applications, providing reliable and long-lasting performance.

Bushing

Beautifully crafted leather products.

Air conditioning bearing bushings, air conditioning refrigeration can not be separated from the compressor, playing the role of the “heart”, and the compressor is an important part of the bearing, today we will look together, those for the compressor to supply energy self-lubricating bearing products!

The working principle of air conditioning system

1、Compression: The compressor compresses the low temperature and low pressure gaseous refrigerant in the refrigeration system into high pressure and high temperature gaseous refrigerant, which enters the condenser.

2、Condensation: The high pressure and high temperature gaseous refrigerant in the condenser heat exchange and emit heat to the air, and the refrigerant liquefies into medium temperature and high pressure liquid refrigerant and enters the capillary tube.

3、Throttling: The medium temperature and high pressure liquid refrigerant is throttled into low temperature and low pressure liquid refrigerant through the capillary tube and enters the evaporator.

4、Evaporation: The low-temperature and low-pressure liquid refrigerant in the evaporator becomes low-temperature and low-pressure gas refrigerant through heat exchange and heat absorption, and enters the compressor.

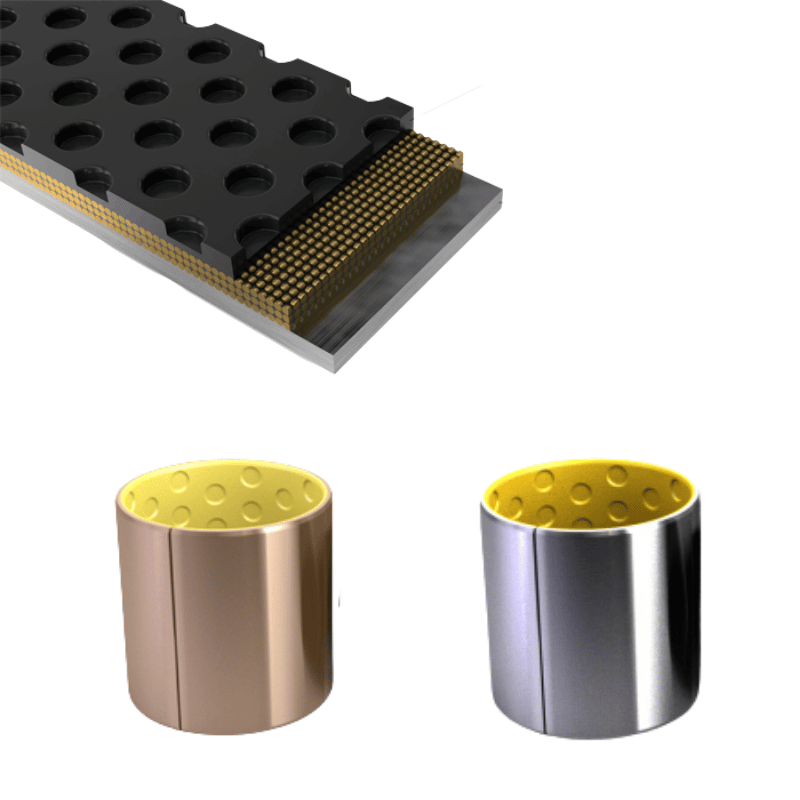

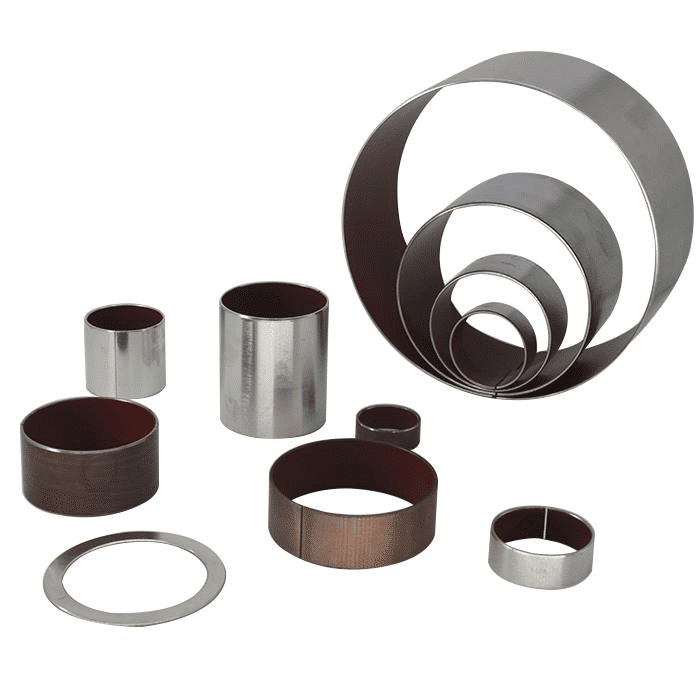

Oil-free plain bearing products for compressor energy supply

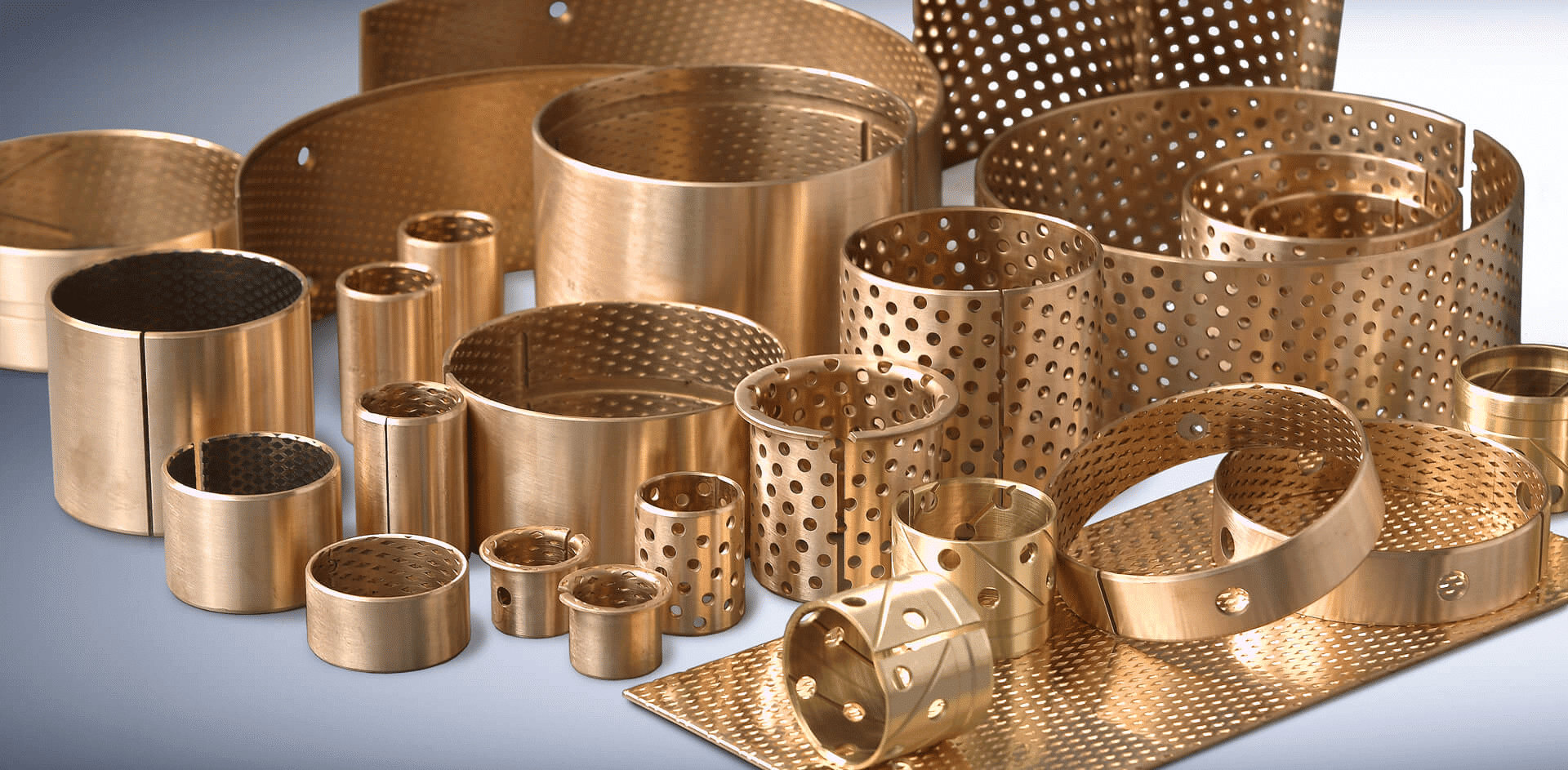

Full range wrapped bronze bushing provider

The compressor is the most indispensable equipment of air conditioning used in daily life.

We offers high-quality, custom bushings, designed to cushion noise, friction and movement.

Air compressor bushing

- An air compressor is a device that converts power (usually from an electric motor, a diesel engine or a gasoline engine) into potential energy by forcing air into a smaller volume and thus increasing its pressure. The energy in the compressed air can be stored while the air remains pressurized. The energy can be used for a variety of applications, usually by utilizing the kinetic energy of the air as it is depressurized.There are numerous methods of air compression, divided into either positive-displacement or negative-displacement types.

