Bronze Sleeve Bushing Metric Flange Size: Everything You Need to Know

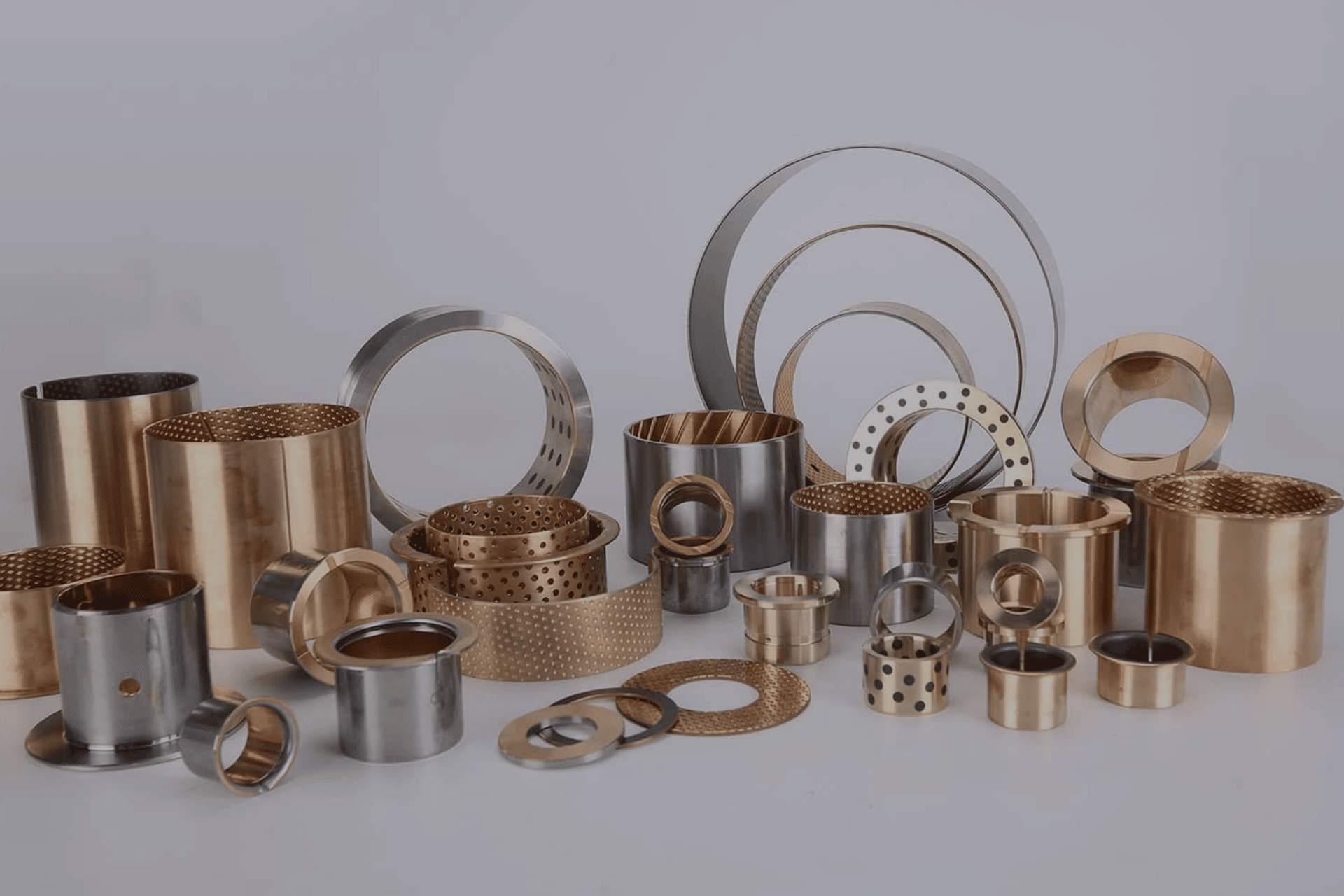

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Bronze Sleeve Bushing Metric Flange Size: Everything You Need to Know

