Machined Problem Meets the Bushings Solutions

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Machined Problem Meets the Bushings Solutions

Custom Design

Self-lubricating Bronze BushingOnline sales

Shop machine bushings and a variety of bronze bushings & bearings products online at www.bronzelube.com.

We offers a complete line of cast bronze bearings and slide plates. Cast bronze sleeve bearings, flange bearings, and custom parts are available with oil grooves or grease grooves. Maintenance-free self-lubricating bronze bearings with graphite filled grooves or graphite plugs are available.

Bushing Selection

Machine Spare Parts at Best Price – Bronze Bushings Online

Online source for bronze bushings.

Bushings, Bearings, Thrust Washers in various sizes. These products satisfy most applications and may be resized, oil grooved, or graphited for special needs.

Custom Machine Bushings & Part Manufacturing Service to Your Exact Specification. Quote Now!

Bearings Bushing – Official Website

Beautifully crafted leather products.

Type of self-lubricated Bushing, Made in china, Stepping forward together with our customers, Technologies for top performance! Large selection, low prices, volume discounts, fast service. Our buyer can get from us a wide range of Machine Bushings which is available in varied sizes, dimensions and surface finishing. Dedicated team of experts provides innovative, reliable and effective solutions. bushing bearings comply with increasingly stricter environmental legislation. Resistant to corrosion. Space & weight savings. Increased durability. “Innovation takes Practice for Superior Level of Excellence .” Self-Lubricating Sliding Material, Factory Price, Contact Us.

Bearings – Global Bushing Manufacturer

Beautifully crafted leather products.

produces the most ample range in the bearings industry with local technical support. Customer Support. Reduced costs. Lightweight & compact. Operating silently. Increased durability. High energy efficiency. Higher load capacity.

Dedicated team of experts provides innovative, reliable and effective solutions. Lead-free bearings comply with increasingly stricter environmental legislation. Operating silently. Lightweight & compact. Space and weight savings.

We machined bushing tailored to your needs.

What is a Machined Bushing?

A machined bushing is a cylindrical component that is used to provide support, reduce friction, and absorb shock in mechanical systems. It is typically made from metal or plastic and is machined to precise specifications to ensure a proper fit and function within the system.

Machined bushings can be used in a wide range of applications, such as automotive engines, aerospace components, industrial machinery, and consumer products. They are designed to withstand high loads and can be made from materials that can resist wear, corrosion, and other forms of damage.

Machined bushings can be produced using a variety of manufacturing techniques, such as turning, milling, drilling, and grinding. They can also be designed to include features such as lubrication grooves, flanges, and mounting holes, depending on the specific requirements of the application.

What Materials are Machined Bushings Made of?

Machined bushings can be made from a variety of materials, depending on the specific requirements of the application. Some of the most common materials used to manufacture machined bushings include:

Steel: Steel is a popular choice for machined bushings because it is strong, durable, and can withstand high loads. It is also relatively inexpensive compared to other materials.

Bronze: Bronze is a material that is often used in bushings because it has good wear resistance and can be self-lubricating. This means that it can reduce friction and wear in the system.

Brass: Brass is a corrosion-resistant material that is often used in bushings for marine and other corrosive environments.

Plastic: Plastic bushings can be made from materials such as nylon, acetal, or polyurethane. They are often used in applications where low friction and noise are important.

Aluminum: Aluminum is a lightweight material that is often used in bushings for aerospace and other weight-sensitive applications.

Other materials such as self-lubricating, and dry sliding bearings can also be used to manufacture machined bushings, depending on the specific requirements of the application.

