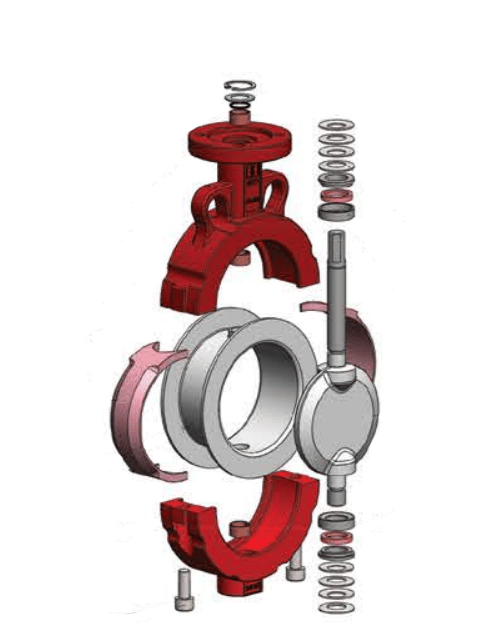

Sliding Bushing Configuration

Industrial Valve Bushing bronzelube.com

Engineering & Manufacturers of Valve Bearings, Gate Bushing, Globe Bushing, Ball Bushing, and Butterfly Valves Bushing Design. Find your valves material bushing now. Valve Bushing Repair. Emergency Services. Our customers look to us to provide them with the highest quality, custom designed plain bearings and tolerance thrust bearing & washer for use in an extensive range of applications. As plain bearing manufacturers, we supply sliding bearings, tolerance thrust bearings and washer self-lubricating bearings to high volume international Original Equipment Manufacturers (OEMs) in various industries. we work alongside engineers and customers wherever they may be. Viiplus supports the valve industry with a broad range of du plain bearing, du thrust washer, du thrust bearing products that provide sealing, retaining and protection.

Company of Self-lubricating Bearings, Sesimic Isolation and Vibration for Various Industries.

isolating valves plain bearings

Bearing of the shaft journal in maintenance-free isolating valves

Plain bearings that work according to the hydrodynamic principle can meet various requirements relatively well. In this way, with the aid of modern calculation methods, oil-lubricated plain bearings in particular can be designed for optimum and reliable operation. Low-maintenance plain bearings are usually lubricated with grease. The amount of grease used during the mounting process is usually sufficient to last the entire service life. If grease-lubricated plain bearings are used under difficult conditions, subsequent lubrication is recommended. The shaft journal and the valve disc are mounted with plain bearing bushes. Other designations for isolating valves: Butterfly valves Plain Bearings…

In cases where oil or grease lubrication is not possible or not permitted, maintenance-free dry-running plain bearings can be used. Sleeve-type bearings (self-lubricating) for isolating valves plain bearings!

Product Quality Index

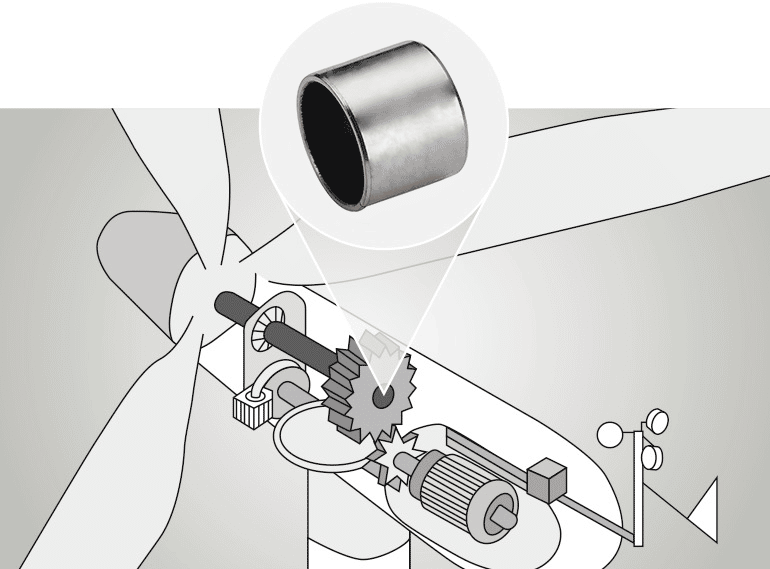

Energy Generation

Projects

Make your space useful and different

Experience of over 10 years of successful projects on creating unique and modern interior designs all over the world.

