providing factory services of superior quality with focus on efficiency.

01.

Providing Quotes for Custom Parts and Large-Scale Production Orders

02.

Satisfaction guaranteed

03.

Ensuring timely delivery

04.

Revolutionize How You Produce Custom Components

We Stand by Your Side from Initial Prototyping through to Production and Further.

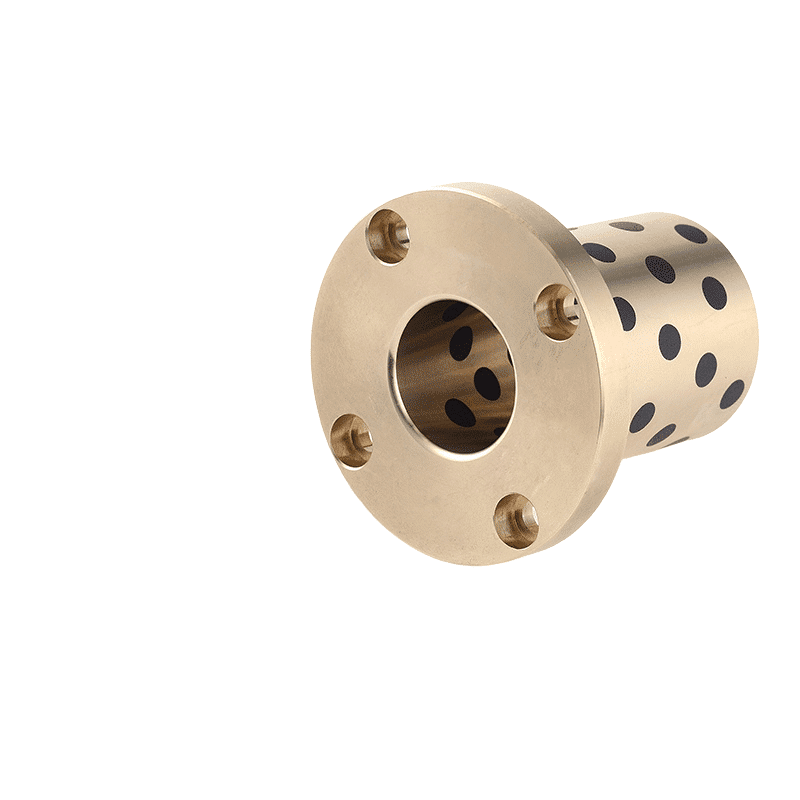

Enhancing Efficiency with Graphite Impregnated Bronze Bushings: A Study on Self-Lubrication and Extended Service Life

Graphite impregnated bronze bushings represent a significant advancement in bearing technology, offering a sustainable solution that reduces the need for frequent lubrication. Our research delves into the efficacy of these bushings under operational conditions that typically require minimal to no oil lubrication. By examining their performance and durability, we aim to provide insights that could revolutionize maintenance protocols and enhance the longevity of mechanical components.

Understanding the Self-Lubricating Mechanism

The cornerstone of graphite impregnated bronze bushings lies in their self-lubricating properties. This is primarily attributed to the presence of graphite within the bronze matrix, a material renowned for its lubricating capabilities. When these bushings are put to use, the friction between their surfaces initiates the release of graphite particles, which form a thin, protective film over the contacting areas.

This transfer film acts as a self-renewing lubricant layer, continuously replenishing itself during the bushing’s operation. It significantly reduces metal-to-metal contact, diminishing wear and tear while enhancing the bushing’s performance and service life.

Advantages of Graphite Impregnated Bronze Bushings

Reduced Lubrication Requirement: The inherent lubricity of graphite diminishes the necessity for external oil lubrication, aligning with environmentally friendly and maintenance-reducing goals.

Wear Resistance: The protective film formed by graphite not only lubricates but also shields the bushing and adjoining components from wear, thereby prolonging their operational lifespan.

Operational Efficiency: These bushings maintain their lubricating efficacy under various conditions, ensuring consistent performance and reducing downtime associated with maintenance.

Environmental Impact: Minimizing the use of oil-based lubricants contributes to a reduction in environmental hazards associated with lubricant disposal and leakage.

Research Objectives and Outcomes

Our study aims to refine the understanding of how graphite impregnated bronze bushings function under diverse conditions, particularly focusing on scenarios where minimal lubrication is feasible. By optimizing the graphite distribution within the bronze matrix, we seek to enhance the self-lubricating film’s formation and durability, thus extending the bushing’s service life.

The anticipated outcomes of this research include:

Enhanced Material Formulation: Developing a bronze-graphite composite that maximizes lubrication efficiency and wear resistance.

Operational Guidelines: Providing insights into the operational limits and maintenance practices that ensure the optimal performance of these bushings.

Application Specific Solutions: Tailoring the use of graphite impregnated bronze bushings to suit various industrial applications, optimizing their benefits across different mechanical settings.

Conclusion

Graphite impregnated bronze bushings offer a promising solution for industries seeking reliable and maintenance-efficient bearing options. Our research is dedicated to unlocking their full potential, ensuring that these bushings can deliver exceptional performance and longevity in applications where reducing external lubrication is a priority. By understanding and enhancing the self-lubricating properties of these bushings, we pave the way for more sustainable and cost-effective mechanical designs.