Long-lasting, self-lubricating

Air compressor bushing manufacturers & supplier

- The compressor plays the role of compressing and driving the refrigerant in the refrigerant loop of the air conditioner, which can compress the gas and change the low pressure gas into high pressure gas. The common scroll compressor and rotor compressor provide the refrigerant with energy that absorbs heat from the high temperature environment and releases heat from the high temperature environment, so as to help the refrigerant circulation to go smoothly.

- Air conditioning compressor is generally installed in the outdoor unit. The air conditioning compressor extracts the refrigerant from the low pressure area and sends it to the high pressure area after compression for cooling and condensation. The heat is emitted into the air through the radiator, and the refrigerant also changes from a gas state to a liquid state, and the pressure rises.

We manufacturer metal composite bushing tailored to your individual needs.

Reimagining the power of software

How to systematically design metal-polymer bearings in compressors

China Tribology Solutions

As a life partner that everyone can’t live without, air conditioning affects people’s quality of life, of which the compressor is the core component for its temperature regulation, and the selection of bearings with high performance and stability is crucial for the life of the compressor.

Since metal-polymer bearings, we have been a leader in system tribology optimization. For the operating conditions of air conditioning compressors, we offer self-lubricating metal-polymer bearings that help improve performance and reliability.

Plain Bushes & Dry Bushings Longer Lasting

Self-Lubricating Bronze Bearing with Through Holes. Bushing Manufacturer Delivering High-Quality Bearing Parts.

Metal-polymer compressor bearing bushings, Conventional Compressor Bearings vs. Metal-Polymer Bearings

