Plastic bushings vs. bronze bearings

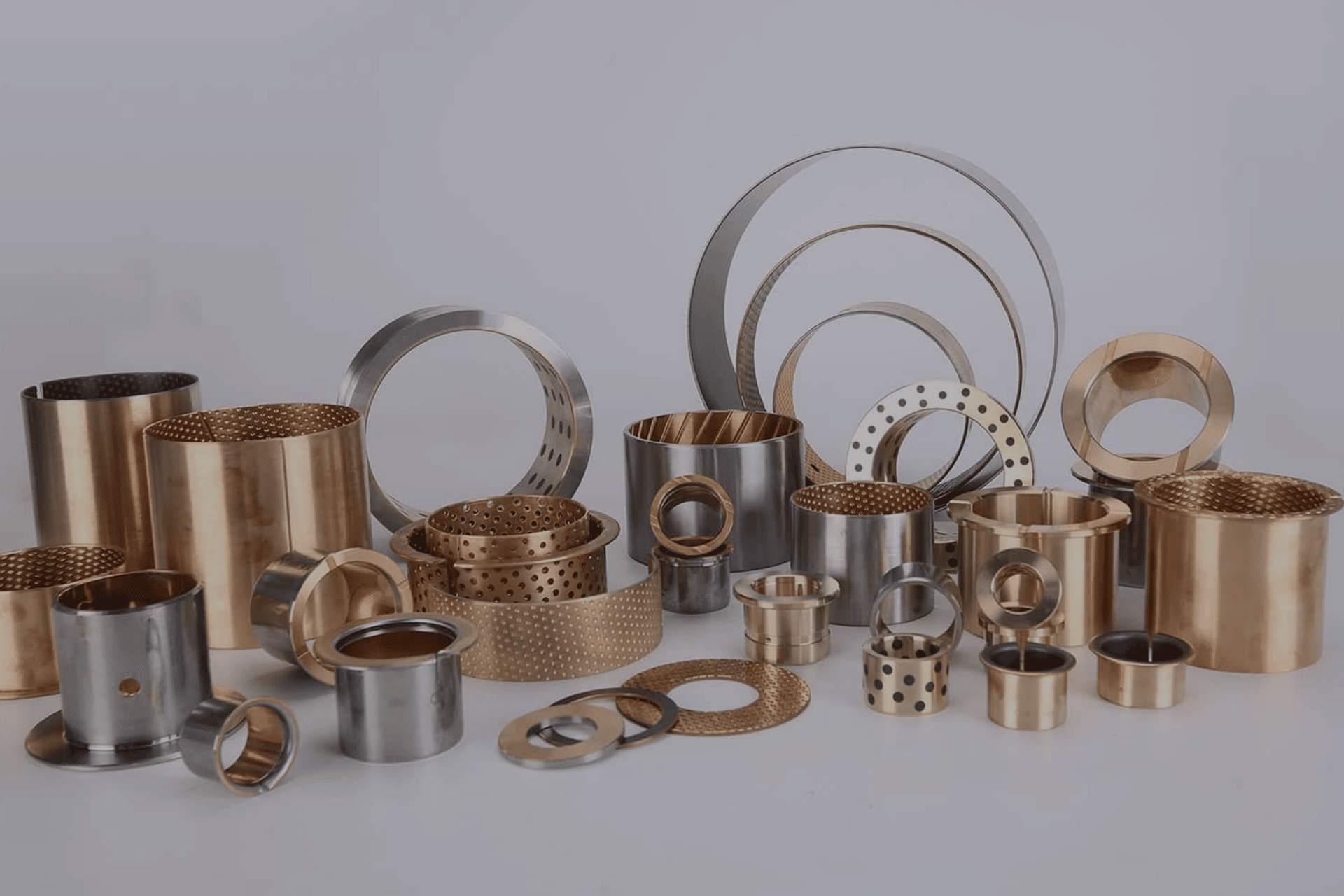

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Plastic bushings vs. bronze bearings

Bronze vs. Plastic Bushings: What’s the Difference?

Bearings & Cast Materials Made To Order The Standard Size.

Shop Our Huge Range Of Sizes! Quality Made Manufacturing.