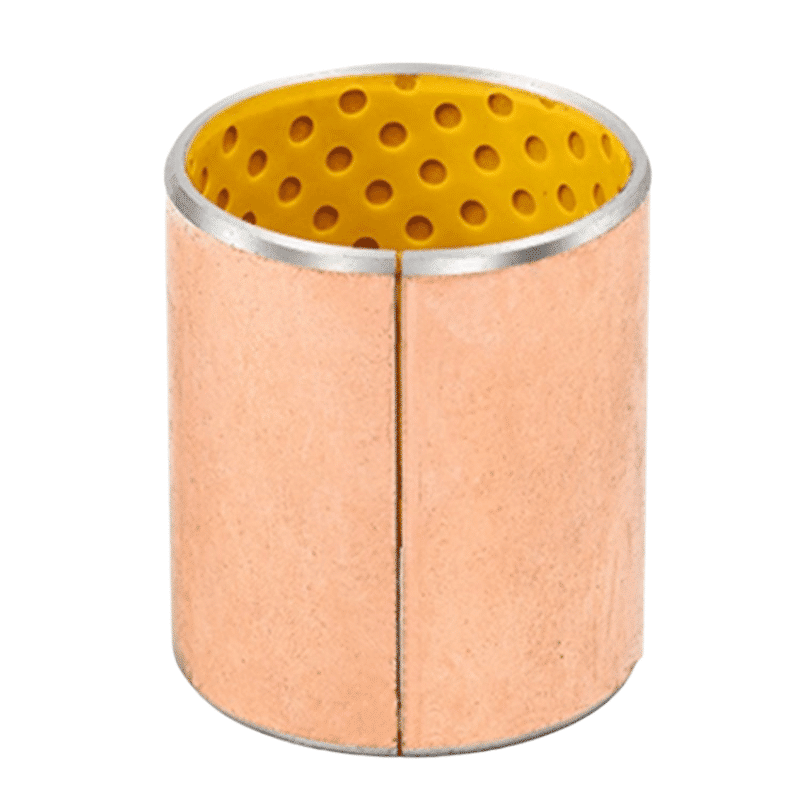

Machined Bronze Bushings

Machined bronze bushings are cylindrical components made from bronze that are machined to precise specifications to provide support, reduce friction, and absorb shock in mechanical systems. Bronze is a popular material for bushings because it has good wear resistance, high load-carrying capacity, and can be self-lubricating.

Machined bronze bushings can be produced using a variety of manufacturing techniques, such as turning, milling, drilling, and grinding. They can be designed to include features such as lubrication grooves, flanges, and mounting holes, depending on the specific requirements of the application.

Bronze bushings are often used in applications where a metal-to-metal contact would cause excessive wear and tear or noise. They can be self-lubricating, which means that they can reduce friction and wear in the system without requiring external lubrication. Machined bronze bushings are commonly used in industrial machinery, automotive engines, agricultural equipment, and other heavy-duty applications. They are also used in consumer products such as appliances, furniture, and sporting goods.

Advantages of Custom Machined Bronze Bushings

Custom machined bronze bushings offer a number of advantages over off-the-shelf or standard bushings. Some of the advantages of custom machined bronze bushings include:

Precise fit: Custom machined bronze bushings can be made to exact specifications to ensure a precise fit within the mechanical system. This can reduce the risk of wear, vibration, and noise.

Customized features: Custom machined bronze bushings can be designed to include specific features such as lubrication grooves, flanges, and mounting holes to meet the specific requirements of the application.

Increased durability: Custom machined bronze bushings can be made from high-quality materials and with special treatments to increase their durability and resistance to wear, corrosion, and other forms of damage.

Enhanced performance: Custom machined bronze bushings can be optimized for performance by selecting the right material, size, and shape for the application. This can result in improved efficiency, reduced energy consumption, and longer service life.

Cost-effective: Custom machined bronze bushings can be more cost-effective in the long run because they are designed to meet the specific requirements of the application, which can reduce the risk of costly repairs, downtime, and replacement.

Overall, custom machined bronze bushings can provide a more reliable, efficient, and cost-effective solution for a wide range of mechanical applications.

Regenerate response

Machined Self-lubricating Bushings, Custom Machined Bushing Manufacturer in China

Machined self-lubricating bushings are an important component in many mechanical systems, providing support, reducing friction, and absorbing shock. They are especially important in applications where frequent lubrication or maintenance is difficult or impossible, or where high wear and tear or noise would be problematic. Custom machined self-lubricating bushings can offer even greater advantages, as they can be tailored to meet the specific needs of the application. In this article, we will discuss why machined self-lubricating bushings are important and introduce a custom machined bushing manufacturer in China.

Why Are Machined Self-Lubricating Bushings Important?

Machined self-lubricating bushings offer a number of important benefits over traditional bushings. Here are some reasons why they are so important:

Reduced Maintenance: Machined self-lubricating bushings are designed to be self-lubricating, which means they can operate without the need for external lubrication. This reduces maintenance requirements and can save time and money in the long run.

Increased Durability: Self-lubricating bushings are made from materials that are specifically formulated for high wear resistance, which can increase their durability and reduce the risk of wear and tear.

