How to Choose Bushing for Forklift?

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

How to Choose Bushing for Forklift?

Custom Forklift Bronze Bearings Bushing Manufacturer

Visit us at www.bronzelube.com, your one-stop solution for a wide range of Self-Lubricating Bearings. We specialize in custom bronze bearings and bushings, designed to meet your specific application requirements. Our product lineup includes various types and sizes of bearings, all engineered for exceptional performance and durability.

Experience

With a robust inventory in stock and ready to ship, we guarantee fast delivery so you can get the bushings and bearings you need when you need them. Our commitment to quality and customer satisfaction drives growth and profits for our clients, as we continually strive to provide the best in bronze bushings and bearings.

Bearing Solutions

Whether you’re in the market for Graphite Plug Type Bronze Bushes, Plain Bronze Major Toggle Bushes with Spiral Grooves, Minor Toggle Bushes, or Bronze Graphite Oilless Bearings, www.bronzelube.com is ready to serve your needs. Browse our comprehensive offerings today to find the perfect solution for your injection molding application.

24/7 Support

Remember, our expert team is always ready to guide you in choosing the right components for your machinery. Experience the difference of quality and service with www.bronzelube.com, your trusted partner in custom bronze bearings and bushings.

HIGH QUALITY – VAST RANGE – IN STOCK – EXEMPLARY SERVICE

Introducing our Custom Material Handling Equipment, specifically designed for forklift operations. Our offering includes Custom Self-Lubricating Plain Bush Bearings tailored to enhance equipment reliability and extend lifespan. These robust bearings are perfect for demanding applications such as rugged, durable roll handler lift trucks.

With our focus on superior quality and service, we strive to exceed customer expectations. Each of our bushings is designed with application specificity, ensuring the perfect fit and functionality for your unique needs.

Proudly made in China, our bearings and bushings are a testament to meticulous craftsmanship and cutting-edge engineering. Our commitment to quality is uncompromised, and we always strive to deliver the best possible solutions to our customers.

Explore our wide range of customized bearings and bushing services. We stand ready to meet your unique needs with high-quality solutions that drive equipment performance and productivity. Your satisfaction is our priority, and our team is always available to help you find the perfect fit for your equipment. Trust us for all your bearing and bushing requirements and experience the difference of top-notch quality and service.

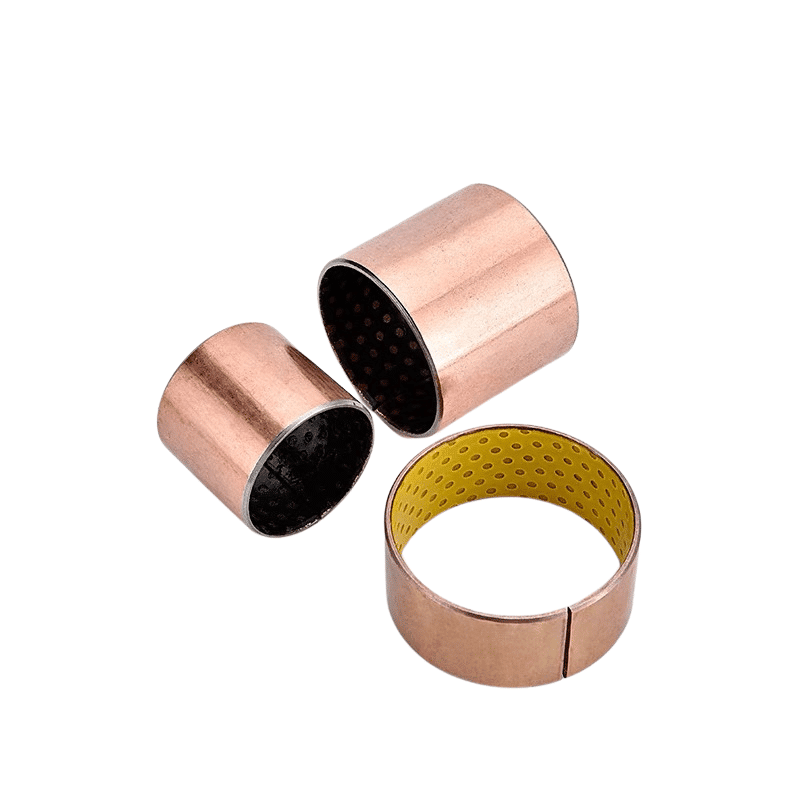

Multilayer Bearings & Bushings

Quality Plain Bearings for Forklifts – Trust in our high-grade forklift bushings!

Leverage our extensive experience in self-lubricating bearings parts. We are your go-to source for Forklift Plain Bearings and Forklift Bushings. As specialists in Truck Roller Bushing Bearings, we offer a wide range of sizes and materials in our comprehensive selection of forklift bushings.