See Our Online Catalog & Request A Free Quote…

Experience

Replacing a plastic bushing with bronze? Bronze bushings are more resistant to deformation and fracture than other materials.

Bearing Solutions

Bushing vs. Bearing: What is Best for Your Application?

Online Support

Selecting Bearings or Bushings for your industry!

Self-lubricating bushes in various materials

Various self-lubricating bushing material

Metallic, self-lubricating flange bushings are made up of one of four basic compositions: Strong Cast Bronze, Bronze Wrapped Bushings, Bearing Bronze….

The bushings and are designed from either cast bronze or bronze-based metal to withstand high load.

Long-lasting, Self-lubricating Bronze Bearings

Bronze bearings, on the other hand, are made from various bronze alloys, such as phosphor bronze and aluminum bronze. They are known for their high strength, durability, and high-load capacity. Bronze bearings are also resistant to corrosion and wear and tear, making them an excellent choice for applications that require high strength and durability.

self-lubricating bronze bushings can provide cost savings over time due to their reduced maintenance requirements, increased durability, improved efficiency, and better performance in harsh environments. While the initial cost of self-lubricating bronze bushings may be higher than other types of bearings, the long-term cost savings can make them a more cost-effective option.

Get the Best Deals on Self-Lubricating Flange Bearings Bushings from China. Inquire Now!

Sourcing bronze bushings from China.

Bronze bearings are suitable for high-load and high-speed applications, making them ideal for heavy machinery, industrial equipment, and automotive applications. They are also more heat-resistant than plastic bushings, making them suitable for applications that involve high temperatures.

However, bronze bearings require regular lubrication to maintain their performance, and they are more expensive than plastic bushings. They are also heavier than plastic bushings, which can be a disadvantage for some applications.

Save Time and Money with Self-Lubricating Flange Bearings Bushings from China. Order Today!

Choosing the right type of bearing for your application

Choosing the right type of bearing for your application is essential to ensure optimal performance and longevity. When it comes to plastic bushings vs. bronze bearings, the choice depends on your specific application needs.

If your application requires a low-friction, self-lubricating, and chemically resistant bearing that is lightweight and cost-effective, plastic bushings may be the best choice. However, if your application requires a high-load, high-speed, and heat-resistant bearing that is durable and long-lasting, bronze bearings may be the better option.

Ultimately, the choice between plastic bushings and bronze bearings depends on your specific application requirements, including load, speed, temperature, and environmental factors. By carefully considering these factors, you can choose the best type of bearing for your application and ensure optimal performance and longevity.

High-Quality Self-Lubricating Flange Bearing

Benefit of Self-lubricating Plastic Bushings

Plastic bushings are made from various materials, including PTFE, POM, and acetal. They are known for their low friction, chemical resistance, and self-lubricating properties. Self-lubricating Plastic bushings are also lightweight and cost-effective, making them a popular choice for many applications.

One of the main benefits of plastic bushings is their ability to operate without the need for additional lubrication. This can be a significant advantage for applications where maintenance is challenging, and frequent lubrication is not possible. Plastic bushings are also resistant to many chemicals and have a high resistance to wear and tear.

However, plastic bushings are not suitable for high-load applications as they can deform under heavy loads, which can cause premature wear and tear. Additionally, plastic bushings have lower heat resistance than other types of bearings and can experience creep under high loads.

Self-lubricating plastic bushing vs Self-lubricating Bronze Bearings What’s the Difference?

Self-lubricating plastic bushings and self-lubricating bronze bearings are both types of bearings designed to reduce friction and provide smooth movement between two moving parts. However, there are some key differences between these two types of bearings.

Material Composition:

Self-lubricating plastic bushings are made from a variety of plastic materials, such as PTFE, nylon, or acetal. These materials typically have a low coefficient of friction and can provide good wear resistance. Self-lubricating bronze bearings, on the other hand, are made from a bronze alloy with embedded solid lubricant particles, such as graphite or PTFE. This provides self-lubricating properties and can provide higher load capacities than plastic bushings.

Load Capacity:

Self-lubricating bronze bearings generally have a higher load capacity than plastic bushings. This is due to the strength and durability of the bronze alloy used in the bearings. This makes them a good choice for applications that require high load capacity and where plastic bushings may not be suitable.

