Custom Part Services

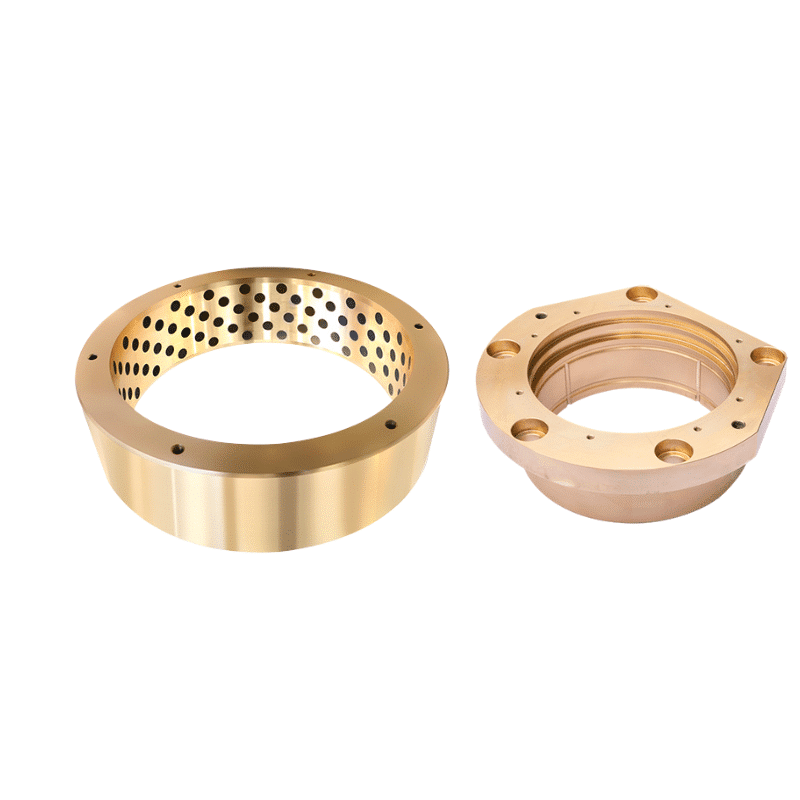

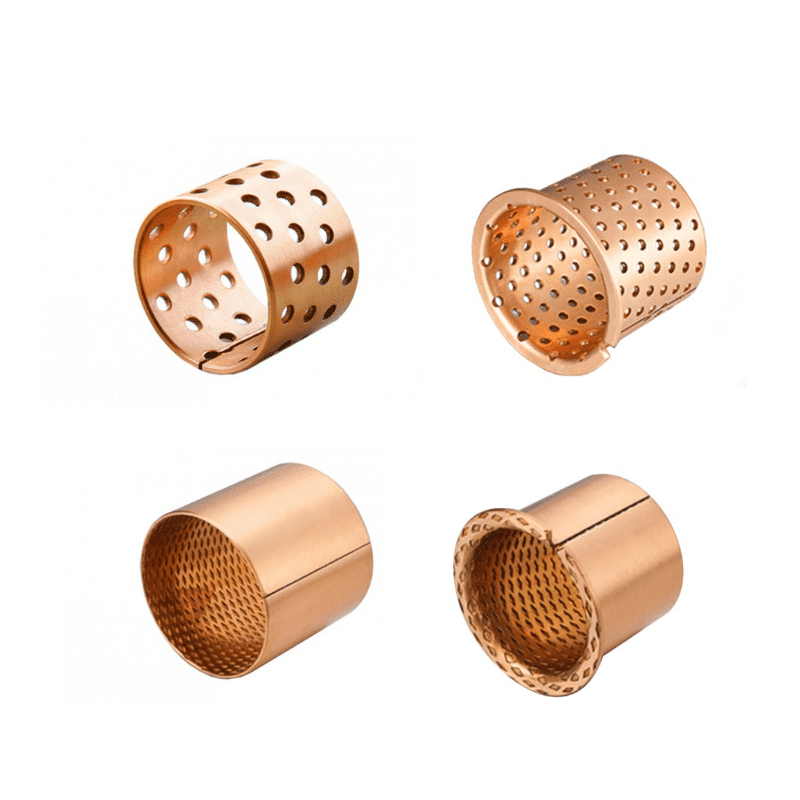

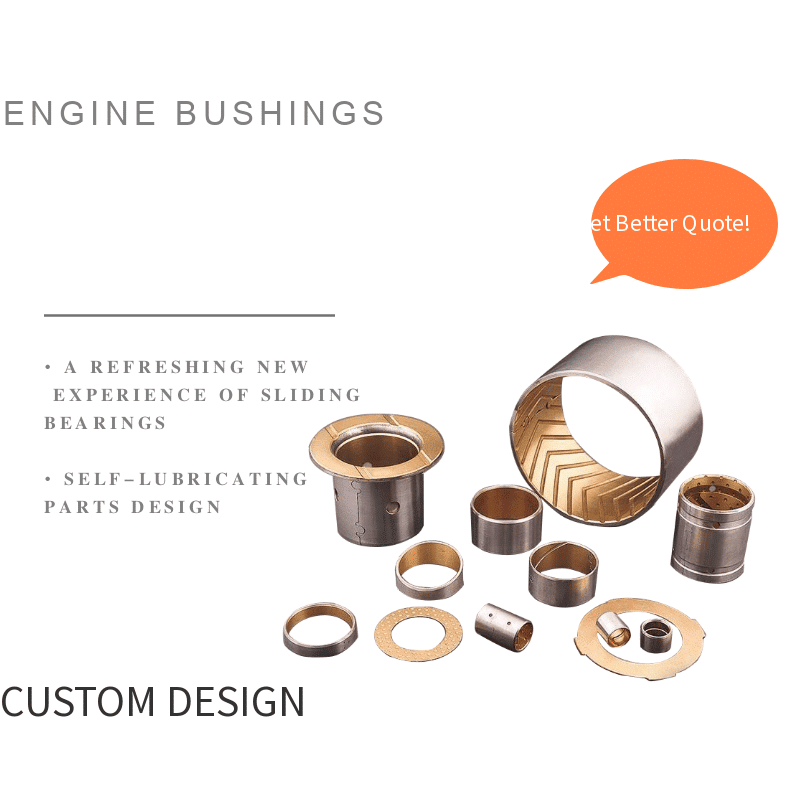

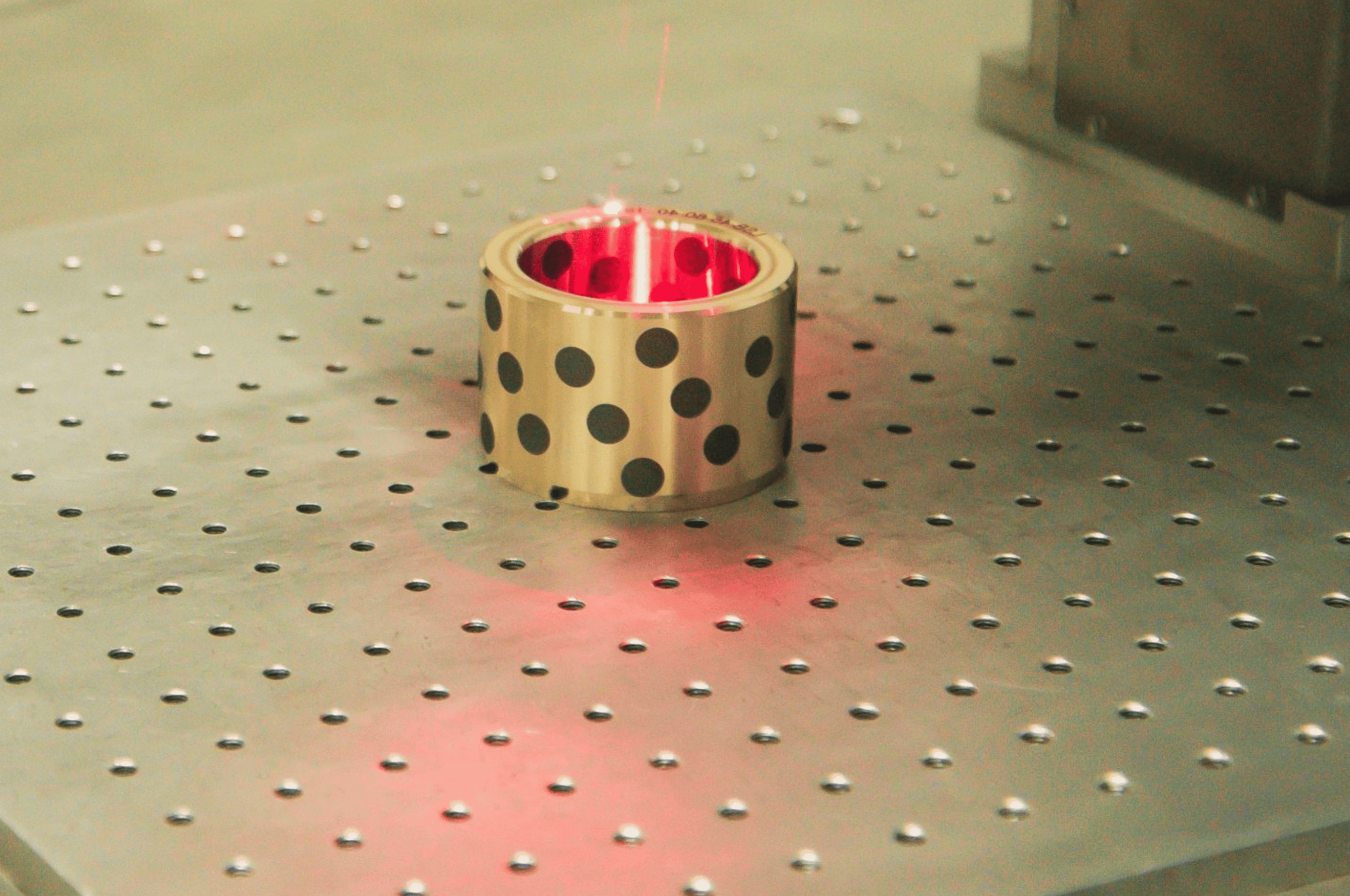

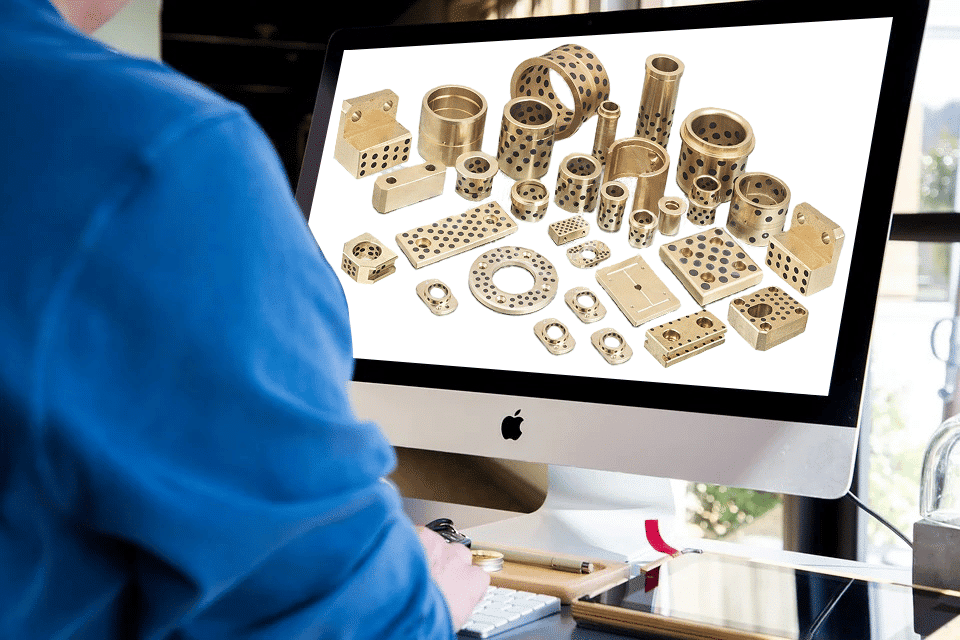

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Custom Part Services

Custom Pain Bearings

Custom Plain Bearings Made From Self-lubricating Material

We offers self-lubricating bearings materials designed for wear resistance. Whether your application is exposed to

high temperatures, chemicals, or water – viiplus has a solution.

What Is the IATF 16949 Standard?

16949 certification is TS16949 certification, ISO/TS16949:2009 is the international automotive industry technical specifications, is based on ISO9001, added to the automotive industry technical specifications.

ISO/TS16949:2002 developed by IATF under the support of ISO/TC 176 quality management and quality assurance Technical Committee. The third edition of ISO/TS16949 canceled and replaced by the second edition, is based on the ISO9001:2008 technical revision. Because ISO/TS16949:2009 has included all the content of ISO9001:2008, so ISO/TS16949:2009 certification, also marks compliance with ISO9001:2008 standard. Requirements for the auditee:

ISO/TS16949:2009 certification registration, only applicable to the automotive plant and its direct parts manufacturers. These manufacturers must be directly related to the production of automobiles, have processing and manufacturing capabilities, and through the realization of this capability to add value to the product.

ISO/ TS16949:2009 certification registration of the company must have at least 12 consecutive months of production and quality management records, including internal review and management review of the complete record.

IATF 16949 certification emphasizes the development of a process-oriented quality management system that provides for continual improvement, defect prevention, and reduction of variation and waste in the supply chain. The goal is to meet customer requirements efficiently and effectively.