Accredited and Focused on Quality

With a variety of processes at your disposal, such as CNC machining, sheet cutting, and injection molding, we stands as your comprehensive solution for custom manufacturing.

Our High Volume Production Service Provides Dedicated Assistance For Custom Manufacturing Endeavors, Accommodating Projects Of Any Complexity And Scale.

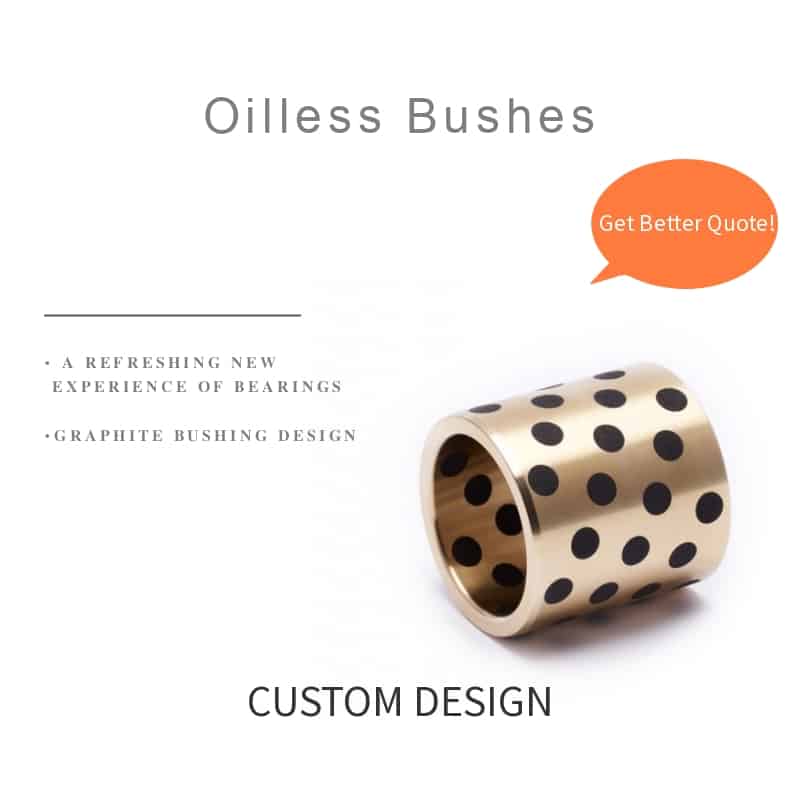

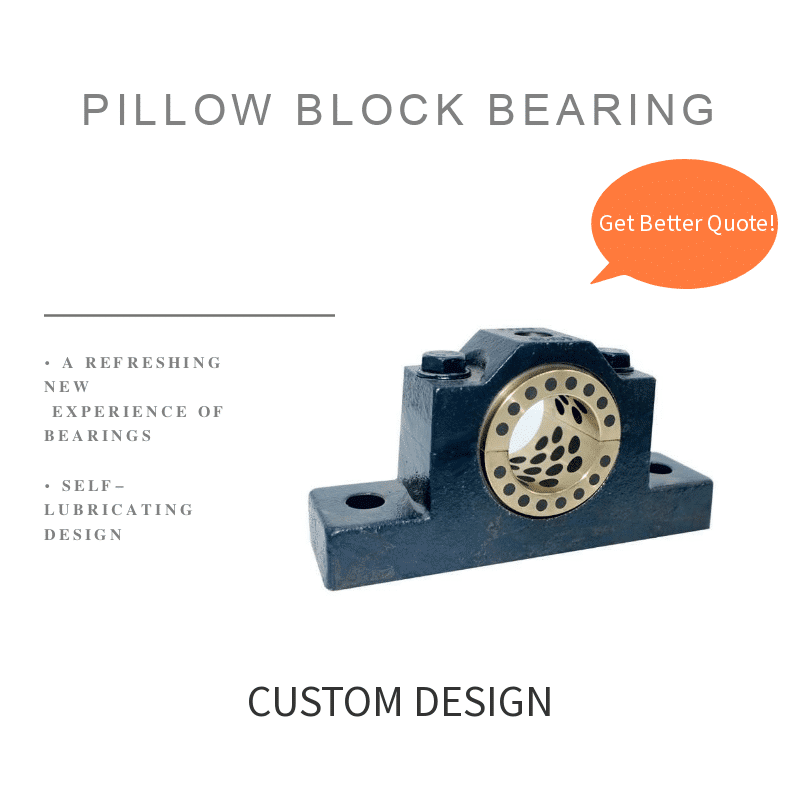

▪ Metal Bearing Production Solutions

Your comprehensive answer for production, our team stands as the ideal choice for your manufacturing requirements.

▪ self-lubricating Bearings Solutions

With our technical specialists, the convenience of our secure quotation platform, and extensive global manufacturing capabilities, we are equipped to meet your needs.

Produce custom components as needed

We’re Your Partner From Prototyping to Production and Beyond

We provide a variety of services to assist you in creating functional prototypes and transitioning to production components. Manufacture custom parts as needed, utilizing various materials for self-lubricating bearings. Reach out to us to benefit from our expert applications engineering team’s production capabilities.

Product Quality Index

Energy Generation

Ready to get started on your custom self-lubricating bearing quote?

Breathtaking design for home living.

The variety of materials, cost-effective custom manufacturing per unit, and rapid production pace make it an excellent choice for prototyping.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.