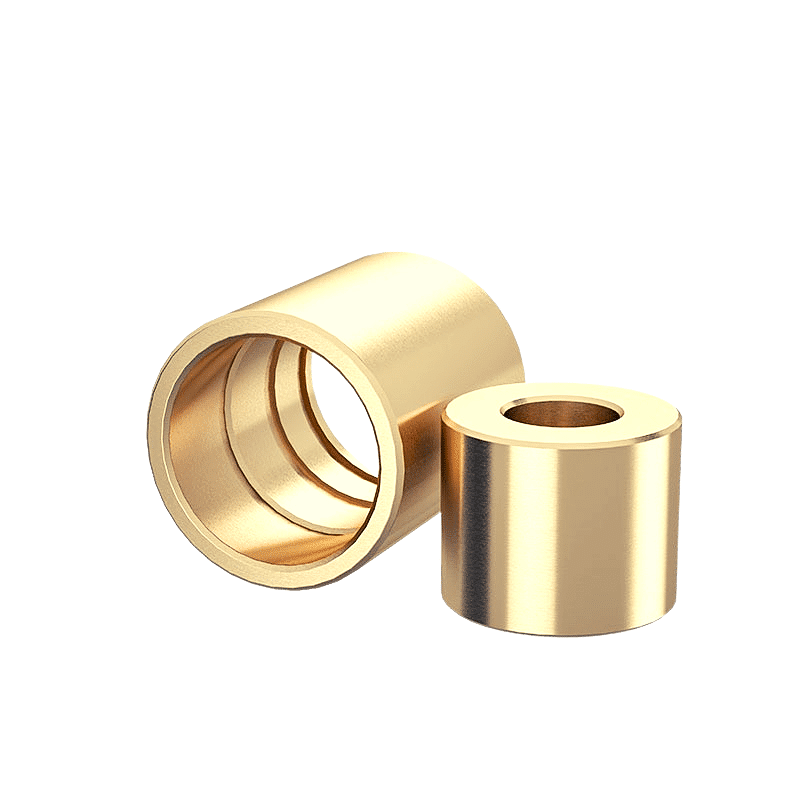

Oversized Bronze Bearing Types

Increased Load Capacity: The larger diameter increases the load capacity of the bearing, making it suitable for heavy-duty machinery and equipment. There are several types of bronze bearings, including oversized bronze bearings, cast bronze bearings, self-lubricating bronze bearings, and large-diameter bronze bearings. Self-lubricating finished bronze graphite bearing parts and large diameter self-lubricating graphite bronze bearings offer a range of benefits, including reduced maintenance needs, improved durability, and higher load capacity. These properties make them an excellent choice for various applications, particularly in heavy-duty machinery and equipment.

Oversized Bronze Bearings- Cost-Effective Production

These are larger than standard bearings and are used in heavy-duty industrial applications where a larger bearing surface is required. They are typically made of bronze because of the metal’s excellent properties, including high wear resistance, low friction, and resistance to corrosion. Improved Stability: Large diameter bearings provide better stability and alignment, leading to more precise and efficient operation. Cost-Effective Production: Since the centrifugal casting process can produce parts that require minimal machining or finishing, it can be a cost-effective method for producing oversized and large diameter bronze bearings.

