L-GIB

L-GIB

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

L-GIB

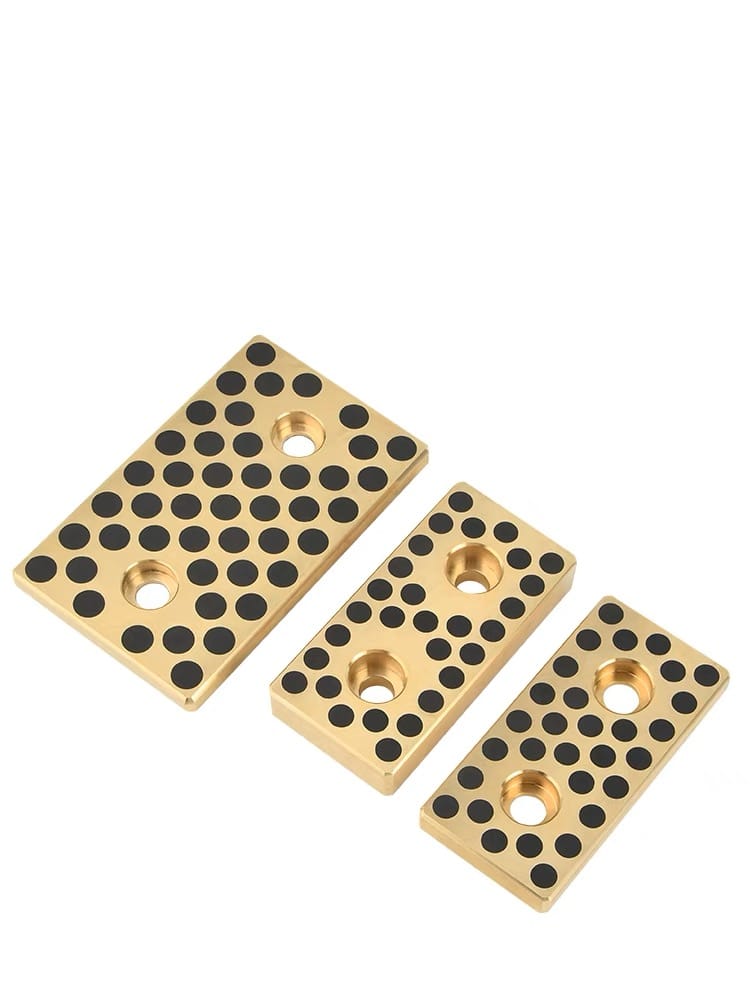

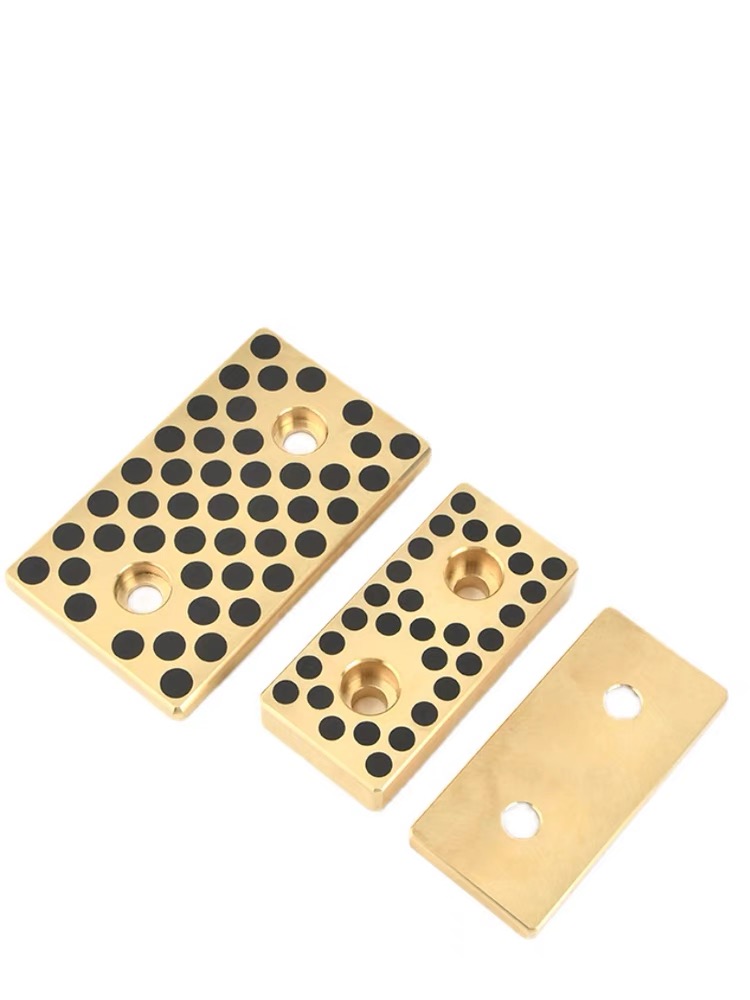

L-GIB Bronze Wear Plates, also known as L-Gibs, are essential components in mold and die products, particularly for creating custom cams and slides within gib assemblies. These components are typically made from aluminum bronze material, which is known for its strength, hardness, and corrosion resistance. Aluminum bronze typically contains approximately 9-14% aluminum and often includes other alloying agents such as iron, nickel, manganese, and silicon to enhance its properties.

L-Gibs serve as part of the sliding mechanism in machinery, facilitating smooth movement and alignment. Functionality: These components play a crucial role in maintaining precision and stability within machinery, ensuring efficient operation

L-GIB Bronze Wear Plate & – Mold and Die Products, Gib Assemblies L-Gibs, Self-Lubricating

L-GIB Bronze Wear Plates, also recognized as L-Gibs, play a pivotal role in the manufacturing of mold and die products, especially in the crafting of custom cams and slides for gib assemblies. Crafted from aluminum bronze, these components boast notable strength, hardness, and resistance to corrosion. The composition of aluminum bronze typically ranges from 9-14% aluminum, with the addition of other elements like iron, nickel, manganese, and silicon to boost its performance.