16949 certification objectives:

I. Continuous improvement in the supply chain

1. Quality improvement

2. Productivity improvement

3. Cost reduction

Second, emphasize the prevention of shortcomings

1. Application of SPC

2, error prevention measures

Third, reduce variation and waste

1. Ensure inventory turnover and minimum inventory

2. Quality cost

3. Additional cost of non-quality

Custom Part Services

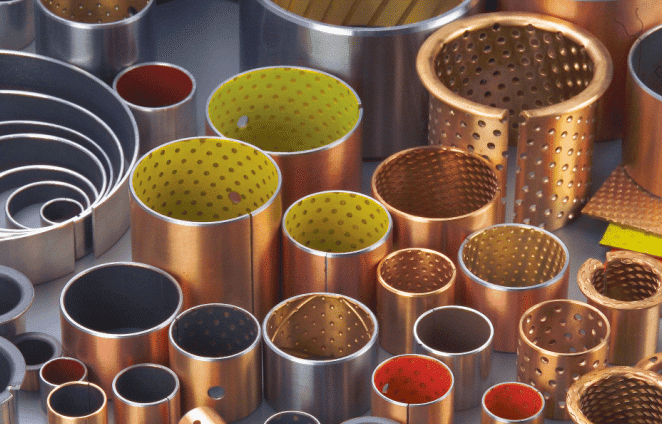

We provides a variety of high-quality bushing bearing. We are always ready to provide you a product that serves your industry, demands and needs. We serves many industries including but limited to: oil & gas, agriculture, pharmaceutical, mining, and automotive.

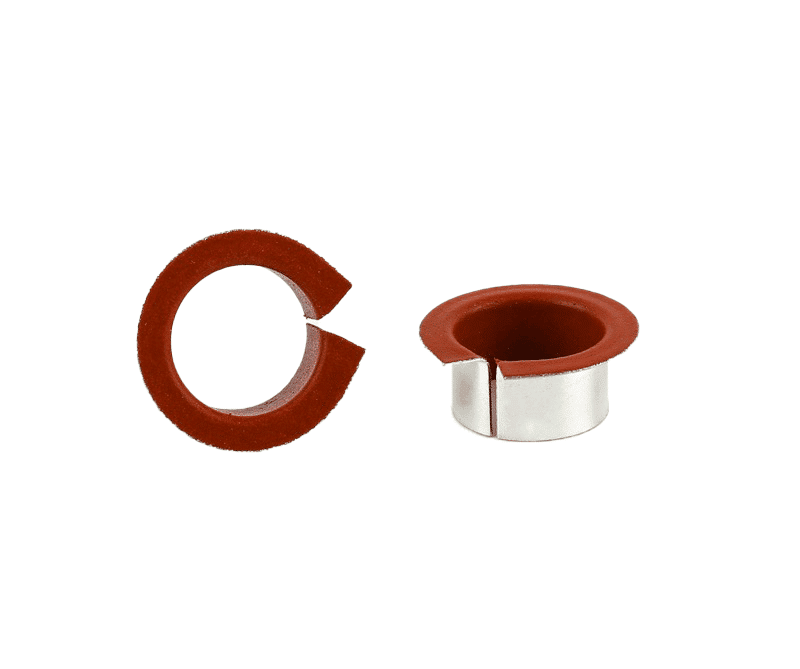

Metal PTFE bushings – Wear resistance, Custom Bearings & Bushings

Global SourcingSelf-lubricating Bearing

Global Sources – Find & Meet Reliable Bearing Bush Exporter

ind PTFE Bushes, PTFE RED Bush manufacturers, suppliers & exporters in China. Get contact details & address of companies manufacturing. Metal-Polymer Low Friction Plain Bearings Inch & Metric Size.

Metal Steel Lubricated Bushings: The Self-Lubricating Effect | bronzelube.com

We seeks out collaborative, long-term relationships with each one of our customers. Our diverse expertise gives us a deep understanding of the challenges you face. When you partner with us early, our engineering team is able to review your assemblies and make sure both the bearing and surrounding components are optimized for performance and cost-effectiveness.

Wast is PTFE material?

PTFE is a polymer chemical material containing polytetrafluoroethylene. Widely used in packaging, electronic and electrical, chemical energy, corrosion-resistant materials, Teflon high-performance special coatings are fluorine coatings with PTFE as the matrix resin.

Polytetrafluoroethylene is produced by free radical polymerization of tetrafluoroethylene. Industrial polymerization is carried out with stirring in the presence of a large amount of water to disperse the heat of reaction and to facilitate temperature control. The polymerization is generally carried out at 40-80°C and a pressure of 3-26 kgf/cm2. Inorganic persulfates and organic peroxides can be used as initiators, and redox initiation systems can also be used.

Self-lubricating Bushings & Bearings – Select, configure, order.

Search and find the the standard part that meets your application needs. Once you find the part you need, request a quote and we’ll process your request as quickly as possible.

Connect with the China Verified Bushing Supplier. Source online for self-lubricating bearing bush and oilless bearings products from our featured Manufacturers in China. Effective Sourcing. Wide Range Of Products. Rich Experience. Source For The RED PTFE Bush Products From Quality Suppliers In Your Industry! Find & Meet Reliable Bushing Exporters From China. Discover More!

We are offering RED PTFE Bush. We provides a variety of high-quality bearing bush from china. For more information on how bronzelube.com can help you today, contact us to find out how we can help you and your specific need.

PTFE OR Teflon Bushes is a thermoplastic polymer that is used in the manufacture of various components that are of great demand in the polymer and other industries.

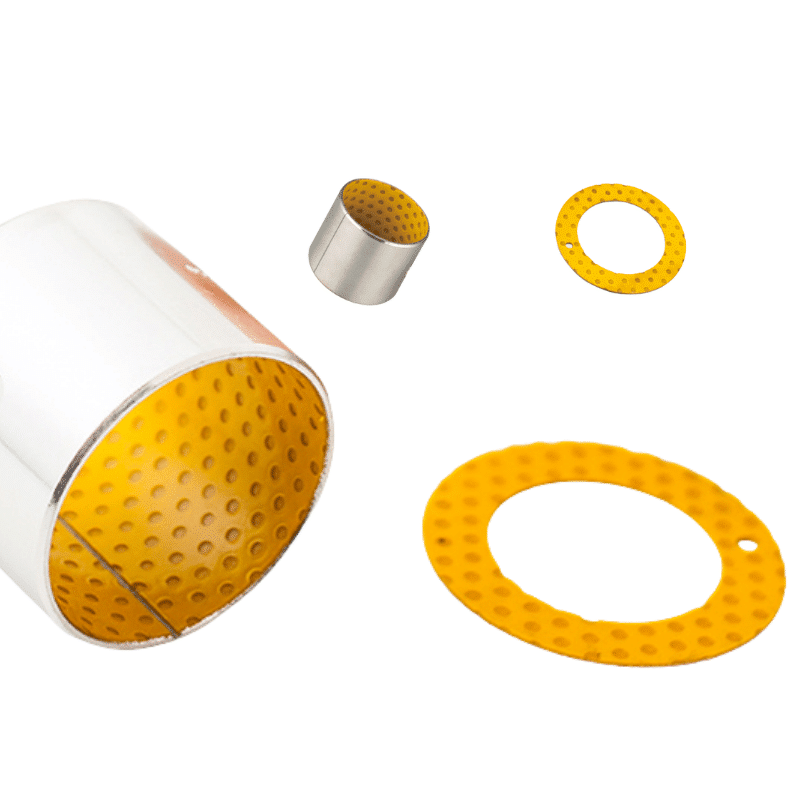

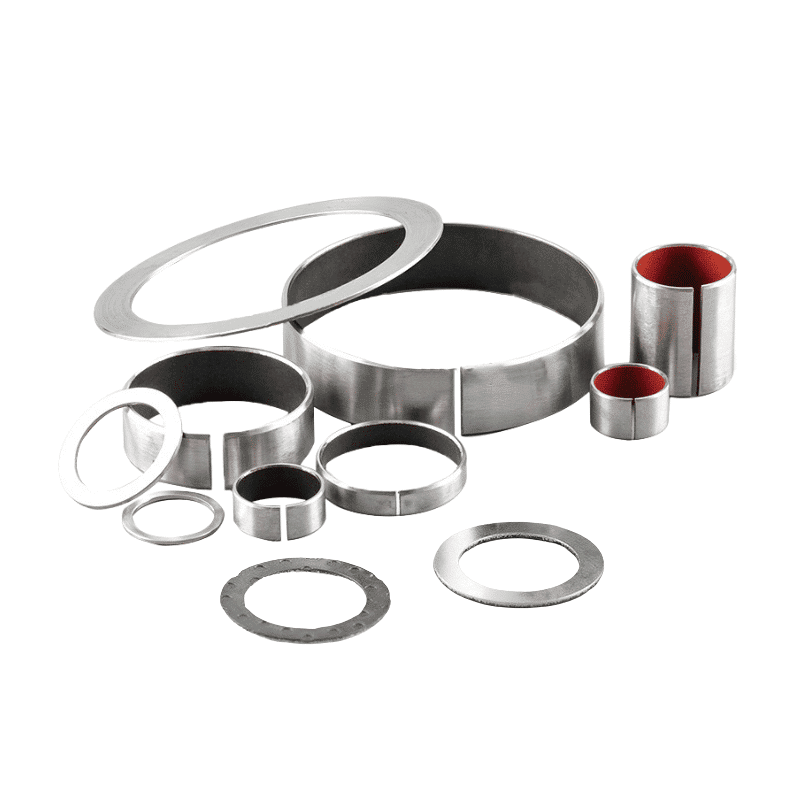

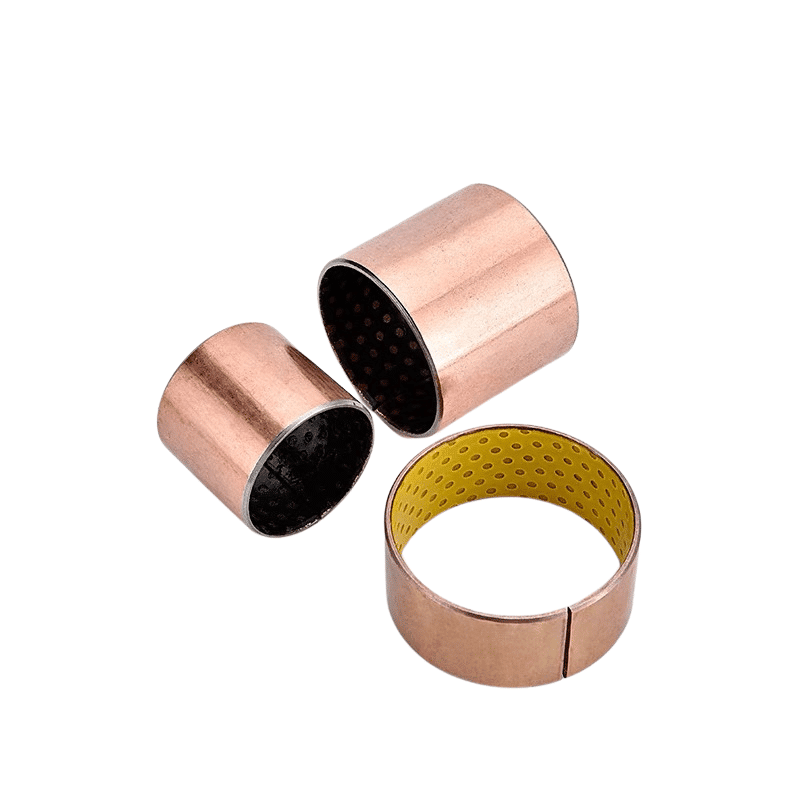

- Self-lubricating Layer: PTFE Mixture 0.01- 0.03mm.

- Porous Bronze Layer Provides a strong surface to bond the Self-Lubricating PTFE layer.

- CS Backing Layer: Provides load a thermal conductivity Copper/ TinLayer

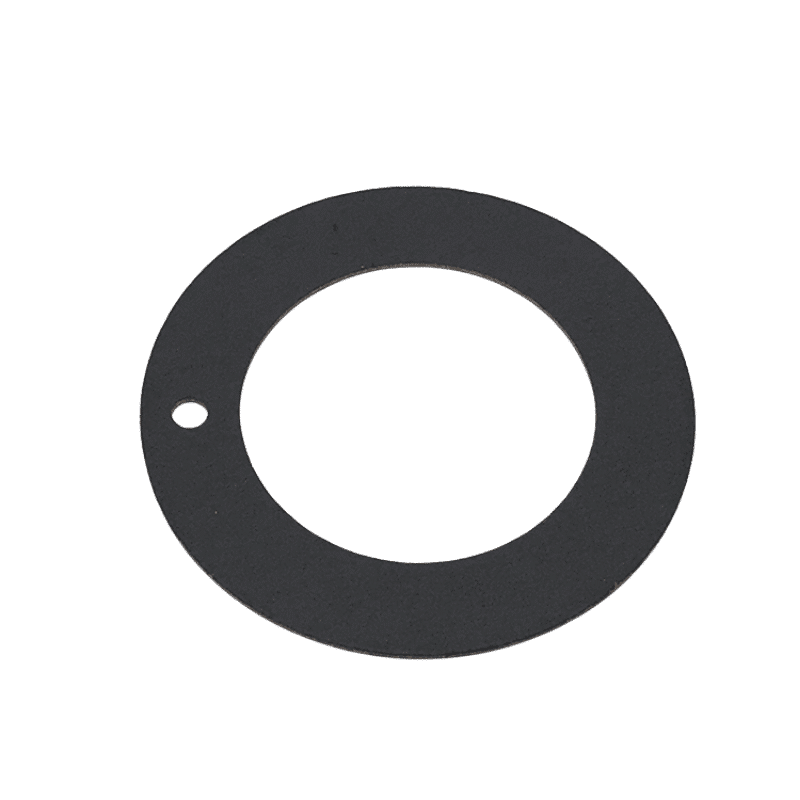

PTFE Self-Lubricated, GGB bushing Replacement, Maintenance Free Bushing. We can supply a wide variety of composite gaskets

Professional Bushing supplier & manufacturers in China, welcome to buy customized and low price RED PTFE bushing or get its free sample from our factory.