Bronze Sleeve Bushing Metric Flange Size: Everything You Need to Know

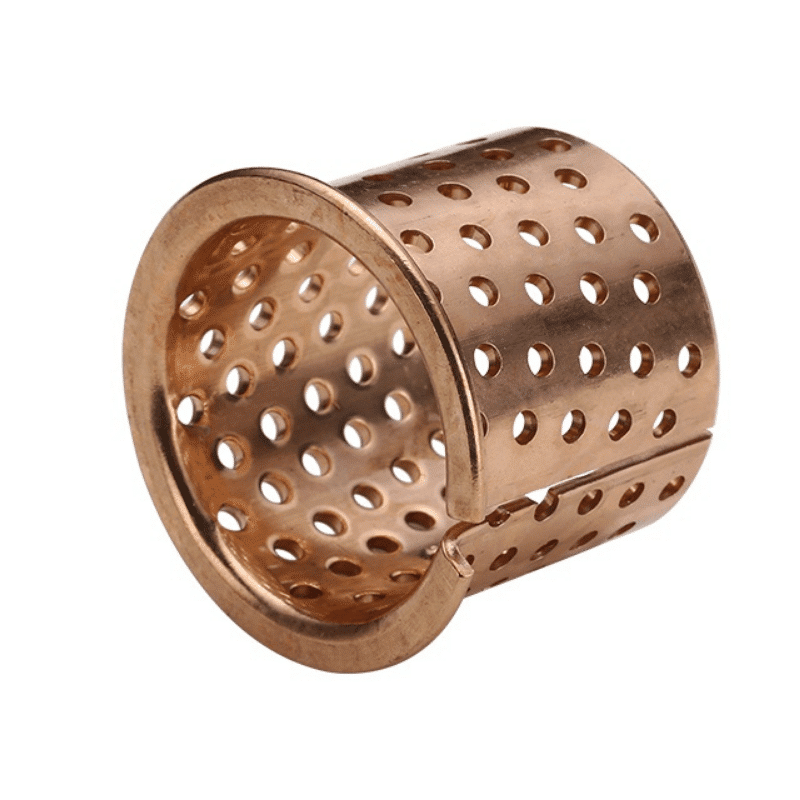

A bronze sleeve bushing with a flange is a type of plain bearing made of bronze material with a flange on one or both ends. The flange provides additional support and stability to the bushing, preventing it from rotating or moving axially. The bronze material is known for its excellent wear resistance, high load capacity, and good thermal conductivity, making it ideal for various industrial applications.

Experience

Long-lasting flange sleeves

Bearing Solutions

Superior flange bushings

24/7 Support

The ultimate flange sleeves

Introduction, Bronze sleeve bushings for metric flange sizes

Bronze sleeve bushings are a type of plain bearing that is used to reduce friction between two parts. These bearings are made of bronze and are used in a variety of applications, including machinery, automotive, and aerospace industries. One important factor to consider when purchasing bronze sleeve bushings is the flange size. In this article, we will discuss everything you need to know about bronze sleeve bushing metric flange size.

What Are Bronze Sleeve Bushings?

Bronze sleeve bushings are cylindrical shaped bearings made of bronze, which is a metal alloy composed of copper, tin, and sometimes other elements such as zinc or lead. Bronze is an ideal material for bushings because it is strong, durable, and has good anti-corrosive properties.

The purpose of bronze sleeve bushings is to reduce friction between two parts that are in contact with each other. The bushing is placed between the two parts and acts as a barrier, allowing them to move against each other without causing damage.

Improve your machine’s performance

The Importance of Flange Size

The flange size of a bronze sleeve bushing is an important factor to consider because it determines how the bushing will be installed and secured in place. The flange is the flat rim on the end of the bushing that protrudes from the surface it is installed on. The flange provides a surface for the bushing to rest against, and it also helps to keep the bushing in place.

Trustworthy flange sleeve solutions

How Does a Bronze Sleeve Bushing Metric Flange Work?

The bronze sleeve bushing with a flange works by providing a low friction surface between two moving parts. The bushing is pressed into a housing or machine part, and the rotating shaft passes through the center of the bushing. The bushing acts as a barrier between the shaft and housing, reducing friction and wear on both components.

The flange on the bushing provides additional support to the bushing and prevents it from moving or rotating axially. This helps to maintain the alignment of the rotating shaft and ensures that it operates smoothly and efficiently.

Choose the right flange sleeve for your project

Advantages of Using Bronze Sleeve Bushing Metric Flange

There are several advantages of using bronze sleeve bushings with flanges in industrial applications, including:

High Load Capacity: Bronze material has a high load capacity, making it ideal for heavy-duty applications.

Excellent Wear Resistance: Bronze material is known for its excellent wear resistance, ensuring a longer lifespan for the bushing and other components.

Good Thermal Conductivity: Bronze material has good thermal conductivity, allowing for better heat dissipation and reducing the risk of overheating.

Low Friction: Bronze sleeve bushings with flanges provide a low friction surface between two moving parts, reducing wear and tear on both components.

Cost-Effective: Bronze sleeve bushings with flanges are cost-effective compared to other types of bearings.

Factors to Consider When Selecting a Bronze Sleeve Bushing Metric Flange

When selecting a bronze sleeve bushing with a flange, there are several factors to consider, including:

- Load Capacity: The load capacity of the bushing should be sufficient to handle the weight and forces of the application.

- Speed: The speed of the rotating shaft should be within the recommended range for the bushing.

- Temperature: The operating temperature of the application should be within the recommended range for the bushing material.

- Shaft Diameter: The bushing inner diameter should match the diameter of the rotating shaft.

- Housing Bore: The bushing outer diameter should match the diameter of the housing bore.