Temperature Resistance:

Self-lubricating plastic bushings typically have a lower temperature resistance than self-lubricating bronze bearings. Plastic bushings may begin to deform or lose their strength when exposed to high temperatures, whereas bronze bearings can typically handle higher temperatures without degrading.

Corrosion Resistance:

Self-lubricating bronze bearings generally have better corrosion resistance than plastic bushings. The bronze alloy used in these bearings is resistant to corrosion and wear, making them a good choice for applications where corrosion is a concern.

Cost:

Self-lubricating plastic bushings are generally less expensive than self-lubricating bronze bearings. However, the long-term cost may vary depending on the specific application requirements. Bronze bearings can have a longer lifespan and require less maintenance, which may offset their higher initial cost.

Overall, the choice between self-lubricating plastic bushings and self-lubricating bronze bearings will depend on the specific requirements of the application. Plastic bushings are a good choice for low-load, low-speed applications with moderate temperature and corrosion resistance requirements. Bronze bearings are a good choice for high-load, high-speed applications with high-temperature and corrosion resistance requirements.

Cost saving, choose our self-lubricating bearing bushing

Self-lubricating bronze bushings can provide significant cost savings over time compared to other types of bearings, such as standard bronze bearings or plastic bushings.

- Reduced maintenance costs: Because self-lubricating bronze bushings do not require additional lubrication, they can significantly reduce the time and cost associated with maintenance. You do not need to grease or oil the bearings regularly, which reduces the need for downtime and maintenance labor costs.

- Increased durability: Self-lubricating bronze bushings are designed to be durable and have a longer lifespan than some other types of bearings. This can help reduce the need for replacements or repairs, saving you money on replacement parts and labor costs.

- Improved efficiency: By reducing friction and wear, self-lubricating bronze bushings can improve the efficiency of your machinery. This can result in reduced energy consumption and lower operating costs over time.

- Better performance in harsh environments: Self-lubricating bronze bushings are designed to perform well in harsh environments, such as those with high temperatures or exposure to chemicals. Because they are resistant to corrosion and wear, they can last longer in these environments than other types of bearings, which can help save money on replacement parts and maintenance costs.

We manufacture bearing bushing tailored to your individual needs.

Self-lubricating Composite Bushing vs. Bronze Bearings: What is the different?

Self-lubricating composite bushings and bronze bearings are two popular types of bearings used in various industrial and mechanical applications. While both are designed to reduce friction and provide smooth movement, there are some key differences between the two. In this article, we’ll explore the differences between self-lubricating composite bushings and bronze bearings.

Self-lubricating Composite Bushings

Self-lubricating composite bushings are made from a variety of materials, including thermoplastics, thermosets, and composite materials. These materials have self-lubricating properties, which means that they can operate without additional lubrication, reducing the need for maintenance.

Self-lubricating composite bushings are also resistant to corrosion, chemicals, and wear and tear. They are lightweight and cost-effective, making them an attractive option for many applications. These bushings are also quiet and vibration-free, providing a smooth and quiet operation.

One of the main advantages of self-lubricating composite bushings is their ability to operate without additional lubrication. This means they can be used in applications where maintenance is difficult or impossible. They are also resistant to a wide range of chemicals and have a high resistance to wear and tear, making them ideal for use in harsh environments.

Plastic bushing construction

Plastic bushings are a type of bearing designed to provide a low-friction interface between two moving parts, such as a shaft and a housing. They are made from various types of plastic materials, including nylon, acetal, PTFE (polytetrafluoroethylene), and UHMW (ultra-high-molecular-weight polyethylene).