General Description: RED PTFE Bushing is a three-layer bushes, maintenance free bushing. It has a base of low carbon steel, onto which a porous bronze laver is sintered. A PTFE mixture permeates the intervening space of the bronze layer, after the rolling process is completed. RED PTFE bushings are designed to be used in many applications, RED PTFE bushings are design to provide Self-Lubrication, Ant-Ware. Low Friction and Reduced Noise.

High Performance RED PTFE Bearing forms available in standard dimensions

- Cylindrical du bushes

- Flanged du bushings

- Thrust washers

- Flanged washers

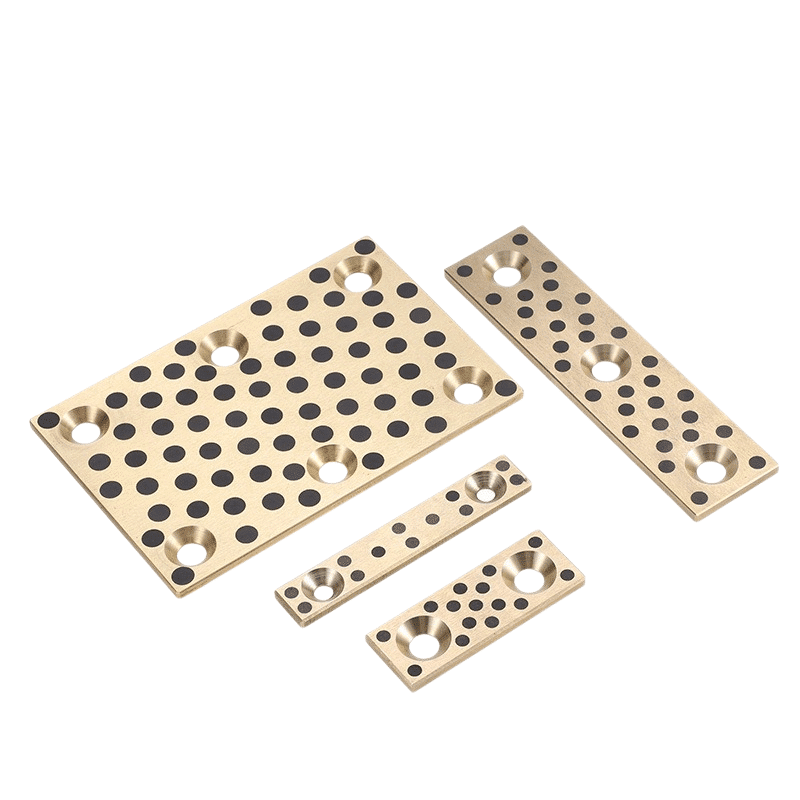

- Sliding plates

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping or deep drawing, customized bushing designs.

We are excited to work with so many great industry partners from many different industries. These include:

- Oil & Gas

- Agriculture: From Equipment OEM’s

- Mining

- Power Generation: Wind, Turbine, Hydro and Solar power generation

- Medical Equipment: Surgical, dental, and rehabilitative tools and equipment support

- Pulp & Paper: From conveyors, to hydraulic systems we can help

- Food & Beverage: FDA Approved materials, Specialized wear parts for production assemblies and more

- Industrial Design & Engineering: We’re happy to work with your team from concept to production and everywhere in between.

- Marine

- Manufacturing: From 1 to 1million, we can support your demand

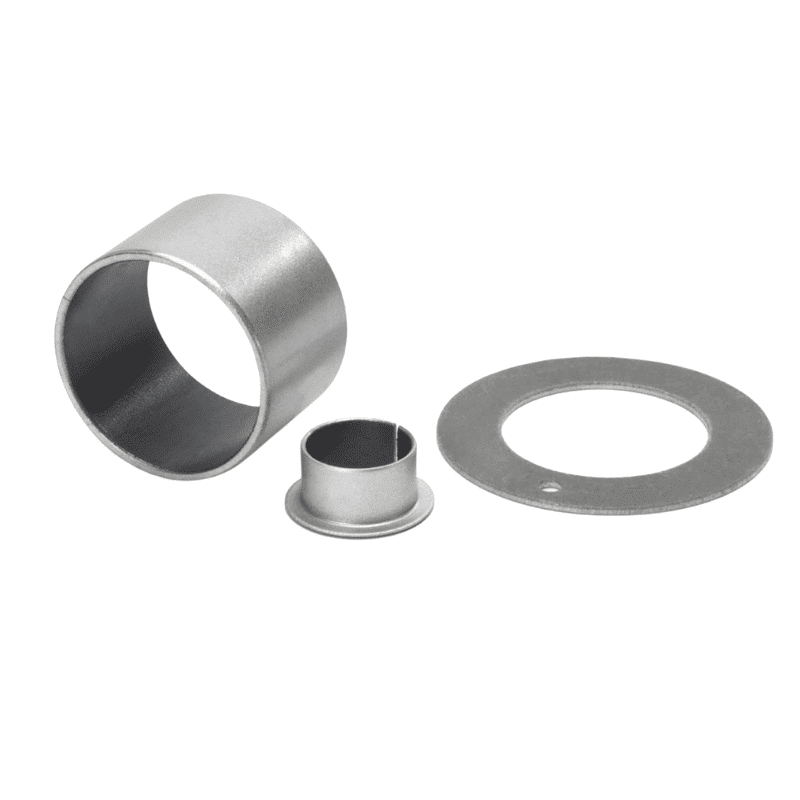

Self-lubricating Maintenance-free, steel bearings

Self Lubricating Du Bushings – Factory Direct & Fast Shipping!

HIGH QUALITY BEARING BUSHING PROVIDER

We provide only the highest quality RED PTFE products to meet your companies needs.As we work with our customers, the goal is simple, to identify and determine just how we can help your business.DP4 Slide Bearing Red Teflon Bushing Size: various sizes; Material: carbon steel/stainless steel+bronze powder+PTFE+polymer; PTFE: 0.01-0.03mm

Eliminate unplanned downtime with PTFE bearings by bronzelube.com. Small minimum order! Dry-running, corrosion-resistant, and able to withstand any environment. Shop now.

WE VALUE OUR COMMITMENT TO YOU

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Proven, long-lasting bushings.

Primary Metals Bearings Bushing

Broadest range of standard-size bushing bearings in the industry. Manufacture and Supply of Bronze Bearings – Sleeves, Flanges, Washers. Cast Bronze. Meet your challenge with reliable and Metal, long-lasting bushings. For self-lubricating bushings, the applicable subheading for customs classification in the United States is 8483.30.8090 under the HTSUS (Harmonized Tariff Schedule of the United States). This classification is crucial for customs clearance to ensure accurate import/export procedures and avoid potential issues like additional fees or delays in shipment.

Self-lubricating bushing exporter

A self-lubricating bushing exporter is a company that specializes in exporting self-lubricating bushings. Self-lubricating bushings are a type of bearing that do not require external lubrication, as they contain a solid lubricant embedded within the material. These bushings are commonly used in applications where lubrication is difficult or impossible, such as in high-temperature environments or in areas where access for maintenance is limited. If you are looking for a self-lubricating bushing exporter, you may want to search online for companies that specialize in this type of product and have experience exporting to your desired location.

Bushing HS code, Understanding the Importance of Harmonized System Codes for Bushings

Self-Lubricating Bearing Bushing HS Code: What You Need to Know

Self-lubricating bearing bushings are an important component of industrial machinery, providing a low-maintenance, high-performance solution for reducing friction and wear between moving parts. However, when it comes to importing or exporting these bearings, it’s important to know the correct HS code to ensure smooth and compliant international trade.

The HS code for self-lubricating bearing bushings varies depending on the material and type of bearing. For example, self-lubricating bearings made from sintered metal may fall under HS code 8483.30, which covers “Bearing housings, not incorporating ball or roller bearings; plain shaft bearings.” Other types of self-lubricating bearings made from plastic or composite materials may fall under different HS codes.

It’s important to note that HS codes are not universal and can vary from country to country. It’s essential to research the specific HS code requirements for your intended import or export destination to ensure compliance with local regulations.

The correct HS code is crucial for customs clearance and can impact the cost and timeline of your international trade. Incorrectly classifying your bearings can result in additional fees, fines, or delays in shipment. Therefore, it’s crucial to work with a knowledgeable logistics provider or customs broker who can assist with the correct classification of your self-lubricating bearing bushings.

In addition to the correct HS code, it’s important to ensure that your self-lubricating bearing bushings comply with any other regulations or standards in your intended import or export destination. This may include compliance with environmental regulations, safety standards, or material certifications.

Self-lubricating bearing bushings are an important component of industrial machinery, providing a low-maintenance and high-performance solution for reducing friction and wear. However, when it comes to international trade, it’s essential to know the correct HS code to ensure smooth and compliant customs clearance. By working with a knowledgeable logistics provider or customs broker, you can ensure that your self-lubricating bearing bushings are correctly classified and comply with all necessary regulations for your intended import or export destination.

Bushing HS Code: Understanding the Importance of Harmonized System Codes for Bushings

Bushing HS code, also known as harmonized system code, is an important aspect of international trade that helps to classify and identify different products for customs purposes. It is a standardized system of product coding that is used globally to ensure that all products are properly classified and recorded for trade purposes. Understanding the bushing HS code is important for anyone involved in the import or export of bushings, as it helps to ensure that products are correctly classified and that duties and taxes are correctly applied.

The HS code for bushings is a six-digit code that is used to identify the product and its classification within the harmonized system. The HS code system is divided into 21 sections, which are further divided into chapters and subheadings. The HS code for bushings falls under Chapter 84 of the harmonized system, which covers machinery, mechanical appliances, electrical equipment, and parts thereof.

The specific HS code for bushings depends on the type of bushing and the material it is made from. For example, the HS code for steel bushings is 84.81, while the HS code for rubber bushings is 40.09. It is important to note that the HS code for bushings is not the same in every country, as some countries may have additional codes or subcodes that are specific to their trade regulations.

In addition to helping to identify and classify bushings for customs purposes, the bushing HS code also plays an important role in determining the duties and taxes that are applied to imports and exports. Understanding the bushing HS code is essential for anyone involved in international trade, as it helps to ensure that products are correctly classified and that all necessary duties and taxes are correctly applied.

In conclusion, the bushing HS code is a critical aspect of international trade that helps to classify and identify bushings for customs purposes. Understanding the HS code for bushings is important for anyone involved in the import or export of bushings, as it helps to ensure that products are correctly classified and that duties and taxes are correctly applied. By understanding the bushing HS code, you can ensure that your trade transactions are compliant and that your products are properly classified and recorded for trade purposes.

What is the bushing hs code, slide bearing bushing hs code

The HS code for slide bearing bushings would typically fall under Chapter 84 of the Harmonized system, which covers machinery, mechanical appliances, electrical equipment, and parts thereof. The specific HS code for slide bearing bushings would depend on the type of material used to manufacture the bushings, as well as the application for which they are intended.

For example, the HS code for bronze slide bearing bushings may be 84.81, while the HS code for plastic slide bearing bushings may be 39.26. It is important to note that the HS code for slide bearing bushings may vary between countries, as some countries may have additional codes or subcodes that are specific to their trade regulations.

In addition to helping to identify and classify slide bearing bushings for customs purposes, the HS code also plays an important role in determining the duties and taxes that are applied to imports and exports. Understanding the HS code for slide bearing bushings is essential for anyone involved in international trade, as it helps to ensure that products are correctly classified and that all necessary duties and taxes are correctly applied.

In conclusion, the HS code for slide bearing bushings is an important aspect of international trade that helps to classify and identify these products for customs purposes. Understanding the HS code for slide bearing bushings is critical for anyone involved in the import or export of these products, as it helps to ensure that they are properly classified and that all necessary duties and taxes are correctly applied.

Bushing HS code: 8483300090

If you are doing international business and have any questions about Sleeve Bushing & Plain Bearing HS code, then you need to check this guide, you can find your questions below and check our answer. Bushing CUSTOMS TARIFF and Bushing HS code: CUSTOMS TARIFF: A TARIFF imposed by the CUSTOMS on imported and exported goods with HS code

HS CODE is short for Harmonized Commodity Names and Coding System.

Description BUSHING. Do not risk your high performance on bushing. We offers the genuine quality bushing you need.

If you can not find the right answer, then please contact me at any time.

What is the HS Code of your product? What is the HS Code of a Bushing? Search Import Export Data of China Import Export

HS Code is an acronym for “Harmonized System”.

It is an international system of naming and classifying commodities that we want to ship.

It gives room for traded products to be categorized regularly.

This will assist member countries for custom purposes.

At the international level, the HS Code (for the classification of products) is usually a six-digit code.

There are specific guides to be followed for importing products for example self-lubricating bushing from China to any other country using these HS Codes.

To broaden your knowledge about HS Codes, Metal bushing hs code, bush hs code you can check below:

Harmonized Tariff Schedule of the United States (HTSUS)

HS Code 8483308090 … US Import and Export data for HTS 8483.30.8090, Plain Shaft Bearings

8483.30.8090. Parts of Bearing Housings and Plain Shaft Bearings. Parts of Flange, Take-Up, Cartridge and Hanger Units. 8483.90.2000. Parts of Other Units.

As such, it should be classified the same way as the bronze bushing, in subheading 8483.30.80, HTSUS, which provides for

“Transmission shafts (including camshafts and crankshafts) and cranks; bearing housings, housed bearings and plain shaft bearings;

gears and gearing; ball or roller screws; gear boxes and other speed changers, including torque converters; flywheels and pulleys, including pulley blocks; clutches and shaft couplings (including universal joints); parts thereof: Bearing housings; plain shaft bearings: Other.”

The applicable subheading for the bronze bushings will be 8483.30.8090,. HTSUS, which provides for other plain shaft bearings .