We are also recognized experts in composite bushings, with a large variety of options readily available. All of our offerings are proudly manufactured in China, where rigorous quality standards are upheld.

Discover more about our Plain Bearings for Forklifts. Dive deeper into our comprehensive range of Plain Bearings & Bushings. We guarantee quality and reliability with our Forklift Bushes!

For more information on our bushing materials or any other inquiries, please do not hesitate to contact us. Our friendly and knowledgeable staff is always eager to assist you. Your satisfaction is our top priority, and we’re excited to help you find the perfect solutions for your needs!

Forklift sleeve bushing composite bearings

Self-lubricating Bearings Parts

We offer a comprehensive range of Bushing Sleeve Sizes and reliable Flange Bushings Parts. Our key offering is our self-lubricating bearing, which includes PTFE bushings with a steel-backed base that self-lubricates without the need for oil feed. Forklift sleeve bushing composite bearings are designed with high precision operations and cost-effectiveness in mind. These bearings are manufactured with an emphasis on reducing maintenance costs and increasing the operational efficiency of forklifts.

The composite structure of these bearings often features a steel backing for structural support, a bronze interlayer for embedding the lubricants, and an inner lining made of PTFE or similar low friction material. This layered design allows the bearings to be self-lubricating, reducing the need for frequent manual lubrication.

These bearings are adaptable, capable of withstanding high loads and varying temperatures, and can effectively operate under both high and low-speed conditions. Their self-lubricating feature also reduces friction, minimizing wear and tear and enhancing the overall life span of the bearing.

Whether it’s for steering columns, mast support, or tilt cylinders, our forklift sleeve bushing composite bearings are designed to meet your specific application requirements. Visit our website Bronzelube.com for more information about our products.

self-lubricating bearings

Multi-layer bearing

Our self-lubricating bearings have been widely used in all kinds of mechanical sliding parts, making them an essential component for various applications. Feel free to reach out to us for more information on our self-lubricating bearings and their applications. We are always here to help you with your bearing needs.

As a company specializing in self-lubricating bearings, including multi-layer bearings, we offer a diverse range of solutions. Our bearings are widely used in a multitude of applications.

Company Specializing in Self-lubricating Bearings for Forklifts

Our self-lubricating bearings, specifically designed for forklifts, demonstrate robustness, durability, and efficiency, enabling smoother operations in logistics and transportation equipment.

Multi-layer Bearings

Our multi-layer bearings offer superior performance. They consist of a steel backing for strength, a bronze intermediate layer for embedding the lubricants, and a PTFE-based or thermoplastic inner layer for low friction. This structure gives the bearings their self-lubricating property.

Our self-lubricating bearings are widely used across various industries, such as automotive, manufacturing, aerospace, and more, providing superior performance even under challenging working conditions.

Please visit our website Bronzelube.com for more information about our self-lubricating bearings.

WE’RE DOING OUR PART TO KEEP YOU MOVING!

Self-lubricating bearings

selection of Self-lubricating Bearings Parts, Bushing Sleeve Sizes, and Reliable Flange Bushings Parts.

Self-lubricating bearings are a cornerstone of our offerings. They come with a PTFE bushing that has a steel-backed base and self-lubricates without the need for oil.

Oilless Bushing

Solid inlaid self-lubricating bearings (also known as oilless bushes JDB) offer characteristics of both metal bearings and oil-free lubricated bearings. They are lubricated by a special formula of solid lubricating material under load borne by the metal substrate. These bearings offer high bearing capacity, impact resistance, high-temperature resistance, strong self-lubricating ability, and more.

They’re especially suitable for heavy load, low speed, reciprocating or swinging applications that are difficult to lubricate and form oil film. They’re also resistant to water and other acid erosion. These products have been widely used in various industries, offering twice the wear resistance of ordinary bushings.

Contact us for your bushing bearing needs – we’re here to help you find the perfect fit for your equipment!

Looking for Bushing Bearing Parts?

These bearings have been widely used in various mechanical sliding parts.

We are a reliable manufacturer of Oilless Bushes and a trusted supplier of Bronze Bushings Parts. Our self-lubricating bearings come in composite self-lubricating bearings, solid inlaid self-lubricating bearings, and bimetallic materials. Quality Control and Excellent Quality: With numerous years of experience in the Forklift Bushings and Bearings Accessories market, VIIPLUS offers customers a streamlined approach to sourcing and purchasing sliding bearing bushings parts. We’re committed to offering exceptional customer service and sharing our extensive knowledge on oilless parts. Delve into the advantages of plain bearings and our expertly crafted Forklift Bushing Parts Design. The Benefits of Self-Lubricating Bearings (Oil-Free Bearings)

Although many bearings used in various mechanical industries are ball bearings or needle rollers, a certain portion of bearings are now self-lubricating bearings. These types of bearings offer numerous benefits, and we believe that they will become the dominant bearings in the near future.