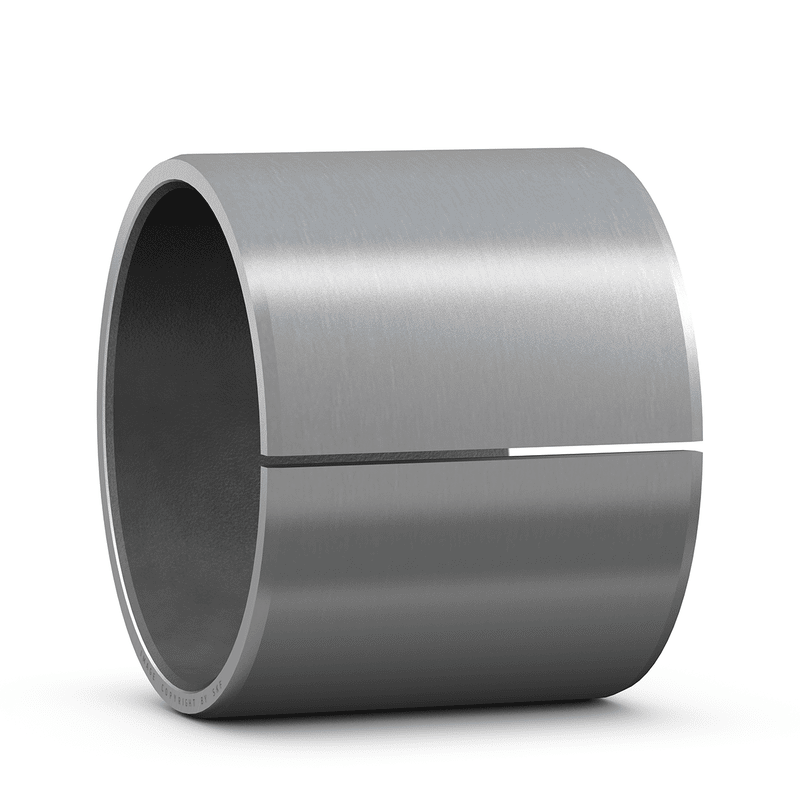

- Metal-Polymer Bearing Structure

- Compressor Bearing System Design

- Factors Affecting Metal-Polymer Bearing Performance

The performance and reliability of conventional compressor bearings (e.g., moving element bearings, leaded bronze or bimetallic bushings) depends heavily on lubrication conditions. The mixed film and boundary lubrication conditions that cause contact between mating surfaces can produce higher friction and excessive wear.

In contrast, metal-polymer bushings have the unique advantage of being self-lubricating so that contact between the mating surfaces does not produce higher wear or friction.

Metal-polymer bearings have been used in commercial compressors for many years, but it is still a relatively new concept for most industries. Without overcoming the engineering hurdles associated with the differences between conventional compressor bearings and metal polymers, commercial applications are unlikely to be successful.

Bearing system design is primarily influenced by the clearances within or between the shaft and bearing surfaces. For compressors, clearance is an important efficiency influencing factor.

Metal-polymer bearings can operate effectively and efficiently within a higher clearance range than bimetallic or needle roller bearings.

In addition, the performance of metal-polymer bearings for compressors depends not only on clearance, but also on the ability of the material to withstand a wide range of speeds, loads, temperatures and corrosive effects under these application conditions. Typical bearing failure modes in compressors include wear, fatigue and cavitation. The ability to design materials that can perfectly cope with wear and fatigue depends on the self-lubricating properties of the material under edge and boundary lubrication conditions.

Find here online price details of companies selling Bronze Bushes. Get info of suppliers, manufacturers, exporters, traders of Bronze Bushes for buying in China.

Safe & Reliable Bronze Bushes Solutions

Find the bushing bearing part for your application. The Good Grease for Lubricating Bushings Bearing

Custom bushing manufacturers, lubricating bushings for longer life!

As the quality custom bushing manufacturers, we discover new lubricating bushings business models, explore opportunities for efficient maintenance and find information about remanufacturing and customization of your industrial equipment.

Discover the complete lubricating bushings.

China Air Compressor Bushing & Plain Bushings Solutions

The working circuit of the air conditioning compressor is divided into the evaporation area (low pressure area) and the condensation area (high pressure area). The indoor and outdoor units of the air conditioning belong to the low pressure or high pressure area respectively (depending on the working state).

The refrigerant flows from the high pressure area to the low pressure area, and is ejected into the evaporator through the capillary tube. The pressure drops sharply, and the liquid refrigerant immediately turns into a gas state, absorbing a large amount of heat in the air through the radiator fin. In this way, the air conditioning compressor continues to work, and the heat at one end of the low pressure area is constantly absorbed into the refrigerant and then sent to the high pressure area to emit into the air, playing a role in regulating the temperature.

Compressor Dry Bushing Supplier – To Satisfy Your Application…

In addition to air conditioning, compressors are also widely used in factory equipment, petrochemical equipment and industrial refrigerators. Due to the particularity of these application scenarios, the plain bearing parts in the equipment need to have low heat, long life, resistance to various working conditions, low noise, low vibration and other properties.

Design or optimize your lubricating bushings to deliver competitive advantage and the best performance.

Efficient Intelligent Air-Compressor Bushing Solutions

Compressors Plain Bushing- Saving Your Cost, Help To Save 30% Discount Or More. Global Compressor Dry Bearing Manufacturer, Composite Bushing Series for All Industries. 24/7/365 Timely Service. Metric Size of Sleeve Bushing. Competitive Cost.

* Our enterprise, is one of the undisputed supplier of the highly competitive bearing bushing industry in china.

Find out more about custom bushing manufacturers custom lubricating bushing capabilities to see how we can help with your next project or application.

As self-lubricating bearing supplier, especially good at according to the different needs of customers custom tribology solutions that benefit from the tribology research for many years, from repeated strict test to absorb the knowledge and experience in many applications, we designed and developed a wide range of surface engineering products, applicable to the compressor sliding composite bearing mainly has the following features:

- Excellent wear resistance and high impact load capacity extend service life, while low friction performance improves equipment performance by reducing power loss.

- Reduce system costs: Plain Bearings do not need to harden and process grease, thus reducing bearing costs. Its compact, one-piece mechanism saves space, reduces weight and is easy to install.

- Reduce energy consumption

- Compressor self-lubricating bearings also help reduce the energy consumption of the hydraulic power system while maintaining higher efficiency.

- Low friction (high wear resistance) bushing: Low friction surface materials reduce power losses and improve output and volumetric efficiency even at low/high pressure conditions.

