Thrust Washer Perforated Self-Lubricating

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Thrust Washer Perforated Self-Lubricating

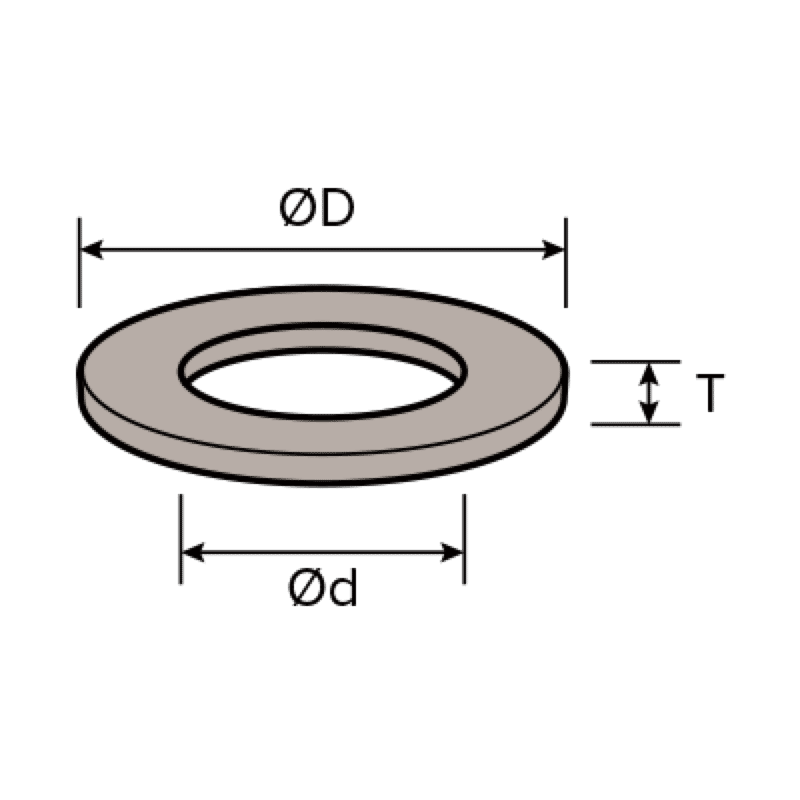

Thrust Washer – Perforated, Self-Lubricating

A thrust washer is a flat, circular component used in various mechanical assemblies to support axial loads and reduce friction between moving parts. They are commonly utilized in automotive, aerospace, and industrial applications. A perforated, self-lubricating Thrust Washer Perforated Self-Lubricating is a specialized version designed to provide reduced friction and increased wear resistance in demanding environments.

High-Quality Products

Thrust Washer

We source our bronze thrust washers from reputable manufacturers, ensuring that you receive top-quality components that meet or exceed industry standards.

Fast Delivery

Thrust Washer – Perforated

We understand the importance of quick turnaround times for your business operations. Our efficient logistics network ensures that your order is processed and delivered promptly.

Competitive Pricing

Focus

Self-Lubricating

We offer competitive pricing on our bronze thrust washers, ensuring that you receive excellent value for your investment.

Customized Solutions

Self-lubricating bronze washer

We understand that every application has unique requirements, and we can provide customized bronze thrust washers tailored to your specific needs.

Bronze Thrust Washer – Perforated, Self-Lubricating Expert Support

Bronze Thrust Washer – Perforated, Self-Lubricating: Bronze thrust washers are circular, flat components designed to support axial loads and reduce friction between moving parts. The perforated design allows for better distribution of lubricant throughout the bearing surface, ensuring consistent lubrication and reduced wear. Made from self-lubricating bronze material, these thrust washers are ideal for demanding environments where high wear resistance and low friction are required.

Our knowledgeable customer support team is available to assist you with any questions or concerns you may have regarding our products and services.

Oilless graphite bronze thrust bearings

Oilless graphite bronze thrust bearings are designed to operate without additional lubrication due to the self-lubricating properties of the graphite embedded in the bronze material. However, in some cases, adding extra lubrication may be beneficial, especially during the initial start-up or in harsh environments.

Oilless graphite thrust washer bearings are designed to support axial loads without the need for external lubrication. These bearings consist of a metal backing, usually made of materials like bronze, steel, or other alloys, and are embedded with solid lubricant graphite plugs. The graphite serves as a self-lubricating agent, reducing friction and wear during operation.

thrust washer perforated, self-lubricating

Composition of the Bearing:

- Base Layer: Crafted from durable steel, providing a robust foundation.

- Intermediate Layer: Features a sintered bronze layer, enhancing strength and stability.

- Bearing Surface: Coated with PTFE, ensuring a smooth, low-friction surface.

Die Components, Guiding Components, Oilless Wear Plates, And Bronze Thrust Washer – Perforated, Self-Lubricating

Die components and guiding components are integral parts of various manufacturing processes, such as stamping, injection molding, and die casting. These components ensure smooth and precise operation of the machinery, contributing to efficient production and high-quality output. Among these components, oilless wear plates and bronze thrust washers play a vital role in reducing friction and wear in the systems. Die components and guiding components are essential for maintaining smooth and efficient operation in various manufacturing processes. Oilless wear plates and bronze thrust washers play a crucial role in reducing friction and wear, contributing to the longevity and reliability of the equipment. These components are widely used in industries like automotive, aerospace, and industrial machinery, where high performance and minimal maintenance are critical.

taxation planning

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

Oilless Thrust washer:

A VIIPLUS thrust washer is a type of mechanical component used in various applications to reduce friction and support axial loads. Here’s what you need to know:

Purpose: Thrust washers, also known as thrust bearings, are designed to handle axial loads, which are forces applied parallel to the axis of rotation or movement.

Material: VIIPLUS offers thrust washers made from various materials, including bronze with graphite plugs, which provides self-lubrication properties, reducing the need for external lubrication.

Variety: VIIPLUS provides a range of thrust washers, including dry thrust washers and solid lubricant washers, to suit different applications and load conditions.

Application: These components are commonly used in machinery and equipment where there is a need to support and reduce friction in axial movements, such as in automotive transmissions, industrial machinery, and more.

We Deliver Bronze Thrust Washer – Perforated, Self-Lubricating Thrust Washer At Your Address

Thrust Washer – Perforated, Self-Lubricating, In-Die & Mould Slide Systems

thrust Bearing:

A perforated, self-lubricating thrust washer is an essential component in various die and mould slide systems, such as in-die applications and core systems in injection moulds. These specialized thrust washers offer numerous benefits, including reduced friction, increased wear resistance, and improved performance under demanding conditions.

Key Features:

Spare Part for In-Die Applications: Perforated, self-lubricating thrust washers are used as spare parts in in-die applications to ensure smooth, efficient functioning of the die system. They help reduce wear and tear on components, resulting in extended service life and reduced maintenance costs.

Spare Part in Core Systems for Injection Moulds: These thrust washers are also utilized as spare parts in core systems of injection moulds. They contribute to the overall efficiency and reliability of the moulding process by minimizing friction between moving parts and providing consistent lubrication.

Heat Resistance: Perforated, self-lubricating thrust washers can withstand temperatures up to 150°C (302°F), making them suitable for various applications with moderate temperature requirements. However, they may not be suitable for high-temperature applications where the operating temperature exceeds this limit.

Graphite self-lubricating thrust washer supplier

Thrust Washer – Perforated, Self-Lubricating thrust Bearing Applications:

Thrust Washer – Perforated, Self-Lubricating Applications:

Perforated, self-lubricating thrust washers are widely used in various die and mould slide systems, such as:

Metal Stamping: In metal stamping processes, these thrust washers help reduce friction and wear in the in-die applications, contributing to smoother operations and improved production efficiency.

Injection Moulding: In plastic injection moulding, these thrust washers are used in core systems to ensure efficient and reliable functioning of the moulds, resulting in high-quality, consistent products.

Die Casting: In die casting processes, perforated, self-lubricating thrust washers contribute to the smooth and efficient operation of the die system, reducing wear and tear on components and extending the service life of the equipment.

In conclusion, perforated, self-lubricating thrust washers play a vital role in die and mould slide systems. They offer several advantages, such as reduced friction, increased wear resistance, and improved performance under demanding conditions. With a heat resistance of up to 150°C, they are suitable for use in various applications with moderate temperature requirements.

Thrust Washer – perforated self-lubricating design:

Thrust Washer – Perforated Self-Lubricating Characteristics:

- Steel Treatment: The steel base is tin-plated, offering additional corrosion resistance.

- Maintenance-Free: These steel composite bearings are designed for maintenance-free operation, especially effective in dry running conditions.

- Versatility in Lubrication: While they excel in dry environments, they are also highly suitable for lubricated applications, particularly those using oil lubrication.

- Load Capacity: Capable of accommodating axial loads during rotational movements. They are adept at handling both cyclic and constant axial loads.

- Performance Features: Exhibits very low wear and friction levels, effectively eliminating the stick-slip effect.

- Chemical and Moisture Resistance: High resistance to chemicals and minimal water absorption, enhancing durability in various environments.