Deliver high-quality products tailored to your specific needs. Feel free to reach out to us for more information, we are always ready and happy to assist you!

Self-lubricating bearing Key benefits include:

The Use of Plain Bearing Bushings in Forklifts: An Essential Component for Optimal Performance

Introduction

Forklifts are crucial in many industrial environments for moving heavy loads across short distances. These machines are required to operate reliably and smoothly in a wide range of conditions, which makes the selection of their components an essential aspect of their design. One such key component is the plain bearing bushing, which plays a significant role in ensuring the proper functioning and longevity of forklifts.

What is a Plain Bearing Bushing?

A plain bearing bushing, also known as a sleeve bearing or a journal bearing, is a simple type of bearing that accommodates sliding motion between two surfaces. It typically consists of a cylindrical sleeve that helps in reducing friction and wear between machine elements, allowing for smooth movement and operation. These bushings are typically made from materials such as bronze, plastic, or composite materials, each offering unique benefits depending on the application.

Plain Bearing Bushings in Forklifts

In forklifts, plain bearing bushings are used in several areas where there is a requirement for relative motion between components. This includes the mast, tilt cylinders, steering columns, and other pivot points. The bushings in these areas must withstand significant loads, often under varying operating conditions, and continue to provide smooth and controlled motion.

For example, in the mast of a forklift – the vertical assembly that does the work of lifting, lowering, and tilting the load – plain bearings are used to facilitate smooth sliding motion. As the mast of a forklift has to carry heavy loads and undergo significant mechanical stress, the bearings used should be robust, wear-resistant, and capable of enduring high-load situations.

The tilt cylinders, which allow the mast to tilt backward or forward to ensure stability during the lifting process, also incorporate plain bearing bushings. These bushings facilitate smooth and precise movement, enabling the forklift to operate safely and efficiently.

Benefits of Plain Bearing Bushings

Plain bearing bushings come with several benefits that make them suitable for forklift applications:

-

Durability: They are designed to be highly durable and can handle heavy loads, making them ideal for the high-stress environment of forklifts.

-

Low Maintenance: They require minimal maintenance as they do not have moving parts. This feature significantly reduces the downtime and maintenance cost of the forklifts.

-

Versatility: They are available in various sizes, materials, and designs, making them versatile for different applications within the forklift.

-

Cost-effective: They are generally cheaper than rolling element bearings but offer comparable performance, making them a cost-effective solution for many applications.

Plain bearing bushings are integral components in the functioning of a forklift. Their ability to withstand high loads and provide smooth movement makes them indispensable in ensuring the reliable and efficient operation of these machines. As such, they will continue to play a crucial role in the design and maintenance of forklifts, contributing to the overall efficiency and effectiveness of material handling in various industries.

Application Characteristics and Advantages of Self-Lubricating Bearings

Oil-Free Lubricated Bearing Series

-

Requires no oil or less oil, ideal for areas where oil addition is difficult or impossible, and operates with minimal or no maintenance.

-

Exhibits good wear resistance, low friction coefficient, and a long lifespan.

-

Features a right amount of elastic-plastic deformation, which distributes stress across a broader contact surface, improving the bearing capacity.

-

Similar static and dynamic friction coefficients help eliminate creep at low speeds, ensuring machine accuracy.

-

Reduces vibration and noise in machinery, prevents pollution, and improves working conditions.

-

Forms a transfer film during operation to protect the grinding shaft without shaft seizure.

-

Requires low hardness for the grinding shaft, eliminating the need for quenching and tempering, and simplifying the processing of related parts.

-

Features a thin-wall structure and light weight, reducing machine volume.

-

The steel back can be plated with various metals, making it suitable for corrosive environments. These bearings have been widely used in various machinery’s sliding parts, such as printing machines, textile machines, tobacco machinery, micromotors, automobiles, motorcycles, agricultural and forestry machinery.

Brass Graphite Self-Lubricating Bushing

Boundary Lubricated Bearing Series

-

Offers good bearing capacity and wear resistance.

-

Suitable for high load and low-speed rotary motion, swing motion, and frequent start-stop under load, where it’s difficult to form hydrodynamic lubrication.

-

Under boundary lubrication, the bearing can be maintained for a long time without refueling, while refueling the upper layer can prolong its service life.

-

A certain allowance can be left in the surface plastic layer during processing and forming, which can be further processed after assembly to achieve better assembly size.

-

These products are mainly used in automobile chassis, metallurgical machinery, mining machinery, water conservancy machinery, construction machinery, agricultural machinery, steel rolling equipment, and more.

