Custom Bearings & Bushings – Get your quote.

WE DELIVER WORLDWIDE

Download our current catalogue and get in touch with us

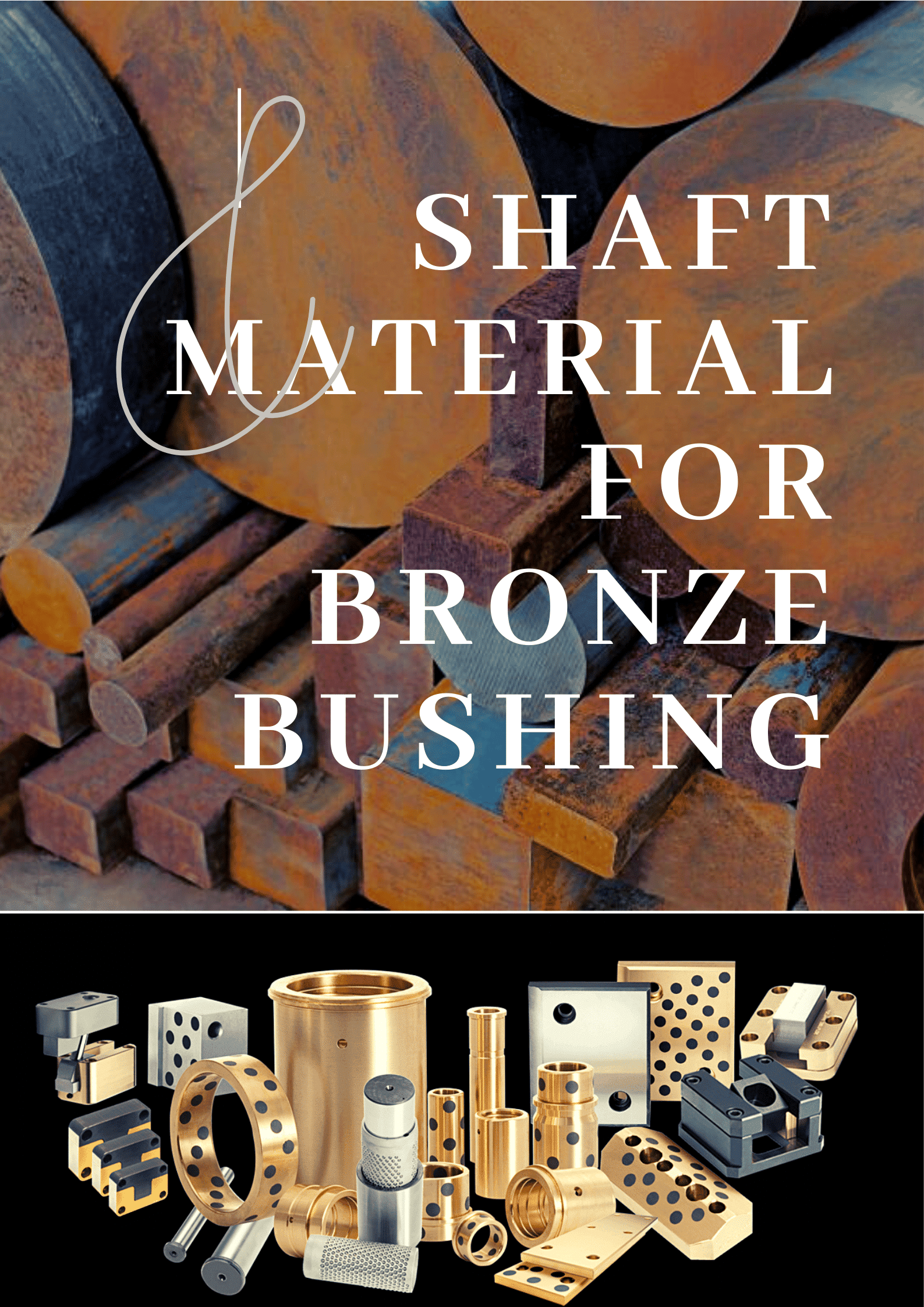

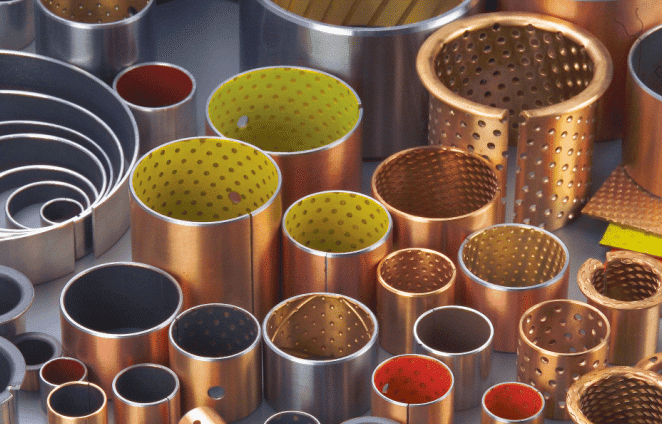

Use Self-lubricating Bushing Bearings For High Performance And Low Maintenance. solid bronze sliding bearing, solid lubricant, maintenance-free. Increased reliability. Hi Temp Bearing Solution. Non-galling. Run dry & keeps running. Reduced costs & downtime. Services: Custom Design, Engineering Support, Short Lead Times. a unique, self lubricating material for wear surfaces. Our designs can be customized to fit your needs. High quality services – performance-based prices – simple solutions–flawless products. We offer an extensive range of sliding bearings and excellent customer service. Contact now. Free Catalogue download. Chat us on our website.