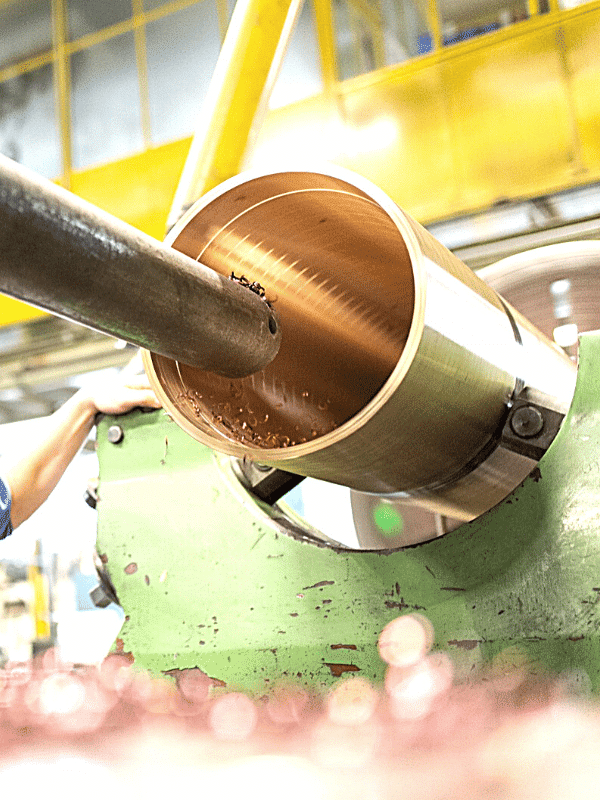

Cast Bronze Bearings- Centrifugal casting

These bearings are made by casting, a process in which molten bronze is poured into a mold and then allowed to cool and solidify. Cast bronze bearings have excellent load-carrying capability and resistance to wear and corrosion, making them suitable for a wide range of applications. Wear Resistance: The combination of bronze and graphite provides excellent wear resistance, further enhancing the durability of these bearings. Centrifugal casting is a method used to produce oversized bronze bearings and large diameter bronze bearings. This process involves pouring molten metal into a spinning mold. The centrifugal force pushes the metal against the mold walls and allows it to solidify into the desired shape. This method is known for its ability to produce parts with fine details and excellent mechanical properties. The centrifugal casting process is well-suited for the production of oversized bronze bearings and large diameter bronze bearings. It offers numerous advantages, including superior material quality, high load-bearing capacity, design flexibility, and cost-effective production. The resulting bearings are durable, corrosion-resistant, and ideal for use in a variety of heavy-duty applications.

Self-Lubricating Bronze Bearings

These bearings are designed to provide their own lubrication to reduce friction and wear. They may be embedded with lubricants or have a porous structure that can be impregnated with oil or grease. This eliminates the need for regular manual lubrication and can extend the life of the bearing. Temperature Resistance: Bronze-graphite bearings can operate under a wide range of temperatures. The graphite acts as a heat conductor, helping to dissipate heat and prevent overheating. Better Heat Dissipation: The larger surface area facilitates more effective heat dissipation, reducing the risk of overheating and consequent damage.

Large Diameter Bronze Bearings

These are bronze bearings with a large diameter. They are used in applications where high load-carrying capacity and durability are required. The large diameter provides a greater contact area, distributing the load more evenly and reducing the pressure on the bearing. Corrosion Resistance and Durability: Bronze bearings made through centrifugal casting exhibit excellent corrosion resistance, making them suitable for use in harsh environments. The process also contributes to the overall durability of the bearing, as the uniform material density reduces wear and prolongs the bearing’s lifespan.

Bronze finished machine parts

Each type of bronze bearing has its own unique advantages and applications. The choice between them depends on the specific requirements of your application, including the load, speed, temperature, and environmental conditions. It’s also essential to consider maintenance requirements and the total cost of ownership when selecting a bearing type. Versatility: The larger size and self-lubricating properties make these bearings versatile and suitable for a range of applications, from construction and mining equipment to heavy-duty industrial machinery.

Custom Oversized Bronze Bearing Size

Corrosion Resistance: Bronze is naturally resistant to corrosion, which is an added advantage in applications where the bearing might be exposed to harsh environments.

Custom oversized bronze bearings are manufactured according to the specific size requirements of the client’s application. This means the diameter, thickness, and inner hole can be tailored to fit precisely into your machinery or device. High Load Capacity: Bronze is a robust material known for its high load-bearing capacity. It can handle substantial loads without deformation, making it ideal for heavy-duty applications.

about the company

Oversized bronze bearing bushings

Oversized bronze bearing bushings, as the name suggests, are larger than standard bushings and are commonly used in a range of heavy-duty applications, particularly in machinery that handles high loads and high-speed operations. These components are crafted from durable, corrosion-resistant bronze. In this article, we’ll delve into the different types of oversized bronze bearing bushings and their specific applications.

Product Quality Index

Energy Generation

Self-lubricating finished bronze graphite bearing parts and thrust washer

Large diameter self-lubricating graphite bronze bearings are specialized types of bearings that offer excellent performance in challenging conditions. Self-lubricating bronze graphite bearing parts are a remarkable innovation in bearing technology. Self-Lubricating: The primary advantage of these bearings is that they are self-lubricating. The graphite within the bronze provides a built-in lubricant, which reduces friction without the need for additional lubrication. This property significantly reduces maintenance needs and costs, while also extending the bearing’s lifespan. Oversized plain bearing thrust washers are a type of bearing specially designed to manage axial loads, i.e., loads parallel to the axis of rotation.