Air Compressor Bushings Straight Dry Bushings, Flanged Bushings – Metric Size

| Product | Bearing Type | Shaft Dia., Nominal (d) (mm) | Bearing Outside Diameter, Nominal(Do) (mm) | Bearing Length, Nominal (B) (mm) | Wall Thickness (S3) (mm) |

| Dry Bushing 0606 | straight | 6 | 8 | 6 | 1.01 |

| Dry Bushing 0608 | straight | 6 | 8 | 8 | 1.01 |

| Dry Bushing 0610 | straight | 6 | 8 | 10 | 1.01 |

| Dry Bushing 0806 | straight | 8 | 10 | 6 | 1.01 |

| Dry Bushing 0808 | straight | 8 | 10 | 8 | 1.01 |

| Dry Bushing 0810 | straight | 8 | 10 | 10 | 1.01 |

| Dry Bushing 0812 | straight | 8 | 10 | 12 | 1.01 |

| Dry Bushing 0815 | straight | 8 | 10 | 15 | 1.01 |

| Dry Bushing 1006 | straight | 10 | 12 | 6 | 1.01 |

| Dry Bushing 1008 | straight | 10 | 12 | 8 | 1.01 |

| Dry Bushing 1010 | straight | 10 | 12 | 10 | 1.01 |

| Dry Bushing 1012 | straight | 10 | 12 | 12 | 1.01 |

| Dry Bushing 1015 | straight | 10 | 12 | 15 | 1.01 |

| Dry Bushing 1020 | straight | 10 | 12 | 20 | 1.01 |

| Dry Bushing 1206 | straight | 12 | 14 | 6 | 1.01 |

| Dry Bushing 1208 | straight | 12 | 14 | 8 | 1.01 |

| Dry Bushing 1210 | straight | 12 | 14 | 10 | 1.01 |

| Dry Bushing 1212 | straight | 12 | 14 | 12 | 1.01 |

| Dry Bushing 1215 | straight | 12 | 14 | 15 | 1.01 |

| Dry Bushing 1220 | straight | 12 | 14 | 20 | 1.01 |

| Dry Bushing 1225 | straight | 12 | 14 | 25 | 1.01 |

| Dry Bushing 1310 | straight | 13 | 15 | 10 | 1.01 |

| Dry Bushing 1320 | straight | 13 | 15 | 20 | 1.01 |

| Dry Bushing 1410 | straight | 14 | 16 | 10 | 1.01 |

| Dry Bushing 1412 | straight | 14 | 16 | 12 | 1.01 |

| Dry Bushing 1415 | straight | 14 | 16 | 15 | 1.01 |

| Dry Bushing 1420 | straight | 14 | 16 | 20 | 1.01 |

| Dry Bushing 1425 | straight | 14 | 16 | 25 | 1.01 |

| Dry Bushing 1510 | straight | 15 | 17 | 10 | 1.01 |

| Dry Bushing 1512 | straight | 15 | 17 | 12 | 1.01 |

| Dry Bushing 1515 | straight | 15 | 17 | 15 | 1.01 |

| Dry Bushing 1520 | straight | 15 | 17 | 20 | 1.01 |

| Dry Bushing 1525 | straight | 15 | 17 | 25 | 1.01 |

| Dry Bushing 1610 | straight | 16 | 18 | 10 | 1.01 |

| Dry Bushing 1612 | straight | 16 | 18 | 12 | 1.01 |

| Dry Bushing 1615 | straight | 16 | 18 | 15 | 1.01 |

| Dry Bushing 1620 | straight | 16 | 18 | 20 | 1.01 |

| Dry Bushing 1625 | straight | 16 | 18 | 25 | 1.01 |

| Dry Bushing 1710 | straight | 17 | 19 | 10 | 1.01 |

| Dry Bushing 1712 | straight | 17 | 19 | 12 | 1.01 |

| Dry Bushing 1720 | straight | 17 | 19 | 20 | 1.01 |

| Dry Bushing 1810 | straight | 18 | 20 | 10 | 1.01 |

| Dry Bushing 1812 | straight | 18 | 20 | 12 | 1.01 |

| Dry Bushing 1815 | straight | 18 | 20 | 15 | 1.01 |

| Dry Bushing 1820 | straight | 18 | 20 | 20 | 1.01 |

| Dry Bushing 1825 | straight | 18 | 20 | 25 | 1.01 |

| Dry Bushing 2010 | straight | 20 | 23 | 10 | 1.51 |

| Dry Bushing 2012 | straight | 20 | 23 | 12 | 1.51 |

| Dry Bushing 2015 | straight | 20 | 23 | 15 | 1.51 |

| Dry Bushing 2020 | straight | 20 | 23 | 20 | 1.51 |

| Dry Bushing 2025 | straight | 20 | 23 | 25 | 1.51 |

| Dry Bushing 2030 | straight | 20 | 23 | 30 | 1.51 |

| Dry Bushing 2210 | straight | 22 | 25 | 10 | 1.51 |

| Dry Bushing 2212 | straight | 22 | 25 | 12 | 1.51 |