Learn More

Reliable, built to last.

Bearing Design – Shapes and Geometries

Valve Bushing Manufacturers, Across different countries

Stainless Steel Bushing Bronze Layer Sliding Bushing PTFE Material: Production Of Industrial Valves Bushing. Isolating Valves Plain Bearing Including Metal-Polymer Composite Self-Lubricating Bushing Material. Stainless Steel Bushing. It Is A Very Effective Corrosion-Resistant Material That Is Made Of Stainless Steel Material As The Matrix, Sintered With Corrosion-Resistant Alloy Powder In The Middle, And Rolled With Low-Friction Material Mainly Made Of PTFE On The Surface. Flexible and custom made design sleeve bearings solutions。 If you’re looking for self-lubricating valve bushings sleeve bearings, you’ve come to the right place. Our main goal is to use our technology and solid know-how to develop and enhance new applications for sleeve bearings.

Maintenance-free bearing bushing

bronzelube.com supports the custom design service, supply & maintenance of your valve bushing.

Bearing PTFE Bushing Material

Isolating valves plain bearings, Valve Bushing Manufacturers and Suppliers from China.

Bushing Selection

Valve bushing & sliding bearing solutions

Self-lubricating bushings and thrust washers for valves and other applications for the Hydraulic, Energy and Primary metals industry. Saves You Time & Money In Valve Bushing Research, Design & Production Costs. “Customized Gate, Globe, Check, Ball, Plug, and Butterfly Valves Bushing For Long Life.”

We manufacturer plain bearing bushing tailored to your valve industry.

Oilless bearings are becoming increasingly popular for underwater water valve applications

Oilless bearings are becoming increasingly popular for underwater water valve applications due to their ability to operate without the need for additional lubrication. These bearings are designed to provide long-lasting, low-friction operation in demanding environments, making them an ideal choice for water valves that must operate in wet environments.

Underwater water valves are subjected to harsh conditions, including exposure to saltwater, high pressures, and corrosive chemicals. Traditional bearings may experience wear and tear over time due to these conditions. To address this issue, oilless bearings have been specifically designed for underwater water valve applications.

Oilless bearings for underwater water valve applications are made of high-performance materials, such as sintered bronze, which have excellent corrosion resistance and durability. These bearings are also designed to operate without the need for additional lubrication, eliminating the risk of oil or grease contamination in the water.

One of the key advantages of oilless bearings for underwater water valve applications is their ability to resist wear and corrosion in wet environments. These bearings have a low coefficient of friction, which reduces the amount of wear on the bearing surfaces. This results in longer bearing life and reduces the need for maintenance, making them a cost-effective choice for underwater water valve applications.

Oilless bearings for underwater water valve applications are also easy to install and maintain. They can be easily inserted into existing valve designs, and their low friction and self-lubricating properties eliminate the need for additional lubrication during operation.

In conclusion, oilless bearings are an excellent choice for underwater water valve applications. Their ability to operate without the need for additional lubrication, resistance to wear and corrosion, and ease of installation and maintenance make them an ideal choice for demanding underwater environments. If you’re looking for a reliable and cost-effective bearing solution for your underwater water valve application, consider oilless bearings.

High-strength brass bearings with embedded solid lubricant have become an increasingly popular choice for water valve

High-strength brass bearings with embedded solid lubricant have become an increasingly popular choice for water valve applications due to their superior performance and reliability. These bearings are designed to provide long-lasting, low-friction operation in demanding environments, making them an ideal choice for water valves that must operate under high pressures and extreme temperatures.

Brass is an excellent material for water valves due to its high strength, corrosion resistance, and thermal conductivity. However, traditional brass bearings can experience significant wear and tear over time due to the abrasive nature of water, especially in high-velocity flow applications. To address this issue, high-strength brass bearings with embedded solid lubricant have been developed.