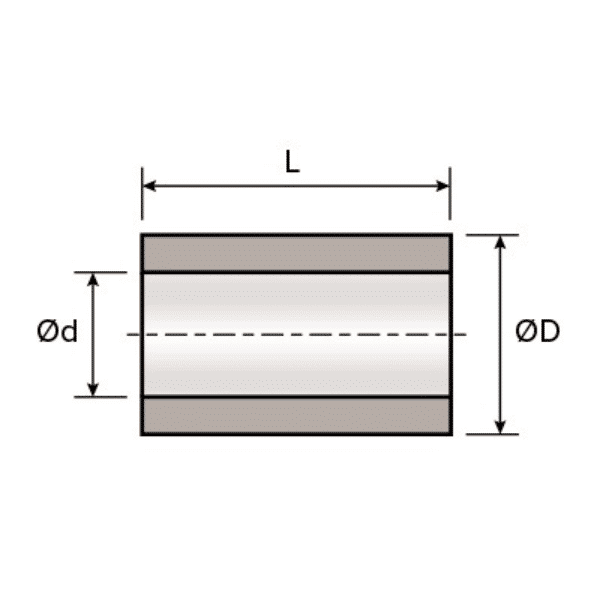

The construction of plastic bushings can vary depending on the specific application requirements. However, most plastic bushings have a similar design consisting of an inner sleeve, an outer sleeve, and a sliding surface.

The inner sleeve of the plastic bushing is designed to fit snugly around the shaft and provide support. It is typically made from a harder plastic material than the outer sleeve, providing durability and wear resistance.

The outer sleeve of the plastic bushing is designed to fit inside the housing and provides a low-friction surface for the shaft to slide against. It is typically made from a softer plastic material than the inner sleeve to reduce friction and prevent damage to the shaft.

The sliding surface of the plastic bushing is the area where the inner and outer sleeves come into contact with each other. This surface is designed to reduce friction and prevent wear and tear, ensuring smooth and long-lasting operation.

Many plastic bushings are also designed with lubrication grooves, which help to distribute lubricant evenly throughout the sliding surface. This helps to reduce friction and prevent damage to the bushing and the shaft.

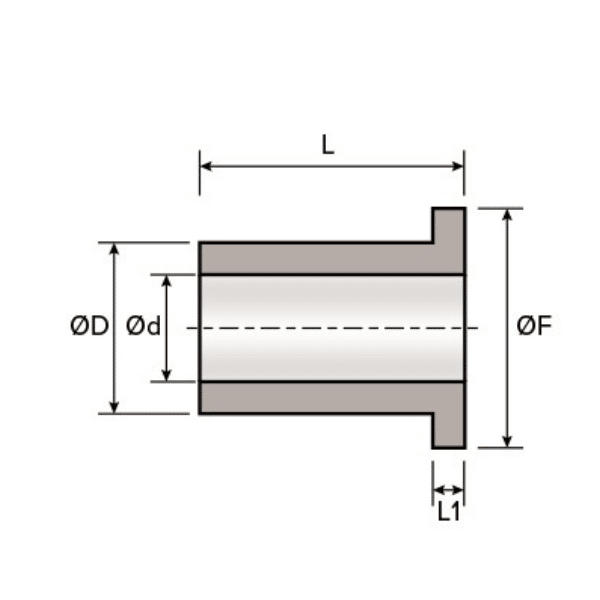

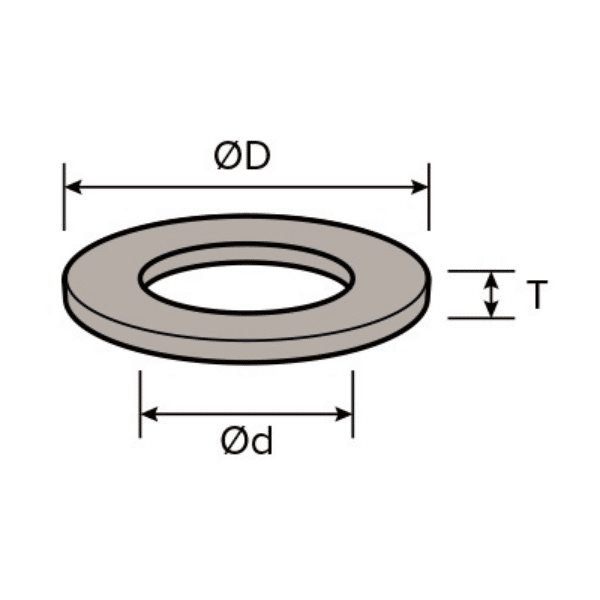

In addition to the standard construction of plastic bushings, some plastic bushings are also designed with additional features such as flanges, collars, or other mounting options. These features are designed to provide additional support or facilitate mounting and installation.