| Dry Bushing 2215 | straight | 22 | 25 | 15 | 1.51 |

| Dry Bushing 2220 | straight | 22 | 25 | 20 | 1.51 |

| Dry Bushing 2225 | straight | 22 | 25 | 25 | 1.51 |

| Dry Bushing 2230 | straight | 22 | 25 | 30 | 1.51 |

| Dry Bushing 2415 | straight | 24 | 27 | 15 | 1.51 |

| Dry Bushing 2420 | straight | 24 | 27 | 20 | 1.51 |

| Dry Bushing 2425 | straight | 24 | 27 | 25 | 1.51 |

| Dry Bushing 2430 | straight | 24 | 27 | 30 | 1.51 |

| Dry Bushing 2510 | straight | 25 | 28 | 10 | 1.51 |

| Dry Bushing 2512 | straight | 25 | 28 | 12 | 1.51 |

| Dry Bushing 2515 | straight | 25 | 28 | 15 | 1.51 |

| Dry Bushing 2520 | straight | 25 | 28 | 20 | 1.51 |

| Dry Bushing 2525 | straight | 25 | 28 | 25 | 1.51 |

| Dry Bushing 2530 | straight | 25 | 28 | 30 | 1.51 |

| Dry Bushing 2540 | straight | 25 | 28 | 40 | 1.51 |

| Dry Bushing 2550 | straight | 25 | 28 | 50 | 1.51 |

| Dry Bushing 2815 | straight | 28 | 32 | 15 | 2.01 |

| Dry Bushing 2820 | straight | 28 | 32 | 20 | 2.01 |

| Dry Bushing 2825 | straight | 28 | 32 | 25 | 2.01 |

| Dry Bushing 2830 | straight | 28 | 32 | 30 | 2.01 |

| Dry Bushing 2840 | straight | 28 | 32 | 40 | 2.01 |

| Dry Bushing 3012 | straight | 30 | 34 | 12 | 2.01 |

| Dry Bushing 3015 | straight | 30 | 34 | 15 | 2.01 |

| Dry Bushing 3020 | straight | 30 | 34 | 20 | 2.01 |

| Dry Bushing 3025 | straight | 30 | 34 | 25 | 2.01 |

| Dry Bushing 3030 | straight | 30 | 34 | 30 | 2.01 |

| Dry Bushing 3040 | straight | 30 | 34 | 40 | 2.01 |

| Dry Bushing 3220 | straight | 32 | 36 | 20 | 2.01 |

| Dry Bushing 3230 | straight | 32 | 36 | 30 | 2.01 |

| Dry Bushing 3240 | straight | 32 | 36 | 40 | 2.01 |

| Dry Bushing 3512 | straight | 35 | 39 | 12 | 2.01 |

| Dry Bushing 3515 | straight | 35 | 39 | 15 | 2.01 |

| Dry Bushing 3520 | straight | 35 | 39 | 20 | 2.01 |

| Dry Bushing 3525 | straight | 35 | 39 | 25 | 2.01 |

| Dry Bushing 3530 | straight | 35 | 39 | 30 | 2.01 |

| Dry Bushing 3540 | straight | 35 | 39 | 40 | 2.01 |

| Dry Bushing 3550 | straight | 35 | 39 | 50 | 2.01 |

| Dry Bushing 3815 | straight | 38 | 42 | 15 | 2.01 |

| Dry Bushing 3830 | straight | 38 | 42 | 30 | 2.01 |

| Dry Bushing 3840 | straight | 38 | 42 | 40 | 2.01 |

| Dry Bushing 4012 | straight | 40 | 44 | 12 | 2.01 |

| Dry Bushing 4020 | straight | 40 | 44 | 20 | 2.01 |

| Dry Bushing 4025 | straight | 40 | 44 | 25 | 2.01 |

| Dry Bushing 4030 | straight | 40 | 44 | 30 | 2.01 |

| Dry Bushing 4040 | straight | 40 | 44 | 40 | 2.01 |

| Dry Bushing 4050 | straight | 40 | 44 | 50 | 2.01 |

| Dry Bushing 4520 | straight | 45 | 50 | 20 | 2.51 |

| Dry Bushing 4525 | straight | 45 | 50 | 25 | 2.51 |

| Dry Bushing 4530 | straight | 45 | 50 | 30 | 2.51 |

| Dry Bushing 4540 | straight | 45 | 50 | 40 | 2.51 |

| Dry Bushing 4550 | straight | 45 | 50 | 50 | 2.51 |

| Dry Bushing 5020 | straight | 50 | 55 | 20 | 2.51 |

| Dry Bushing 5030 | straight | 50 | 55 | 30 | 2.51 |

| Dry Bushing 5040 | straight | 50 | 55 | 40 | 2.51 |

| Dry Bushing 5050 | straight | 50 | 55 | 50 | 2.51 |

| Dry Bushing 5060 | straight | 50 | 55 | 60 | 2.51 |

| Dry Bushing 5530 | straight | 55 | 60 | 30 | 2.51 |

| Dry Bushing 5540 | straight | 55 | 60 | 40 | 2.51 |

| Dry Bushing 5550 | straight | 55 | 60 | 50 | 2.51 |