These bearings are made of a high-strength brass alloy that has been specially formulated to resist wear and corrosion. The embedded solid lubricant provides a consistent source of lubrication, reducing friction and wear between the bearing and the valve shaft. This solid lubricant is also resistant to water washout, ensuring that the bearing continues to operate smoothly even in wet environments.

One of the key advantages of high-strength brass bearings with embedded solid lubricant is their ability to operate at high speeds and under heavy loads without experiencing significant wear. This makes them an ideal choice for water valves that must operate at high pressures or in high-velocity flow applications. They also offer excellent thermal conductivity, helping to dissipate heat and prevent overheating of the valve.

In addition to their superior performance and reliability, high-strength brass bearings with embedded solid lubricant are also easy to install and maintain. They can be easily inserted into existing valve designs, and the embedded solid lubricant eliminates the need for additional lubrication during operation. This results in a lower maintenance and operating cost, making these bearings a cost-effective choice for water valve applications.

In conclusion, high-strength brass bearings with embedded solid lubricant offer superior performance and reliability for water valve applications. Their ability to resist wear and corrosion, operate at high speeds and under heavy loads, and provide consistent lubrication make them an ideal choice for demanding environments. They are also easy to install and maintain, offering a cost-effective solution for water valve applications.

Maintenance-free bearing bushing for isolating valves

What is Isolation valve?

Isolation valve belongs to the switch class of valves, that is, only in the open or closed two states, and the switch valve is different is that it will basically have a requirement for the leakage level. Relatively speaking, the requirements for safety are higher than those for switching valves, and some parts also have higher requirements for opening and closing speed. It should be said that it is a kind of valve that emphasizes the separation of fluid on both sides and higher safety. Many parts without special requirements use on/off valves.

Valve field, used in the valve bushing.

In fluid piping systems, isolating valves are control elements whose main function is to isolate equipment and piping systems, regulate flow, prevent backflow, regulate and discharge pressure. They can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, slurries, oils, liquid metals and radioactive media. Normally, a handwheel is used to rotate the valve stem to open or close the passage inside the valve. However, since there are many sizes of valves on the pipeline, the valve stem will have different diameters and lengths for different sizes of valves. When the staff needs to adjust several different sizes of valves on the pipeline, they need to carry several sizes of handwheels at the same time, which affects the work efficiency and is very inconvenient. When it is necessary to install monitoring devices on the valves, it is also possible that the same monitoring device cannot be applied to different valves due to the different sizes of the valve stems. In order to overcome the defects in the prior art, a sleeve for valves is provided which is simple in structure and has the same shape, thus ensuring that for different valves the same handwheel can be used to control their opening or closing.

Plain Bearing Bushing and thrust washer of the shaft journal in maintenance-free isolating valves, isolating valves plain bushes

Depending on the aggressiveness of the gas or liquid, the sliding bearing bushing material (with steel backing) or (with bronze backing) is used.

Function: The isolation valve regulates the flow of liquids and gases in the pipeline by increasing and decreasing the flow rate. The installed plain bearings are often exposed to chemicals and high or very low temperatures. Liquids cause constant vibration on the valve, etc. Bearings cannot be jammed due to corrosion or the effects of certain temperatures. If used frequently – or indeed rarely – the function of the isolation valve must not be impeded. Bearings cannot be reused once installed, so maintenance-free bearings are required. The isolation valve acts as a safety switch: if the pressure is too high, the isolation valve will open. If a leak occurs in a part of the pipeline, the isolation valve closes.

Bearings with plain bearing bushings :The journal and valve disc are mounted with Steel backed Bronze with PTFE or Bronze backed bronze with ptfe sliding bearing bushings. Sliding bearings do not generate static electricity because they act as conductors after operation. Isolation valves can also be used in environments with explosive atmospheres.

Advantage. Due to the reliable function of self-lubricating composite plain bearings, isolating valves bearing bushing supplier

- Suitable for use with liquids and gases

- High chemical resistance

- Corrosion resistant

- Minimal tendency to swell

- Temperature resistant

- Dry operation. No lubrication required. Sliding bearings can also be used in aggressive media.

