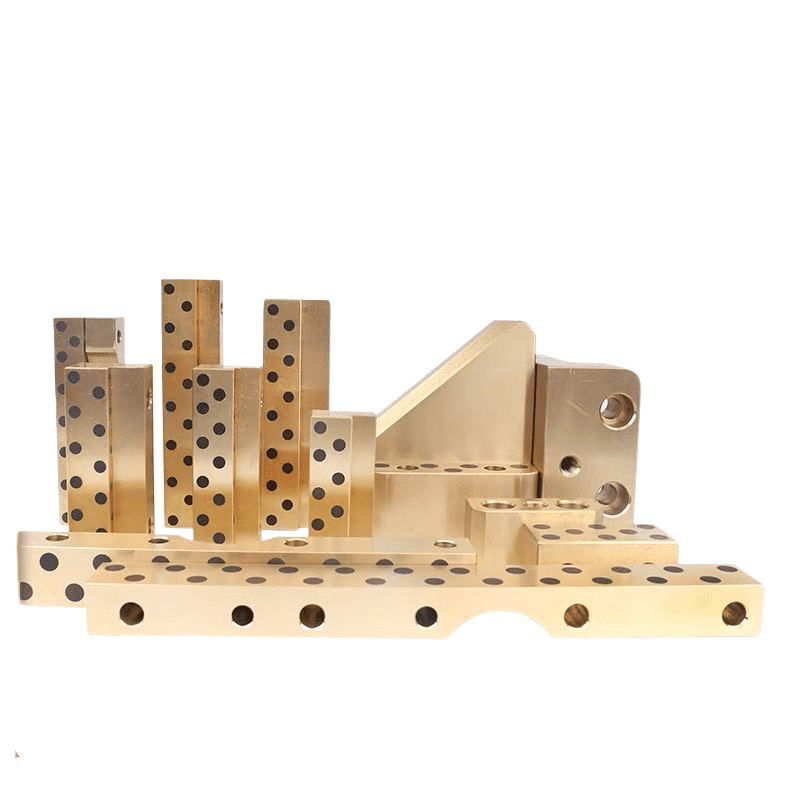

Custom Bronze Wear Plate Manufacture – Customized Plate Solutions

Bronze Wear Plate Material

Grease groove wear plates are wear plates that have a groove or several grooves machined into them to hold lubricating grease. We also provide a selection of standard sliding/wear bronze graphite plates, designed to assist customers in choosing the perfect fit for their new equipment, machinery, or replacement parts. Our standard plate range offers the benefits of a tried-and-tested design, specified dimensions, and a high-quality material. Bronze wear plates are made from a variety of bronze alloys. A wear plate is a piece of very hard material that’s used to reduce the friction between two surfaces that rub against each other, and thus to extend the lifetime of mechanical parts. The exact alloy used for a bronze wear plate can vary, but most bronze wear plates are made from some variation of high-strength bronze alloys. These alloys often contain elements such as aluminum, nickel, manganese, or silicon to increase their strength and wear resistance.

BRONZE WEAR PLATE, Custom Made Sliding/Wear Plates

What Type of Bronze to Use for Wear Plates?

The type of bronze used in a wear plate depends on the specific application. For instance, some applications might require a high level of corrosion resistance, while others might prioritize hardness or load-bearing capacity. Bronze wear plates are often used in machinery, industrial equipment, and transportation vehicles. It’s important to note that bronze wear plates require regular lubrication to prevent excessive wear and to maintain the functionality of the mechanical parts they’re used in.Here are few types of bronze used in wear plates:

Product Quality Index

Energy Generation

Continuous cast alloys, precision bronze wear plates with grooves, and aluminum bronze plates.

“We specialize in crafting custom self-lubricating sliding/wear plates to improve the productivity of your machinery. Engineered to eliminate the need for grease or oil, these plates promise maintenance-free operation that elevates your equipment’s efficiency and performance. Aluminum bronze, as an alloy, is characterized by its high tensile strength and a low coefficient of friction, making it an ideal material for use in wear plates.

Bronze Alloy: Bronze Wear Plate tailored to your individual needs.

Selecting the appropriate bronze alloy for wear plates is a complex yet essential task for product engineers, given the vast selection of hundreds of bronze variants.

Grease groove wear plates, designed to retain lubricating grease, play a crucial role in diminishing friction and wear on machinery components. These plates are distinctively engineered with grooves that facilitate the even distribution of grease over their surface, which significantly prolongs the durability of both the wear plate and its associated machinery part. Available in a range of materials like bronze and steel, these plates can be tailored with various features, including hole patterns, pockets, chamfers, and cutouts, to enhance their protective capabilities. In situations where wear plates embedded with graphite are not feasible, these conventionally lubricated grease groove wear plates serve as an effective alternative. The strategic grooving in these plates ensures an even grease distribution, effectively minimizing friction and wear, which contributes to the longevity of both the plates and the machinery parts they interact with.

