flanged bearing bush

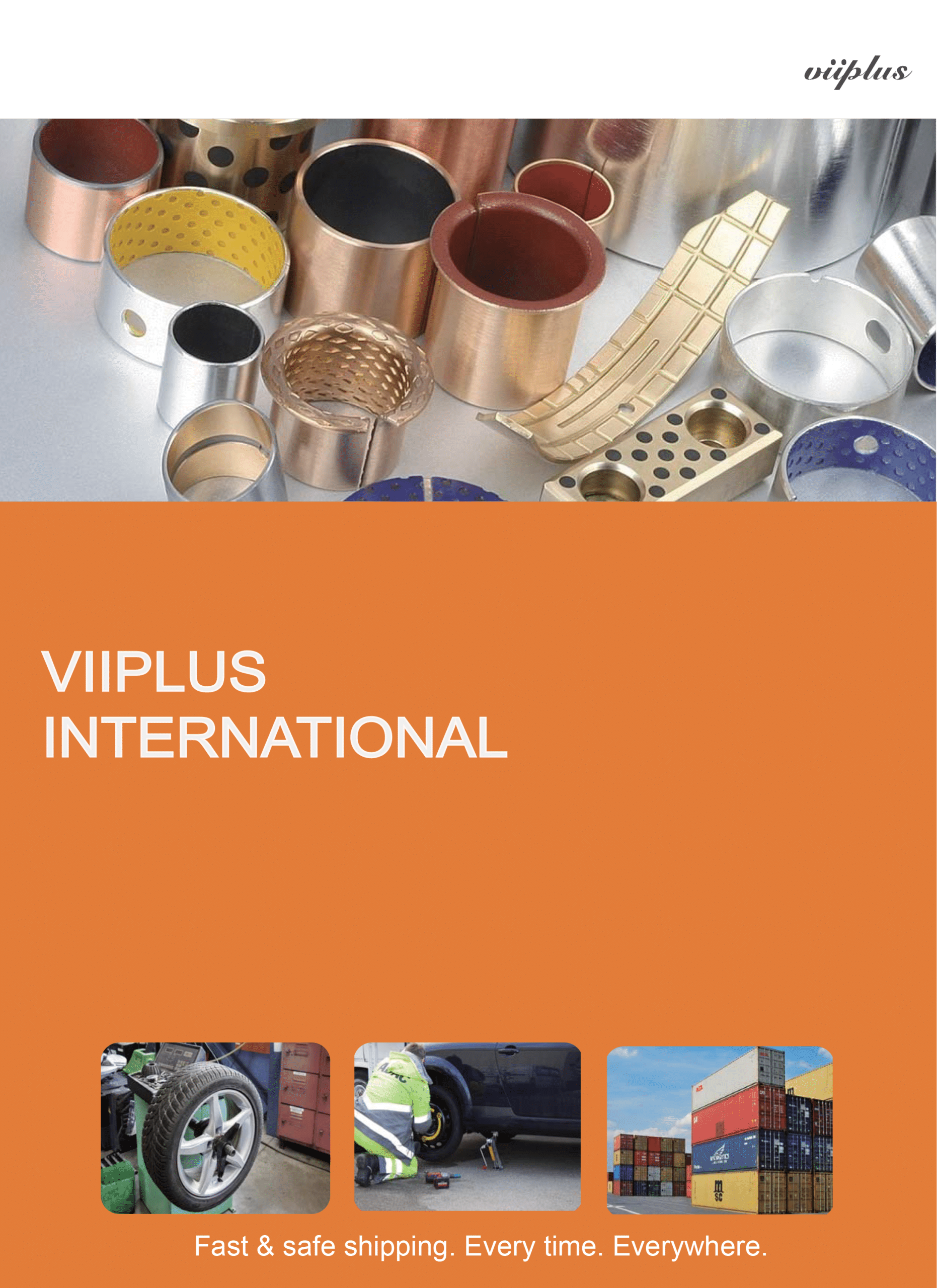

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

flanged bearing bush

Flanged bearing bush – what you need to think about

If you use flanged bearings bushings in your application,

some design considerations will help avoid bearing damage.

Experience

Discover the Benefits of Self-Lubricating Flange Bushings from China. Order Today!

Bearing Solutions

Get the Best Quality Self-Lubricating Flange Bearing Bushings from China. Order Now!

Online Support

Stay Ahead of the Competition with Self-Lubricating Flange Bushings from China. Contact Us!

Self-lubricating flange bushing – Metric Size and Inch Size

A self-lubricating flange bushing is a type of bearing that is designed to operate without requiring additional lubrication. It is commonly used in applications where there is limited or no access to lubrication, or where the use of lubrication is not practical or desirable.

