Dual Mass Flywheel Bushings

Dual Mass Flywheel Bushings

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

Dual Mass Flywheel Bushings

Dual Mass Flywheel (DMF) bushings are a crucial component of high-performance automotive engines. These bushings are responsible for supporting the DMF, which is designed to reduce engine vibration and noise while improving fuel efficiency.

Speak with an automotive bushing expert.

Dual mass flywheel bushings with a lightweight and compact design, enhanced lubrication, and a unique polymer structure can improve the performance of the DMF while reducing system wear and extending design life. The use of PTFE as a material for DMF bushings provides several benefits, including low friction, high durability, resistance to wear and corrosion, and self-lubricating properties. These properties help to improve the efficiency and durability of the DMF and reduce the need for frequent maintenance and replacement. If you are looking to improve the performance and lifespan of your DMF bushing, consider upgrading to a PTFE-coated bushing.

Dual Mass Flywheel Bushing – Self-lubricating Bearing

A Dual Mass Flywheel (DMF) is a component of a vehicle’s transmission system, designed to reduce vibrations, noise, and improve smoothness and comfort. It consists of two flywheels, one connected to the engine’s crankshaft and the other to the transmission. Between these two, a set of springs and dampers are present to absorb the vibrations from the engine.

Now, as for the bushings in this context, these are essentially mechanical components used for reducing friction between two interacting parts. PTFE (Polytetrafluoroethylene) bushings are a specific type of bushing that utilize PTFE for this purpose. PTFE is a polymer characterized by its low friction, excellent chemical resistance, and high temperature tolerance, making it suitable for various mechanical and industrial applications, including automotive ones.

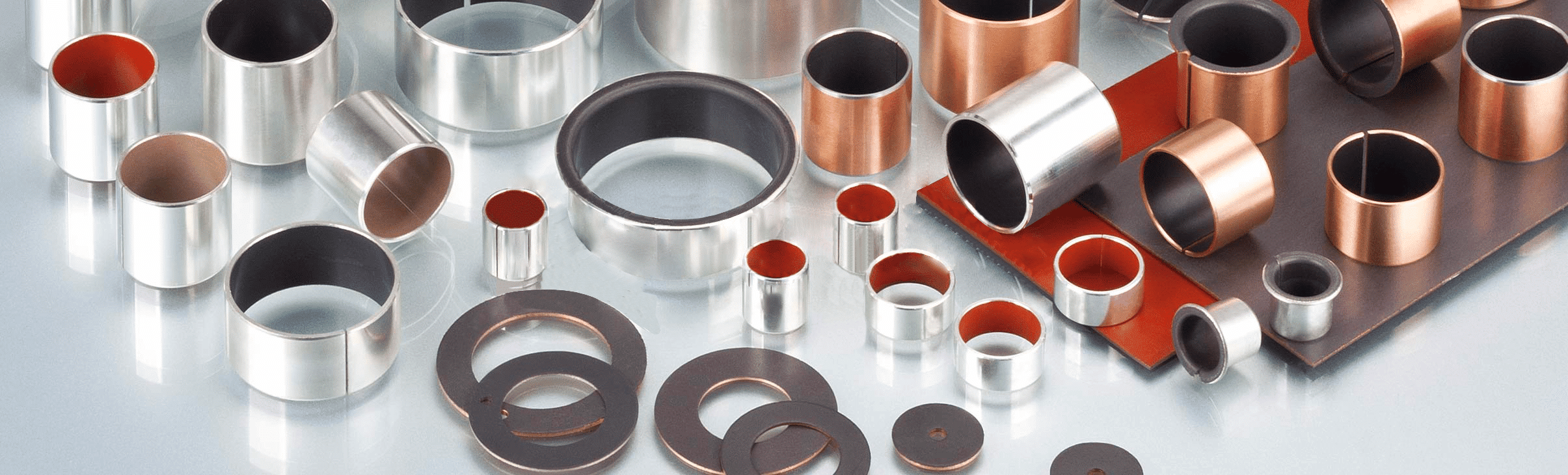

There are different types of bushings, two of which you mentioned:

- Flange Type: These are bushings that have a flange at one end. The flange provides a larger surface area that can endure axial loads, prevent movement, and help to maintain the positioning of the component. PTFE flange type bushings might be used in the DMF system where there is a need to manage both radial and axial loads.