- Maintenance free

- No electrostatic charging, also suitable for explosive media

Plain Bearing Bushing, Slide Bearing Application, For isolating valves

Use of various media in pipelines. Gases, Liquids, Vapors, Acids, Alkalis. Examples of applications for isolation valves.

- Plants in the chemical industry

- Plants in the pharmaceutical industry

- Plants in the gas industry

- Landfill gas plants

- Waste water treatment plants

- Drinking water plants

- Service water plants

- Desalination plants

- Cooling water plants

- Heat supply systems

- Swimming pool technology systems

- Industrial fittings

- Pump systems

- Shipbuilding industry

Design Of The Corrosion Resistance Bearing

The difference between stainless steel 304 valve bushing and 316 valve bushing

The quality of 316 stainless steel Valve Bushing is greater than 304 Valve Bushing stainless steel, 316 stainless steel on the basis of 304 into the metal molybdenum, this element can be more consolidated the molecular structure of stainless steel. 304 stainless steel bushing is commonly used in daily life, while 316 stainless steel bushing is used in valve, medical, or heavy industry equipment.

- Straight Sliding Bushings

- Flanged Sliding Bushings

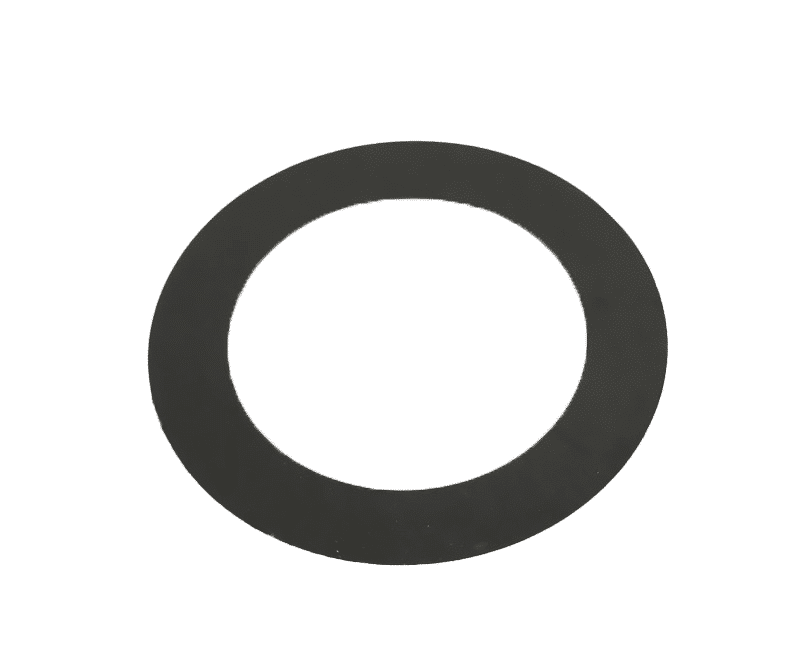

- Thrust Washer Sliding Bushings

- Strip Sliding Bushings

- Customized Sliding Bushings

We are experts in Stainless Steel Bushing for isolating valves.

Beautifully crafted leather products.

Stainless Steel Plain Bearing Bushing and Thrust Washer For isolating valves. The material is based on various high-quality metals, and the surface is covered with a low-friction and wear-resistant woven material mainly made of PTFE and other additives. This material structure has a higher bearing capacity and longer service life than general three-layer composite materials. Stainless steel-backed 304 bushing and Stainless steel-backed 316 bushings have different advantages: It is a self-lubricating, glass-fibre reinforced composite bearing material which is produced using a special winding technology. 304 stainless steel bushing processing performance is good. 316 stainless steel bushing has good corrosion resistance, atmospheric corrosion resistance, and high-temperature strength for valve bushing. Online Sourcing For Maintenance Free Bearing with Metal Backing, Enjoying Buying Self-lubricating Parts Now, Always tested. Always proven. Always Bronzelube.com. Industrial High-Performance Valves Bushing, isolating valves Plain Bearing