The Ultimate Guide to Bushings, Thrust Washers, and Strips: Everything You Need to Know

The Ultimate Guide to Bushings, Thrust Washers, and Strips

When it comes to industrial equipment, bushings, thrust washers, and strips are some of the most essential components that ensure optimal performance and longevity. These products are widely used in various applications, including heavy machinery, automotive, aerospace, and marine industries.

If you’re looking for high-quality bushings, thrust washers, and strips, SKF is a reliable and reputable manufacturer that offers a wide range of products to meet your needs. In this comprehensive guide, we’ll explore everything you need to know about these components, including their types, materials, applications, and benefits.

Types of Bushings, Thrust Washers, and Strips

Bushings, thrust washers, and strips come in various types, each designed to meet specific needs and requirements. Some of the most common types of these components include:

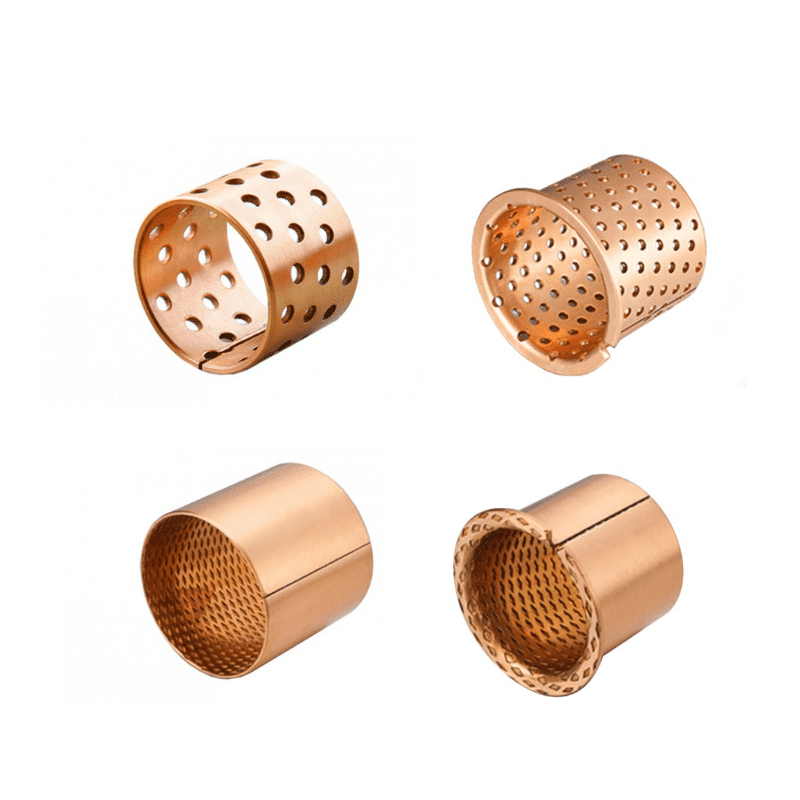

Plain Bushings: These are simple cylindrical bearings that provide smooth and low-friction operation. They’re widely used in various applications, including automotive suspension systems, hydraulic cylinders, and industrial machinery.

Flanged Bushings: These are similar to plain bushings but have a flange on one end, which helps to retain the bearing and prevent it from moving axially. They’re commonly used in applications that require axial guidance, such as conveyor systems, pulleys, and gearboxes.

Thrust Washers: These are flat bearings that support axial loads in a single direction. They’re commonly used in applications such as pumps, compressors, and transmissions.

Strips: These are thin, flat bearings that are used in applications where space is limited. They’re commonly used in linear motion systems, such as guide rails and slide ways.

Materials Used in Bushings, Thrust Washers, and Strips

The choice of material for bushings, thrust washers, and strips depends on the specific application requirements. SKF offers a wide range of materials to meet different needs, including:

PTFE Composite: This material consists of a PTFE-based sliding layer and a steel backing. It provides low friction, high wear resistance, and excellent chemical resistance. It’s commonly used in applications that require high load capacity and low friction.

POM Composite: This material consists of a polyoxymethylene-based sliding layer and a steel backing. It provides low friction, high wear resistance, and good dimensional stability. It’s commonly used in applications that require low to moderate load capacity and low friction.

Stainless Steel: This material provides excellent corrosion resistance and is commonly used in applications that require high resistance to harsh environments.

Bronze: This material provides good wear resistance and is commonly used in applications that require high load capacity and low speed.

about the company

Bronze Sleeve Bushing Metric Flange Size appliation

Bushings, thrust washers, and strips are used in various applications across different industries!Bronze sleeve bushings with metric flange size are commonly used in various industrial applications that require high load capacity and low speed. These bushings consist of a bronze-based sliding layer and a steel flange backing that helps to retain the bearing and prevent it from moving axially. Bronze sleeve bushings with metric flange size are a reliable and durable solution for various applications that require high load capacity and low speed. With their excellent wear resistance and low friction properties, these bushings ensure optimal performance and longevity of the equipment they’re used in.

Product Quality Index

Energy Generation

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.