providing factory services of superior quality with focus on efficiency.

01.

Providing Quotes for Custom Parts and Large-Scale Production Orders

02.

Satisfaction guaranteed

03.

Ensuring timely delivery

04.

Revolutionize How You Produce Custom Components

We Stand by Your Side from Initial Prototyping through to Production and Further.

Supplier Aluminum Bronze Bearing – Large and Small Size

Trying to source a non-standard bronze bearing? Get in touch and we will guarantee to find a solution.

C95400 Aluminum Bronze Bushing / C954 Aluminum Bronze Bearing

Supplier C95400 Aluminum Bronze Bushing- Large and Small Size, Supply A Wide Range Of Bronze And Aluminium Bronze Materials. Discovery Material Properties. C95400 Aluminum Bronze Bearing, also known as C954 Bronze Bushing, is the most popular, all-purpose aluminum bronze alloy. It provides high yield and tensile strength, good ductility.

C95400 Aluminum Bronze Bushing Type, ASTM Casting Copper Alloy

| Chemical Composition mass/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cu | Sn | Al | Fe | Mn | Ni | Pb | Si | P | Zn |

| Min83.0 | – | 10.5-11.5 | 3.0-5.0 | 0.5 | 1.5 | – | – | – | – |

| Mechanical properties | |||

|---|---|---|---|

| Tensile strength Mpa(Min) | Yield strength MPa(Min) | Elongation % | Brinell hardness(HB) |

| 586 | 221 | 12 | 170 |

Note:

1、In Chemical Composition, Single values represent maximums.

2、Mechanical performance of hardness value is only for reference

FIND A BRONZE BEARING

Simply measure your Aluminum Bronze Bushing bearing then choose sizes in Imperial or Metric and the finder will select the Aluminum Bronze Bushing bearing you are looking for.

Accredited and Focused on Quality

With a variety of processes at your disposal, such as CNC machining, sheet cutting, and injection molding, we stands as your comprehensive solution for custom manufacturing.

Our High Volume Production Service Provides Dedicated Assistance For Custom Manufacturing Endeavors, Accommodating Projects Of Any Complexity And Scale.

▪ Metal Bearing Production Solutions

Your comprehensive answer for production, our team stands as the ideal choice for your manufacturing requirements.

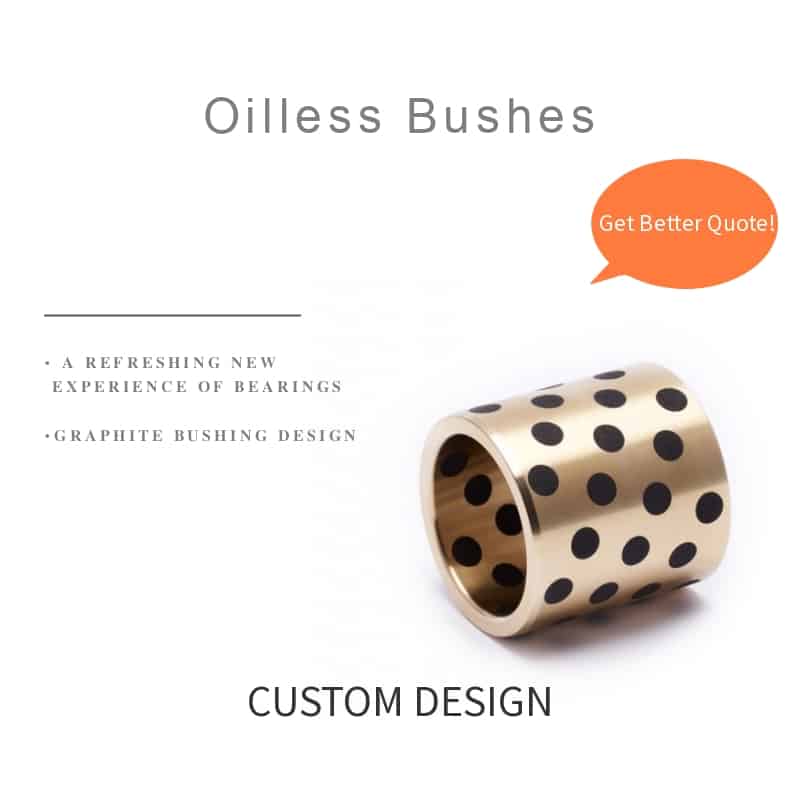

▪ self-lubricating Bearings Solutions

With our technical specialists, the convenience of our secure quotation platform, and extensive global manufacturing capabilities, we are equipped to meet your needs.

Produce custom components as needed

We’re Your Partner From Prototyping to Production and Beyond

We provide a variety of services to assist you in creating functional prototypes and transitioning to production components. Manufacture custom parts as needed, utilizing various materials for self-lubricating bearings. Reach out to us to benefit from our expert applications engineering team’s production capabilities.

Product Quality Index

Energy Generation

Ready to get started on your custom self-lubricating bearing quote?

Breathtaking design for home living.

The variety of materials, cost-effective custom manufacturing per unit, and rapid production pace make it an excellent choice for prototyping.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.