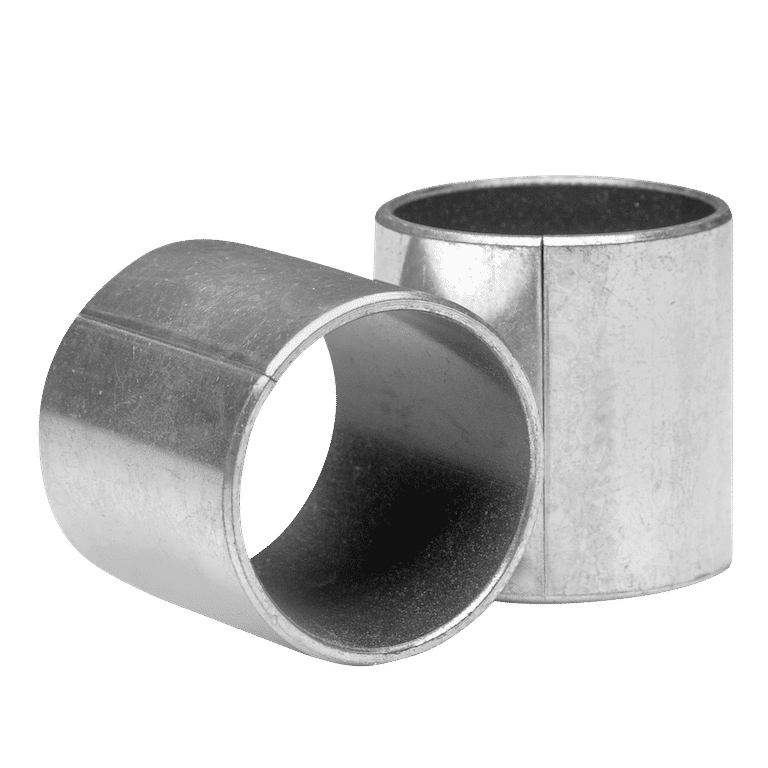

- Straight Type: These are the simplest form of bushings, shaped like a straight cylindrical tube. They are typically used in applications where the load is primarily radial, and the aligned movement of components is needed. PTFE straight type bushings could be used in parts of the DMF system where radial load management is crucial.

The dual mass flywheel (DMF) is an essential component of modern manual transmissions, providing a smooth and efficient power transfer between the engine and transmission. However, the DMF is prone to wear and tear over time, which can cause excessive noise, vibration, and harshness (NVH) in the drivetrain. One critical component of the DMF is the self-lubricating bearing, which plays a crucial role in reducing friction and wear.

A self-lubricating bearing is a type of bearing that does not require external lubrication to function correctly. Instead, it contains a lubricant embedded within the bearing material, which is released gradually as the bearing rotates. This makes self-lubricating bearings ideal for use in high-stress, high-temperature environments, such as those found in the DMF.

The DMF bushing is typically made from a composite material that includes a polymer matrix reinforced with glass or carbon fibers. This material is highly resistant to wear and fatigue, making it ideal for use in the DMF. Additionally, the self-lubricating properties of the bearing material ensure that it remains lubricated even in high-temperature environments, reducing friction and wear.

One significant advantage of the self-lubricating DMF bushing is its ability to reduce NVH in the drivetrain. When the DMF bushing becomes worn, it can cause excessive noise, vibration, and harshness, which can be unpleasant for the driver and passengers. However, the self-lubricating properties of the bearing material ensure that it remains lubricated, even in high-stress environments, reducing the amount of friction and wear on the DMF.

Another benefit of the self-lubricating DMF bushing is its durability. The composite material used in the bearing is highly resistant to wear and fatigue, which means that it will last longer than traditional bushings. This reduces the need for maintenance and repair, saving the driver time and money in the long run.