Self-lubricating bushes in various materials

Various self-lubricating flange bushes material

Metallic, self-lubricating flange bushings are made up of one of four basic compositions: Strong Cast Bronze, Bronze Wrapped Bushings, Bearing Bronze….

The bushings and are designed from either cast bronze or bronze-based metal to withstand high load.

Long-lasting, self-lubricating Flanged bearing bush

To hold the plain bearing in the receiving bore so that it forms a fit, there is a collar or flange on one side or, in some designs, on both sides. If you are using flanged bushings in your application, some design considerations will help avoid bearing damage.

Get the Best Deals on Self-Lubricating Flange Bearings Bushings from China. Inquire Now!

Sourcing self-lubricating flange bearings bushings from China.

China is one of the largest manufacturers and suppliers of self-lubricating flange bearings bushings in the world. Chinese suppliers offer a wide range of options for customers looking for high-quality and cost-effective self-lubricating flange bearings bushings.

When sourcing self-lubricating flange bearings bushings from China, it is important to do your due diligence to ensure that you are working with a reputable and reliable supplier. Look for suppliers with a proven track record of producing high-quality products and providing excellent customer service.

Save Time and Money with Self-Lubricating Flange Bearings Bushings from China. Order Today!

Cylindrical bushings with flange – bronzelube.com

bronzelube self-lubricating flange bushes is a leading manufacturer of cylindrical bushings with flange, which are designed to provide a reliable and cost-effective solution for a wide range of applications. The cylindrical bushings with flange from bronzelube self-lubricating flange bushes are made with high-performance polymers, which offer a number of advantages over traditional metallic bearings.

High-Quality Self-Lubricating Flange Bearing

Benefits of self-lubricating flange bearing bushing

Discover the benefits of our self-lubricating flange bearing bushing. Order today to experience the difference.

Self-lubricating flange bearing bushes offer a number of benefits compared to traditional lubricated bearings. High-Quality Self-Lubricating Flange Bearing Bushings from China. Some things to consider when sourcing self-lubricating flange bearings bushings from China include the material used in the bearings, the manufacturing process, quality control procedures, and delivery times. It is also important to consider factors such as price, minimum order quantities, and payment terms. To find the best deals on self-lubricating flange bearings bushings from China, we offer a wide range of options and allow you to compare prices and specifications to find the best deal for your needs. Sourcing self-lubricating flange bearings bushings from China can be a cost-effective solution, but it is important to do your research and work with a reliable supplier to ensure that you receive high-quality products and excellent service. Contact Us Now!

Collar or flange bearing bushing design, The reputation of the supplier is an important consideration. A supplier with a good reputation is more likely to provide high-quality components and reliable service. Look for reviews and ratings from previous customers, and consider asking for references.

A flanged bearing bush is a type of bearing designed for use in applications where radial or axial loads need to be supported. The flange on the bearing allows it to be securely mounted in a housing, making it an ideal solution for machinery and equipment that requires high levels of precision and stability. If you are considering using a flanged bearing bush in your application, there are several things that you need to think about to ensure that you choose the right product for your needs.

Firstly, it is important to consider the load capacity of the bearing. Flanged bearing bushes are designed to support a certain amount of radial or axial load, and this will vary depending on the size and material of the bearing. It is important to choose a bearing that can handle the expected load in your application to ensure that it operates effectively and doesn’t wear out prematurely.

The next factor to consider is the material of the bearing. Flanged bearing bushes can be made from a variety of materials, including steel, bronze, and plastic. Each material has its own unique properties and advantages, so it is important to choose the right material for your specific application. For example, if your application requires high levels of corrosion resistance, a stainless steel bearing may be the best option.

Another important factor to consider is the lubrication requirements of the bearing. Flanged bearing bushes require proper lubrication to operate effectively and prevent premature wear. Depending on the application, different types of lubrication may be required, such as oil or grease. It is important to choose a bearing that is compatible with the lubricant that will be used in the application.

The size and shape of the flanged bearing bush are also important considerations. The bearing should be the correct size to fit within the housing and provide the necessary support for the application. Additionally, the shape of the flange should be designed to provide a secure and stable mount within the housing, to prevent any movement or misalignment.

Finally, it is important to consider the operating environment of the bearing. Flanged bearing bushes can be used in a wide range of applications, from high-temperature environments to corrosive environments. It is important to choose a bearing that is designed to operate effectively in the specific environment where it will be used, to ensure that it performs as expected and has a long service life.