| Dry Bushing 5560 | straight | 55 | 60 | 60 | 2.51 |

| Dry Bushing 6030 | straight | 60 | 65 | 30 | 2.51 |

| Dry Bushing 6040 | straight | 60 | 65 | 40 | 2.51 |

| Dry Bushing 6050 | straight | 60 | 65 | 50 | 2.51 |

| Dry Bushing 6060 | straight | 60 | 65 | 60 | 2.51 |

| Dry Bushing 6070 | straight | 60 | 65 | 70 | 2.51 |

| Dry Bushing 6530 | straight | 65 | 70 | 30 | 2.51 |

| Dry Bushing 6540 | straight | 65 | 70 | 40 | 2.51 |

| Dry Bushing 6550 | straight | 65 | 70 | 50 | 2.51 |

| Dry Bushing 6560 | straight | 65 | 70 | 60 | 2.51 |

| Dry Bushing 6570 | straight | 65 | 70 | 70 | 2.51 |

| Dry Bushing 7040 | straight | 70 | 75 | 40 | 2.51 |

| Dry Bushing 7050 | straight | 70 | 75 | 50 | 2.51 |

| Dry Bushing 7060 | straight | 70 | 75 | 60 | 2.51 |

| Dry Bushing 7070 | straight | 70 | 75 | 70 | 2.51 |

| Dry Bushing 7080 | straight | 70 | 75 | 80 | 2.51 |

| Dry Bushing 7530 | straight | 75 | 80 | 30 | 2.51 |

| Dry Bushing 7540 | straight | 75 | 80 | 40 | 2.51 |

| Dry Bushing 7550 | straight | 75 | 80 | 50 | 2.51 |

| Dry Bushing 7560 | straight | 75 | 80 | 60 | 2.51 |

| Dry Bushing 7570 | straight | 75 | 80 | 70 | 2.51 |

| Dry Bushing 7580 | straight | 75 | 80 | 80 | 2.51 |

| Dry Bushing 8040 | straight | 80 | 85 | 40 | 2.49 |

| Dry Bushing 8050 | straight | 80 | 85 | 50 | 2.49 |

| Dry Bushing 8060 | straight | 80 | 85 | 60 | 2.49 |

| Dry Bushing 8070 | straight | 80 | 85 | 70 | 2.49 |

| Dry Bushing 8080 | straight | 80 | 85 | 80 | 2.49 |

| Dry Bushing 80100 | straight | 80 | 85 | 100 | 2.49 |

| Dry Bushing 8540 | straight | 85 | 90 | 40 | 2.49 |

| Dry Bushing 8560 | straight | 85 | 90 | 60 | 2.49 |

| Dry Bushing 8580 | straight | 85 | 90 | 80 | 2.49 |

| Dry Bushing 85100 | straight | 85 | 90 | 100 | 2.49 |

| Dry Bushing 9040 | straight | 90 | 95 | 40 | 2.49 |

| Dry Bushing 9050 | straight | 90 | 95 | 50 | 2.49 |

| Dry Bushing 9060 | straight | 90 | 95 | 60 | 2.49 |

| Dry Bushing 9080 | straight | 90 | 95 | 80 | 2.49 |

| Dry Bushing 90100 | straight | 90 | 95 | 100 | 2.49 |

| Dry Bushing 9550 | straight | 95 | 100 | 50 | 2.49 |

| Dry Bushing 9560 | straight | 95 | 100 | 60 | 2.49 |

| Dry Bushing 9580 | straight | 95 | 100 | 80 | 2.49 |

| Dry Bushing 95100 | straight | 95 | 100 | 100 | 2.49 |

| Dry Bushing 10050 | straight | 100 | 105 | 50 | 2.49 |

| Dry Bushing 10060 | straight | 100 | 105 | 60 | 2.49 |

| Dry Bushing 10080 | straight | 100 | 105 | 80 | 2.49 |

| Dry Bushing 100115 | straight | 100 | 105 | 115 | 2.49 |

| Dry Bushing 10560 | straight | 105 | 110 | 60 | 2.49 |

| Dry Bushing 10580 | straight | 105 | 110 | 80 | 2.49 |

| Dry Bushing 105115 | straight | 105 | 110 | 115 | 2.49 |

| Dry Bushing 11060 | straight | 110 | 115 | 60 | 2.49 |

| Dry Bushing 11080 | straight | 110 | 115 | 80 | 2.49 |

| Dry Bushing 110115 | straight | 110 | 115 | 115 | 2.49 |

| Dry Bushing 12060 | straight | 120 | 125 | 60 | 2.47 |

| Dry Bushing 12080 | straight | 120 | 125 | 80 | 2.47 |

| Dry Bushing 120100 | straight | 120 | 125 | 100 | 2.47 |

| Dry Bushing 12560 | straight | 125 | 130 | 60 | 2.47 |

| Dry Bushing 125100 | straight | 125 | 130 | 2.47 | |

| Dry Bushing 125115 | straight | 125 | 130 | 115 | 2.47 |