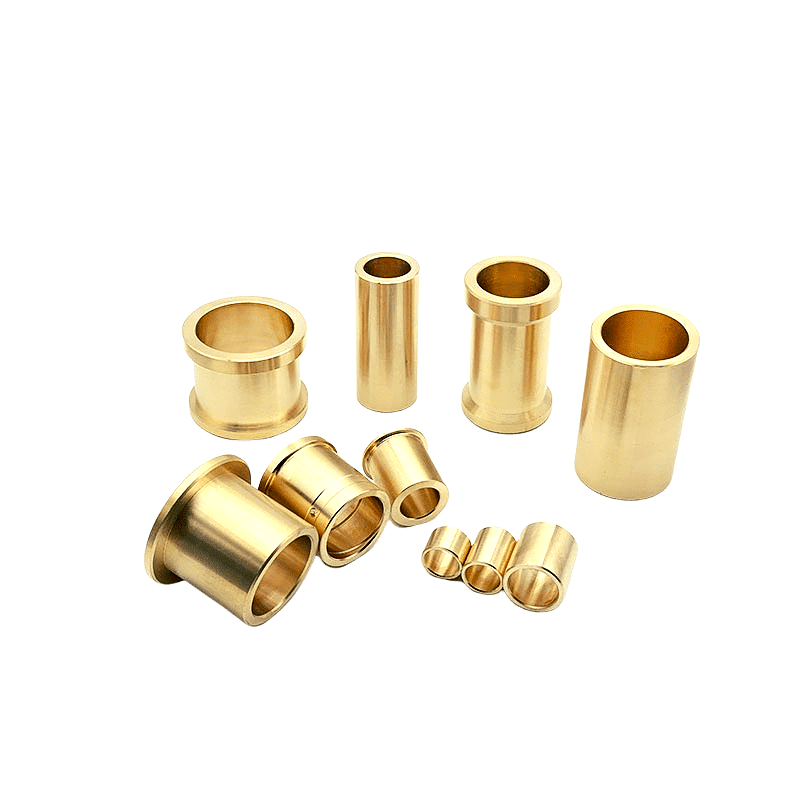

Types of Oversized Bronze Bearing Bushings:

Share your wedding moments with your guests

Sleeve Bushings: Also known as plain bearings, sleeve bushings are perhaps the most commonly used type. They provide a sliding surface with a high load-carrying capacity and excellent heat dissipation characteristics. The bushing is often cylindrical and fits directly into the housing to guide and restrain the motion of mechanical parts.

Flanged Bushings: These are similar to sleeve bushings but come with a flange at one end. The flange provides an integrated thrust bearing surface and aids in location, preventing axial movement in one direction. They are ideal for applications where a structure requires extra support or where there is no housing shoulder.

Oversized bronze bearings are indeed manufactured in a variety of sizes and shapes to suit diverse applications. Let’s discuss the different types and the custom features often incorporated into these bearings.

- One Piece Sleeve Bearings: These are cylindrical bearings that are solid and don’t have any seams. They are ideal for applications where a high load capacity and durability are required. They offer excellent resistance to wear and tear.

- Split Bearings: These bearings are split along their length or diameter, allowing them to be installed without having to disassemble the associated equipment. This feature makes them convenient for maintenance and replacement.

- Flanged Bearings: These bearings have a flange or rim at one end, which prevents them from moving past a certain point. This design helps to maintain alignment and positioning in the machinery.

- Thrust Washers: These are flat bearings that are used to support axial loads. They help to reduce friction and wear in applications where components slide against each other.

- Wear Plates: Wear plates are flat pieces of metal that are used to reduce friction and prevent wear between moving parts in machinery. They can be made from bronze to take advantage of its excellent wear resistance.

