Sand Casting

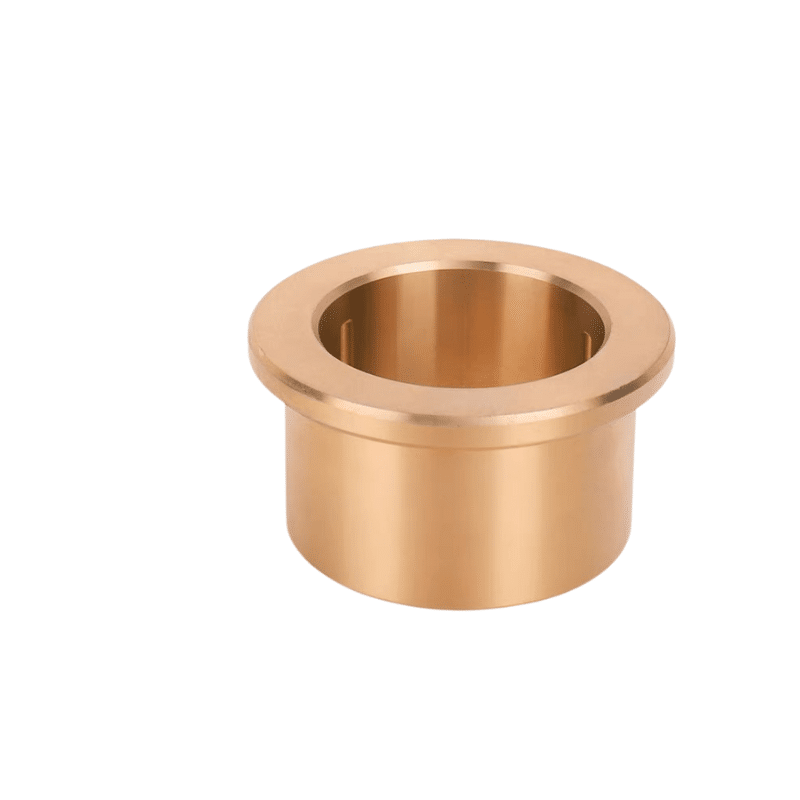

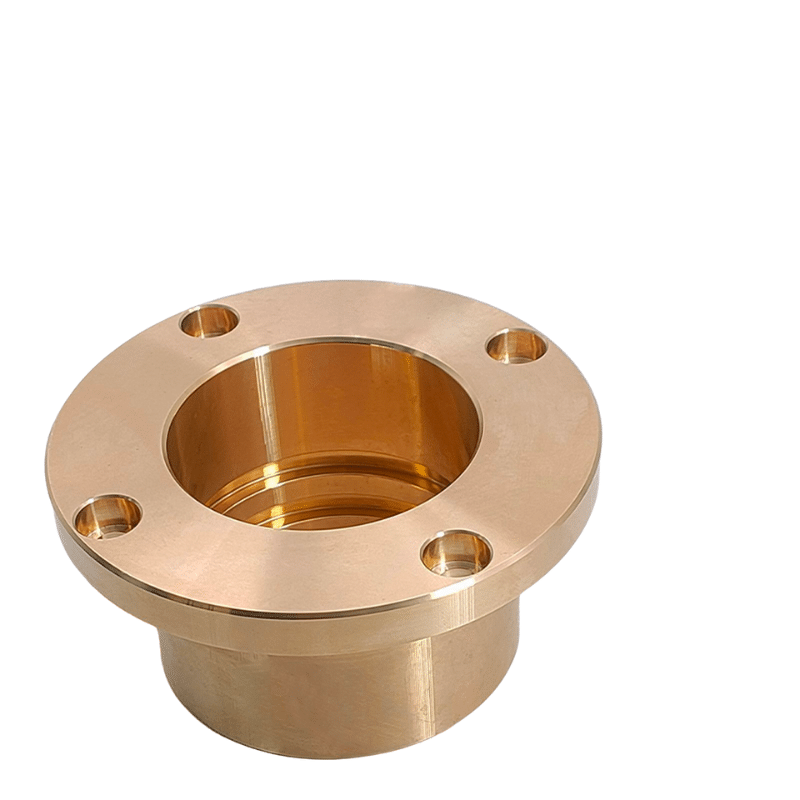

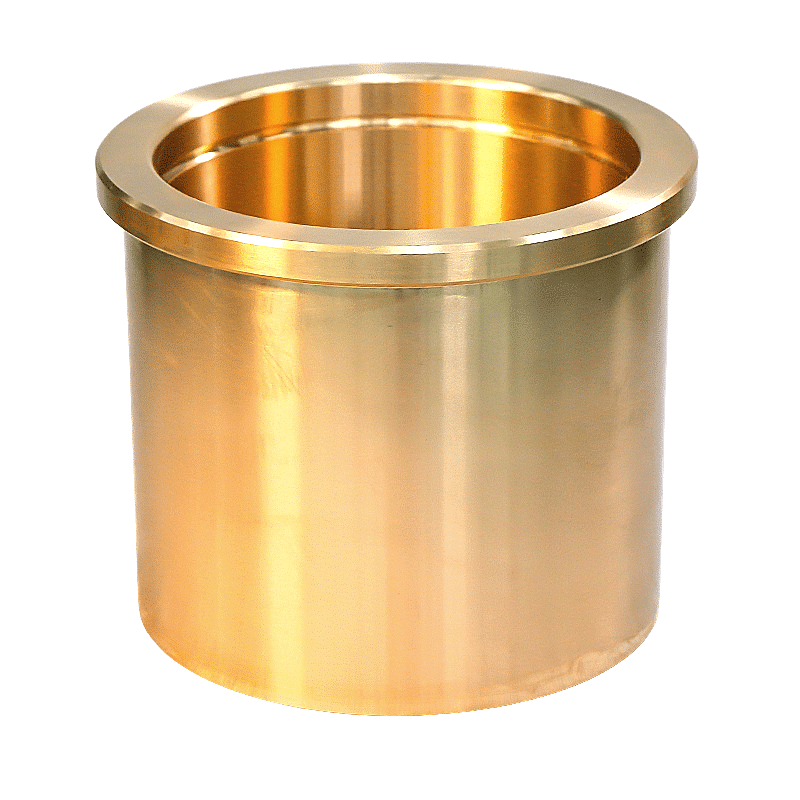

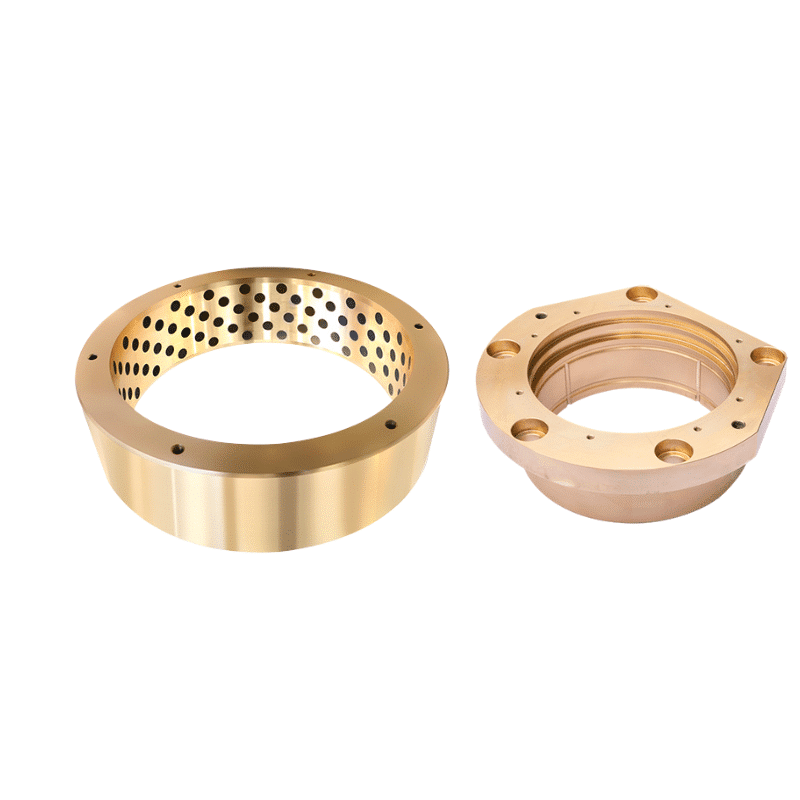

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Sand Casting

Start Sourcing The Bronze Bearing Today

Give us a call to schedule your purchasing oder for the bronze bushing.