The applicable subheading for the bronze bushings will be 8483.30.8090,

HTSUS, which provides for other plain shaft bearings without housing.

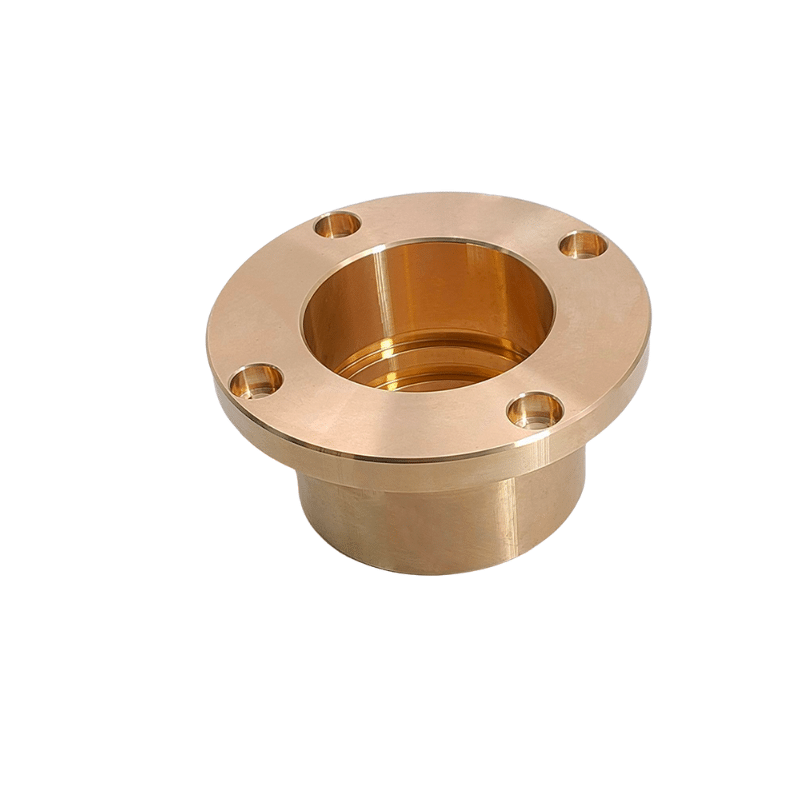

- Cylindrical du bushes

- Flanged du bushings

- Thrust washers

- Flanged washers

- Sliding plates

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping or deep drawing, customized bushing designs.

What is HTS?

This is the Harmonized Tariff Code Schedule (HTS).

It is a 10-digit method of classifying goods specifically imported from the United States.

They capture their first digits from the international HS code and add an extra four digits to make it more extensive.

For example, for bushing can use 8483.30.8090 or 8485.90.0080.

Or DDP (Delivered Duty Paid) Get better bushing price rates to reduce your costs.

Bearing Bushing Exporter, Bearing prototype, Straight Bushing Supplier!

As a bearing bushing exporter, there are several key considerations that must be taken into account in order to ensure the success of your business. These considerations include:

Quality: It is important to ensure that the bearing bushings you are exporting meet high quality standards in order to satisfy your customers and maintain a good reputation in the industry. Consider working with a trusted manufacturer or supplier to ensure that your products are of the highest quality.

Pricing: Competitiveness in pricing is crucial in the global market. It is important to research market prices and trends, and to offer competitive prices while still maintaining profitability.

Market research: Understanding your target market is critical to the success of your business. Research your target market to determine their needs, preferences, and buying patterns.

Compliance with trade regulations: As an exporter, it is important to comply with all local, national, and international trade regulations, including customs and export regulations. Familiarize yourself with the regulations that apply to your business, and make sure that your products are compliant.

Shipping and logistics: Proper shipping and logistics are critical to ensuring that your products reach your customers on time and in good condition. Consider working with a reliable shipping and logistics provider that has experience in exporting bearing bushings.

Customer service: Providing excellent customer service is important in maintaining customer loyalty and building a positive reputation in the industry. Make sure that your customers have access to helpful and knowledgeable representatives who can assist them with any questions or concerns.

By taking these factors into consideration, you can position your business for success as a bearing bushing exporter. Additionally, it is always a good idea to seek out advice and guidance from industry experts, trade organizations, and government agencies in order to stay up-to-date with the latest developments in the industry. Ships the Bushing From China to Your Country – Save up to 80% on Shipping. Avoid Surprises. Estimate Shipping Costs to Your City.Bearing Bushing Shipping Rate Calculator, Calculate Your Shipping Costs Now. Save Up to 80%!

Worldwide Cargo Shipping – Door to Door Pricing 24/7, VIIPLUS offers cross-border bearings bushing transport solutions on all routes from and to Your Country. Bushing Supplier, Freight Forwarder. – Wholesale Suppliers Online

Freight solutions: Bearing bushing hs tariff. The tariff classification of bushings from China. http://wmsw.mofcom.gov.cn/wmsw/m

Bushing – China Customs HS Code & China Import Tariffs for …

China HS Code & tariff for bushing – Tariff & duty, regulations & restrictions, landed cost calculator, customs data for bushing.

Bushing hs tariff code, Contact Us Today!

What is Bushing HS Code: The Definitive FAQ Guide

Custom export data, Bushing Custom Tarif: The Custom Tariff for self-lubricating bushings refers to the duties and taxes that are applied to the import or export of these products. The specific Custom Tariff for self-lubricating bushings would depend on the country of origin, destination, and the type of material used in the manufacture of the bushings.

For example, the Customs Tariff for self-lubricating bushings made from plastic materials may be lower compared to those made from metal materials, as plastic materials are typically considered to be less valuable. On the other hand, self-lubricating bushings intended for specialized applications may be subject to higher tariffs, as they are considered to be of higher value.

It is important to note that the Custom Tariff for self-lubricating bushings may vary between countries, as each country has its own set of trade regulations and tariffs. Additionally, trade agreements and preferential tariffs may also impact the Custom Tariff for self-lubricating bushings.

In conclusion, the Custom Tariff for self-lubricating bushings is an important aspect of international trade, as it helps to ensure that duties and taxes are correctly applied to imports and exports. As a self-lubricating bushing exporter or importer, it is important to understand the Custom Tariff that applies to your products, in order to ensure compliance with trade regulations and to avoid any potential penalties or fines.

Find Bushing Exporter from China Countries with Trade Value, Customs Data and more.

We offer a wide range of high quality of bushings & plain bearings parts, galcier garlock bearing part alternative. alternative part DANA 806334

Custom Part Services

View detailed Export data, bushing price, bushing material, bushing types, major exporting countries, major ports of end bushing under HS Code 84833000.

Safe & On Time Delivery

Bushing Application,Leave your goods and let us handle the rest.

Plain bearings, Bearing Sleeve HS code, Self Lubricating Bushings – Factory Direct & Fast Shipping!

How are HTS codes chosen? HS Code 84833080 – Plain, shaft, bearings.

-

Plain shaft bearings for machinery, they are usually administered by the United States International Trade Commission.

-

All US importers need to understand the use of correct HTS-US codes. Bearing bushing HS code.This is because custom duties are assessed based on this classification. Explore More Sleeve Bearings Products from china, Experienced Self-lubricating Bushing Supplier in China.

Bushing Supplier

24/7 emergency callout

Sliding Bushing Solution and Bearing Resources

The most basic structure of sliding bearing is divided into bearing bush and journal.

Learn how sliding bearings are used in high speed, high precision, heavy load, and there are low speed impact machines.

High Quality Sliding Bushing With Competitive Price

Self-lubricating, Maintenance Free

High load capacity sliding bearings

Welcome to bronzelube.com

- Simple structure, Convenient manufacturing, processing and disassembly.

- Good impact resistance and good vibration absorption performance, smooth operation, high rotation accuracy.

Reliable & safe sliding bushings solution

Provider of individual solutions for sliding bearings & bushings.

Rolling Bushings VS Sliding Bearings

Rolling bearings are more widely used

According to the friction properties of different bearings can be divided into rolling (friction) bearings and sliding (friction) bearings, it is obvious that rolling bearings must be smaller than sliding bearings friction resistance, fast starting, high efficiency, this is the advantages of rolling bearings.

Compared with sliding bearings, rolling bearings have larger radial size, poor vibration reduction ability, low life at high speed and larger noise.That’s the downside.

Choose your correct bearings to meet your requirements

What are the differences between rolling bearings and sliding bearings?What are the advantages and disadvantages of each?

Differences between rolling bearings and plain bearings — definitions and advantages and disadvantages

Rolling bearing, refers to the friction between the shaft and the shaft seat of mechanical operation is a rolling friction bearing, but the sliding bearing is still working under sliding friction.The structure of the rolling bearing is clear, and the uniform distribution of the rolling body can effectively reduce friction. Therefore, the mechanical starting is very fast and good, and the maintenance is also simple and convenient.In addition, it is more suitable for medium speed work, high speed work noise is relatively large, and will reduce its service life.In addition, the rolling bearing works with large vibration.Comparatively speaking, the sliding bearing runs smoothly and has no noise, but the starting resistance is relatively large.

Difference between rolling bearings and plain bearings — structure

The rolling bearing is composed of an inner ring, an outer ring, a rolling body and a cage, among which the outer ring is fixed and does not act as a support;The inner ring rotates with the shaft;The rolling body is the most important, which is related to the performance and service life of the bearing.The cage is used to assist the rolling body to make it evenly distributed.Sliding bearings do not have the above structure, in which the key role is the production material of sliding bearings.

In addition, the main role of bearings is to reduce friction, among which, the size of the friction force of rolling bearings is related to the level of manufacturing technology, that is, whether it is accurate.However, the size of the friction force of sliding bearings is related to its manufacturing materials. Usually, metal sliding bearings and non-metal sliding bearings (mostly plastic) are discussed.

Although rolling bearings and sliding bearings belong to mechanical parts, their operation is not the same.In addition, in the use of machinery, but also pay attention to the daily maintenance and repair of rolling bearings and sliding bearings.

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Custom Part Services

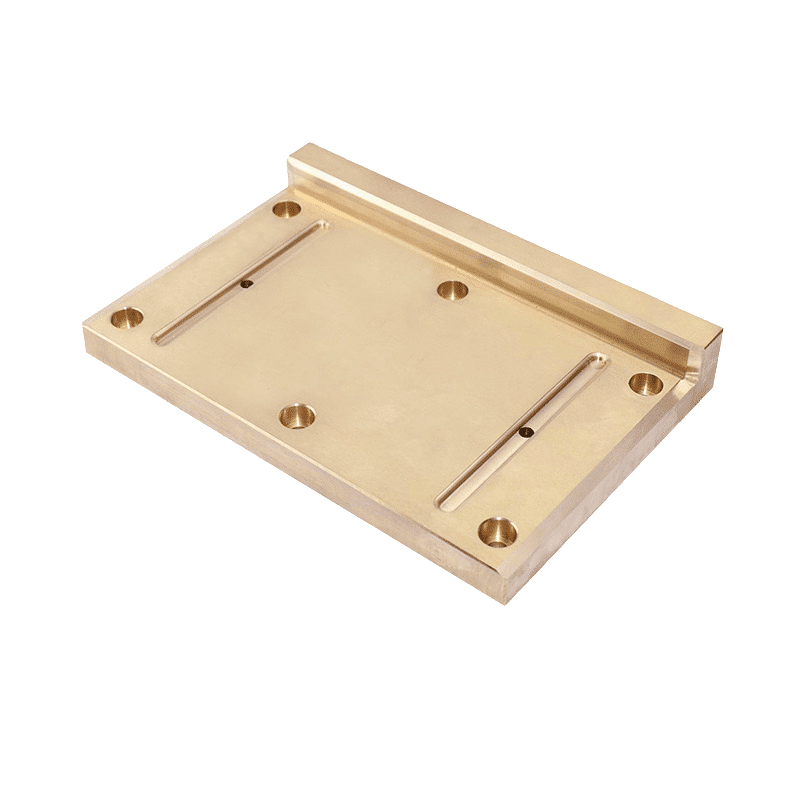

Slide bearings facilitate precise linear motion and accommodate structural expansion.

Optimal sliding bearing solution

Custom Sliding Bearing & Part Manufacturing Service to Your Exact Specification. Quote Now! The Predictable Bearings Life Offers High Planning Reliability To Help You Save On Cost.

Full range, even for hard-to-find bearing parts.

Quality design and supply of Sliding Bearings materials

The plain bearing assembly consists of structural spacers, PTFE (or other low friction material) sliding surfaces, and plain bearing plates. Plain bearing subtypes include linear ball bearings and linear rolling bearings. Plain bearings can also be called linear bearings, pilot bearings, or linear plain bearings.

They can be used in applications such as construction (bridge expansion brackets) and precision tools.

Plain bearings, also referred to as bushes, bushings or sleeve bearings, are cylindrical shaped and have no moving parts.

Plain bearings are used for sliding, rotating, oscillating or reciprocating movements. In sliding applications, they serve as plain bearings, treads and wear plates. In these applications, the sliding surfaces are generally flat, but can also be cylindrical, and the movement is always linear rather than rotary. Plain bearing construction can be solid or with a split seal (wrapped bearings) for easier installation.

Plain bearing advantages

Plain bearings are manufactured from a variety of materials including metal-polymer, recycled plastics, fiber-reinforced composites, and metals that reduce noise, increase service life, eliminate lubricants, and improve performance. The material of the plain bearing contributes to its mechanical and tribological properties.

Sliding Bearing

Experienced bearing specialist with rich knowledge and know-how

Plain bearings are bearings in which only sliding friction is generated. The shaft is usually supported on the sliding surface and the oil and air in between facilitates the sliding. Plain bearings are lightweight and have a long life, while introducing minimal vibration or noise.

We offer a portfolio of quality sliding bearings designed to improve the reliability and efficiency of plain bearing that keep bearing in motion.

The best sliding bearing solutions come only when the problem is comprehensively understood.

Sliding bearings: a complete range for all your needs

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Custom Part Services

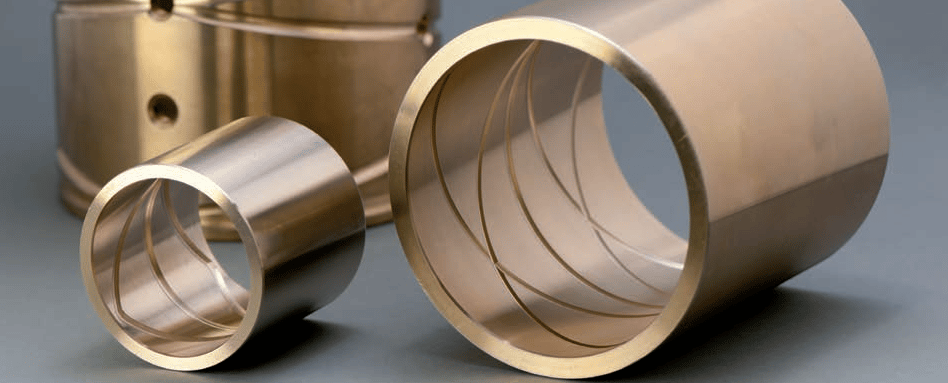

Bronze is a versatile and commonly used material for bushings because it comes in many alloys and compositions.

More Efficiency Today,

Greater Resilience Tomorrow

With our growing portfolio of self-lubricating bearings and bushings product, we invest in growing markets, such as bushings & bearings, for a more efficient present and more resilient future.

Advancing Our Bearing Position as a Global Industrial Leader

Bronze bushings or bronze bearings are hard and strong, unlike brass bushings which are softer and more easily deformed. Therefore, bronze bushings have a longer service life than brass bushings. They are shock and impact resistant, wear and corrosion resistant.

Bronze bushing application

They are more often used in low-speed, high-load and heavy industrial equipment, as well as in the production of iron and steel, food processing, injection molding, automotive engineering, mechanical engineering. earthworks, pumps and other industries.

Two common bronze bushing materials and their uses include:

Oilite: Oil-impregnated bronze bushings formed using powder metallurgy. Applications depend on the type of oil used and can accommodate high and low speed machines, high and low temperature machines and food grade applications.

Copper: Most often it is an alloy of bronze with tin, aluminum or silicon. These alloys are highly corrosion resistant, making them ideal for marine applications.

Popular designs include oil-free graphite bronze bushings, flanged bronze bushings and sintered bronze bushings.

Self-lubricating bronze bushings

Cultivating the Next Generation of Self-lubricating Bronze Bearing Experts

We offer a portfolio of quality brands designed to improve the reliability and efficiency of self-lubricating bronze bushings & bearings that keep bearings in motion.

Our growing line of self-lubricating bronze bearings products is designed to meet our customers’ evolving needs everywhere we do business.

More Bushing Bearings Products from china, Experienced Self-lubricating Bushing Supplier in China.

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Custom Part Services

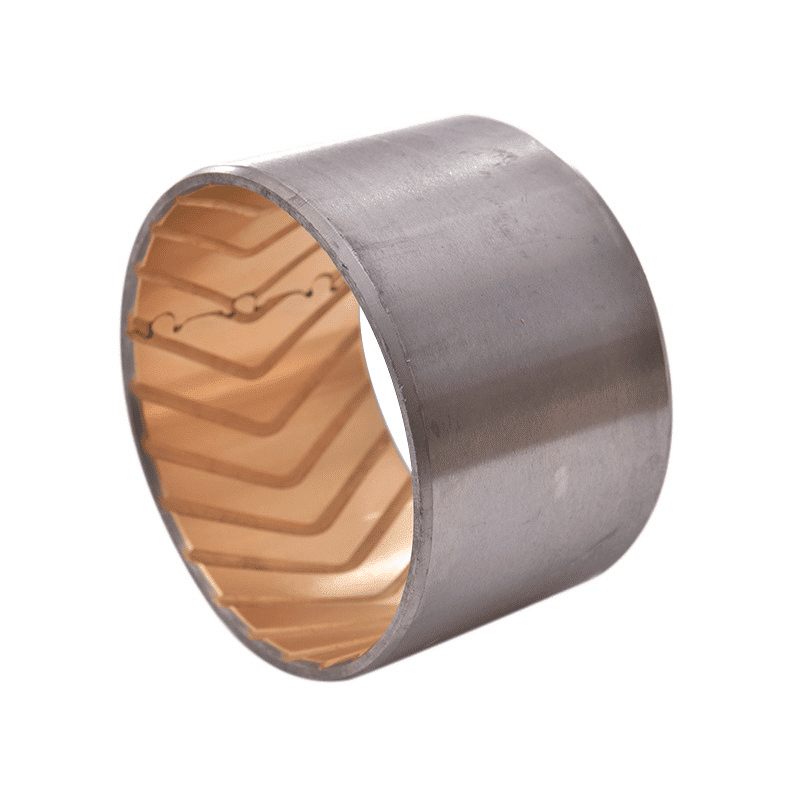

Bearings made of this material combined the high load capacity and dimensional rigidity of lubricated metallic bearings with the performance and economic benefits of self-lubrication.

Self-lubricating bushings for longer life

Select high quality Du Bushing products in best price from Chinese manufacturers

We offer a wide range of high quality of self-lubricating bronze bushings parts. COMPOSITION: Metal-Polymer Composite Self-lubricating Bushing Material, Steel Back + Porous Bronze Sinter + PTFE + Lead!

Self-lubricating Bushings & Bearings – Select, configure, order.

Beautifully crafted leather products.

The low friction of the du bushings reduces power losses for improved energy efficiency, while the wear-resistant bronze layer provides extended service life. Being self-lubricating, the bearings require little to no maintenance. However they can also be used with lubricant to prevent potential shaft/bearing seizure under boundary conditions.

The compact, lightweight design and thin-wall construction of the du bushings provide space and weight savings, and because there are no moving parts or metal-to-metal contact the bearings are quieter. In addition, assembly can be done quickly and easily without costly mounting tools.

du bushings characteristics

Du self-lubricating bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions.

Bushing material suitable for lubricated applications

Anti-friction bearing suitable for linear, oscillating and rotating movements

Bearing forms available in standard dimensions

- Cylindrical du bushes

- Flanged du bushings

- Thrust washers

- Flanged washers

- Sliding plates

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping or deep drawing, customized bushing designs.

Du bushings for use in numerous applications in a wide range of industries

- Agricultural

- Off-highway equipment

- Automotive including trucks

- Aviation

- Garden, lawn and outdoor equipment

- Hydraulics and valves

- Homes appliances and consumer goods

- Material handling

- Medical and dental

- Packaging

- Marine

- Recreational vehicles

- Railway equipment

- Textile equipment and tools, etc.

Rolled Bushing Supplier, Metal-Polymer Anti-Friction Plain Bearings

Beautifully crafted leather products.

Self-lubricating steel backed bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions. Du Rolled BushingS material suitable for lubricated applications. Anti-friction bushes bearing suitable for linear, oscillating and rotating movements. Metal-Polymer Anti-Friction Plain Bearings made to order from bronzelube.com

Huge bushing selection

Self-Lubricating Plain Bearings, Bushing Metal-Polymer Anti-Friction Self Lubricating Plain Bushes Manufacturer.

Self Lubricating Du Bushings – Factory Direct & Fast Shipping!

Metal-Polymer Composite Self-lubricating Bushing Material

Steel Back + Porous Bronze Sinter + PTFE + Lead

Du self-lubricating bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions.

It is of low friction coefficient, anti-wear, anti-corrosion and low noise, compact and light.

Custom Part Services

High performance plastic bushings are often confused with PTFE coated and metal backing bushings, which are much older technology.

We manufacturer PTFE lined steel backed bushing tailored to your individual needs.

PTFE (polytetrafluoroethylene) bushings

Our PTFE-based metal-polymer materials offer exceptionally low friction and high wear. Superior PTFE and thermoplastic-based metal-polymer bearings.

PTFE (polytetrafluoroethylene) bushings are commonly used in many industrial and engineering applications due to their low friction, chemical resistance, and dimensional stability. If you are looking for alternatives to PTFE bushings, some of the options you can consider include:

Nylon Bushings: Nylon is a lightweight and durable material that is often used as an alternative to PTFE in low-load applications. Nylon bushings offer good wear resistance and are relatively inexpensive compared to PTFE.

Polyurethane Bushings: Polyurethane is a versatile plastic that offers a good balance of wear resistance, load-bearing capacity, and low friction. It is often used in applications where a soft, flexible bushing is required.

Bronze Bushings: Bronze is a metal that is known for its high strength and durability. Bronze bushings are commonly used in applications that require high load capacity and good wear resistance.

Steel Bushings: Steel is a strong and durable material that is often used in high-load applications. Steel bushings are typically more expensive than other alternatives, but they offer excellent durability and wear resistance.

Fiber-Reinforced Plastic Bushings: Fiber-reinforced plastic bushings are made from a composite material that combines plastic with fibers such as glass or carbon. These bushings offer good wear resistance, high load capacity, and low friction.

Each of these alternative materials has its own unique advantages and disadvantages, and the best choice for a particular application will depend on factors such as load capacity, operating temperature, and environmental conditions.

With excellent bearing quality to promote the progress of modern industry

Here are the four main reasons to replace PTFE lined liners with plastic liners for greater design flexibility.

1. Thinner wear surface

The PTFE lined sleeve consists of a metal sheath and a very thin polymer coating (PTFE) applied inside. These types of bushings typically have a maximum wear surface of 0.06 millimeters (0.002 inch), but when the PTFE coating is broken during operation, the metal coating is exposed. This creates a metal on metal effect between the sleeve and the shaft and can cause serious damage. This problem often occurs when there are high edge loads or oscillating movements.

By comparison, plastic bushings are made of advanced synthetic compounds that contain solid lubricants embedded in millions of tiny chambers throughout the material.

During operation, lubricant is transferred to the shaft in order to lower the coefficient of friction and wear. Unlike PTFE-lined bushings, plastic bushings eliminate the risk of metal-to-metal contact. This is a great advantage as the acceptable wear can be determined by the type of application (as opposed to the PTFE lined bushing which fails when the wear rate exceeds 0.06 millimeters).

2. Increased weight

Bushings lined with PTFE weigh more than plastic bushings. Using a heavier bushing will require more energy for the bushing to work, regardless of the material. This can be particularly problematic in automotive, aerospace, recreational vehicle, and bicycle applications.

In contrast, plastic bushings are lightweight, which helps to reduce fuel consumption and carbon dioxide emissions. The reduced weight can also help to reduce the emission of carbon dioxide, decrease masses and, consequently, decrease energy consumption.

3. No corrosion or chemical resistance

The metal shell of a PTFE coated bushing is not ideal for applications where water or caustic chemicals are present. In these types of applications, PTFE coated bushings can rust, corrode, contaminate sensitive areas, and eventually fail. Since plastic bushings are made only from high performance polymers, they offer both corrosion and chemical resistance and work unaffected in these types of environments.

4. No resistance to biofuels

The trend towards increasing use of biofuels and biodiesel creates problems with PTFE lined liners; After limited exposure to moisture, parts of the metal sleeve cover may start to peel off.

However, these types of applications open up new doors for plastic sleeves. As they are corrosion resistant, the plastic bushings remain intact, despite the fact that biodiesel tends to absorb a lot of water.

Seek bearings solutions to meet stringent performance requirements and quality expectations.

If you are looking for an alternative to PTFE-lined steel bushings, some options you can consider include:

Bronze Bushings: Bronze is a high-strength metal that is commonly used in applications that require high load capacity and good wear resistance. Bronze bushings can be a good alternative to PTFE-lined steel bushings because they offer good corrosion resistance and low friction.

Polyurethane Bushings: Polyurethane is a versatile plastic that offers a good balance of wear resistance, load-bearing capacity, and low friction. It is often used in applications where a soft, flexible bushing is required.

Nylon Bushings: Nylon is a lightweight and durable material that is often used as an alternative to PTFE in low-load applications. Nylon bushings offer good wear resistance and are relatively inexpensive compared to PTFE.

Fiber-Reinforced Plastic Bushings: Fiber-reinforced plastic bushings are made from a composite material that combines plastic with fibers such as glass or carbon. These bushings offer good wear resistance, high load capacity, and low friction.

Ceramic Bushings: Ceramic bushings are made from a hard, wear-resistant material that offers good load capacity and low friction. Ceramic bushings are typically more expensive than other alternatives, but they offer excellent durability and wear resistance in high-temperature applications.

Each of these alternative materials has its own unique advantages and disadvantages, and the best choice for a particular application will depend on factors such as load capacity, operating temperature, and environmental conditions.

Well-designed, reliable, quality-bearing bushing solutions

“Viiplus’ quality standards and expectations are very high because we operate in challenging markets that require well-designed, reliable, quality solutions.” It doesn’t matter where you go.While there may be differences in customer service, sales, and vendor interaction, the standards for quality are very consistent.

PTFE (Polytetrafluoroethylene) bushings are a type of self-lubricating bearing made of a metal shell with a PTFE lining. They are used in a variety of industrial and mechanical applications where low friction and high wear resistance are required.

The metal shell of a PTFE bushing provides support and rigidity, while the PTFE lining provides a low-friction surface that reduces wear and tear on moving parts. The PTFE material has a very low coefficient of friction, meaning that it requires very little lubrication to operate smoothly. This makes PTFE bushings ideal for use in applications where traditional lubrication methods are not practical or where a clean, lubricant-free environment is required. PTFE bushings are also resistant to a wide range of chemicals and high temperatures, making them suitable for use in harsh operating environments. They are commonly used in applications such as automotive suspension systems, robotics, and medical equipment.

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Browse Custom Bearings

Browse, get a quote and order products easily in Maintenance-free, self-lubricating eCatalog

Cost-effective,Browse Custom Bearings. Discuss your project with a bushing bearings expert. Providing high-performance bushing parts for your application. Along with our standard PTFE plain bearings and bushings, custom bushing are produced daily. We manufactures the exact sleeve bearing, or bushing, that you need at a low cost.

Custom Part Services

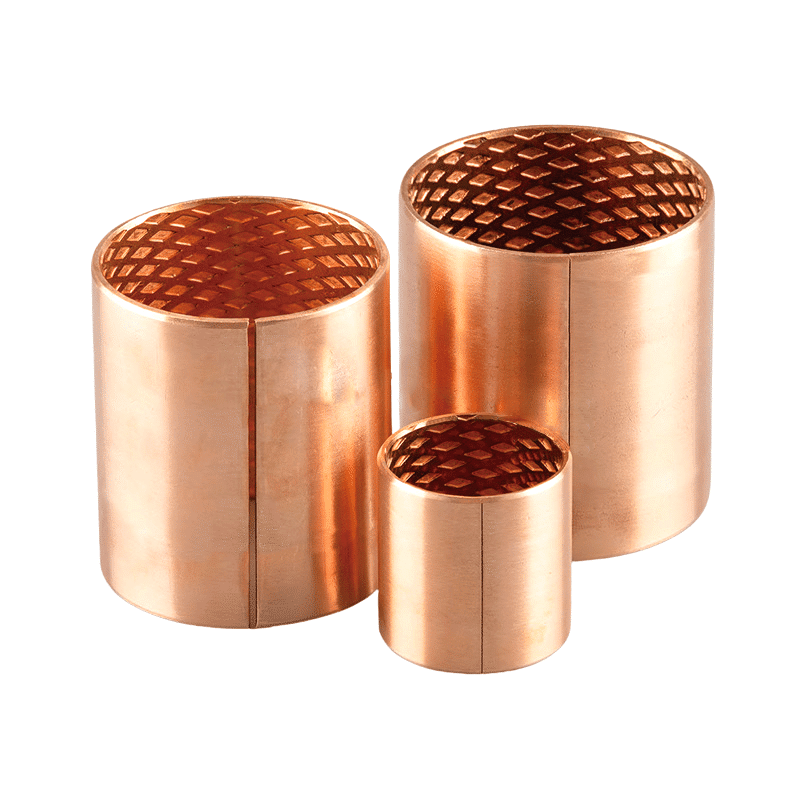

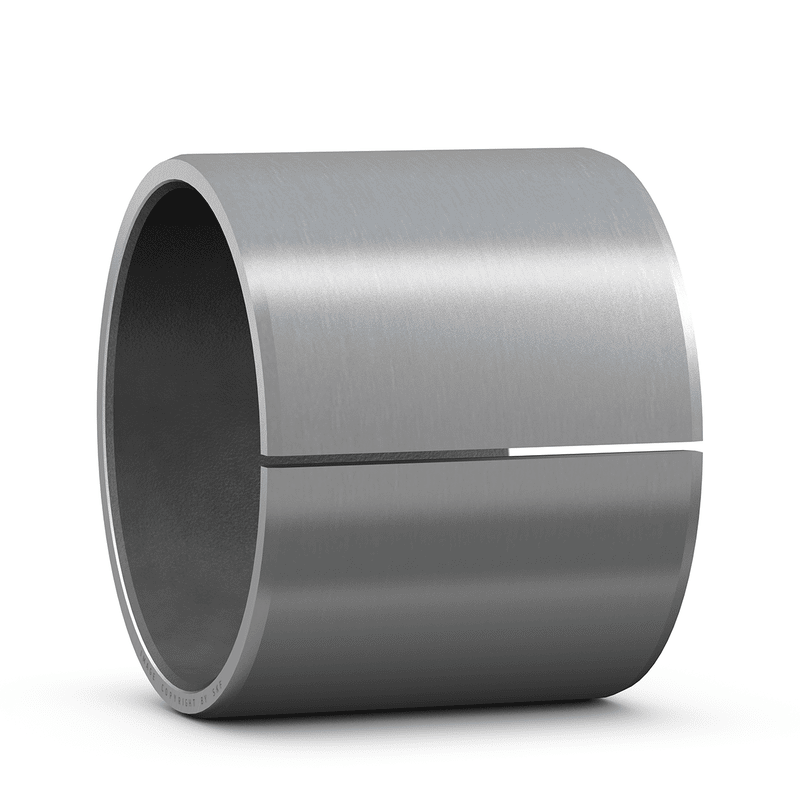

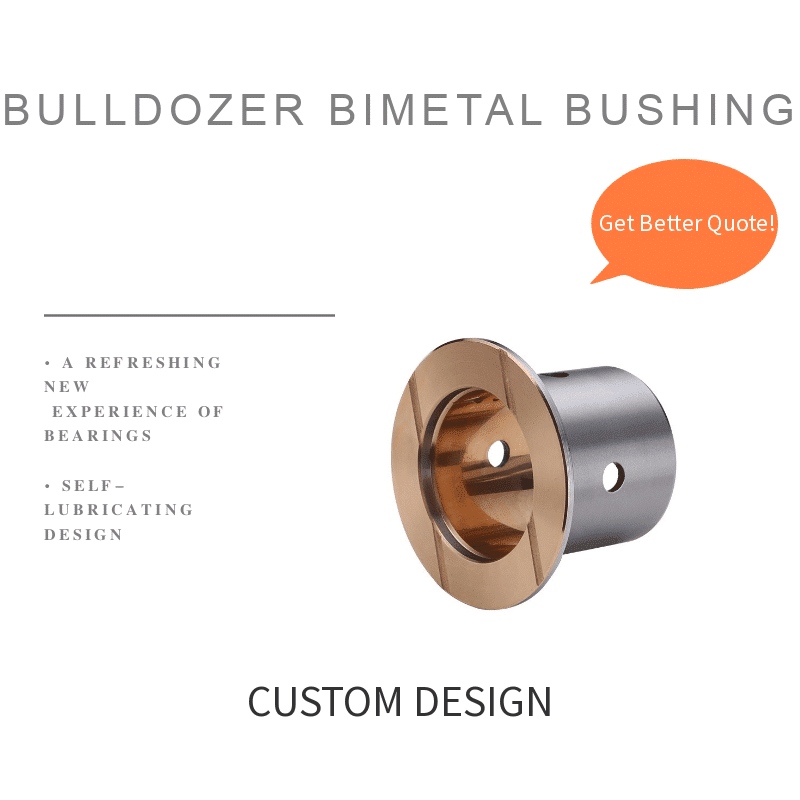

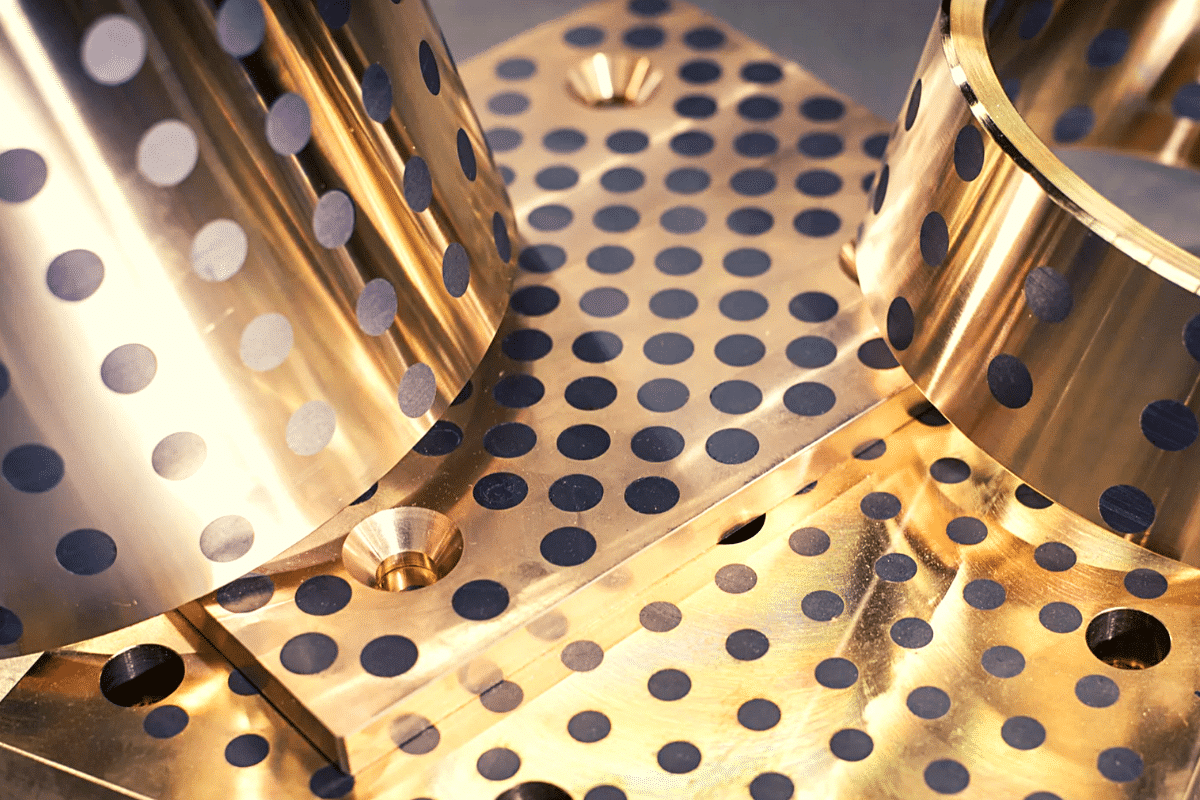

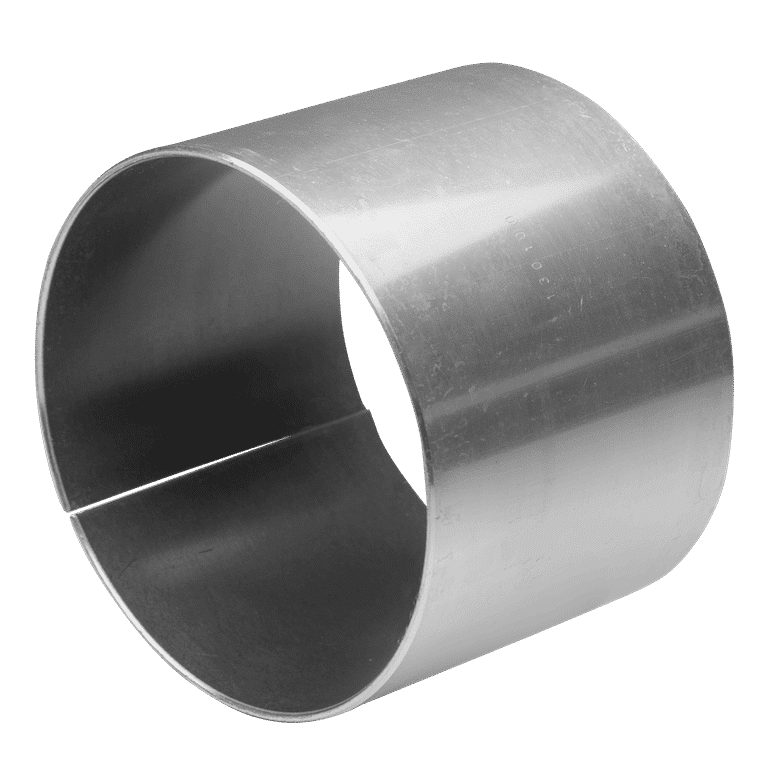

A bimetal bearing is one of the oil-free lubricating bearings

Buy Online and Get Free Delivery

We offer a portfolio of quality bushings & bearings designed to improve the reliability and efficiency of industry that keep industry in motion.

Viiplus is a global bearing leader with a growing portfolio of bushings & bearings. With more than a century of knowledge and innovation, we continuously improve the reliability and efficiency of global industries to move the world forward.

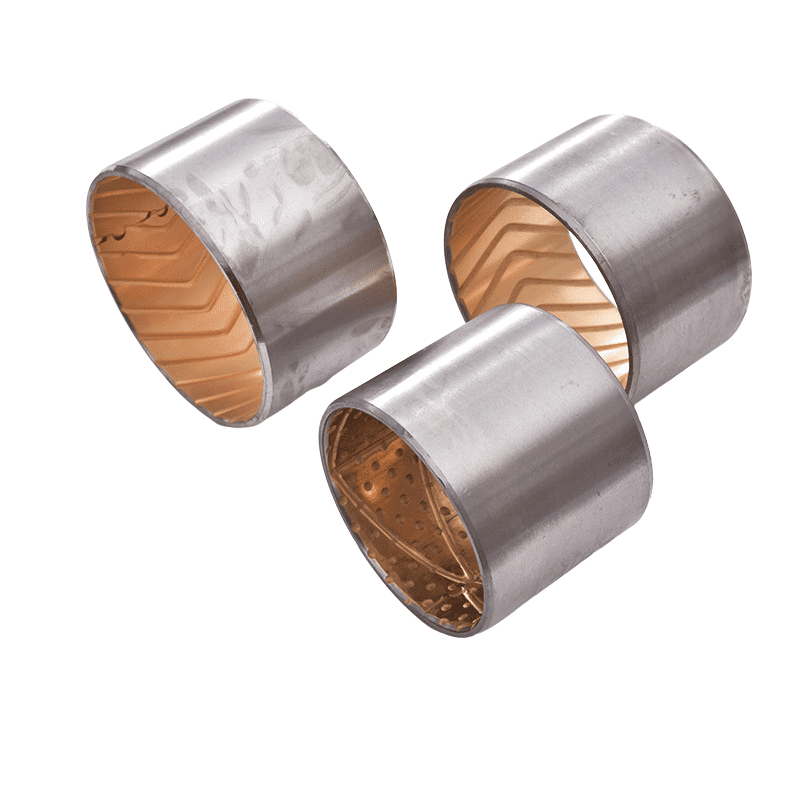

Lightest & Hardest Bimetal Bearings In The Industry

The product is based on a high quality low carbon steel backing and the surface is sintered with an alloy of lead, tin and bronze. After high temperature sintering and thick rolling several times, it is a bimetal integrated with copper and steel. The strip is rolled and suitable for a variety of applications such as bushings and thrust washers capable of withstanding medium speeds and high shock loads.