Designed in an ‘L’ shape, L-Gibs serve the critical function of guiding and managing linear motion within machines, with dimensions commonly specified in inches for standardization and seamless integration with existing systems. They are equipped with screw holes and spot drilling for dowels, streamlining the installation process and ensuring accurate placement in the mold assembly.

A standout feature of L-Gibs is the incorporation of graphite plugs, catering to grease-free operations. This graphite serves as a self-lubricating agent, diminishing friction and wear to prolong the equipment’s service life. This characteristic is exceptionally advantageous in high-production molds requiring consistent operation and minimal upkeep.

The bronze coating on these parts, applied through electroplating, further enhances their strength and lubrication qualities. Electroplating involves depositing a metal layer onto a conductive base using an electrical current, improving aspects like corrosion resistance and surface durability.

In essence, L-GIB Bronze Wear Plates are constructed from high-quality aluminum bronze and are integral to standard gib assemblies. They feature self-lubricating graphite for grease-less applications and are designed for effortless installation with pre-drilled holes for screws and dowels. These components are essential for achieving precise movement, reducing friction, and improving the durability and efficiency of mold and die machinery.

L-GIB Bronze Wear Plate

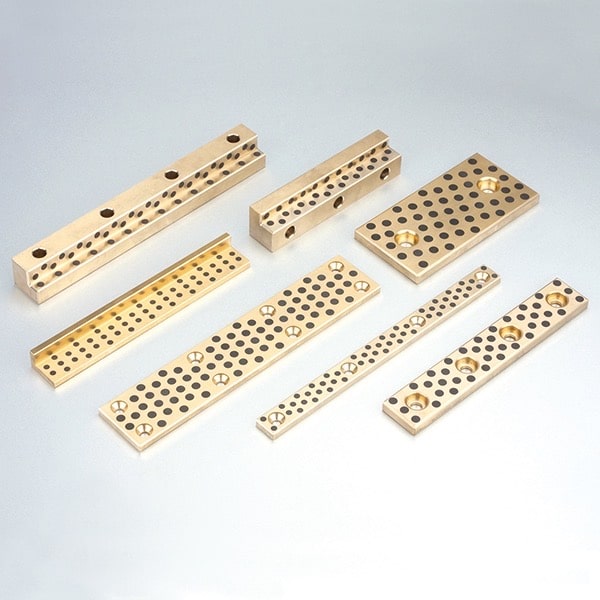

Wear components like wear plates, wear strips, and gib base plates play a vital role in the mold and die sectors, recognized for their superior wear resistance. These parts are engineered to manage and direct linear movement in heavy-duty machinery, proving invaluable in scenarios involving intense forces, such as in metal stamping dies, molds, specialized machines, and bulky equipment.

Standard Wear Plate (Inch) These wear plates adhere to industry norms and are offered in a wide array of sizes. Manufactured from steel, they can be equipped with self-lubricating graphite to minimize the need for further lubrication.

Standard Wear Plate (Metric) Metric wear plates, akin to their inch counterparts, meet industry standards and come in diverse sizes to accommodate various needs. These plates are crafted from steel and may feature self-lubricating graphite.

Standard Wear Strips Wear strips, offering a wider size range than wear plates, fulfill the same objective of reducing machinery friction and wear.

Gib Base Bronze Wear Plates As integral elements of the gib assembly that oversees linear motion, gib base plates are typically made from robust materials like aluminum bronze and might incorporate self-lubricating functionalities.

L-Gib for Gib Assemblies L-Gibs, shaped in an ‘L’, are made from steel and bronze-electroplated for enhanced strength and lubricity. Suited for standard gib assemblies, they come prepared with screw holes and dowel spots, including graphite plugs for applications without grease.

L-Gib Self-Lubricating Wear Plate These L-Gibs are designed for a durable wear surface in molds needing slides, cams, or flat areas, particularly where friction is an issue. Constructed from aluminum bronze with oil-infused graphite plugs, they offer extended wear life.

L-Gib Standard Standard L-Gibs, akin to the self-lubricating variant, may not always have graphite plugs. They are critical for standard gib assemblies, guiding components within the machinery efficiently.

Self-Lubricating Square Gibs Square gibs with self-lubricating features are made from materials such as bronze, integrated with graphite plugs, ideal for applications necessitating reduced friction and wear.

Self-Lubricating Wear Strips Designed for maintenance-free operation, these wear strips are utilized in molds and dies to lessen friction among moving parts, typically made from bronze with graphite inclusions.

Side Bronze Plate Side plates form part of the mold and die machinery, requiring wear-resistant properties for smooth functionality and durability.

Standard Gib Assemblies These assemblies, composed of a base and two L-gibs, come with an option for self-lubricating graphite. They are offered as a complete set and can be tailored to specific dimensions.

T-Slides for Gib Assemblies T-slides are employed in gib assemblies to aid the movement of parts within mold or die machinery, designed to be compatible with standard wear plates and gibs.

Standard Bronze Wear Plate Inch Request Form For those requiring standard inch wear plates, a request form is typically accessible to detail specific needs such as size and material, ensuring the plates fulfill application requirements precisely.

In essence, wear products are indispensable in the mold and die industries for diminishing friction and wear, promoting accuracy, and prolonging the lifespan of machines. These items, available in various forms and sizes, both in inch and metric units, often come with self-lubricating features to boost performance and lower maintenance demands.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally