fitness repair bushing parts

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

fitness repair bushing parts

Quality Bushings Manufacturer – Inch, Metric & Custom Sizes

Our Knowledge Extends From Self-lubricating Bearings To Advanced Fitness Repair Bushing Parts Solutions. Ease Of Installation. Custom Design. The Optimal Sliding Bearings For Every Requirement. Maximum Precision. High Quality. Customized Products. Bushing & Bearing Technologies.

Quality bearing online

We are dedicated to helping you maintain your fitness repair bushing parts as cost-effectively as possible.

Industry status:

At present, the mechanical joint parts of fitness equipment are made of metal materials such as rolling bearings and copper sleeves, which are complicated in structure and do not meet the requirements of low-cost and lightweight trend. Regular filling of lubricating oil or grease may cause leakage and pollute the environment, resulting in high maintenance costs.

New Repair Bushing Parts For Your Fitness Equipment

Order self-lubricating bushings online

Team up with us to transform your bearing business

● Standard material of sliding layer: high wear-resisting and low starting friction material can be selected

● The shell material is aluminum alloy, stainless steel is optional

● Self-lubrication, maintenance free

● Smooth operation, no noise

● High speed operation, long life

● Operating temperature ±200℃

● Suitable for rotation, swing and linear motion

Great customer support and skilled advice. We love to help you!

Choose your proper bearings from our selection of self-lubricating bushings.

Professional manufacturer of fitness repair bushing parts

Viiplus brand stands for premium quality bearings products and services, from product design, fabrication, engineering support and sales. Our highest commitment is to provide the highest quality, innovative, environment friendly bearing products, high level of services for various specific application.

Worldwide shipping

Self-Lubricating, Low Maintenance, Light Weight, Low Noise, Environmental Protection

Viiplus Self-lubricating Bearings Technology Solutions

Start with a bearing, make fitness a kind of enjoyment!

Low noise, low maintenance, self – lubricating

Fitness equipment such as long-term use of products, in order to maintain the sense of use and prolong the service life of equipment also need regular maintenance, can enhance the safety and stability in the use of equipment.

For example, after long-term use of the treadmill, the running belt and the running board friction for a long time, damage is inevitable, good lubrication will play a vital role in the maintenance of equipment.

It is important to choose a low-noise, low-maintenance, self-lubricating fitness equipment.

This has to say that most of the fitness equipment in the production process to use a component – bearing, although it is very humble, and even often ignored by us, but it is indispensable.

For example, the sliding and rotating parts of the combination of fitness equipment such as swivel chair adjusting mechanism, treadmill, rowing machine, and the position of the seat adjustment height of the fitness bike will use bearings.

Stronger. By Design.

Strength, knowledge, perseverance and skills honed over 10 years of hard work.

Prototype Services

Building components for your evaluation.

The following are the bearings that can be used in fitness equipment. They are not only simple and convenient to install, but also free of lubrication, so that professional fitness equipment can ensure its excellent reliability, lightness, quiet and soft movement in the continuous use and operation of high intensity…

Fitness Repair Bushing Parts PTFE Composite Bushings

Material organization

1. The mixture of PTFE and fiber is 0.01~0.03mm, which can form a good layer of transfer film to protect the pair and provide the self-lubricating performance of the bearing.

2. Copper powder layer 0.20~0.35mm, with good bearing capacity and wear resistance, good thermal conductivity can timely transfer the heat generated in the process of bearing operation.The composite material penetrates into the pore of spherical copper powder, which improves the bonding strength.

3. Low carbon steel, provides a good bearing capacity and heat transfer.

Application characteristics

It is suitable for the working parts that can not be refueled or difficult to be refueled. It has good wear resistance, low friction coefficient, good walking performance, low noise, no pollution and good corrosion resistance.The transfer film formed in operation can protect the grinding shaft, and there is no phenomenon of biting shaft.The processing requirements of dual parts are reduced, which reduces the processing cost of users.It is widely used in general industry.

Aluminum Alloy With PTFE Tape Bushing

Material structure

1. PTFE mixture soft belt provides the self-lubricating characteristics of the bearing.

2. Aluminum alloy substrate provides better bearing performance and corrosion resistance of bearings.

Application characteristics

The design of thicker working layer can be used for reshaping after assembly to improve the fitting accuracy. The surface working layer has better wear resistance, self-lubricating properties and damping and noise reduction, while the aluminum alloy substrate can meet the requirements of lightweight design and has excellent corrosion resistance.

High Performance, Quality, Oil-free and Maintenance-free Bearings for Various industries.

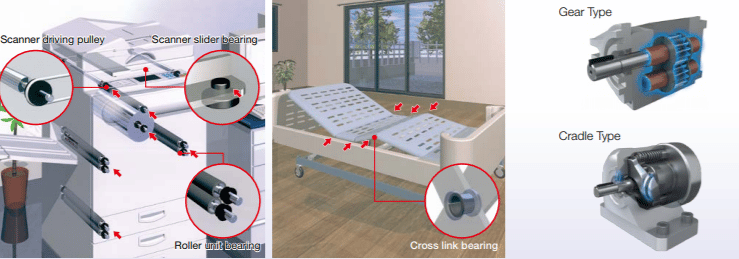

Self-lubricating bearings provide relief and safety in close relation to social infrastructure. They also contribute to realization of smart cities and environmentally-friendly future cities through their applications to various energy devices.

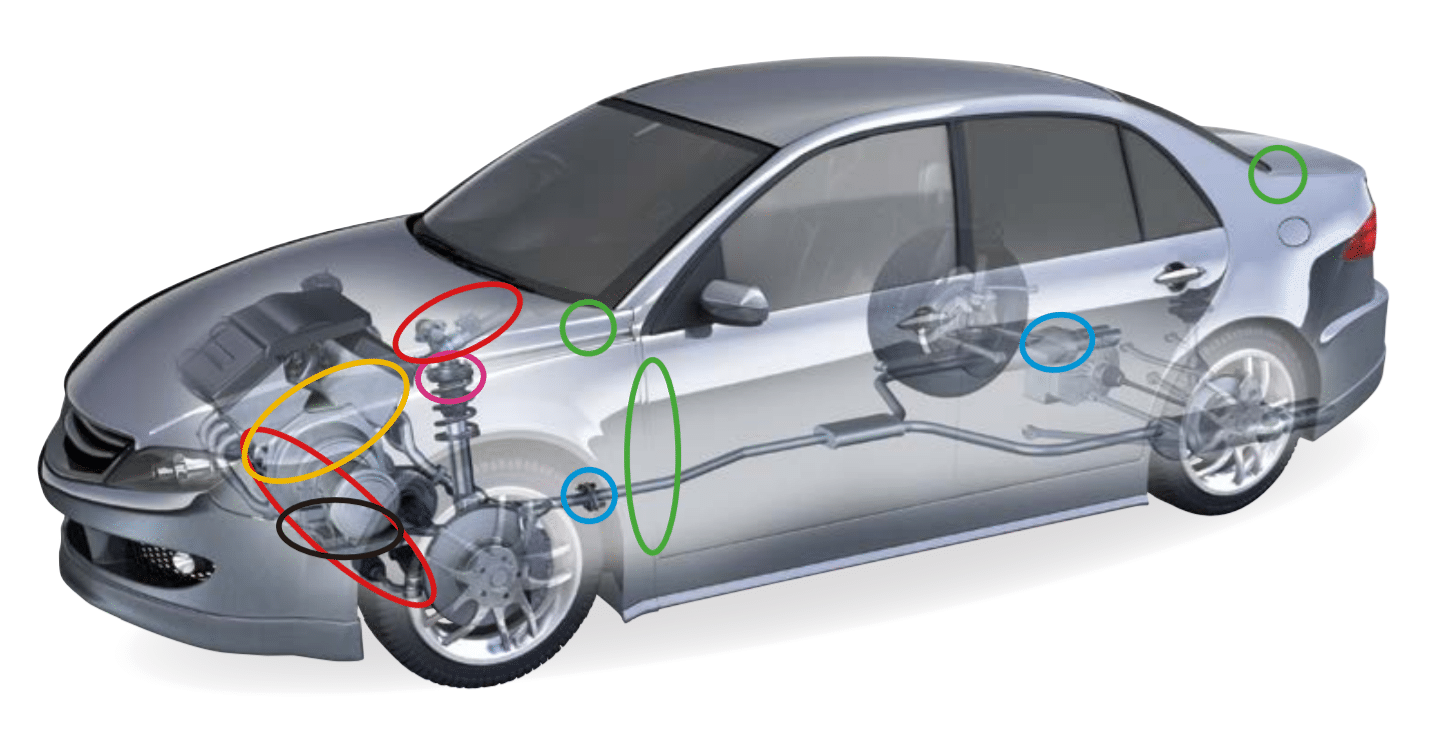

Automotive Bushings

Self-lubricating bearings are excellent in the automotive industry and enable vehicles to advance technological advances with their high durability. Self-lubricating bearings can improve quietness, driving comfort and provide smooth steering through adequate friction.

Hydro Power

Viiplus is experienced in the hydro power industry.The number of customers who chooses and continues apply to oilles bearings, is increasing.

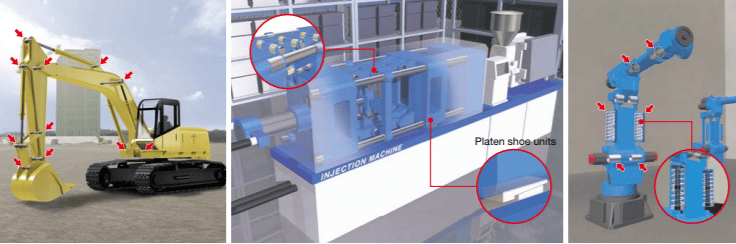

Excavators, Injection molding machines, Industrial robots, Care beds, Hydraulic pump

Join Over 500,000 Customer Enjoying Buying Self-lubricating Parts Now

Always tested. Always proven. Always VIIPLUS.com

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.