In conclusion, choosing the right flanged bearing bush for your application requires careful consideration of a range of factors, including load capacity, material, lubrication requirements, size and shape, and operating environment. By taking the time to carefully evaluate each of these factors, you can ensure that you choose the right bearing for your specific needs, and that it will operate effectively and reliably over the long term.

Cost saving, choose our flange bearing bush

Cost is always a consideration, but it should not be the only factor in selecting a flange bearing bush supplier. A lower cost may indicate lower quality components or service. Look for a supplier that offers a fair price for high-quality components and reliable service.

selecting the right flange bearing bush supplier is critical to ensuring the quality and performance of this important component. Consider factors such as reputation, quality, customization, technical expertise, delivery and lead times, and cost when selecting a supplier. By taking the time to carefully evaluate suppliers and select a reliable and trustworthy partner, you can help avoid potential issues and ensure the long-term success of your projects and equipment.

We manufacture flange bearing bushing tailored to your individual needs.

Self-lubricating flange bearing bush metric size and inch size

Metric Size:

Self-lubricating flange bushings are available in metric sizes, which are expressed in millimeters (mm). The dimensions of a metric flange bushing may include the inside diameter (ID), outside diameter (OD), and length, as well as the thickness of the flange. Metric sizes can range from as small as a few millimeters to as large as several hundred millimeters.

Inch Size:

Self-lubricating flange bushings are also available in inch sizes, which are expressed in inches. The dimensions of an inch flange bushing may include the inside diameter (ID), outside diameter (OD), and length, as well as the thickness of the flange. Inch sizes can range from as small as a fraction of an inch to as large as several inches.

Both metric and inch size self-lubricating flange bushings can be made from a variety of materials, including sintered bronze, brass, steel, and plastic. The choice of material will depend on the specific application requirements, such as load capacity, temperature range, and chemical compatibility.

Benefits of self-lubricating flange bearing bush

Plastic Bushings: The Self-Lubricating Effect

Here are some of the main advantages of self-lubricating flange bearing bushes:

Low Maintenance: One of the biggest advantages of self-lubricating flange bearing bushes is that they require very little maintenance. Since they are designed to be self-lubricating, they do not need to be regularly greased or oiled like traditional bearings, reducing the need for maintenance and extending the life of the component.

Reduced Friction: Self-lubricating flange bearing bushes are made with a low-friction material such as sintered bronze or polymer, which reduces friction and wear. This can help to reduce energy consumption and improve the efficiency of the equipment.

Increased Service Life: Because self-lubricating flange bearing bushes are made with high-quality materials and designed to reduce wear, they often have a longer service life than traditional bearings. This can reduce the need for replacement parts and help to extend the life of the equipment.

Corrosion Resistance: Some self-lubricating flange bearing bushes are made with materials that are highly resistant to corrosion and can withstand harsh environments. This can help to reduce the risk of damage or failure due to corrosion and extend the service life of the component.

Quiet Operation: Self-lubricating flange bearing bushes are often designed to operate quietly, reducing noise and vibration in the equipment. This can help to improve operator comfort and reduce the risk of damage to other components due to vibration.

Customization: Self-lubricating flange bearing bushes can be customized to meet specific application requirements. They are available in a range of sizes, materials, and configurations, allowing them to be tailored to the specific needs of the equipment.

In conclusion, self-lubricating flange bearing bushes offer a number of advantages over traditional lubricated bearings. They require less maintenance, reduce friction, have a longer service life, are corrosion-resistant, operate quietly, and can be customized to meet specific application requirements. These benefits can help to improve the performance and efficiency of equipment and reduce the need for maintenance and replacement parts.

Here are some of the key features and benefits of bronzelube self-lubricating flange bushes cylindrical bushings with flange:

1.Self-lubricating: bronzelube self-lubricating flange bushes cylindrical bushings with flange are designed to be self-lubricating, which eliminates the need for regular maintenance and reduces the risk of bearing failure due to lack of lubrication. This can save time and money and improve the efficiency of the equipment.

2.Low Friction: The high-performance polymers used in bronzelube self-lubricating flange bushes cylindrical bushings with flange offer a low coefficient of friction, which reduces energy consumption and improves the performance of the equipment. This can help to reduce operating costs and extend the service life of the equipment.

3. Corrosion Resistance: bronzelube self-lubricating flange bushes cylindrical bushings with flange are highly resistant to corrosion and can withstand harsh environments. This makes them ideal for use in applications where traditional metallic bearings may be prone to corrosion and wear.

4.Quiet Operation: The low-friction design of bronzelube self-lubricating flange bushes cylindrical bushings with flange helps to reduce noise and vibration in the equipment, which improves operator comfort and reduces the risk of damage to other components.