Bronze alloys have found widespread use in wear plate applications over the years. Many materials traditionally used in equipment construction are ineffective as wear surfaces, a challenge that bronze wear plates effectively address. They act as an ideal bearing surface between moving parts, significantly reducing maintenance costs and downtime by serving as sacrificial elements.

Aluminum bronze is predominantly used in the manufacture of our wear plates, although bearing bronze alloys are also popular for bushing applications. Aluminum bronze wear plates exhibit impressive wear resistance paired with a low friction coefficient, preventing galling and material transfer when interacting with dissimilar base materials.

The design considerations for aluminum bronze wear plates should factor in the alloy’s availability and cost. Most of the wear plates produced are made from C95400 aluminum bronze due to its wide accessibility, affordability, and variety in sizes and shapes. The uniform, fine grain structure of this continuous cast alloy further enhances its mechanical properties, making it an optimal choice for wear plate applications.

Please follow the provided links for more detailed information about Aluminum Bronze Alloys, C954 Aluminum Bronze, and Bronze Wear Plates.

What Type of Bronze to Use for Wear Plates?

Bronze Wear Plate Material. Self-lubricating, Plugged Graphite.

For wear plates that require self-lubricating properties, you might want to consider bronze alloys that are specifically designed for this purpose. Bronze alloys containing graphite plugs are an excellent choice, as the graphite provides a self-lubricating property. This kind of bronze is commonly referred to as “Oilite” or “Graphite Plugged Bronze.”

There are a variety of bronze alloys that can be used for this purpose, each with their unique properties and benefits:

C93200 (SAE 660) Bearing Bronze: This alloy is commonly used for bearings, bushings, and wear plates. It offers excellent machinability and superior wear resistance. It’s also easy to incorporate graphite plugs in this alloy for enhanced lubrication.

C95400 Aluminum Bronze: This is a very hard, strong alloy that resists wear and has excellent load-carrying capacity. Its hardness and strength make it a bit more difficult to machine, but it can handle more extreme wear conditions than C93200.

C86300 (SAE 430B) Manganese Bronze: This alloy is known for its high strength and hardness, as well as its excellent resistance to wear, making it ideal for heavy-duty applications. It’s more difficult to machine, but it’s a good choice for conditions where high load and impact resistance are required.

Remember that the choice of material often depends on the specific requirements of your application, including the load, speed, operating temperature, and the type of motion (rotary, oscillating, or linear). You should also consider factors like cost, availability, and machinability. Always consult with a materials engineer or a similar professional when selecting materials for specific applications to ensure you’re making the most informed decision.

Bronze Wear Plates:the alloy, or its applications

Bronze Wear Plates:

Bronze wear plates are components utilized in machinery to minimize wear and tear between moving parts. They function as a bearing surface to reduce friction and wear, which extends the life of the machine and reduces maintenance costs.

Alloy Composition: Bronze wear plates are typically made from aluminum bronze alloys, such as C95400. This alloy consists primarily of copper, with aluminum being the major alloying element. C95400, in particular, contains approximately 83% copper, 11% aluminum, 3-5% iron, and 2-4% nickel. This alloy has superior mechanical properties, including excellent wear resistance, strength, and hardness.

Applications: Bronze wear plates find widespread use in a variety of applications. Due to their properties, they are used in situations where high wear resistance and low friction are needed, such as:

Heavy machinery: In industries such as construction and mining, where machinery undergoes significant wear and tear, bronze wear plates are used to prolong the life of the equipment.

Automotive: They are used in the manufacturing of parts in automobiles to reduce friction and wear, leading to less frequent replacements and maintenance.

Industrial applications: They are used in pumps, valves, cylinders, and other equipment to reduce friction and wear between moving parts.

The high wear resistance and low friction properties of bronze wear plates, particularly those made from aluminum bronze alloys, make them an excellent choice for a wide variety of industrial and mechanical applications.

Our custom options extend to:

Design: Our focus is on designing highly efficient sliding/wear plates. We aim to offer these at a competitive price point, without compromising on performance, quality, or longevity. Our designs are tailored to your specifications and requirements.

Dimensions: We cater to a wide range of needs when it comes to the dimensions of the sliding/wear plates. We are capable of creating plates as thin as 1.5mm to as thick as 50mm. Our maximum dimension extends up to 2000mm. For more details, feel free to reach out to our sales team.

Materials: Our material options include self-lubricating bronze graphite materials, spanning metallic, bi-metallic, and non-metallic categories. Depending on your needs, we offer materials that are either self-lubricating or ones that require lubrication.

Our engineering team is available to suggest the most suitable design, material, dimension, and types for your needs. Let us help you maximize the efficiency and durability of your equipment with our custom-made sliding/wear plates.”

General overview of bronze and its use in wear plates, along with a few common types of bronze alloys and their general properties.

- C95400 Aluminum Bronze: Also known as C954, it is one of the most popular bronze alloys, providing high strength, excellent hardness, and very good wear resistance. It’s often used for heavy duty applications where friction and wear are a problem.