Custom features often incorporated into oversized bronze bearings include:

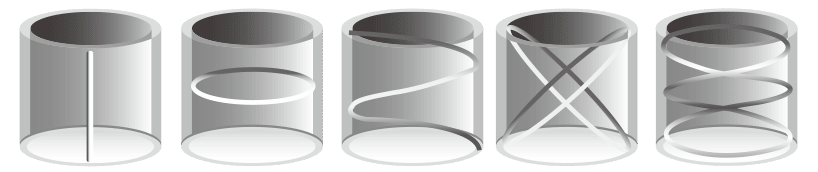

- Custom Oil Grooves: Oil grooves can be added to the bearing surface to distribute lubricant more evenly. This feature helps to reduce friction, prevent overheating, and extend the lifespan of the bearing.

- Threading: Threads can be added to the inside or outside of the bearing to allow it to be screwed into place. This feature provides a secure fit and prevents the bearing from slipping out of position.

- Drill Holes: Holes can be drilled into the bearing for various purposes, such as allowing the passage of lubricant or mounting the bearing to a surface.

In conclusion, oversized bronze bearings are versatile and customizable, making them suitable for a wide range of applications. Whether you need a solid sleeve bearing for a high-load application or a split bearing for easy maintenance, there’s an oversized bronze bearing that can meet your needs. Additionally, custom features like oil grooves, threading, and drill holes can further enhance the performance and functionality of these bearings.

When ordering custom oversized bronze bearings, you will typically need to provide the following information:

- Bearing Type: Specify the type of bearing needed, such as plain, flanged, or self-lubricating.

- Inner Diameter (ID): This is the diameter of the hole in the middle of the bearing where the shaft will go.

- Outer Diameter (OD): This is the total diameter of the bearing.

- Length or Width: Depending on the bearing’s shape, this could be the length (for cylindrical bearings) or width (for flange or block bearings).

- Material: In this case, it would be a type of bronze, but there can be different bronze alloys to choose from depending on the application requirements.

- Additional Features: Any additional features such as lubrication type (oil or grease), presence of flanges, grooves, or other specifications.

Once you provide these specifications, the manufacturer can then produce the custom oversized bronze bearing to your exact requirements.

Remember, it’s always best to consult with a bearing expert or the manufacturer to ensure the custom bearing will meet the demands of your specific application. Factors such as load capacity, speed, operating temperature, and environmental conditions should all be considered when designing a custom bearing.

Large-diameter self-lubricating graphite bronze bearings are specialized types of bearings that offer excellent performance in challenging conditions. Here’s a bit more information about them:

Material: These bearings are typically made from a bronze alloy, which is known for its durability, high load-bearing capacity, and resistance to wear and corrosion.

Self-lubricating: The self-lubricating feature means these bearings are designed to reduce friction without the need for additional lubrication. This is typically achieved by impregnating the bearing with oil or embedding lubricant in the material itself. In this case, graphite is used as the lubricant.

Graphite: Graphite has excellent lubricating properties and can withstand high temperatures, making it an excellent choice for bearings that operate under high load or high-temperature conditions. In self-lubricating graphite bronze bearings, graphite plugs or particles are typically embedded in the bearing material. These graphite elements release lubricant when the bearing is in operation, reducing friction and wear.

Large Diameter: Large diameter bearings are designed for applications where a high load-bearing capacity is required. The large diameter provides a greater contact area, which helps to distribute the load more evenly and reduces pressure on the bearing.

These types of bearings are commonly used in industries such as heavy machinery, automotive, aerospace, and marine applications due to their durability, low maintenance, and ability to operate smoothly under challenging conditions.

Remember, it’s always important to consider the specific requirements of your application when choosing a bearing, including factors such as load, speed, temperature, and environmental conditions.

Oversized Plain Bearing Thrust Washer

Oversized plain bearing thrust washers are a type of bearing specially designed to manage axial loads, i.e., loads parallel to the axis of rotation. Here’s a look at some of their key features:

- Load Management: These thrust washers are particularly effective at handling axial loads, helping to prevent movement along the shaft axis and ensuring the machinery operates as intended.

- Reduced Friction: Made from materials like bronze or steel, these washers help reduce friction between the moving parts of machinery, leading to smoother operation and less wear and tear.

- Increased Durability: Their oversized design increases the surface area in contact with the rotating components, spreading the load over a larger area, which helps minimize wear and prolong the lifespan of both the bearing and the machinery.