5. Customizable: bronzelube self-lubricating flange bushes offers a wide range of cylindrical bushings with flange in different sizes and configurations, which can be tailored to meet the specific needs of the equipment. This ensures that the bushings are optimized for the specific application, which improves performance and extends service life.

6.Cost-Effective: bronzelube self-lubricating flange bushes cylindrical bushings with flange are cost-effective compared to traditional metallic bearings. They offer longer service life, require less maintenance, and have a lower total cost of ownership over the life of the equipment.

7. In conclusion, bronzelube self-lubricating flange bushes cylindrical bushings with flange are a reliable and cost-effective solution for a wide range of applications. They offer self-lubrication, low friction, corrosion resistance, quiet operation, customizability, and cost-effectiveness, which make them a popular choice for many different industries. Whether you are looking for a replacement part for an existing system or designing a new piece of equipment, bronzelube self-lubricating flange bushes cylindrical bushings with flange can help to improve performance and reduce operating costs.

Avoid flange bearing bush damage

Flange bearing bushes are important components used in a wide range of industrial machinery and equipment. They are designed to provide support and reduce friction between moving parts. However, if not properly installed, maintained, or operated, flange bearing bushes can become damaged, leading to expensive repairs and downtime. Here are some important steps that can help avoid flange bearing bush damage:

Proper Installation: Proper installation is key to ensuring that a flange bearing bush operates effectively and does not become damaged. This includes making sure that the housing hole is the correct size and tolerance, that the bearing is properly aligned, and that the bearing is not subjected to excessive force during installation.

Lubrication: Proper lubrication is essential to the performance and longevity of a flange bearing bush. Without sufficient lubrication, the bearing can become damaged due to excessive friction and wear. It is important to use the correct type and amount of lubricant, and to ensure that the lubricant is applied at regular intervals.

Monitoring: Regular monitoring is key to identifying potential issues with a flange bearing bush before they become serious problems. This includes checking for unusual noise or vibration, inspecting the bearing for signs of wear or damage, and monitoring operating conditions such as temperature and load.

Avoid Excessive Loads: Excessive loads can cause a flange bearing bush to become damaged or fail. It is important to ensure that the bearing is designed and rated for the specific load and operating conditions of the application. Overloading the bearing can cause it to wear prematurely or fail catastrophically.

Avoid Contamination: Contamination from dirt, dust, or other debris can cause a flange bearing bush to become damaged or fail. It is important to ensure that the bearing and surrounding area are kept clean and free of debris, and to use appropriate protective measures such as seals or covers to prevent contamination.

Regular Maintenance: Regular maintenance is essential to ensuring the long-term performance and reliability of a flange bearing bush. This includes tasks such as cleaning and lubricating the bearing, inspecting for signs of wear or damage, and replacing the bearing when necessary.

In conclusion, by following these important steps, you can help avoid flange bearing bush damage and ensure that your industrial machinery and equipment operates effectively and reliably over the long term. Proper installation, lubrication, monitoring, load management, contamination prevention, and regular maintenance are all critical to the longevity and performance of flange bearing bushes.

Flange Bearing Bush The housing hole

The housing bore should be perpendicular to the surface of the part. Otherwise, the bushing flange will not lie flat on the surface. Then, depending on the material, the flange can deform or even fracture during assembly or under the mechanical stress of the application.

The hole should also be free of burrs and preferably have a chamfer. A relatively small chamfer is sufficient. An excessively large chamfer can affect the load capacity of the flange or bushing on the running surface.

Burrs along the edges of the bore must be avoided. Even with the correct chamfer and vertical drilling, residual burrs can cause undesired dimensional changes and even damage to the bushing

The housing hole for a flange bearing bush is a critical element in ensuring that the bearing operates effectively and has a long service life. The housing hole should be carefully designed to provide a secure and stable mount for the bearing, while also allowing for proper lubrication and clearance. Here are some important factors to consider when designing the housing hole for a flange bearing bush:

Size and Tolerance: The housing hole should be the correct size and tolerance to provide a tight fit for the bearing. The recommended tolerance for a housing hole is usually H7, which means the hole diameter is slightly larger than the bearing outer diameter to allow for proper clearance.

Surface Finish: The surface finish of the housing hole is also important, as it can affect the bearing’s performance and life. The recommended surface finish is typically between 0.8 and 1.6 microns, which is sufficient to prevent damage to the bearing and provide proper lubrication.

Chamfer: A chamfer on the edge of the housing hole can help to prevent damage to the bearing as it is inserted into the housing. The recommended chamfer is usually around 0.5mm to 1mm, which is enough to prevent any burrs or sharp edges from causing damage to the bearing.

