providing factory services of superior quality with focus on efficiency.

01.

Providing Quotes for Custom Parts and Large-Scale Production Orders

02.

Satisfaction guaranteed

03.

Ensuring timely delivery

04.

Revolutionize How You Produce Custom Components

We Stand by Your Side from Initial Prototyping through to Production and Further.

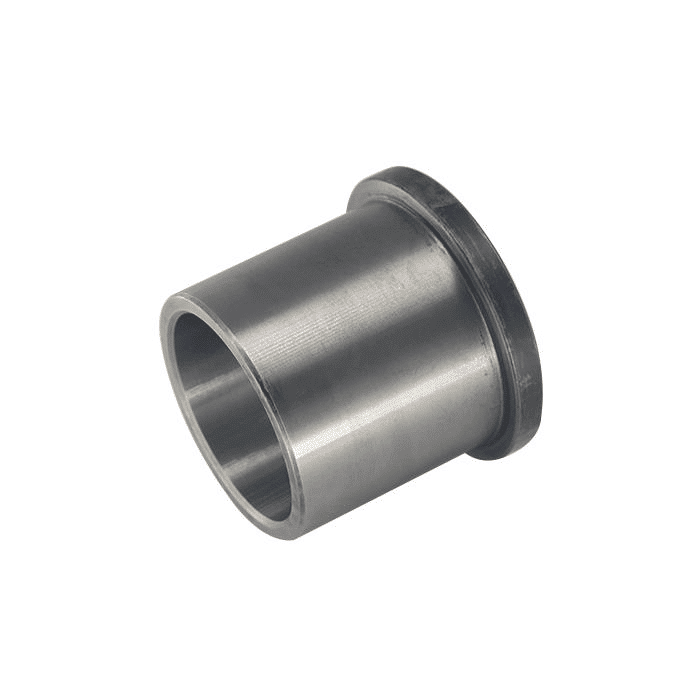

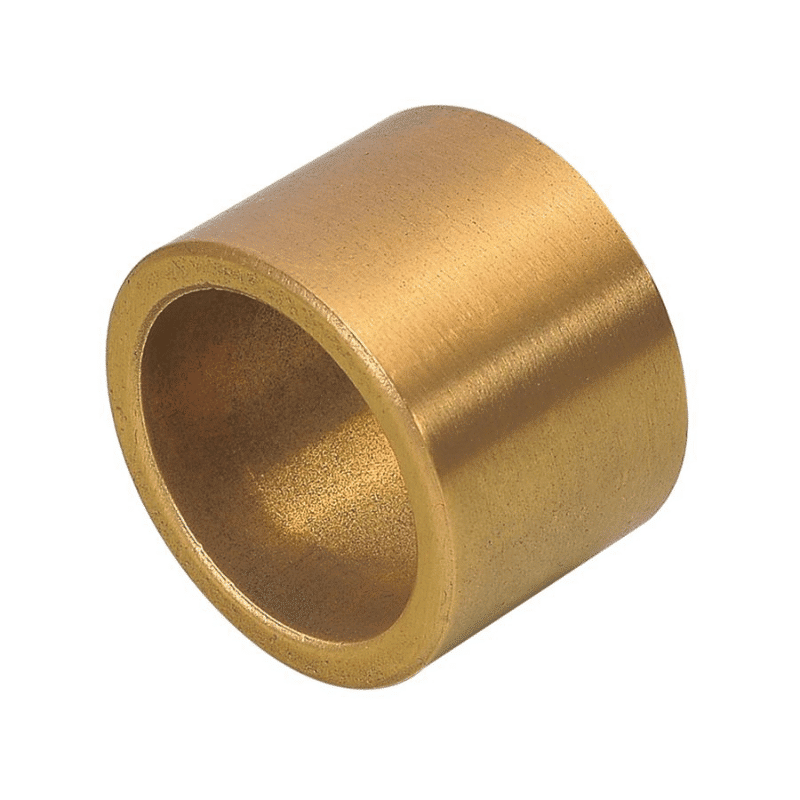

Oil-impregnated bronze, specifically SAE 841 bronze, is a material widely used for manufacturing self-lubricating bearings and bushings.

The oil-impregnated sintered bronze’s high wear resistance and anti-friction characteristics make it an outstanding choice for guide bushings.

Oil-impregnated bronze, especially the SAE 841 variant, is a favored choice for crafting self-lubricating bearings and bushings. This bronze type is celebrated for its superior wear resistance and extended service life, which is crucial in scenarios where standard lubrication methods are impractical. SAE 841 bronze, a powdered metal, is infused with oil and subjected to intense heat and pressure to mold it into desired shapes, such as round rods or hollow bars. During operation, the bearing exudes a thin oil layer from the material, ensuring continuous self-lubrication for the interacting shaft. Once the machinery halts, the bearing’s capillary action draws the oil back into the bronze, ready for the next cycle of operation.

Accredited and Focused on Quality

With a variety of processes at your disposal, such as CNC machining, sheet cutting, and injection molding, we stands as your comprehensive solution for custom manufacturing.

Our High Volume Production Service Provides Dedicated Assistance For Custom Manufacturing Endeavors, Accommodating Projects Of Any Complexity And Scale.

▪ Metal Bearing Production Solutions

Your comprehensive answer for production, our team stands as the ideal choice for your manufacturing requirements.

▪ self-lubricating Bearings Solutions

With our technical specialists, the convenience of our secure quotation platform, and extensive global manufacturing capabilities, we are equipped to meet your needs.

Produce custom components as needed

We’re Your Partner From Prototyping to Production and Beyond

We provide a variety of services to assist you in creating functional prototypes and transitioning to production components. Manufacture custom parts as needed, utilizing various materials for self-lubricating bearings. Reach out to us to benefit from our expert applications engineering team’s production capabilities.

Product Quality Index

Energy Generation

Ready to get started on your custom self-lubricating bearing quote?

Breathtaking design for home living.

The variety of materials, cost-effective custom manufacturing per unit, and rapid production pace make it an excellent choice for prototyping.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.