Such bearings have the advantages of good wear resistance. Especially suitable for medium-speed, medium-load, and low-speed and high-load occasions. Thanks to special technology, various oil grooves, oil pockets and oil holes can be machined on the friction surface in order to adapt to use under different lubrication conditions. Products are widely used in automotive engines, chassis, motorcycle clutches, gear pump wipers, and hoists.

The bimetal ring is lined with high quality low carbon steel with a tin-lead-bronze alloy (CuSn10Pb10) sintered on its surface. To effectively reduce abrasion, its alloy surface can be machined with ball-shaped oil rings for easier oil storage. If required, it can be copper or tinned on the steel back. It can be applied at intermediate load conditions with medium or high travel speed and conditions with huge impact load. In mechanical applications, the bimetallic bush is used to make wrapped bushings, thrust washers and bushings at the gas engine connecting rod.

Bimetal Bushings & Bearings

Self-Lubricating Graphite Plugged Bronze Sleeve Bushings Now Available Online

For heavy loads and shock loading conditions, bimetal bearings have anti-corrosion capabilities and are easy to install, making them ideal for emergency replacements.

Bimetallic bearings can be fabricated with a thicker lead bronze coating for applications where the bearing needs to be machined after assembly. The material of the layer can be adapted to the particular needs of the application in question.

Driving the Future of Global Bearing

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Custom Part Services

manufacturer of bronze and self lubricating bronze parts

Maintenance-free plain bearings bushing

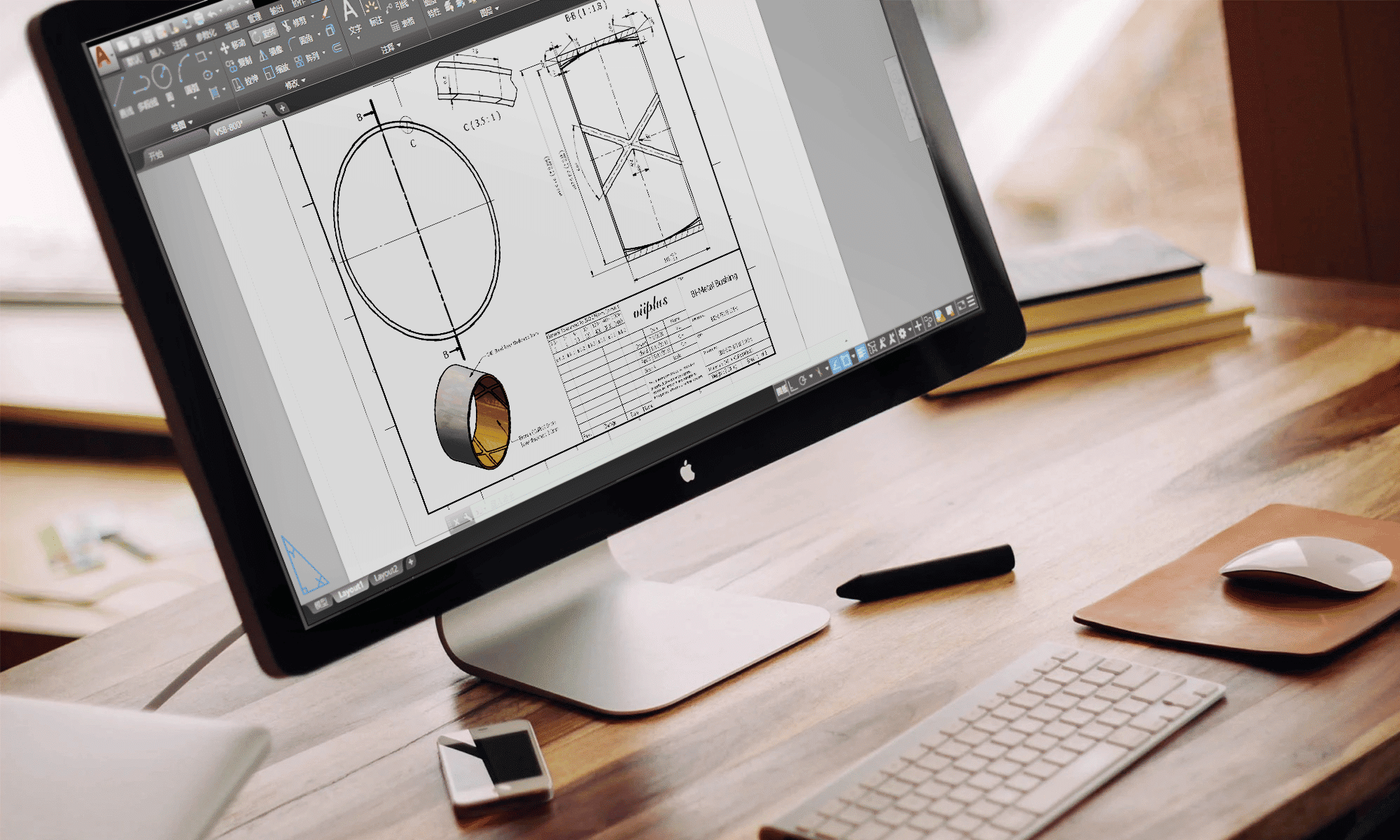

We have manufactured bushings, plates and other bronze pieces according to drawings, offering our services to clients worldwide.

Self Lubricating Bronze Bearings Which Are Maintenance Free Due To Them Being Manufactured Incorporating Solid Lubricant Materials Such As Graphite Inserts.

Team up with us to transform your bearings

We machine self lubricating bronze bearings according to clients’ drawings.

The graphite plugged bushings are especially suited for applications where it is difficult to carry out manual lubrication or where oil or grease lubricants cannot be used. They offer excellent lubrication in heavy load and low speed conditions.

The graphite plugged bushings base material is always bronze or high tensile brass.

Oilless Bushes Design

Self-Lubricating Graphite Plugged Bronze Sleeve Bushings Now Available Online

A graphite bushing is a type of bearing in the form of a straight or flanged tube for sliding applications.

- Manual lubrication not required

- Maintenance free

- Applications where it is difficult to add oil / grease lubricants

- Heavy loads and low speed

Quick specialty bronze bushings manufacturing solutions

The Graphite plugged bushings are made of strong cast bronze based metal with special solid lubricants embedded.

- May work without oil for long periods

- Extremely high load capacity, with good anti-wear and lower friction

- Particularly appropriate for low speed and high load

- Suitable for reciprocating, oscillation, or Intermittent motion where an oil film is hard to form

- Good chemical resistant and anti-corrosion characteristics

- Can be used in wide range of temperature from -40°c~+300°c

Search Your Graphite Plugged Bushings By Size

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Custom Part Services

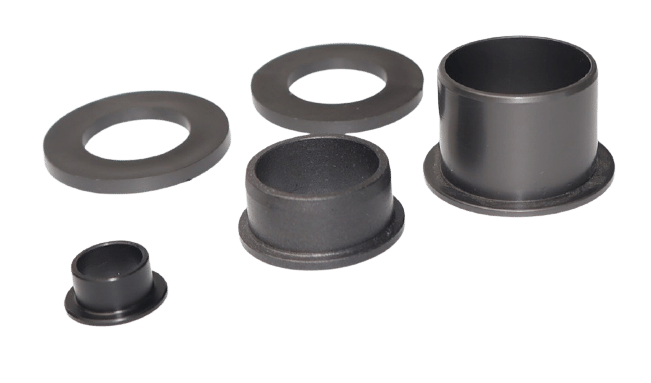

Plastic plain bearing, plastic linear bearing, plastic joint bearing, plastic deep groove ball bearing

Maintenance-free plain bearings bushing

Viiplus offers a growing portfolio of plastic bearings products and services to keep industries moving efficiently and reliably. We bring to life know-how and innovation, providing true marketplace advantage.

Team up with us to transform your bearings

We are specialized in bearing industry for many years and have rich experience.

Discover new bearing business models, explore opportunities for efficient maintenance and find information about remanufacturing and customization of your plastic bearings.

Precision plastic bearings

- Precision plastic bearings are better than traditional plastic bearings in terms of precision, roughness and tolerance.

- The steel materials used in precision plastic bearings, injection molding equipment, process flow and tasting standards are fully European standards, and every process is well controlled.

- On the basis of maintaining some of the traditional advantages of plastic bearings, it can be applied to some extreme conditions such as precision, high-speed operation, cold resistance and high temperature.

Corrosion resistant plastic bearings

Corrosion-resistant plastic bearings have a variety of material solutions for those different application conditions, even in the most severe acid/alkali/salt/solvent/oil/gas/seawater erosion can still run freely to ensure ideal durability Sex and life expectancy.

Acid and alkali resistant plastic bearings

Acid and alkali resistant plastic bearings, HDPE, PE, UHMWPE and other materials have proven to be used in relatively weak acid-base cross-environment (30% CuCl2 solution and 30% NaOH solution test OK), and can be used in strong acid and strong alkali environments PVDF and PTFE materials. Of these materials, PTFE can be used in all concentrated acid and alkali situations, even in strong acid environments such as HF and fuming sulfuric acid and nitric acid (above 98%).

Plastic bearing seat and plastic outer spherical bearing

Plastic seated bearings have properties that other plastic bearings do not have, such as light weight, easy installation, corrosion resistance, maintenance-free, etc., and they also have the unique performance of vibration reduction and impact resistance that commonly used cast iron seats or stamping seats do not have.

Plastic bearing selection

With the continuous development of various new plastic materials, this type of bearing is increasingly being used in various projects.

Engineering plastic bearings have the following advantages over metal bearings:

- Lubricating material, long service life

- Sliding bearings will not rust and are resistant to corrosion during use, while metal bearings are easy to rust and cannot be used in chemical liquids;

- Sliding bearings are lighter than metal, which is more suitable for modern lightweight design trends;

- The manufacturing cost of plastic sliding bearings is lower than that of metal;

- Plastic bearings are processed by injection molding and are more suitable for mass production;

- Plastic sliding bearings have no noise during operation and have a certain vibration absorption function;

- Plastic sliding bearings are suitable for high and low temperature work -200~+250 degrees;

Select your plastic bearings to meet your requirements

The plastic bearings currently used can generally be divided into plastic rolling bearings and plastic sliding bearings;

The working principle of plastic rolling bearing and plastic sliding bearing can be distinguished by the name. The friction that occurs when plastic rolling bearing is working is rolling friction, and what occurs when plastic sliding bearing is working is sliding friction;

The size of the rolling friction mainly depends on the manufacturing accuracy;

The friction of plastic sliding bearings mainly depends on the material of the sliding surface of the bearing.

Help you find the right bearings solution for your specific application.

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Custom Part Services

sleeve bearing with flange, mm

Maintenance-free plain bearings bushing

Lowering costs and increasing service life without lubrication and reducing maintenance work – everything is delivered immediately from stock – that is the core idea and goal of all polymer plain bearings

Selecting the right sliding bearing for the equipment and application is essential to the successful operation of that equipment.

- Cost factors

Cost reduction is very important to most companies.Whether low-cost shaft materials can be used depends on the choice of bearings.

For example, ball bearings require very hard (60HRC or higher) and smooth shafts.Bronze bearings are similar: the shaft must be harder than the bronze material used.Because of these requirements, the choice of axes is very limited.Cheaper shaft materials may not be suitable for these applications.

Plastic bushings offer more options as they can be matched with many different shafts.

Plain bearings can be made of many materials:

So you can use the lowest cost shaft to match the bearing material most suitable for the application and/or the required service life.The service life of bearings and shafts only needs to be as long as the service life of the entire machine/equipment.

Driving the Future of Plain Bearings

Our growing portfolio of plain bearings & bushings is designed to meet our global customers’ evolving needs.

Bushings Quality and environmental respect are essential to our core values

- Abrasive resistance

In addition to cost factors, there are many other factors to consider when designing shafts for bearing systems.If not considered, many factors will affect the performance of bearings.If the shaft is too rough, wear will be a problem.A shaft that is too rough will act like a file to scrape small particles off the bearing surface during movement.If the shaft is too smooth, the bearing and shaft may stick together, resulting in increased friction.Stick-slip (characterized by a large shrill noise) can become a problem if static and dynamic friction are very different and there is adhesion on the mating surface

Another important factor to consider is how hard and soft particles can damage bearings and shafts.If particles enter the bearing and its mating surface, both will be damaged due to increased wear.Dirt, dust and paper fibers can cause problems.Bearings that lubricate themselves by embedding a solid lubricant last longer in dirt because there is no grease or lubricating oil in the bearing.This means that dirt particles do not enter or stick to the shafts and bearings (for example, you can look at a bicycle chain with a lot of lubrication).You can also use cheaper shafts, even in dirty applications.There are many shaft materials on the market, each of which will have a different impact on the wear of bearings.Shaft materials include aluminum, surface hardened steel, stainless steel and chrome-plated steel.Finally, service conditions and service life requirements will determine the shaft to be used.When selecting the appropriate sliding bearing, basically any standard type of shaft can be used.

Bearing shaft selection

Keeping the Bearing in Motion

Polymer plain bearings are available in three forms, sleeve bearings, flanged bearings and thrust washers.