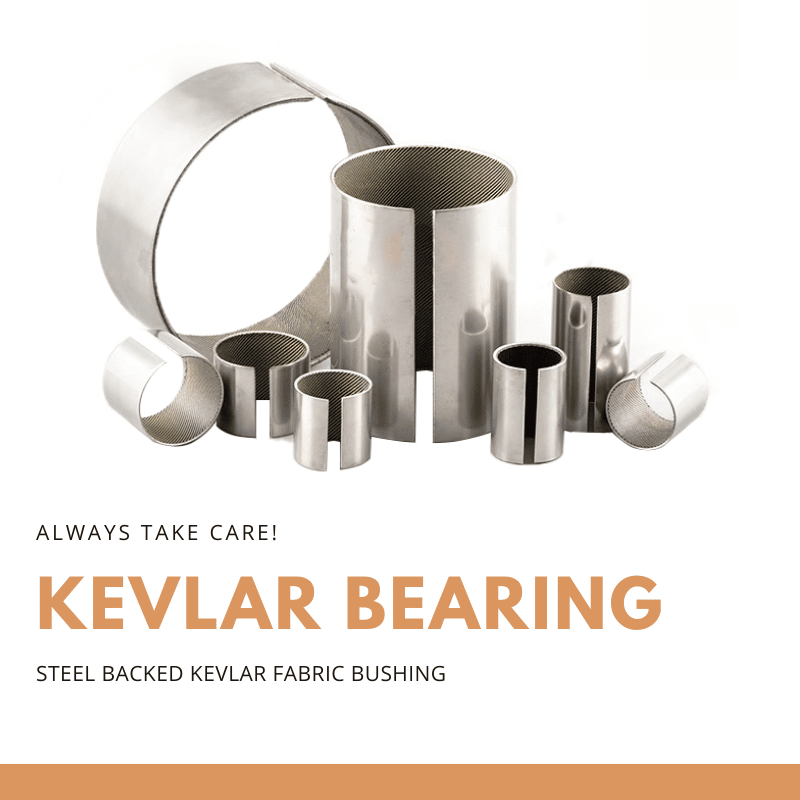

TEX STEEL WITH PTFE FIBRE FABRIC BEARINGS VALVE BUSHING DESIGN

O Ring Thrust Washer and Bushing – Factory Direct & Fast Shipping, TEX steel bushing- based PTFE fabric self-lubricating bearings a high performance self-lubricating sliding material with a glass fiber reinforced carrying layer. The material is made of all kinds of high quality metals, and the surface is covered with PTFE and other additives, which are low friction and friction resistant. This material structure has higher bearing capacity and longer service life than the general three-layer composite bushing material. The base material is low carbon steel MS, stainless steel SS316L, etc. Mainly used in agricultural machinery, construction machinery, automobile chassis parts, isolating valves plain bearings, ball valves, butterfly valves, water pumps and chemical industry and other heavy and low speed but can not refueling occasions.

Self-lubricating bushings and gaskets for valves and other applications, high-performance sealing solutions for hydraulic-marine fluids.

plain bearings are available as bushes, flange bushes, thrust washers, strips or special designs.

The durability of the sliding bearing bush is also influenced by the type of grease used. In particular, the coefficient of friction, the load carrying capacity and the permissible operating temperature all depend on the grease. Anti-aging properties are also of importance for problem-free operation.

Sleeve Bearings designed for Extreme Conditions. High-Performance Sleeve Bearing Solutions. Global China Supplier in Bushing Technology. Operating silently. High energy efficiency. Free of lubricants. Maintanance-free. Increased durability.

Sleeve Bearings – Performance in All Shapes

Find the sleeve bearing you need in our wide range of self-lubricating bearings. Need help to choose the right sleeve bearing for your application? Contact Our Experts! Export Bushing Support. Space and weight savings. Reduced costs. High energy efficiency. Easy assembly.

Our mission is to be the brand of choice for meeting the market’s needs for competitively priced, high-quality check valve bushings with prompt, on-time delivery and exceptional customer service.