Self-Lubricating Bearings Solutions- Guide Bushings

Offers an extensive range of sliding bearings to fulfill your needs! Self-lubricating bearings work by having lubricant impregnated within the sliding layer of the bearing. Self-lubricating bushings, embedded bronze bearing material that combines the graphite, form a strong, resistant bearing surface. Shop Custom Self-lubricating Components: Get High Quality While Saving on Cost and Time. Buy Online From Us Today! We Offers Online Part Configuration, Quoting, & Ordering. We are Your One Stop Shop. Place an Order in Minutes. Oil Free Bushing – PTFE, Straight Bushing, Get a Quote Online. Online Parts Configurator. Please contact to quote and order.

Will Exceed Your Expectations Of A Supplier, Hence Our Customers See viiplus More As A Partner.

Company has a sound engineering know-how, catering mainly to the Marine & Offshore, Mining and Energy Sector, as well as many more industries such as Injection Moulding, Steel Plants, Agricultural, Construction, etc.We offer over many types of bushing materials and we are able provide you with a one-stop solution for your bearing issues.

Market – Sectors

Bornzelube.com known for providing oilless and graphite metal bushing configurable components for the manufacturing industry,

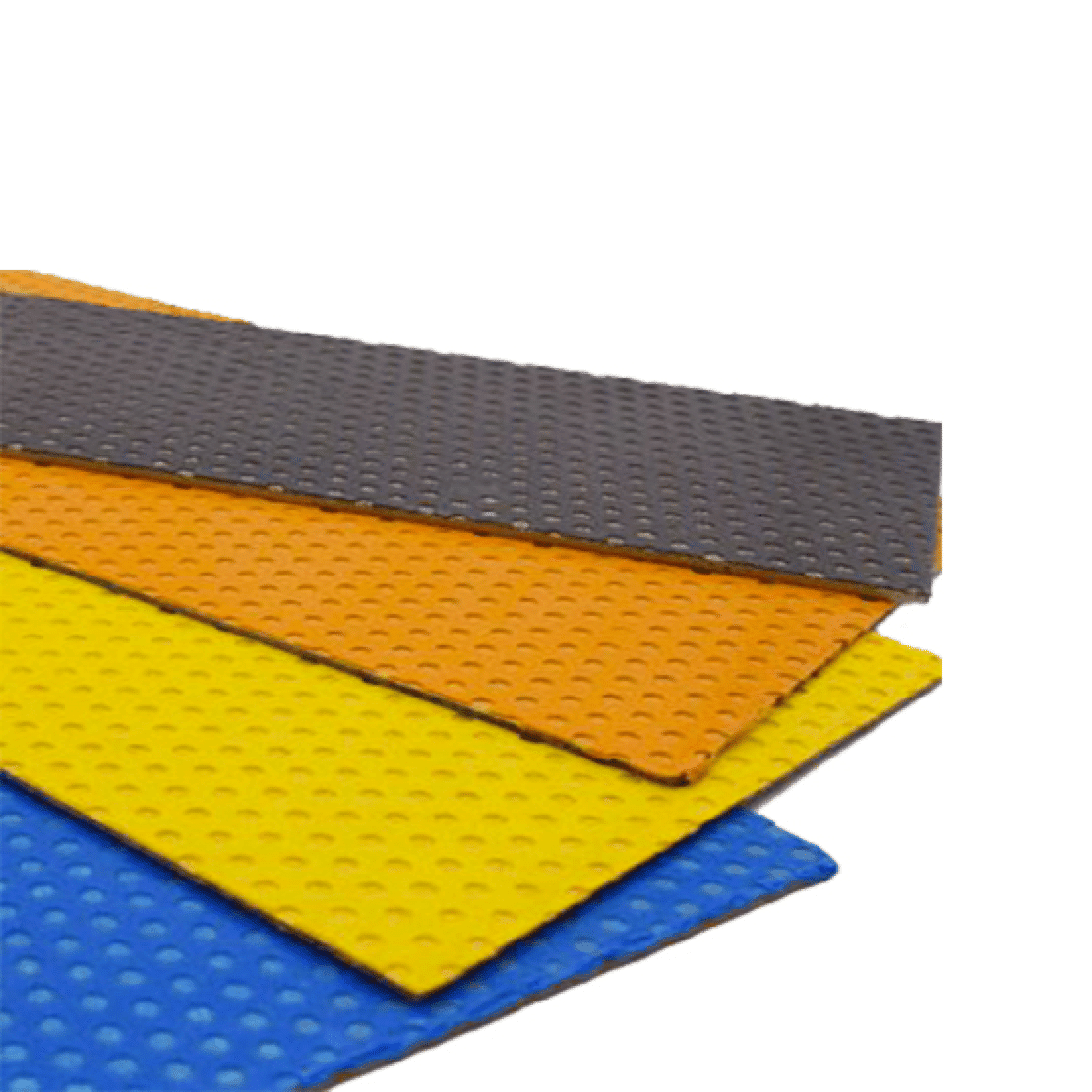

self-lubricating material for bushings.