Our Slide Bearing & Bushing Products

Don’t see what you’re looking for? Contact us. If we don’t have it in our product portfolio, we can review the application and propose a custom solution.

Sand Casting Production

This process involves making a pattern in the shape of the desired part. The pattern is then placed in a box called a jar and packed with sand. A binding agent is added to the sand to help it harden. The mold is cured and the pattern is removed.

Introduction of sand mold

General overview

The basic raw materials for making sand molds are foundry sand and molding sand binder. The most commonly used foundry sand is siliceous sand. When the high temperature performance of silica sand cannot meet the requirements, special sands such as zircon sand, chromite sand and corundum sand are used. In order to make the sand mold and core have a certain strength and not deform or damage during handling, molding and pouring of liquid metal, a molding sand binder is generally added in the casting to bond the loose sand particles to become molding sand. The most widely used molding sand binder is clay, and various drying oils or semi-drying oils, water-soluble silicates or phosphates, and various synthetic resins can also be used as molding sand binders. The outer sand mold used in sand casting is divided into three types: clay wet sand mold, clay dry sand mold and chemical hardened sand mold according to the binder used in the molding sand and the way of building its strength.

clay wet sand

Clay and an appropriate amount of water are used as the main binder of the molding sand, and the sand mold is directly formed and poured in the wet state after it is made. Wet casting has a long history and is widely used. The strength of green sand depends on the clay slurry made by mixing clay and water in a certain proportion. Once the molding sand is mixed, it has a certain strength. After being pounded into a sand mold, it can meet the requirements of molding and pouring. Therefore, the amount of clay and moisture in the molding sand are very important process factors.

A casting method that uses molding sand and core sand as molding materials to make a mold and fills the mold with liquid metal under gravity to produce castings. Steel, iron and most non-ferrous alloy castings can be obtained by sand casting. Because the molding materials used in sand casting are cheap and easy to obtain, the casting mold is simple to manufacture, and can be adapted to single-piece production, batch production and mass production of castings, and has been the basic process in casting production for a long time.

The mold used in sand casting is generally composed of an outer sand mold and a core. In order to improve the surface quality of castings, a layer of paint is often applied to the surface of the sand mold and core. The main components of the coating are powdery materials and binders with high refractoriness and high chemical stability at high temperature. In addition, carriers (water or other solvents) for easy application and various additives are added.

The advantages of clay wet sand casting are: ①Clay is rich in resources and cheap. ② Most of the used clay wet sand can be recycled and reused after proper sand treatment. ③ The cycle of making the mold is short and the work efficiency is high. ④The mixed molding sand can be used for a long time. ⑤ After the sand mold is pounded, it can still tolerate a small amount of deformation without damage, which is very beneficial to drafting and core lowering. The disadvantages are: 1. When mixing sand, the viscous clay slurry should be coated on the surface of the sand grains, and a high-power sand mixing equipment with a kneading effect should be used, otherwise it is impossible to obtain molding sand of good quality. ②Because the molding sand has a very high strength after mixing, the molding sand is not easy to flow during molding, and it is difficult to pound it. It is laborious and requires certain skills when molding by hand. When molding with a machine, the equipment is complicated and huge. ③ The rigidity of the mold is not high, and the dimensional accuracy of the casting is poor. ④ Castings are prone to defects such as sand flushing, sand inclusion, and pores.

Clay dry sand mold The wet moisture of the molding sand used in the manufacture of this sand mold is slightly higher than that of the wet molding sand.

Clay Sand Cores Simple cores made from clay sand.

clay dry sand

The wet moisture content of the molding sand used to make this kind of sand mold is slightly higher than that of the molding sand used for the wet mold. After the sand mold is made, the surface of the cavity should be coated with refractory paint, and then placed in an oven to dry, and it can be formed and poured after it is cooled. Drying clay sand molds takes a long time, consumes a lot of fuel, and sand molds are easily deformed during the drying process, which affects the accuracy of castings. Clay dry sand molds are generally used to make steel castings and larger iron castings. Since the widespread adoption of chemically hardened sand, dry sand molds have tended to be phased out.

chemically hardened sand

The molding sand used in this sand mold is called chemically hardened sand. The binder is generally a substance that can undergo molecular polymerization under the action of a hardener to form a three-dimensional structure. Various synthetic resins and water glass are commonly used. There are basically 3 ways of chemical hardening.

① Self-hardening: Both the binder and the hardener are added during sand mixing. After the sand mold or core is made, the binder reacts under the action of the hardener to cause the sand mold or core to harden by itself. The no-bake method is mainly used for modeling, but it is also used to make larger cores or cores with small production batches.

② Aerosol hardening: Add binder and other adjuncts when mixing sand, without adding hardener first. After molding or core making, blow gaseous hardener or liquid hardener atomized in a gaseous carrier to disperse it in the sand mold or core, resulting in the hardening of the sand mold. Aerosol hardening is mainly used for core making, and sometimes for making small sand molds.

③ Heating hardening: When mixing sand, add binder and latent hardener that does not work at room temperature. After the sand mold or core is made, it is heated, and the latent hardener and some components in the binder react to form an effective hardener that can harden the binder, thereby hardening the sand mold or core. The heat-hardening method is mainly used for core making except for the manufacture of small thin-shell sand molds.

sand moulding broadcast

The material used to make the sand mold is called molding material, the material used to make the sand mold is habitually called molding sand, and the molding material used to make the sand core is called core sand. Usually molding sand is made by mixing raw sand (mountain sand or river sand), clay and water in a certain proportion, of which clay is about 9%, water is about 6%, and the rest is raw sand. Sometimes a small amount of additives such as coal powder, vegetable oil, wood chips, etc. are added to improve the performance of molding sand and core sand.

The quality of molding sand and core sand directly affects the quality of castings. Poor quality of molding sand will cause defects such as pores, blisters, sticky sand, and sand inclusions in castings. Good molding sand should have the following properties:

1) Breathable type

After the high-temperature molten metal is poured into the mold, the mold is filled with a large amount of gas, and these gases must be smoothly discharged from the mold. Otherwise, defects such as pores and insufficient pouring will occur in the casting. The permeability of the mold is affected by factors such as sand particle size, clay content, moisture content, and sand compaction. The finer the particle size of the sand, the higher the clay and moisture content, the higher the sand compactness, and the worse the air permeability.

2) Strength

The ability of molding sand to resist external force damage is called strength. Molding sand must have high enough strength to not cause collapse during molding, handling, and box closing, nor damage the surface of the mold during pouring. The strength of the molding sand should not be too high, otherwise the casting will have defects due to the decrease of air permeability and concession.

3) Fire resistance

After the high temperature metal liquid is poured, it will have a strong thermal effect on the mold, so the molding sand must have the ability to resist the high temperature thermal effect, that is, refractory. For example, the refractoriness of the molding material is poor, and the casting is easy to produce sticky sand. The more SiO2 content in the sand, the larger the sand particles and the better the refractoriness.

4) Plasticity

Refers to the ability of molding sand to deform under the action of external force, and to maintain the existing shape completely after the external force is removed. The plasticity of the molding material is good, the molding operation is convenient, and the sand mold has an accurate shape and a clear outline.

5) Concession

When the casting is condensed, the volume shrinks, and the molding sand should have a certain ability to be compressed, which is called concession. The concession of the molding sand is not good, and the casting is prone to internal stress or cracking. The tighter the molding sand, the less concessional it is. Adding wood chips and other materials to the molding sand can improve the concession.

Related Features Broadcast

The chemical hardening sand casting process is characterized by:

①The strength of chemically hardened sand molds is much higher than that of clay sand molds, and after being made into sand molds, it is hardened to a fairly high strength and then demolded, and no repairing is required. Therefore, the mold can more accurately reflect the size and contour shape of the pattern, and it is not easy to deform in the subsequent process. The obtained casting has high dimensional accuracy.

②Because the viscosity of the binder and hardener used is not high, it is easy to mix with the sand, the sand mixing equipment is light in structure, low in power and high in productivity, and the sand processing part can be simplified.

③The mixed molding sand has good fluidity before hardening, and the molding sand is easy to be pounded during molding, so a large and complicated molding machine is not required.

④When modeling with chemically hardened sand, the pattern materials, such as wood, plastic and metal, can be selected according to the production requirements.

⑤The content of binder in chemically hardened sand is much lower than that of clay sand, and there is no powdery auxiliary material in it. If raw sand with the same particle size is used, the gap between sand particles is much larger than that of clay sand. In order to avoid metal infiltration between the sand grains during casting, the surface of the sand mold or core should be coated with a good quality coating.

⑥ The chemical hardened sand with water glass as the binder has low cost and odorless working environment during use. However, this kind of casting mold is not easy to collapse after the metal is poured; the used old sand cannot be directly recycled and must be regenerated, and the regeneration of water glass sand is more difficult.

⑦The cost of chemically hardened sand with resin as binder is higher, but the casting is easy to separate from the molding sand after pouring, the workload of casting cleaning is reduced, and most of the used sand can be recycled and reused.

Sand Core Type Broadcast

Overview

In order to ensure the quality of castings, the cores used in sand casting are generally dry cores. According to the different binders used in the core, the core is divided into clay sand core, oil sand core and resin sand core.

clay sand core

Simple cores made from clay sand.

oil sand core

The core made of core sand with dry oil or semi-dry oil as binder is widely used. The viscosity of oil is low, the mixed core sand has good fluidity, and it is easy to be compacted during core making. However, the strength of the newly made core is very low. Generally, it is carried by a profiled core board, and then baked in an oven at 200-300 ° C for several hours, and the oil is oxidized and hardened by air. The disadvantage of this core making method is that the core is easily deformed during demoulding, handling and baking, resulting in reduced dimensional accuracy of the casting; long baking time and high energy consumption.

resin sand core

Various cores made of resin sand. The core is hardened in the core box and then taken out to ensure the tolerance of the shape and size of the core. According to different hardening methods, the manufacture of resin sand cores is generally divided into three methods: hot core box core making, shell core making and cold core box core making. ①Hot box method core: Appeared in the late 1950s. Usually furan resin is used as core sand binder, and latent hardener (such as ammonium chloride) is also added to it. When the core is made, the core box is kept at 200-300 ℃. After the core sand is injected into the core box, the ammonium chloride reacts with the free formaldehyde in the resin at a higher temperature to generate acid, so that the core hardens quickly. It takes about 10 to 100 seconds to build demold strength. Using the hot core box method to make the core, the dimensional accuracy of the core is relatively high, but the process device is complex and expensive, the energy consumption is high, the irritating gas is discharged, and the working conditions of the workers are also very poor. ②The shell core is made by the hot method of overmolded sand, which has high strength and good quality; ③The cold box method of core making: appeared in the late 1960s. Use urethane resin as the core sand binder. When the core is made by this method, the core box is not heated, and the core can be hardened by blowing amine steam into it for a few seconds. This method is superior to the hot box method in terms of energy, environment, and production efficiency. In the mid-1970s, the furan resin cold box method of blowing sulfur dioxide hardening appeared again. The hardening mechanism is completely different from the urethane cold core box method, but the process characteristics, such as fast hardening and high core strength, are roughly the same as the urethane cold core box method.

water glass sand core

Sand cores made of water glass as binder can be divided into the following types: water glass CO2 method, ester hardened water glass self-hardening method, water glass methyl formate cold core box method.

Casting Advantage Broadcast

Sand casting crusher wear-resistant parts are still very common in China, such as jaw plate, high-chromium blow hammer, crushing wall, rolling mortar wall, etc., because in the crusher equipment, as a relatively large wear-resistant casting, Relatively speaking, the accuracy is not very high, especially for the jaw plate, the finished product almost does not need lathe grinding, and the broken wall, rolling mortar wall, roll skin and the like only need lathe grinding in part of the casting, so it is especially suitable for sand casting. , Because the wear parts of sand casting jaw plate, high chromium plate hammer, crushing wall, rolling mortar wall, roller skin, etc. are more durable than other products such as lost foam casting. However, lost foam casting has high dimensional accuracy, small machining allowance, convenient dry sand falling out, cleaning and grinding workload is reduced by more than 50%, and labor costs are saved, so the price of lost foam casting is relatively low.

Sand casting is one of the casting processes. The mold used in sand casting is generally composed of an outer sand mold and a core. Because the molding materials used in sand casting are cheap and easy to obtain, the casting mold is simple to manufacture, and can be adapted to single-piece production, batch production and mass production of castings, and has been the basic process in casting production for a long time. At present, in the international production of all castings, 60 to 70% of the castings are produced with sand molds, and about 70% of them are produced with clay sand molds.