Reduced Friction and Noise: Self-lubricating bushings reduce friction between moving parts, which can help to reduce noise and vibration, and increase the efficiency of the system.

Customizable: Custom machined self-lubricating bushings can be made to exact specifications to fit specific applications. This can help to optimize performance, reduce downtime, and lower maintenance costs.

Custom Machined Self-Lubricating Bushing Manufacturer in China

custom machined self-lubricating bushing manufacturer in China, professional manufacturer of custom machined self-lubricating bushings in the industry.

we offers a wide range of self-lubricating bushings made from different materials, including bronze, graphite, and composite bearings. They have a team of experienced engineers who can work with customers to develop custom solutions that meet their specific needs. we also committed to providing high-quality products and excellent customer service, which has earned them a reputation as a reliable and trusted supplier of custom machined self-lubricating bushings.

Machined self-lubricating bushings are an important component in many mechanical systems, providing support, reducing friction, and absorbing shock. Custom machined self-lubricating bushings offer even greater advantages, as they can be tailored to meet the specific needs of the application. If you’re looking for a custom machined self-lubricating bushing manufacturer in China, consider working with a company like viiplus, which has the expertise and experience to deliver high-quality products and excellent customer service.

Machined Bushings Characteristics

Bronze bushing is a part of mechanical equipment, it is mainly used in the sling machine, and is widely used. Bronze bushing is an indispensable part in the application of mechanical equipment. It is mainly used to make amorphous single and magnetic materials.The main materials used for bronze bushing are centrifuge casting and die casting.Most of its exterior colors are cyan and yellow. Bronze bushing and other mechanical equipment, also has its own characteristics.

1. Wear resistance

The wear resistance of copper bushing is relatively good, the equipment of different material has different characteristics.The internal organization of copper bushing parts is still relatively tight, will not appear too loose phenomenon, it is no pores trachoma, so from the outside looks like copper bushing is relatively bright, its color is more special.And most importantly, it’s relatively hard.

2. The corrosive

Another characteristic of copper bushing is corrosion resistance, corrosion performance is relatively good.It is mainly used in the atmosphere and fresh water because the environment is relatively good.In the process of using copper bushing, it is not easy to bite to death.Corrosion resistance of copper bushing is mainly manifested in some chemical elements, such as: dilute sulphuric acid, hydrochloric acid and fatty acid, and so on elements, so the copper bushing corrosion resistant ability is very good, it is not be killed comparison mainly due to its own characteristics, its performance is better, even without lubricant and lubricant of water quality is still can be normal work, the sliding resistance and self-lubricating performance can still be maintained.

3. Ability to withstand pressure

The compressive resistance of copper bushing is also quite good, its surface pressure is very large, can bear the bearing side pressure very well, in the case of high load pressure copper bushing can also be operated.

Lubrication solutions for high temperature applications up to 600°C .

We Design and Manufacture C86300,C86200,C83600,C93200,C95400 Material Bronze Bushing with Oil Groove in metric size & inch size.

To see more bronze bushing types of our online website click the link below: www.bronzelube.com| The Premier China Source for Bronze Bushings Online.

Through state of the art research and development facilities and a collaborative approach to problem solving, we partner with our customers to understand their unique bearing requirements and develop solutions precisely tailored to their individual needs.

Bushing Manufacturing Technology

Manufacturing Technology for engineers involved with the new design and installation of self-lubricating bearings for different markets at reasonable cost.Choose from self lubricating bearings based on our experience and industry preferences to customize the items for your requirement. Small Minimums, Online Sale.Made-to-order from china.Get a Quote Today.Large Inventory. In Stock. Leading Manufacturer. Custom Size. Types: Solid Bearing Stock, Sleeve Bushing Stock, Flange Washer Stock.

Sliding bearing structure & material design and the reasonable of bearing’s tolerance and fit, mounting , lubrication ,lubricating bearing life for your area of use and the budget for the plain bearings.Quality customized self lubricating bearings & bronze bushings delivered on time.Save Cost.High Precision machined bronze bushings manufacture, standard bronze bushings bearings, bronze bushings stock, bronze sleeve bushings bearings, cast bronze bushings bearings, flange bushings, sleeve bushings, graphite thrust washers, grooving or graphite lubrication bearings.

Participating in your future are our privilege. Know what’s happening in your industry.Keeping your business running smoothly is our top priority. Always tested. Always proven. Always Bronzelube.com

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.