Overall, plastic bushings are a versatile and cost-effective solution for a wide range of industrial and mechanical applications. The construction of plastic bushings can vary depending on the specific application requirements, but most designs share a similar construction consisting of an inner sleeve, an outer sleeve, and a sliding surface. By choosing the right type of plastic material and design for the application, plastic bushings can provide a low-friction and durable solution for many applications.

Bronze Bearings

Bronze Bearings

Bronze bearings are made from bronze alloys, such as phosphor bronze, aluminum bronze, or brass. They are known for their high strength, durability, and high-load capacity, making them an ideal choice for heavy-duty industrial applications.

Bronze bearings require lubrication to maintain their performance, and they can operate at high temperatures without losing their lubricating properties. They are also resistant to corrosion and wear and tear, making them ideal for use in harsh environments.

One of the main advantages of bronze bearings is their high load capacity, making them ideal for use in heavy machinery and equipment. They are also suitable for high-speed applications and can operate at high temperatures without losing their lubricating properties.

Differences between Self-lubricating Composite Bushings and Bronze Bearings

The main difference between self-lubricating composite bushings and bronze bearings is the need for lubrication. Self-lubricating composite bushings can operate without additional lubrication, while bronze bearings require regular lubrication to maintain their performance. This means that self-lubricating composite bushings are lower maintenance and can be used in applications where maintenance is difficult or impossible.

Another difference between the two is their load capacity. Bronze bearings have a higher load capacity than self-lubricating composite bushings, making them ideal for heavy-duty industrial applications.

Finally, self-lubricating composite bushings are generally more cost-effective than bronze bearings, making them a popular choice for many applications.

Bronze vs. Plastic Bushings: What’s the Difference?

Self-lubricating composite bushings and bronze bearings are both popular types of bearings used in various industrial and mechanical applications. The choice between the two depends on the specific application requirements, including load capacity, temperature, and environmental factors. Self-lubricating composite bushings are ideal for applications where maintenance is difficult or impossible, while bronze bearings are ideal for heavy-duty industrial applications with high load capacity requirements. By carefully considering the application requirements, you can choose the best type of bearing for your application and ensure optimal performance and longevity.

made to order self-lubricating bronze bushing

Self-lubricating bronze bushings are a type of bearing designed to reduce friction and provide smooth movement between two moving parts. They are made from a bronze alloy with embedded solid lubricant particles, such as graphite or PTFE, that provide self-lubricating properties.

If you need a self-lubricating bronze bushing for a specific application, you can have them made to order. Here are the steps typically involved in the process:

Identify the application requirements: The first step in ordering a self-lubricating bronze bushing is to identify the specific application requirements. This includes factors such as load capacity, temperature range, speed, and environmental conditions. By understanding these requirements, you can choose the right material and design for your bushing.

Choose the material: Self-lubricating bronze bushings can be made from various bronze alloys, such as phosphor bronze, aluminum bronze, or brass. Each alloy has unique properties, such as strength, wear resistance, or corrosion resistance. You should choose the right material based on the application requirements.

Choose the lubricant: The lubricant particles embedded in the bronze alloy can also vary, depending on the application requirements. For example, graphite is a good choice for high-temperature applications, while PTFE is ideal for applications with low friction requirements.

Choose the design: The design of the self-lubricating bronze bushing can also vary depending on the application requirements. This includes factors such as the shape, size, and mounting options. You may need to work with a manufacturer or engineer to determine the best design for your application.

Order the bushing: Once you have identified the application requirements, chosen the material, lubricant, and design, you can place an order with a manufacturer or supplier that specializes in custom self-lubricating bronze bushings. The manufacturer will then produce the bushing to your specifications.

BUSHING DEAIGN

Custom Self-lubricating Bearing Bushing We are happy to assist you!

Overall, having a self-lubricating bronze bushing made to order allows you to get a custom solution that is tailored to your specific application requirements. By choosing the right material, lubricant, and design, you can ensure optimal performance and longevity for your bushing.

We support you in the design of your bearing flange bushing, from the selection of the right shape and the most suitable production process to the subsequent implementation and delivery. Please get in touch with us!

Top quality

The self-lubricating bronze bushings are long-lasting and corrosion resistant

A Guide to Bearings and Bushings

Selecting the right bearing bush supplier is critical to ensuring the quality and performance of this important component.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.