| Dry Bushing 13060 | straight | 130 | 135 | 60 | 2.47 |

| Dry Bushing 13080 | straight | 130 | 135 | 80 | 2.47 |

| Dry Bushing 130100 | straight | 130 | 135 | 100 | 2.47 |

| Dry Bushing 14060 | straight | 140 | 145 | 60 | 2.47 |

| Dry Bushing 14080 | straight | 140 | 145 | 80 | 2.47 |

| Dry Bushing 140100 | straight | 140 | 145 | 100 | 2.47 |

| Dry Bushing 15060 | straight | 150 | 155 | 60 | 2.47 |

| Dry Bushing 15080 | straight | 150 | 155 | 80 | 2.47 |

| Dry Bushing 150100 | straight | 150 | 155 | 100 | 2.47 |

| Dry Bushing 16060 | straight | 160 | 165 | 60 | 2.47 |

| Dry Bushing 16080 | straight | 160 | 165 | 80 | 2.47 |

| Dry Bushing 160100 | straight | 160 | 165 | 100 | 2.47 |

| Dry Bushing 160115 | straight | 160 | 165 | 115 | 2.47 |

| Dry Bushing 18080 | straight | 180 | 185 | 80 | 2.47 |

| Dry Bushing 180100 | straight | 180 | 185 | 100 | 2.47 |

| Dry Bushing 19080 | straight | 190 | 195 | 80 | 2.47 |

| Dry Bushing 190100 | straight | 190 | 195 | 100 | 2.47 |

| Dry Bushing 20060 | straight | 200 | 205 | 60 | 2.47 |

| Dry Bushing 20080 | straight | 200 | 205 | 80 | 2.47 |

| Dry Bushing 200100 | straight | 200 | 205 | 100 | 2.47 |

| Dry Bushing 22080 | straight | 220 | 225 | 80 | 2.47 |

| Dry Bushing 220100 | straight | 220 | 225 | 100 | 2.47 |

| Dry Bushing 25080 | straight | 250 | 255 | 80 | 2.47 |

| Dry Bushing 250100 | straight | 250 | 255 | 100 | 2.47 |

| Dry Bushing 26080 | straight | 260 | 265 | 80 | 2.47 |

| Dry Bushing 260100 | straight | 260 | 265 | 100 | 2.47 |

| Dry Bushing 28080 | straight | 280 | 285 | 80 | 2.47 |

| Dry Bushing 280100 | straight | 280 | 285 | 100 | 2.47 |

| Dry Bushing 30080 | straight | 300 | 305 | 80 | 2.47 |

| Dry Bushing 300100 | straight | 300 | 305 | 100 | 2.47 |

| Dry Bushing F06040 | flanged | 6 | 8 | 4 | 1.01 |

| Dry Bushing F06070 | flanged | 6 | 8 | 7 | 1.01 |

| Dry Bushing F08055 | flanged | 8 | 10 | 5.5 | 1.01 |

| Dry Bushing F08075 | flanged | 8 | 10 | 7.5 | 1.01 |

| Dry Bushing F10070 | flanged | 10 | 12 | 7 | 1.01 |

| Dry Bushing F10090 | flanged | 10 | 12 | 9 | 1.01 |

| Dry Bushing F100120 | flanged | 10 | 12 | 12 | 1.01 |

| Dry Bushing F12070 | flanged | 12 | 14 | 7 | 1.01 |

| Dry Bushing F12090 | flanged | 12 | 14 | 9 | 1.01 |

| Dry Bushing F120120 | flanged | 12 | 14 | 12 | 1.01 |

| Dry Bushing F14120 | flanged | 14 | 16 | 12 | 1.01 |

| Dry Bushing F14170 | flanged | 14 | 16 | 17 | 1.01 |

| Dry Bushing F15090 | flanged | 15 | 17 | 9 | 1.01 |

| Dry Bushing F15120 | flanged | 15 | 17 | 12 | 1.01 |

| Dry Bushing F15170 | flanged | 15 | 17 | 17 | 1.01 |

| Dry Bushing F16120 | flanged | 16 | 18 | 12 | 1.01 |

| Dry Bushing F16170 | flanged | 16 | 18 | 17 | 1.01 |

| Dry Bushing F18120 | flanged | 18 | 20 | 12 | 1.01 |

| Dry Bushing F18170 | flanged | 18 | 20 | 17 | 1.01 |

| Dry Bushing F18200 | flanged | 18 | 20 | 20 | 1.01 |

| Dry Bushing F20115 | flanged | 20 | 23 | 11.5 | 1.51 |

| Dry Bushing F20165 | flanged | 20 | 23 | 16.5 | 1.51 |

| Dry Bushing F20215 | flanged | 20 | 23 | 21.5 | 1.51 |

| Dry Bushing F22150 | flanged | 22 | 25 | 15 | 1.51 |

| Dry Bushing F22200 | flanged | 22 | 25 | 20 | 1.51 |

| Dry Bushing F25115 | flanged | 25 | 28 | 11.5 | 1.51 |