A thrust washer with a perforated self-lubricating design offers unique advantages in certain applications. Here’s some information about thrust washers with a perforated self-lubricating feature:

Perforated Design: A thrust washer with a perforated design incorporates small holes or perforations in its structure. These perforations serve multiple purposes, including facilitating the distribution of lubrication and providing a path for lubricant flow between the sliding surfaces of the washer.

Self-Lubricating Properties: The self-lubricating feature of thrust washers helps reduce friction and wear, enhancing their performance and extending their service life. The perforations in the washer allow the lubricant, typically a solid lubricant embedded in a matrix material, to be evenly distributed across the sliding surfaces. As the thrust washer moves, the lubricant is released from the perforations, forming a lubricating film between the sliding surfaces, reducing friction and preventing metal-to-metal contact.

Lubricant Selection: The choice of lubricant depends on the specific application requirements. Commonly used solid lubricants in perforated thrust washers include PTFE (polytetrafluoroethylene), graphite, molybdenum disulfide, or other proprietary lubricating materials. These lubricants offer low friction coefficients and excellent self-lubricating properties.

Benefits: Thrust washers with a perforated self-lubricating design offer several advantages, including:

Reduced Friction: The self-lubricating feature minimizes friction between the sliding surfaces of the thrust washer, resulting in smoother operation and improved efficiency.

Wear Resistance: The presence of a lubricating film helps reduce wear and prolong the service life of the thrust washer by preventing direct metal-to-metal contact and minimizing abrasive wear.

Maintenance-Free: The self-lubricating properties eliminate the need for frequent re-lubrication, reducing maintenance requirements and associated costs.

Consistent Lubrication: The perforations in the thrust washer ensure a continuous supply of lubricant, providing consistent and reliable lubrication throughout the operation.

Applications: Thrust washers with a perforated self-lubricating design are well-suited for various applications where low friction, wear resistance, and minimal maintenance are essential. They can be found in machinery and equipment such as automotive transmissions, industrial machinery, hydraulic systems, and other applications that require axial load support and smooth sliding motion.

When considering the use of thrust washers with a perforated self-lubricating design, it’s important to assess the specific requirements of the application, including load capacity, operating conditions, and the compatibility of the chosen lubricant with the surrounding environment. This will ensure the optimal performance and longevity of the thrust washer in the intended application.

Self-lubricating bronze washer supplier

Guiding Components:

Guiding Components: Guiding components, such as guide pins, bushings, and guide posts, are used in manufacturing equipment to ensure accurate alignment and stability of the moving parts. These components help maintain the precise positioning of the machinery, contributing to consistent product quality and reduced wear and tear on the equipment.

Special Production Mold Sets: Custom mold sets are produced to cater to specific requirements and applications, ensuring that the end product meets the unique needs of a project.

Technical Support and Engineering Services: Expert engineers provide technical support and engineering services to help with product design, optimization, and troubleshooting, ensuring efficient solutions and high-quality outcomes.

Excellent Quality-Price Combination: By using advanced technology and optimizing production processes, manufacturers can offer products with an outstanding combination of quality and affordability.

Fast Delivery: By streamlining production and logistics, manufacturers can deliver products quickly, reducing lead times and ensuring customer satisfaction.

Precise Engineering Services and Technical Support: Manufacturers work closely with their partners, providing precise engineering services and technical support to find the most efficient solutions, ensuring both quality and customer satisfaction.

Advanced Technology Final Measurement and Reporting Skills: Utilizing advanced technology for final measurements and reporting, manufacturers can guarantee the highest levels of quality and accuracy in their products, ensuring customer satisfaction and compliance with industry standards.

Self-lubricating bronze thrust washer supplier

Die Components:

Die components are specialized parts used in metal stamping, injection molding, and die casting processes. These components ensure proper alignment, smooth movement, and precision during the production process. Examples of die components include punches, dies, and stripper plates.

Our delivery service ensures that the required bronze thrust washers reach your address in a timely and efficient manner. We understand the importance of reliable components for the smooth operation of your machinery, and our goal is to provide you with the best possible solutions to meet your needs.

For more specific information and product details, you can visit the official VIIPLUS website, which offers a range of thrust washers and related products[1][2][3][4][5].

Please note that additional technical specifications and product availability may be found on the VIIPLUS website.

Sources:

- VIIPLUS Thrust Washers – Official Website

- Bronze Thrust Washer with Graphite Plugs – VIIPLUS

- Graphite Thrust Washers – Viiplus

- Large Metal Washers – Thrust Bearing Supplier – VIIPLUS

- Dry Thrust Washer – Thrust Bearing Supplier – VIIPLUS

Self-lubricating bronze graphite washer supplier

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.