However, due to the many influencing factors, calculating the expected service life of grease-lubricated plain bearings is fraught with uncertainty and should only be used as a guide.

Valve Bushing Services

Discover our international global services.

isolating valves plain bearings

Quality Valve Bushings Supplier

Designs, manufactures self-lubricating bushing materials and solutions which are key ingredients in the wellbeing of each of us and the future of all. They can be found everywhere in our living places and our daily life: in buildings, transportation, infrastructure and in so many industrial applications. Understood that valve bushings qualities are exactly what any customer demands from a qualified supplier. Dry Good (PTFE/MoS2)

Valve Sliding Bearing Technology

Gather oilless bearings solutions to save energy, provide protection, improve comfort and sustain the environment for a variety of markets. Valve Bushing & Bearing forms made to order: Nonstandard parts Bearing forms available in standard dimensions:

Plain cylindrical bushes

Plain flanged bush

Sliding Bearing World Development, isolating valves bushing

Viiplus is a manufacturer of self-lubricating bearing bushing solutions for mechanical pipe connection systems!Engineered sleeve bearings offer low friction, longer wear and noiseless operation. Discover our range.

Online shopping for du plain bearing for valve- Self-lubricating Bearings from a great selection at www.bronzelube.com

THE FUTURE IS VALVE BUSHINGS

Designed to be self-lubricating, wear-resistant, and maintenance-free, buy sleeve bearings directly from www.bronzelube.com today!

Metal Sleeve Bushing – Extended Service Life we offers a wide range of high performance sleevebearing materials, services and solutions. Bronzelube bushings offer high performance, maintenance-free solution for many applications. Free of lubricants. Higher load capacity. Resistant to corrosion. Maintanance-free. China Sleeve Bushing Supplier.

Stainless steel backing du bushing for valves

The du plain bearing is a composite structure consisting of a carbon steel backing, an intermediate layer of sintered bronze and a PTFE based sliding lining. Available in inch and metric sizes.

Bushings with no moving parts and options such as self lubrication (thus requiring no lubrication) are often the right choice for water treatment applications.

Applications

Bronzelube self-lubricating bearing products are designed for a wide range of industrial applications and services.

Unlike Other Self-lubricating Bushing Companies, We Supply Different Materials of Valve Bushing Products, Watergates, valves bushes. Give Us A Call Now! We’re Committed To Continuous Improvement Of Quality, Delivery, & Service To Our Customer. Quick Deliveries. Green Manufacturing. Engineering Expertise. China Factory Price.

Butterfly Valve Seat Universal Teflon Bushing

Specialized Sleeve Bearings Solutions for Valve Applications

Application of sleeve bearings (self-lubricating) in the valves

- bearings of the valve

- bearings connecting a servomotor with the valve lever

- servomotor pin bushings

Explore More Valve Bushing, Self-lubricating Fabric Composite Bearing

Valve oil-free bearing basics

Oil-free bearing (SF-1) is a kind of novel lubrication bearing that has the characteristics of both metal bearing and oil-free lubrication bearing, the load is borne by the metal matrix, and the specially formulated solid lubricating material plays the role of lubrication.

It is widely used in a metallurgical continuous casting machines, rolling rigid equipment, mining machinery, ships, steam turbine, hydraulic turbine, injection molding machine,s and equipment production lines.

Advantages

The advantages of oil-free bearings are well known, all machinery must use some kind of bearing for smooth operation.

Oil-free bearing is a kind of novel lubrication bearing that has both the characteristics of metal bearing and oil-free lubrication bearing, the load is borne by the metal matrix, and the specially formulated solid lubricating material plays the role of lubrication.

It has a high bearing capacity, impact resistance, high-temperature resistance, self-lubricating ability, and other characteristics, especially for heavy load, low speed, reciprocating or oscillating, and other difficult to lubricate and form the oil film occasions, but also not afraid of water and other acid corrosion and erosion. The majority of users generally reflect that inlay bearings not only save oil, and energy, and their working life is also longer than ordinary sliding bearings.