In conclusion, the self-lubricating DMF bushing is an essential component of the dual mass flywheel, providing smooth and efficient power transfer while reducing NVH in the drivetrain. The self-lubricating properties of the bearing material ensure that it remains lubricated even in high-temperature environments, reducing friction and wear. The durability of the composite material used in the bearing ensures that it will last longer than traditional bushings, reducing the need for maintenance and repair.

High Performance Dual Mass Flywheel Bushings (DMF)

PTFE (polytetrafluoroethylene) BUSHING FOR Double volant amortisseur (DVA)

“Double volant amortisseur” translates to “Dual Mass Flywheel” in English, abbreviated as DMF. It’s a key component in many automobile engines that helps to reduce vibration and improve the operation of the transmission system.

As for PTFE (Polytetrafluoroethylene) bushings for a DMF, they are mechanical components used to reduce friction between two interacting parts within this system. PTFE, known for its low friction, excellent chemical resistance, and high temperature tolerance, makes an excellent material for bushings in such a demanding environment.

These bushings would fit into the DMF assembly and provide a low-friction surface to facilitate the relative motion of parts within the assembly. By using PTFE, the system can operate more smoothly and with less wear, increasing the lifespan of the components and reducing the need for maintenance.

However, it’s important to note that as of my knowledge cutoff in September 2021, bushings in DMFs are typically not serviceable separately. They are integrated into the flywheel assembly and not designed to be replaced independently.

If you’re looking for specific PTFE bushings for a DMF, I would recommend consulting a part catalog for the specific make and model of vehicle, contacting the manufacturer, or speaking with a professional mechanic. They would have the most accurate and up-to-date information.

The bushing you described is a composite or layered bushing, commonly used in various applications including automotive ones such as in Dual Mass Flywheels (DMF). Here’s a breakdown of the three layers you mentioned:

- Steel Backing Strip: This provides the mechanical strength and rigidity to the bushing. It forms the outer layer, supports the other layers, and helps to evenly distribute the load across the bearing surface.

- Porous Bronze Matrix: This layer is typically sintered onto the steel backing and acts as a reservoir for the PTFE/lead bearing material. It also provides a measure of mechanical strength and wear resistance.

- PTFE/Lead Bearing Material: This is the bearing surface of the bushing, impregnated into the porous bronze matrix and often overlaid on top as well. PTFE (Polytetrafluoroethylene) is known for its excellent low-friction properties, which reduce wear and extend the life of the bushing. The addition of lead improves the bearing’s performance at high loads and temperatures.

Together, these three layers form a robust bushing that is suitable for the demanding environment of a DMF, reducing friction and wear, and promoting smooth operation of the system.

Self-Lubricating Metric Flanged Bushing, bearings combine the advantages of many conventionally lubricated, metallic plain bearings-particularly high load capacity and dimensional rigidity-with the design freedoms of self-lubricating materials, including the ability to operate successfully well beyond the scope of conventional lubricants.

Dual Mass Flywheel (DMF) bushings are a crucial component of high-performance automotive engines. These bushings are responsible for supporting the DMF, which is designed to reduce engine vibration and noise while improving fuel efficiency.

High-performance DMF bushings are typically made of advanced materials such as polyurethane or Delrin, which are much more durable than the standard rubber bushings found in most stock vehicles. These materials are better able to withstand the higher levels of stress and heat generated by high-performance engines, ensuring that the DMF remains securely in place during operation.

In addition to their increased durability, high-performance DMF bushings may also offer improved performance over stock bushings. They can help to reduce the amount of engine movement, which can improve the responsiveness of the vehicle and provide a more direct driving experience.

Overall, high-performance DMF bushings are a great investment for those who are serious about improving the performance of their vehicle. They can help to improve both the durability and performance of the DMF, leading to a smoother, more responsive driving experience.