- Adaptability: Oversized plain bearing thrust washers can be used in a variety of heavy-duty applications, including construction, mining, and industrial machinery.

Large Diameter Bronze Bearings

Large diameter bronze bearings offer several unique advantages, particularly for heavy-duty applications:

- High Load Bearing Capacity: Bronze is a robust material known for its high load-bearing capacity. Large diameter bronze bearings are designed to handle substantial loads without deformation.

- Corrosion Resistance: Bronze is naturally resistant to corrosion, making it suitable for applications where the bearing might be exposed to harsh environmental conditions.

- Superior Durability: The combination of bronze’s inherent toughness and the larger size of these bearings helps distribute the load over a larger area, reducing wear and prolonging the bearing’s life.

- Versatility: Large diameter bronze bearings are versatile and can be used in a wide range of applications, from heavy-duty machinery to automotive components.

Oversized plain bearing thrust washers and large diameter bronze bearings offer a range of advantages, including improved load management, reduced friction, increased durability, and versatile application. These properties make them ideal for use in various heavy-duty machinery and equipment.

Oversized bushing bearings Informational The Advantages of Using Oversized Bushing Bearings in Heavy Machinery Discover the benefits of using oversized bushing bearings in heavy machinery, and how they can improve your equipment’s performance and durability.

Bushing bearings play a vital role in the smooth operation of any piece of heavy machinery. They reduce friction, facilitate smooth rotation, and maintain alignment between different parts. However, the specific benefits offered by oversized bushing bearings set them apart, and make them an ideal choice for heavy-duty equipment.

- Increased Load Capacity: Oversized bushing bearings are designed to handle larger loads compared to standard-sized bearings. This capability is crucial in heavy machinery applications, which often involve substantial weights and forces. The ability to accommodate these extreme loads without failure helps to maintain operational efficiency and minimizes the risk of equipment damage or breakdown.

- Improved Durability and Longevity: Given their larger size, oversized bushing bearings have a greater surface area in contact with the rotating component. This property distributes the load over a larger area, reducing localized wear and tear. Consequently, the lifespan of both the bearing and the machinery is extended, leading to lower replacement costs and less downtime for maintenance.

- Enhanced Stability and Precision: Oversized bushing bearings can improve the stability and accuracy of heavy machinery operation. Because they offer a better fit and more substantial contact with moving parts, they can enhance the precision of movements, leading to higher-quality output, especially in applications where accuracy is paramount.

- Better Heat Dissipation: In any machinery, friction generates heat, which, if not properly managed, can lead to premature failure. Oversized bushing bearings, due to their larger size and increased surface area, dissipate heat more effectively, thus reducing the risk of overheating and consequent damage.

- Greater Resistance to Shock Loads: Heavy machinery is often subject to sudden or extreme loads, known as shock loads. Regular bearings might fail under such conditions. However, oversized bushing bearings, due to their robust design and increased load capacity, can absorb these shock loads better, protecting the machinery from potential damage.

- Flexibility in Material Selection: Oversized bushing bearings can be produced using a variety of materials, including bronze, plastic, or composite material. This flexibility allows them to be customized to the specific needs of the machinery, whether that involves resistance to corrosion, high temperatures, or other challenging conditions.

The use of oversized bushing bearings in heavy machinery offers several distinct advantages, including improved durability, increased load capacity, and enhanced operational precision. By integrating these components into your equipment, you can ensure a longer lifespan, more efficient operation, and ultimately, a higher return on your investment.

Large bushing bearings Informational Why Large Bushing Bearings are Essential for Heavy Equipment Learn why large bushing bearings are crucial for heavy equipment, and how they improve equipment durability and performance.

Bushing bearings are pivotal components of heavy machinery, significantly contributing to its optimal performance and longevity. Large bushing bearings, in particular, are essential due to the unique benefits they offer in heavy-duty applications.

- Exceptional Load Bearing Capacity: Large bushing bearings are designed to accommodate greater loads. This feature is crucial in heavy machinery, where high forces are commonplace. The enhanced load-bearing capacity of these bearings helps to prevent equipment failure, ensuring continuous and efficient operations.

- Superior Durability: With a larger size, these bushing bearings have a more significant surface area in contact with the rotating components. This characteristic spreads the load over a larger area, reducing the strain on any single point and minimizing wear and tear. This results in a prolonged lifespan for both the bearing and the machinery.

- Enhanced Stability and Precision: The larger size of these bushing bearings provides a better fit and more substantial contact with moving parts, leading to more stable and precise operation. This is particularly beneficial in heavy machinery where precision is critical.

- Effective Heat Dissipation: Friction-induced heat is a common issue in machinery operation. If not managed correctly, it can lead to premature failure of the components. Large bushing bearings, with their increased surface area, are better at dissipating this heat, reducing the risk of overheating and subsequent damage.

- Greater Shock Load Resistance: Heavy equipment often faces sudden or extreme loads, known as shock loads. Smaller bearings might fail under such conditions, but large bushing bearings, with their robust design and superior load capacity, are better equipped to absorb these shock loads, thereby safeguarding the machinery from potential damage.

- Versatility in Material Selection: Large bushing bearings can be made from a range of materials, including bronze, plastic, or composite materials. This flexibility allows for customization based on the specific requirements of the machinery, such as resistance to corrosion, high temperatures, or other harsh conditions.

In conclusion, large bushing bearings are not just essential but indispensable for heavy equipment. By ensuring improved durability, increased load-bearing capacity, and enhanced operational precision, these bearings play a crucial role in enhancing the performance and lifespan of your machinery. Incorporating large bushing bearings into your heavy equipment design can lead to more efficient operation and a better return on your investment.

Applications Oversized bushing bearings for mining equipment Informational The Role of Oversized Bushing Bearings in Mining Equipment Learn how oversized bushing bearings are used in mining equipment, and how they can improve the performance and durability of the equipment.

Mining equipment operates in some of the harshest environments on Earth. These heavy-duty machines must handle extreme loads, shock, vibration, and abrasive dust, all while operating continuously for extended periods. The role of oversized bushing bearings in such equipment is crucial, offering several benefits that enhance the performance and durability of these machines.

- Handling Extreme Loads: Mining equipment often deals with massive amounts of materials, putting a significant strain on the machine. Oversized bushing bearings are specifically designed to accommodate these high loads, helping to ensure the machinery operates smoothly and efficiently without risking premature failure.

- Resisting Shock Loads: Mining operations frequently involve sudden, extreme forces, known as shock loads. Oversized bushing bearings, due to their robust design and larger size, are better equipped to absorb these shock loads, reducing the risk of sudden equipment failure and subsequent costly downtime.

- Withstanding Abrasive Conditions: In the mining industry, equipment is often exposed to abrasive materials and dust. Oversized bushing bearings can be made from materials like bronze, which offers excellent resistance to abrasion, ensuring the longevity of the bearings and the equipment.

- Increasing Operational Precision: Oversized bushing bearings can enhance the precision of mining machinery. Their larger size provides a better fit and more substantial contact with moving parts, leading to more stable and accurate operation. This feature is particularly beneficial in applications like drilling, where precision is paramount.

- Ensuring Effective Heat Dissipation: Mining equipment often operates for extended periods, generating significant heat due to friction. The larger surface area of oversized bushing bearings facilitates better heat dissipation, reducing the risk of overheating and consequent damage to the equipment.

- Improving Equipment Longevity: By managing extreme loads, resisting shock, and reducing wear and tear, oversized bushing bearings can significantly extend the life of mining equipment. This benefit leads to lower maintenance costs, less downtime, and higher overall productivity.

In conclusion, the use of oversized bushing bearings in mining equipment is crucial, as they offer enhanced durability, superior load-bearing capacity, and improved operational precision. By incorporating these bearings into mining machinery, operators can ensure efficient, reliable operation even under the most challenging conditions, significantly improving the performance and lifespan of their equipment.

Maintenance Lubrication of oversized bushing bearings Informational How to Properly Lubricate Oversized Bushing Bearings for Longevity Learn the proper techniques for lubricating oversized bushing bearings to ensure their longevity and improve the performance of heavy machinery.

Proper lubrication of oversized bushing bearings is critical to ensure their longevity and optimal performance in heavy machinery. Here are some steps and techniques to correctly lubricate these bearings:

- Choose the Right Lubricant: The first step in proper lubrication is choosing the right lubricant for the bearing and the application. Factors such as the type of material, the operating temperature, the load, and the environmental conditions (like dust or moisture) will affect the choice of lubricant. Lubricants can include oils, greases, or solid film lubricants, each having its own set of advantages and disadvantages.