The product is made of steel plate as the substrate, the middle layer of sintered spherical bronze powder, and the surface layer of rolled PTFE and lead mixture. It has a small coefficient of friction, wear and corrosion resistance. Oil-free self-lubrication and long service life, the use of which can reduce costs, reduce noise, and prevent sticky, and slippery.

Classification

Metal-based solid inlay oil-free bearings

In the metal substrate, inlaid graphite and MoS2 composite solid lubricant, a high-performance solid lubrication products. It breaks through the limitation of general bearing relying on oil film lubrication. In the process of use, the solid lubricant rubs with the shaft through frictional heat, forming excellent conditions for oil and powder coexistence lubrication, which not only preserves the protection of the shaft from wear, but also makes the solid lubrication characteristics eternal.

Its hardness is twice as high as general copper sleeve, and its wear resistance is also twice as high. At present, it has been widely used in metallurgy even casting machine, train bracket, steel rolling equipment, mining machinery, ships, gas turbines and other high temperature, high load, low speed heavy load and other occasions.

Multi-layer composite oil-free bearing

With steel plate as the substrate, the middle sintered spherical bronze powder, the surface rolled polytetrafluoroethylene (PTFE) and lead mixture, is rolled into a sliding bearing. It has the characteristics of small friction coefficient, good wear resistance, corrosion resistance and oil-free lubrication.

The use of this product can reduce the cost, reduce the size of machinery, to avoid the phenomenon of gnawing shaft and reduce mechanical noise and other advantages. The products have been widely used in the sliding parts of various machines, such as printing machines, elevators, textile machines, tobacco machines, fitness machines, hydraulic trucks, micro motors, solenoid valves, automobiles, motorcycles and household machinery.

Others

Linear bearings, non-standard parts, teflon soft tape, FB bronze bearings, JF bimetal bearings, SF-1 oil-free lubricated bearings, SF-2 boundary lubricated bearings, FZ steel ball cage series, powder metallurgy oil-containing bearings, graphite inlaid self-lubricating bushings, TF graphite loose inlaid alloy bearings, alloy inlaid high wear-resistant bearing shingles.

Production process

Oil-free bearing is a kind of novel lubrication bearing which has both the characteristics of metal bearing and oil-free lubrication bearing, the metal matrix bears the load and the special formula of solid lubricating material plays the role of lubrication.

Due to the requirements of the production process, certain key equipment of industrial and mining enterprises operate under extremely harsh working conditions. Due to the heavy equipment, high ambient temperature, dust or air containing acidic corrosive gases CO, SO2, etc., the lubrication of the equipment brings many problems, friction and wear serious.

Up to now, most of the above domestic enterprises are still using the traditional oil, grease lubrication, and the fact that these mining conditions have gone beyond the scope of oil, grease lubrication, extremely easy to occur in the bearing and other frictional vice of the bite or bite, causing serious parts wear and damage, often leading to equipment downtime.

In order to produce continuous operation, in addition to the original design requires the installation of multiple equipment rotation repair, but also must be invested in a large number of maintenance personnel. Seriously limit the increase in productivity, spare parts and energy consumption is great, has become an important obstacle to the development of production.

Automobile manufacturing, cement production, petrochemical and other enterprises are proposed to provide complex working conditions under the special lubrication material requirements. To this end, the inlay self-lubricating composite materials research, in the material formulation and preparation process to highlight their own characteristics, material performance has reached the international advanced level, for the enterprise to solve the problem of lubrication under special working conditions, and brought obvious economic and social benefits. However, due to a variety of reasons more domestic enterprises have not been adopted, the above situation still exists.

Key technology principle

Inlaid self-lubricating composite material is a new type of anti-polar pressure solid lubricating material, consisting of a metal substrate and a solid lubricant paste embedded in the hole or slot of the substrate. During the friction process, the metal substrate bears most of the load.

After friction, the solid lubricant in the hole or slot is transferred or counter-transferred to the friction surface, forming a well-lubricated, firmly attached and uniformly covered solid transfer film on the friction surface, which greatly reduces frictional wear. As the friction proceeds, the embedded solid lubricant is continuously provided to the friction surface, ensuring good lubrication in long-term operation.