Lubrication: The housing hole should be designed to allow for proper lubrication of the bearing. This can be achieved by ensuring that there is sufficient clearance around the bearing to allow the lubricant to flow freely.

Mounting: The housing hole should be designed to allow for easy and secure mounting of the bearing. This can be achieved by ensuring that the flange on the bearing is designed to fit securely within the housing and that there are no obstructions or misalignments that could cause the bearing to become dislodged.

In conclusion, the housing hole is a critical element in ensuring that a flange bearing bush operates effectively and has a long service life. By carefully considering factors such as size and tolerance, surface finish, chamfer, lubrication, and mounting, you can ensure that the housing hole provides a secure and stable mount for the bearing, while also allowing for proper lubrication and clearance.

Flange Bearing Bush The load

Edge loading due to the introduction of torsional or tilting moments can result in adverse stresses on the plain bearing. Shear forces can be generated between the collar and the cylindrical body of the bearing and cause separation of the flange, resulting in axial displacement of the plain bearing from the housing bore.

When a number of bearing points are arranged in sequence, these edge loads are often caused by self-alignment deficiencies. Tolerances and dimensional deviations lead to alignment errors, which then result in edge loads in the plain bearing.

In the corresponding application case, torques also act on the plain bearing if the load is outside the bearing’s center of gravity. Additional support can help.

The load capacity of a flange bearing bush is an important factor to consider when selecting and using this type of bearing. The load capacity refers to the maximum amount of load that the bearing can support without experiencing premature wear or failure. Here are some important considerations to keep in mind when it comes to the load capacity of a flange bearing bush:

Radial Load: A radial load is a force that acts perpendicular to the axis of the bearing. The load capacity of a flange bearing bush for radial loads will depend on several factors, including the size and material of the bearing, as well as the operating conditions.

Axial Load: An axial load is a force that acts parallel to the axis of the bearing. The load capacity of a flange bearing bush for axial loads will depend on several factors, including the size and material of the bearing, as well as the operating conditions.

Combined Load: In many applications, both radial and axial loads may be present. The load capacity of a flange bearing bush for combined loads will depend on the size and material of the bearing, as well as the operating conditions.

Operating Conditions: The load capacity of a flange bearing bush can be affected by a range of operating conditions, such as temperature, speed, and vibration. It is important to consider these factors when selecting a bearing to ensure that it is capable of handling the expected load in the specific operating environment.

Safety Factor: To ensure that the bearing has a long service life and does not experience premature wear or failure, it is important to apply a safety factor to the calculated load capacity. The safety factor is usually expressed as a multiple of the expected load and can vary depending on the application.

In conclusion, the load capacity of a flange bearing bush is an important factor to consider when selecting and using this type of bearing. By considering factors such as radial load, axial load, combined load, operating conditions, and safety factor, you can ensure that the bearing is capable of handling the expected load and will operate effectively and reliably over the long term.

Bushing Design, If all else fails, uncouple.

If the housing bore still does not have a different design, or if torsional or tilting moments cannot be adequately absorbed, a two-component solution can be considered. A simple cylindrical bushing is used instead of a flanged bushing and an additional thrust washer is used as axial support. In this way, these components can absorb the necessary forces independently of each other. However, this solution also has disadvantages that need to be considered. Multi-component solutions require more delicate assembly and tend to be slightly more expensive.

self-lubricating metallic bearing materials, two-piece, double-flanged solid polymer bearings.

Technical Expertise: A supplier with technical expertise can provide valuable guidance and support in selecting the right flange bearing bush for a particular application. Look for a supplier that has experienced engineers and technical staff who can answer questions and provide advice.

BUSHING DEAIGN

Custom Flange Bearing Bushing We are happy to assist you!

Customization: Every application is unique, and a good flange bearing bush supplier will be able to offer customization options to meet specific needs. Look for a supplier that offers a range of customization options, such as different materials, sizes, and configurations.

Timely delivery is important to ensure that projects are completed on time and that equipment downtime is minimized. Look for a supplier that offers reliable and timely delivery and has short lead times.

We support you in the design of your bearing flange bushing, from the selection of the right shape and the most suitable production process to the subsequent implementation and delivery. Please get in touch with us!

Top quality

The quality of the flange bearing bush is essential to its performance and longevity. Look for a supplier that offers high-quality components made from durable materials that are designed to withstand the specific operating conditions of the application.

Flange bearing supplier

Selecting the right flange bearing bush supplier is critical to ensuring the quality and performance of this important component.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.