Advancing Our Position as a Global Bearing Leader

We offer bushing & bearing of quality designed to improve the reliability and efficiency of industrial equipment and machinery that keep industry in motion.

Explore more plain bearings to meet your requirements

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Custom Part Services

Reliable & Professional Plain Bearing Solution Supplier

Variety Plastic Plain Bearings Online

Viiplus provides a variety of self-lubricating plastic sliding bearings made from modified engineering plastics to meet a variety of customer needs.At the same time according to the actual production needs of customers to provide different colors, performance, economic.

The plastic plain bearing improve the reliability of machinery, reduce costs and environmental protection.

Negative lubrication and light weight

- Plastic bearings are all lubricating materials with long service life;

- Plastic bearings will not rust in use and are corrosion resistant, while metal bearings are easy to rust and can not be used in chemical liquids;

- The quality of the plastic bearing is lighter than the metal, which is more suitable for the modern lightweight design trend;

- The manufacturing cost of plastic bearings is lower than that of metals;Plastic bearings are made of injection molding, which is more suitable for mass production.

- Plastic bearings in operation without any noise, with a certain vibration absorption function;

- Plastic sliding bearing suitable for high and low temperature work -200 ~ +250 degrees;

Environmentally-friendly plastic bushing

VIIPLUS plastic bearings do not require any lubricating oil or grease, so they do not pollute the environment.

Bushings Quality and environmental respect are essential to our core values

Here are four reasons to use environmentally friendly plastic bushings:

- Plastic bushings do not require lubrication, which makes the environment cleaner. Thanks to the continual advances in tribology-optimized plastic sleeve technology, Viiplus is able to provide alternative metal sleeves that are more environmentally compliant for an increasing number of applications. Unlike metal or bronze bearings that require sloppy lubrication, each plastic bushing uses solid lubricants embedded in millions of tiny chambers that cannot be squeezed out. This means that the bushings do not require oil or grease, so no pollutants are released into the environment.

- The plastic bushings are extremely light, which helps reduce fuel consumption and carbon dioxide production. The reduced weight leads to lower masses and consequently to lower energy consumption.

- An additional positive ecological aspect is the high chemical resistance of the plastic sleeve. To achieve this effect, metals often have to be coated with an environmentally unfriendly, high-energy zinc bath.

- Less energy is required to produce a plastic bushing compared to a metal bearing.

Environmentally-friendly

All new plastic bushings finder for bearing online

The use of dry-running plastic bushings can significantly reduce the negative impact on the environment.

Environmentally friendly for many years

Choose from our selection of plastic bushings bearing in a wide range of styles and sizes. In stock and ready to ship.

Select the correct plastic plain bearings to meet your requirements

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Saves You Time & Money In Self-lubricating Bearings Research, Design & Production Costs.

Custom Part Services

Reliable & Professional Plain Bearing Solution Supplier

Bushings and Plain Bearings – Mounting

Skill and care in assembly are prerequisites for a long bearing life. In addition, cleaning and understanding the causes of premature bearing failure can also help.

Check that the support surface (shaft seat) and other components, such as the housing, are clean, deburred and do not contain abrasive particles. Also check the shaft for sharp edges, burrs or surface defects, which can damage the sliding surface of the bushings. After cleaning and checking all components, the bushing is ready to be installed.

Low-maintenance and maintenance-free plain bearings

Long-Lasting, Low-Wear Sliding

One of the factor that have influence on reliable work of bearing and its life is properly conducted mounting process.

Before a bearing is ready to be mounted, should confirm:

- Housing and shaft are clean, undamaged, and dimensionally accurate

- Lubricant is clean and correctly specified

- Necessary tools and equipment are on hand

- Proper safety precautions are in place

Before starting the installation, check the bearing seats and stops, remove any damage from the surfaces of the seats and, if necessary, clean it with Antikor kerosene. As a rule, new bearings should not be washed, but in the case of used bearings, they can also be cleaned with Anticor kerosene. Before installing the bearings, the seats and stops should be lightly greased with oil or grease to facilitate assembly and protect surfaces from corrosion.

High performance self-lubricating bearings

Self-Lubricating Sliding Material, Factory Price, Contact Us!

Reliable, Cost-efficient Bushing & Bearing Solution

Plain Bearing Mounting Press-In Force And Joint Pressure

Press-in force and joint pressure are interdependent. The connection pressure occurs between the housing bore and the surface of the socket jacket. It can be understood as a measure of how secure the socket is in the housing. Joint pressure, along with other factors, affects the insertion force.

Design and layout of bearing assembly: housing

The bushings are pressed into the housing and fixed radially and axially. No further action is necessary.

Calibrating the bearing bore after mounting

Plain bearings are ready for installation on delivery and should only be calibrated if the tighter tolerance cannot otherwise be achieved.

Bearing Mounting

First & most reliable self-lubricating bearings

To install bushings, with or without flange, Viiplus recommends using an assembly trolley with the respective shaft tolerance in particular for:

Explore more bearing mounting method

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Custom Part Services

Self-lubricating, maintenance-free plain bearings

Bearing design, Selection support

Application performance can be improved by eliminating lubricants as many greased and oiled bearings fail prematurely due to inadequate lubrication and lack of regular or improper maintenance. Work with Viiplus and get the performance you need for your application without expensive lubrication systems and lubricants.

Due to the special structure of the materials, which usually consist of a thermoplastic matrix, fiber reinforcements and the so-called solid lubricants … the already good wear and friction properties of the matrix or the base material are further optimized by the solid lubricants. Sufficient solid lubricant particles are always present on the bearing surface during operation. Additional external lubrication with grease or oil is usually neither necessary nor practical.

Specializes in a variety of bearing manufacturing delivering bearings critical solutions to our customers.

Superior quality, excellent reliability and high performance

These PTFE plain bearing materials enable extremely low coefficients of friction for plain bearings and rod ends as well as bushings, washers and strips while ensuring low wear and very long life cycles.

Maintenance-free plain bearings significantly reduce lubrication and maintenance costs as they require no oil or grease and are also very environmentally friendly.

Custom self-lubricating bearings products are also available

Viiplus are the leading bearing specialists and distributors for many industry leading manufacturers. We offer genuine, high quality bearings, backed by a full manufacturer’s warranty.

Self-lubricating bearings, as the name suggests, provide their own lubrication during operation without requiring the application of grease or lubricating oil.

Here are some of the reasons and benefits when lubricants are eliminated

- Periods of regular maintenance for relubrication can reduce operating efficiency which increases TCO (Total Cost of Ownership) due to stoppage and downtime of the machine

- Potential harm to the bearings leading to premature equipment failure can be caused by using an incorrect lubricant or topping up with an incompatible lubricant

- Additional costs are incurred due to machining of grease paths or oil ways in the shaft or housing, as well as the expensive sealing systems needed to retain the lubricants

- Additional savings result from the elimination of lubricants and lubrication systems, as the costs for lubricants can rise quickly and the overall costs for maintenance and project construction increase

- Improve machine efficiency by eliminating the loss of power due to surface contact of lubricating seals with the shaft

- Better for the environment due to the risk of soil contamination from relubrication or oil changes in the field – the environmental aspect should be emphasized

Bearing Lubrication Free

Plain Bearing Design and Service Life

Self-lubricating bearings are also referred to as maintenance-free or grease-free bearings because they do not require relubrication or lubrication. An example of a self-lubricating bearing is our grease-free bearing.

Welcome to bronzelube.com

Compared with normal plain bearings, our bearing are superior in wear resistance, seizure resistance and friction properties, and realize performance enhancement and maintenance-free devices.

Providing Customized Self-lubricating Bearings Solutions For Many Years

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Custom Part Services

Bearing Materials – Chrome Steels, Stainless Steels, and Plastics

Bushings Designs One Bearing at a Time

Plain Bearing (sliding bearing), sliding friction in the work of the bearing. Sliding bearings work smoothly, reliably and noiseless. Under the condition of liquid lubrication, the sliding surface is separated from the lubricating oil without direct contact, which can greatly reduce the friction loss and surface wear, and the oil film also has a certain vibration absorption ability. But the starting friction resistance is larger. The part of the shaft supported by the bearing is called the journal, and the parts matching the journal are called the bearing bush. In order to improve the friction properties of the surface of the bearing bush, the friction reducing material layer cast on its inner surface is called the bearing lining. The materials of bearing bush and bearing lining are collectively referred to as sliding bearing materials. Plain bearings are generally used in high speed and light load conditions.

The main features Sliding bearing

Common sliding bearing materials are bearing alloy (also known as Babbitt alloy or white alloy), wear-resistant cast iron, copper and aluminum based alloy, powder metallurgy materials, plastics, rubber, hardwood and carbon-graphite, polytetrafluoroethylene (Teflon, PTFE), modified polyformaldehyde (POM), etc.

Sliding bearings absorb and transfer the forces between the relative moving parts to maintain the position and positioning accuracy of the two parts. In addition, it is necessary to convert directional motion into rotary motion (such as reciprocating piston engine).

The structure

Sliding friction occurs when sliding bearings work; The size of sliding friction depends mainly on the manufacturing accuracy; The size of sliding bearing friction force mainly depends on the material of the sliding surface of the bearing. Sliding bearings have self-lubricating function in general working face; Sliding bearings are divided into non-metallic sliding bearings and metal sliding bearings according to materials.

Non-metallic sliding bearings are mainly plastic bearings, plastic bearings are generally made of engineering plastics with better performance; More professional manufacturers generally have the engineering plastic self-lubrication modification technology, through fiber, special lubricant, glass beads and so on on the engineering plastic self-lubrication enhancement modification to achieve a certain performance, and then use the modified plastic through injection molding processing into self-lubrication plastic bearings.

The most commonly used metal sliding bearings in the early 21st century are three-layer composite bearings. This kind of bearing is generally based on carbon steel plate. Through sintering technology, a layer of spherical copper powder is sintered on the steel plate first, and then a layer of PTFE lubricant about 0.03mm is sintered on the copper powder layer. The main role of a spherical layer of copper powder in the middle is to enhance the binding strength between the steel plate and PTFE, of course, in the work also plays a certain bearing and lubrication role.

Manufacturing material

1) Metal materials, such as bearing alloy, bronze, aluminum base alloy, zinc base alloy, etc

Bearing alloy: Bearing alloy is also called the white metal, mainly tin, lead, antimony and other metal alloy, because of its good wear resistant, high plasticity, running-in performance is good, good thermal conductivity and good resistance to adhesive and and good and oil adsorption, thus suitable for overloading, high-speed cases, the strength of the bearing alloy is small, the price is more expensive, must be cast in bronze, steel or cast iron shell, Form a thinner coating.

2) Porous metal materials (powder metallurgy materials)

Porous metal material: Porous metal is a kind of powder material, it has porous organization, if it is immersed in lubricating oil, so that the micro hole is filled with lubricating oil, into an oil-bearing, with self-lubricating performance. Porous metal materials have low toughness and are only suitable for stable non-impact load and medium to low speed conditions.

3) Non-metallic materials

Bearing plastics: commonly used bearing plastics include phenolic plastics, nylon, polytetrafluoroethylene, etc., plastic bearings have greater compressive strength and wear resistance, can be lubricated with oil and water, but also have self-lubricating performance, but poor thermal conductivity.

The bearing industry uses different materials for the production of the various bearing components. The bearing materials are processed to achieve desirable properties to maximize bearing performance and life.

The variety of materials has arisen from a commitment to meet the diverse requirements of customers over the past nearly two decades. Making a good bearing material is often associated with a square circle. If you optimize in a certain direction, it is done mainly at the expense of another function.– The vast majority of applications can technically be covered by five standard materials – G, J, X, W300 and M250.

But if it has to do with very special or sophisticated applications, the exhaustion of recent technical reserves, or a recent price / performance optimization for high-volume production, other materials are becoming increasingly important. Over the past few years, the limitations of the use of dry running plain bearings have also changed with the use of new materials.

The bearings must be of the right material and have the proper lubricant to ensure reliability, efficiency, and cost-effectiveness.

Self lubricating Metals Bearing Material, Factory Price, Contact Us!

Product Categories Sliding bearing

There are many kinds of sliding bearings:

According to the direction of the load can be divided into radial (centripetal) sliding bearings and thrust (axial) sliding bearings.

② According to the types of lubricants, they can be divided into seven categories: oil-lubricated bearings, oil-lubricated bearings, water-lubricated bearings, gas-lubricated bearings, solid-lubricated bearings, magnetofluid bearings and electromagnetic bearings.

③ According to the thickness of the lubricating film, it can be divided into thin film lubricated bearings and thick film lubricated bearings.

④ According to the bearing material, it can be divided into bronze bearings, cast iron bearings, plastic bearings, gem bearings, powder metallurgy bearings, self-lubricating bearings and oil-bearing.

⑤ According to the bearing structure, it can be divided into round bearings, elliptical bearings, three oil vane bearings, step surface bearings, tilting tile bearings and foil bearings.

The bearing bush is divided into split and integral structure. In order to improve the friction properties of the bearing bush surface, often in its inner diameter surface casting a layer or two layers of antifriction material, usually known as the bearing lining, so the bearing bush has a bimetal bearing bush and three metal bearing bush.

Bearing bush or bearing lining is an important part of sliding bearing. The material of bearing bush and bearing lining is collectively referred to as bearing material. Because the bearing bush or bearing liner is in direct contact with the journal, the general journal part is more wear-resistant, so the main failure form of the bearing bush is wear.

Bearing wear and journal material, bearing material itself, lubricant and lubrication state is directly related, the selection of bearing material should be considered comprehensively these factors, in order to improve the service life and performance of sliding bearings.

Self-lubricating Bearings Made of Stainless Steels

Stainless steel materials are used to make bearing components as they are more resistant to surface corrosion due to the higher chromium content (~ 18%) with the addition of nickel. Chromium reacts with oxygen to form a layer of chromium oxide on the surface, creating a passive film.