Application areas

The basic material requirements for bearings are largely dependent on the working performance of the bearing. The suitability of the material selected for the manufacture of rolling bearings will have a great influence on their performance and life.

In general, the main damage of rolling bearings is in the form of fatigue spalling under the action of alternating stress, as well as the loss of bearing accuracy due to frictional wear. In addition, there are cracks, indentations, rust and other reasons for the abnormal destruction of the bearing.

Therefore, rolling bearings should have high resistance to plastic deformation, less frictional wear, good rotational accuracy, good dimensional accuracy and stability, and long contact fatigue life. And many of these properties are determined by the material and heat treatment process together.

Metal-based inlaid solid self-lubricating bearings

It is a kind of novel lubricating bearing which has the characteristics of both metal bearing and self-lubricating bearing, with the metal matrix bearing the load and the specially formulated solid lubricating material playing the role of lubrication. It has high bearing capacity, impact resistance, high-temperature resistance, self-lubricating ability and other characteristics.

Due to the advantages of low noise and self-lubrication, the traditional oil bearing has become the new favorite of computer CPU fan bearing with high market demand; in addition, with the increasing demand for noisy, the application of oil bearing in daily household appliances is also expanding.

Oil-free self-lubricating bearings

The product is made of steel plate as the substrate, the middle layer of sintered spherical bronze powder, and the surface layer of rolled PTFE and lead mixture. It has a small coefficient of friction, wear and corrosion resistance. Oil-free self-lubrication and long service life, the use of which can reduce costs, reduce noise, and prevent sticky, and slippery. It is widely used in the sliding parts of various machinery such as printing machines, textile machines, hydraulic trucks, tobacco machines, pharmaceutical machinery, fitness equipment, micro motors, automobiles, motorcycles, etc.

SF-2 plus boundary lubrication bearing

Acid poly methyl with aldehyde, with high wear resistance, bearing surface with a regular arrangement with oil storage pit assembly must be coated with lubricating grease, especially suitable for high load and low speed under the rotary motion, swing motion and often under the load, opening and closing and not easy to form fluid lubrication parts, in the boundary lubrication conditions, can be used for a long time without refueling maintenance, and the process of refueling can make the bearing life can be more At present, it is suitable for metallurgical machinery, mining machinery, water conservancy machinery, automobile parts, construction machinery, agricultural machinery, etc.

Cautions

First, should determine whether the shaft core and shaft shell of the mating surface has bruises, protrusions, etc.

Second, whether there is dust or mold sand attached to the surface of the bearing shell.

If there is a slight bump or protrusion, remove it with an oil-polishing stone or fine sandpaper.

In order to avoid bruises when mounting, the surface of the shaft and housing should be lubricated with a small amount of oil. To install the bearing in the shaft center, force should be applied in the inner ring, and to install the bearing in the bearing housing, force should be applied in the outer ring. When applying force to the bearing, it is important to make the force vertical and even, and the bearing will be injured if it is deflected. For this reason, absolutely try to avoid bias hits.

V. The hardness of the bearing will be reduced by overheating, therefore, it must not exceed 100 degrees. In this case, the bearing must be suspended by steel wire, or placed on top of the metal wire frame or support plate, never on the bottom of the groove. When the bearing reaches the desired temperature (below 100 degrees), it should be taken out of the groove immediately and put into the shaft quickly. The bearing will shrink as the temperature drops, and sometimes a gap will arise between the shaft shoulder and the bearing end face.

Sixth, the oil-free bearing retainer and sealing plate should not be used to apply force. The installation method of using a hammer and sleeve is a common method because it will damage the bearing, so do not hit it directly. Always hammer in the bearing with the sleeve in between as shown. The hammer should be tapped lightly. If the machine is constructed in such a way that the inner and outer rings are tightly fitted, use a pad so that the force can be applied to both the inner and outer rings and pressed in.

If only the inner ring is pressed in, the force will go through the ball and press into the outer ring, thus causing a scar on the track surface. When mounting a bearing with a large margin on a shaft, the bearing is heated to 80-90 degrees in clean oil to expand the inner diameter, and this method is widely used.