The main reasons are: compared with other casting methods, sand casting has low cost, simple production process and short production cycle. Therefore, castings such as engine cylinder blocks, cylinder heads, crankshafts, etc. of automobiles are produced by the clay green sand process. When the wet type cannot meet the requirements, consider using the clay sand surface dry sand type, dry sand type or other sand type. The weight of castings produced by clay wet sand casting can range from a few kilograms to tens of kilograms, while the castings produced by clay dry casting can weigh dozens of tons. Because sand casting has the above advantages, it is more and more widely used in the foundry industry. In the future, it will play an increasingly important role in the foundry industry.

Foundry Trends Broadcast

More than 80% of the products in the foundry industry are completed by sand casting, so the casting we usually talk about generally refers to sand casting, that is, sand casting.

During the “Eighth Five-Year Plan” period, foundry was highly valued by the former Ministry of Mechanical and Electrical Engineering, and it invested the largest special technical transformation loan and research expenses since the founding of the People’s Republic of China, which supported the development and development of products in the foundry machinery industry. “Manufacture of large-scale shot blasting machine”, “vertical parting boxless injection molding machine”, “development of sodium silicate sand recycling equipment”, “metal mold casting equipment” and so on have been developed and applied one after another.

During the “Ninth Five-Year Plan” period, the foundry industry has undertaken and established the task of “complete sets of technologies and equipment for refined and efficient modeling and cleaning of car casting blanks”. In 1999, the national high-level air punch molding line project was successfully completed.

During the “Tenth Five-Year Plan” period, the average annual growth of the main economic indicators of the foundry industry was above 30%, which was higher than the average growth level of the machine tool industry. High market sales level. In addition, the complete set of resin sand casting equipment can basically meet the needs of the domestic market, changing the situation of mainly relying on imports in the past; it has been able to produce a high-level automatic casting production line, reaching a level that can partially replace imports, and partially solve the problem of car engines Cylinder block, cylinder head and other casting blanks are also imported; high-level automatic core making machine, automatic casting cleaning machine, automatic sand processor, large automatic die casting machine and precision casting equipment and other casting machinery can basically be produced in China. . It should be said that the product level of the foundry machinery industry has been greatly improved during the “Tenth Five-Year Plan” period, laying a good foundation for the further development of China’s foundry machinery industry in the future.

During the “Eleventh Five-Year Plan” period, stimulated by huge market demand, the foundry industry will continue to maintain a relatively high growth rate. As the technical level of foundry machinery products is still far from the market demand, there is huge development potential and room for expansion in the development of the industry, bringing opportunities for the rapid growth of the foundry machinery industry.

During the “Twelfth Five-Year Plan” period, the entire foundry industry has to work on new casting processes and new materials. The price of foundry materials remains high, requiring the precision casting industry to rapidly develop new alternative low-cost new materials; downstream The continuous improvement of customers’ requirements drives us to improve the technological level; the continuous increase of human resource costs, we must make more efforts, more development and more investment in precision casting equipment! For example, the China Foundry Association and the International Foundry Consulting Network, the Chinese foundry authority, unanimously recommended the new material precision casting special steel.

Technical Data:

|

Material |

CuZn25AI5Mn4Fe3 |

CuSn5Pb5Zn5 |

CuAI10Ni5Fe5 |

CuSn12 |

CuZn25AI5Mn4Fe3 |

|

Density |

8 |

8.9 |

7.8 |

8.9 |

8 |

|

Hardness |

≥210 |

≥70 |

≥150 |

≥75 |

≥235 |

|

Tensile strength |

≥750 |

≥250 |

≥500 |

≥270 |

≥800 |

|

Yield strength |

≥450 |

≥90 |

≥260 |

≥150 |

≥450 |

|

Elongation |

≥12 |

≥13 |

≥10 |

≥5 |

≥8 |

|

Coefficient linear expansion |

1.9×10-5/℃ |

1.8×10-5/℃ |

1.6×10-5/℃ |

1.8×10-5/℃ |

1.9×10-5/℃ |

|

Max. Temp. |

-40~+300℃ |

-40~+400℃ |

-40~+400℃ |

-40~+400℃ |

-40~+300℃ |

|

Max. dynamic load |

100 |

60 |

50 |

70 |

120 |

|

Max. speed(Dry) |

15 |

10 |

20 |

10 |

15 |

|

N/mm²*m/s(Lubrication) |

200 |

60 |

60 |

80 |

200 |

|

Compression deformation |

< 0.01 mm |

< 0.05mm |

< 0.04mm |

< 0.05mm |

< 0.005mm |

Typical Applications

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.