JDB Solid Inlaid Bearing Series

This is a versatile basic product that can adapt to high pressure, low pressure, high temperature, low temperature, oil lubrication, no oil lubrication, or water lubrication. The matrix of the product is high-strength brass, which has over twice the hardness and wear resistance compared to the general copper sleeve. They’re extensively used in light industry machinery, heavy industry machinery, construction machinery, metallurgical machinery, conveying machinery, continuous casting machines, rolling mills, injection molding machines, paper machines, die guide columns, ships, machine tools, and more.

Looking for quality forklift bushing & plain bearings?

Explore our extensive range of forklift bushes. At Bronzelube.com, your business-to-business supplier, we offer a large stock, short delivery times, and a one-stop-shop for Forklift Bushing Design Parts. Our styles include plain bearings, solid bronze bearings, bronze bearings, and bimetal bushing. Check us out today!

Made-to-Order Online: Bushing for Forklift

Forklift self-lubricating bushings play a vital role in logistics and transportation equipment. These bushings meet the ISO DIN Bronze material standard, which includes a minimum fatigue requirement. They are a key component in forklifts and lift trucks, which you can easily source and purchase online from us at VIIPLUS. Request a free quote today.

How to Choose a Bushing for Your Forklift?

When choosing a self-lubricating bearing bushing, consider the mechanical structure, material, processing, and geometric size. These bushings are efficient, multi-functional, reliable, energy-saving, compact, lightweight, and aesthetically pleasing.

At VIIPLUS, we supply dry bearing bushings for forklifts and mast self-lubricating guide bushings and sliding bearings ideal for material handling and loading and unloading machines. These metal self-lubricated bushings can also be used in palletizers, cranes, hoists, horizontal and vertical lift units, and forklift trucks.

Industry Application

Whether you need flange bearings, split bushings, PTFE bushes, thrust washers, sleeve bearings, bimetal bearings, or solid bronze bushings, VIIPLUS offers a vast selection of dependable forklift bushings. These are ideal for a variety of industries and applications, including:

- Axial applications

- Brake systems

- Port machinery

- Forestry machines

- Forklifts

Key Technology Principle

Inlaid self-lubricating bearings use a composite material composed of a metal substrate and solid lubricant paste embedded in the substrate’s hole or groove. During friction, the metal substrate bears most of the load, while the solid lubricant provides continuous lubrication to the friction surface, significantly reducing friction and wear.

Forklift Bushing Suppliers and Manufacturers

VIIPLUS offers self-lubricating bronze bushings and sleeve bearings that suit most standard forklifts. These bushings address the lubrication issues faced by industrial and mining enterprises operating under harsh conditions with heavy equipment, high temperatures, and corrosive atmospheres.

Logistics Application

VIIPLUS’s self-lubricating bearings are designed for the most severe conditions. They are shock-resistant and operate well in dusty, dry conditions, reducing the cost and time of lubricant maintenance. They are especially suitable for industries such as mining, earthmoving, wastewater treatment, crane operation, elevators, and heavy machinery.

Fork Lift Bushing Bearing – Forklift Bearing Exporter from China

Looking for quality forklift bearings? Visit VIIPLUS to browse our wide range of sliding bearings, forklift parts, and accessories.

Choosing the right self-lubricating bearings manufacturer can be a challenge. But at VIIPLUS, we believe in delivering quality as it is the lifeblood of our company, and we ensure timely delivery as it is our promise to our customers. We hope to build a win-win relationship with our customers both domestically and overseas.

Integrated Production for Timely Delivery

We offer integrated production right from material to processing. Our strong production capacity and rapid response help us organize material production for our customers in no time, significantly reducing the production time.

Our advanced production equipment includes state-of-the-art CNC machine tools, CNC lathes, processing centers, and other major equipment.

Innovative Sliding Bearing Technology

With substantial experience in the self-lubricating bearing industry, we possess numerous invention patents and practical patent products.

We use centrifugal casting production, allowing us to adjust the product size and material composition according to the diverse needs of our customers. This way, we provide customers with the most suitable self-lubricating bearings.

Contact Us Today!

If our range of products doesn’t meet your requirements, we’re more than ready to develop self-lubrication bearings specifically for your application. Get a free quote from us today!

Explore Our Forklift Bushing Plain and Specialty Bearings

Have a project we can assist you with? We invite you to explore our variety of forklift bushing plain and specialty bearings.

Source Chinese self-lubricating bronze bushing parts from our official website – BronzeLube.com. We’re looking forward to working with you.

In addition, these bearings are designed to minimize wear and extend the service life of these parts, further enhancing their cost-effectiveness. They also provide smoother operation, which can contribute to increased operator comfort and potentially enhanced productivity.

For more information on self-lubricating bearings and their applications within the forklift and heavy machinery industries, please visit our website at Bronzelube.com.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.