- Clean the Bearing Surface: Before applying the lubricant, ensure that the bearing surface is clean. This process might involve removing the old lubricant and any dust, debris, or residue. Cleaning prevents contamination, which can increase friction, wear, and tear.

- Apply the Lubricant: Apply a thin, even layer of lubricant to the bearing surface. For grease, you might use a brush or a specialized grease gun. For oil, a dropper or oil can might be suitable. Be sure not to over-lubricate, as excess lubricant can attract dirt or cause excessive heat due to churning.

- Ensure Even Distribution: Rotate the bearing slowly to ensure the lubricant is evenly distributed. This rotation helps the lubricant to penetrate into all the nooks and crannies, providing optimal coverage and protection.

- Regular Inspections and Maintenance: Regularly inspect the bearings and lubricant condition. Look for signs of wear, contamination, or depletion of the lubricant. Regular maintenance will help identify any issues early, preventing potential bearing failure.

- Follow Manufacturer’s Guidelines: Always follow the manufacturer’s guidelines for lubrication. These guidelines will provide specific instructions based on the design and material of the bearing and the intended application.

Proper lubrication of oversized bushing bearings is vital to reduce friction, prevent wear and tear, and ensure the smooth operation of heavy machinery. By following these steps, you can extend the lifespan of the bearings, reduce maintenance costs, and improve the overall performance of your equipment.

Applications Oversized bushing bearings for construction equipment Informational The Advantages of Using Oversized Bushing Bearings in Construction Equipment Discover how oversized bushing bearings can improve the performance and durability of construction equipment, and reduce maintenance costs. Applications Oversized bushing bearings for agricultural equipment Informational How Oversized Bushing Bearings Help Agricultural Equipment Perform Better Learn how oversized bushing bearings can improve the performance of agricultural equipment, and increase equipment longevity.

The Advantages of Using Oversized Bushing Bearings in Construction Equipment

The construction industry relies heavily on various types of machinery to carry out a range of tasks. Here’s how oversized bushing bearings can significantly improve the performance and durability of construction equipment:

- Enhanced Load Capacity: Construction equipment often has to carry heavy loads. Oversized bushing bearings are designed to handle these loads, ensuring the efficient operation of the machinery.

- Improved Durability: The larger size and robust design of these bearings distribute the load evenly, reducing wear and tear. This feature enhances the lifespan of the bearings and the equipment.

- Reduced Maintenance Costs: Due to their improved durability and ability to handle extreme loads, oversized bushing bearings can decrease the frequency of maintenance, leading to cost savings.

- Increased Stability and Precision: Oversized bushing bearings offer better fit and more substantial contact with moving parts, which can enhance the stability and precision of the machinery, an essential aspect in construction operations.

- Effective Heat Dissipation: The larger surface area of oversized bushing bearings allows for better heat dissipation, reducing the risk of overheating, which could lead to premature equipment failure.

How Oversized Bushing Bearings Help Agricultural Equipment Perform Better

Agricultural equipment, such as tractors and harvesters, can also greatly benefit from the use of oversized bushing bearings:

- Resilience Under High Loads: Agricultural equipment often operates under high load conditions, such as plowing or harvesting. The high load capacity of oversized bushing bearings makes them ideal for such conditions.

- Extended Equipment Lifespan: By evenly distributing the load and reducing wear and tear, these bearings can significantly extend the lifespan of agricultural equipment.

- Improved Precision: The stability offered by oversized bushing bearings can improve the precision of agricultural equipment, which is crucial for tasks like seeding or harvesting.

- Lower Maintenance Needs: The durability of these bearings can reduce the need for frequent maintenance, resulting in less downtime and lower costs.

- Greater Resistance to Harsh Conditions: Agricultural machinery often operates in harsh conditions, including dust and varying temperatures. The robust design and material versatility of oversized bushing bearings make them well-suited to withstand these challenging environments.

In conclusion, the use of oversized bushing bearings in both construction and agricultural equipment offers numerous benefits, including improved performance, increased durability, and cost savings. By incorporating these bearings, you can ensure a longer lifespan and more efficient operation of your machinery.