- C93200 (SAE 660) Bearing Bronze: Commonly used in bearings, pumps, and valves, this bronze alloy has excellent machining properties, good hardness, strength and wear resistance, and excellent antifriction qualities.

- C95900 Aluminum Bronze: C959 is used for applications involving heavy loads, abrasive wear resistant, friction, abrasive wear and corrosion. It is resistant to impacts and is good for heavy duty applications.

Typical properties for these alloys might include:

C95400 Aluminum Bronze:

- Tensile strength: 85,000 PSI

- Yield strength: 32,000 PSI

- Hardness: 195 BHN

- Elongation: 12%

C93200 Bearing Bronze:

- Tensile strength: 35,000 PSI

- Yield strength: 20,000 PSI

- Hardness: 65 BHN

- Elongation: 10%

C95900 Aluminum Bronze:

- Tensile strength: 95,000 PSI

- Yield strength: 45,000 PSI

- Hardness: 262 BHN

- Elongation: 14%

Please note that these are generalized values and may vary based on different factors such as the specific manufacturing process used. For accurate data, you should refer to the manufacturer’s technical data sheets or other official resources. If you’re in the process of designing new machinery or looking to replace parts, our standard plates provide an excellent starting point. They combine our expertise in materials and design with the flexibility to accommodate a wide range of applications. Each plate is crafted from our top-grade bronze graphite material, promising durability and performance.

In addition to our custom solutions, these standard plates serve as an accessible and efficient option for those seeking quality and reliability. They exemplify our commitment to enhancing your machinery’s productivity through superior wear solutions. For further assistance in selecting the most suitable standard plate, don’t hesitate to reach out to our expert team.”

These grooves provide a path for the grease to spread across the surface of the wear plate, reducing friction and wear, and extending the life of both the wear plate and the corresponding part. They are used in industrial applications such as pumps, valves, cylinders, and other equipment to reduce friction and wear between moving parts. The dimensions of these plates can vary, with the capability to create plates as thin as 1.5mm to as thick as 50mm, and a maximum dimension extending up to 2000mm. The materials used for grease groove wear plates include self-lubricating bronze graphite materials and metallic options. Common configurations include custom hole patterns, grease grooves, and mounting holes.

C95400 Aluminum Bronze Wear Plate

C95400 aluminum bronze, also known as “Aluminum Bronze 9C” or “C954”, is the most common aluminum bronze alloy. The composition of this alloy typically includes about 83% copper, 11% aluminum, 3-5% iron, and 2-4% nickel. C95400 aluminum bronze is well known for its exceptional strength, hardness, and wear resistance, along with its excellent corrosion resistance. These characteristics make it an ideal material for use in harsh and demanding applications.

When used in wear plates, C95400 aluminum bronze provides a durable, low friction surface that can withstand a high degree of wear and tear, helping to extend the lifespan of the machinery in which it’s used. It’s an excellent material for applications where galling (the transfer of material between sliding surfaces) is a concern.

This bronze alloy is often used in the manufacture of heavy duty machinery components, marine hardware, bearings, bushings, and of course, wear plates. Due to its impressive mechanical properties, C95400 aluminum bronze is widely used in the production of wear plates that require superior wear resistance, strength, and corrosion resistance.

Continuous cast alloy: Precision Bronze Wear Plates with Grooves:

Continuous casting is a refined process of casting that’s used in the manufacturing of alloys, including bronze. This method is preferred because it produces materials with improved mechanical properties and a uniform, fine grain structure. The process involves continuously pouring molten metal into a mold, where it cools and solidifies. As the solid metal is continuously drawn out of the other side of the mold, more molten metal is poured in, creating a constant production cycle. Precision bronze wear plates with grooves are specially designed wear plates that have grooves in their surfaces. The grooves can be beneficial for several reasons. They can help with the distribution of lubricant across the wear plate, reducing friction and wear even further. Also, in some applications, these grooves can help channel away debris, preventing it from causing damage or further wear to the plate or to the machinery components that are interacting with the plate.

High Tensile Strength:

The tensile strength of a material is a measure of how much stress it can withstand without breaking. High tensile strength in aluminum bronze means that it can withstand a considerable amount of pressure and stress, which is common in machinery and industrial applications where wear plates are used. This high strength contributes to the durability and longevity of the wear plates, reducing the need for frequent replacements.

Low coefficient of friction

The low friction coefficient of aluminum bronze is also a crucial property for wear plates. A lower coefficient of friction means that there is less resistance when one material moves across another. In the context of wear plates, this means that there’s less wear and tear on both the wear plate itself and the part it interacts with, resulting in less maintenance and longer machine life.

Self-lubricating Bronze Plate

When these characteristics are combined with the excellent corrosion resistance of aluminum bronze, it’s clear why this material is often the bronze alloy of choice for wear plates in various industries. The wear plates made from this alloy can effectively reduce the friction and wear in machinery, extending its service life and reducing maintenance costs.

BRONZE WEAR PLATE MATERIAL

Special parts request