| Dry Bushing F25165 | flanged | 25 | 28 | 16.5 | 1.51 |

| Dry Bushing F25215 | flanged | 25 | 28 | 21.5 | 1.51 |

| Dry Bushing F30160 | flanged | 30 | 34 | 16 | 2.01 |

| Dry Bushing F30260 | flanged | 30 | 34 | 26 | 2.01 |

| Dry Bushing F35160 | flanged | 35 | 39 | 16 | 2.01 |

| Dry Bushing F35260 | flanged | 35 | 39 | 26 | 2.01 |

| Dry Bushing F40260 | flanged | 40 | 44 | 26 | 2.01 |

| Dry Bushing F40400 | flanged | 40 | 44 | 40 | 2.01 |

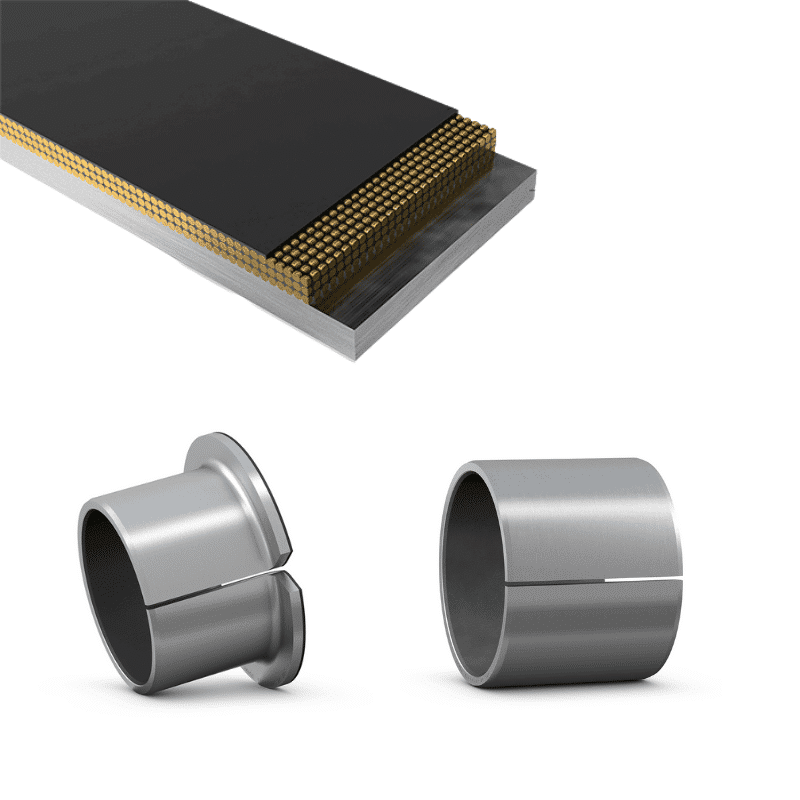

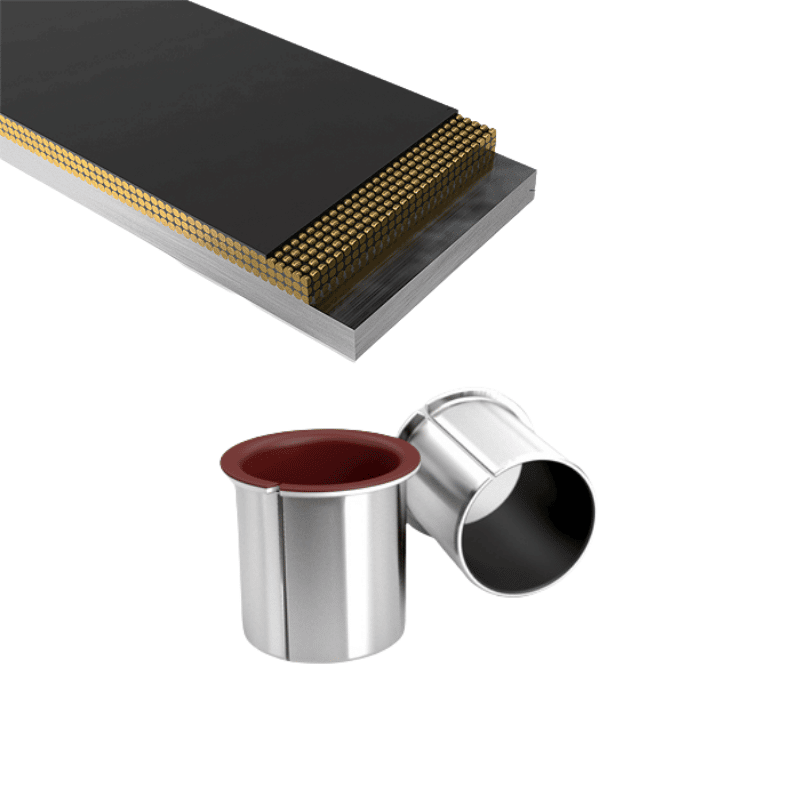

Steel Backed Bushing

Features

It is suitable for working parts where it is impossible to add oil or difficult to add oil, and has excellent wear resistance, walking together, corrosion resistance, low friction factor, and low noise and no pollution; the transfer film formed during operation plays a role in protecting the shaft against wear, and there is no shaft gnawing; the processing requirements for the coupling are reduced, and the processing cost for the user is reduced. It has been widely used in general industry.

Material organization

1. PTFE and fiber mixture 0.01~0.03mm, which can form a good transfer film to protect the counterpart and provide self-lubricating performance of the bearing.

2. Copper powder layer 0.20~0.35mm, which has good bearing capacity and wear resistance, and good thermal conductivity can transfer the heat generated during the operation of the bearing in time. The composite material penetrates into the pores of the spherical copper powder to improve the bonding strength.

3. Low carbon steel, which provides good load-bearing performance and heat transfer.

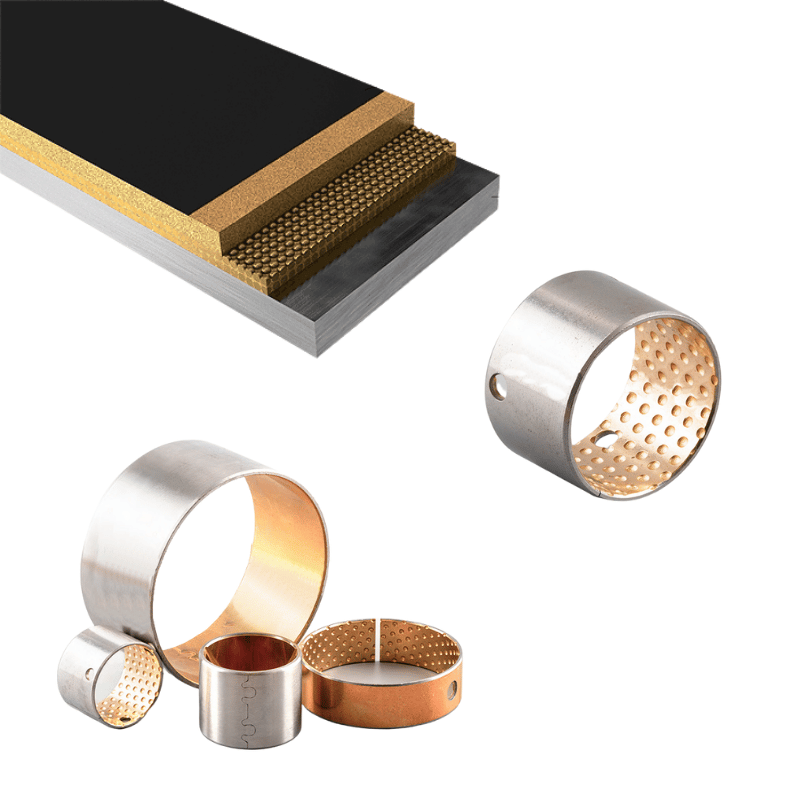

Self-lubricating Steel Bushing

Features

Designed for applications requiring high anti-wear properties, dry friction self-lubrication, and maintenance-free requirements. The thicker resin layer can meet the requirement of reworking after assembly to improve mating accuracy, and also provide noise reduction and sound absorption. It is recommended for belt tensioner pulley, idler pulley, solenoid valve, and re-processing occasions requiring high precision tolerance fit, such as air conditioning compressor main and secondary shaft bushings, etc.

Material organization

1.PTFE/Fluorine resin layer, which provides self-lubricating performance of the bearing and can be reprocessed.

2. Copper powder layer 0.20~0.35mm, which has good bearing capacity and wear resistance, and good thermal conductivity can transfer the heat generated during the operation of the bearing in time. The composite material penetrates into the pores of the spherical copper powder, which improves the bonding strength.

3. Low carbon steel, which provides good load-bearing performance and heat transfer.

Thanks to the advancement of self-lubricating coating technology, we can provide not only cast copper alloy matrix and bimetal bearings, but also higher performance self-lubricating copper bushings to meet higher design requirements.

Train

Running pulley

Pumps

High temperature

Agriculture

Construction

Sliding bearings & surface engineering techniques

Help create a dynamic world and minimize friction losses