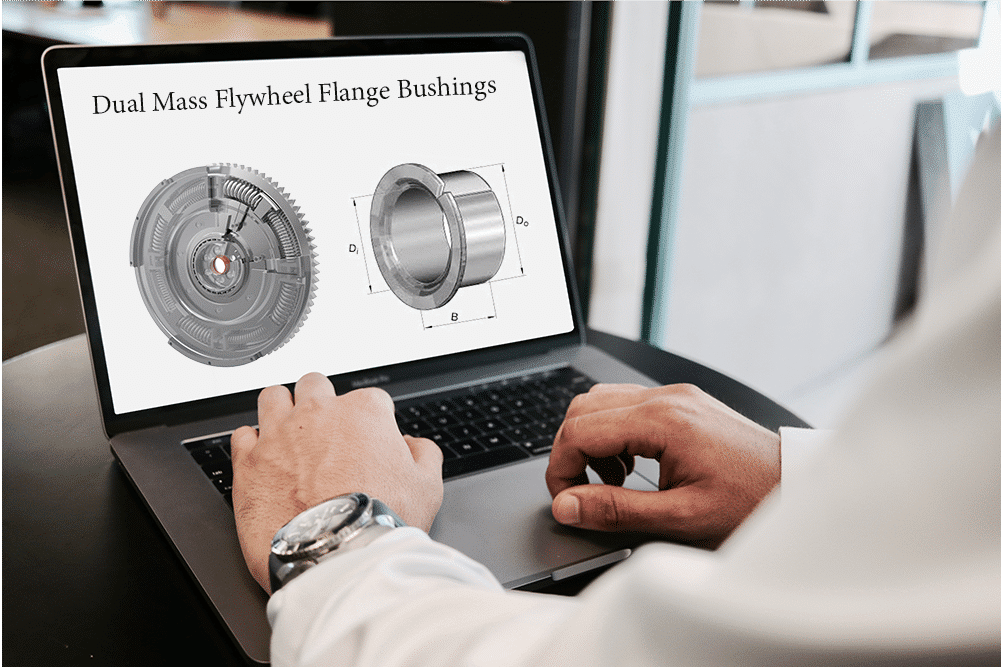

Dual Mass Flywheel Bushings – Bearing, Dimensions

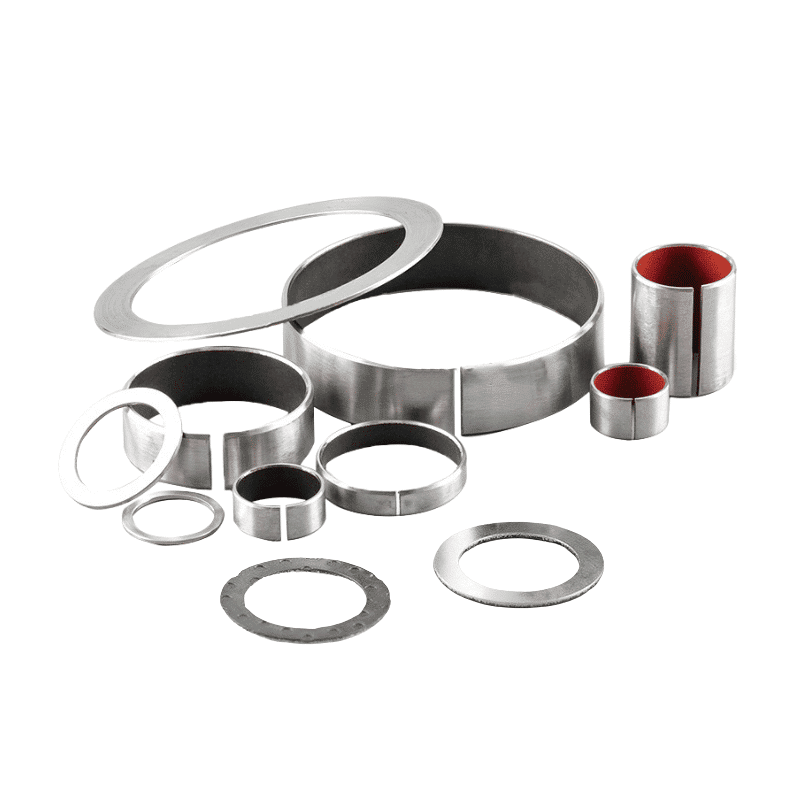

The dual mass flywheel (DMF) is a key component in many modern manual transmission systems. It helps to smooth out the power transfer between the engine and the transmission, reducing vibrations and making the driving experience more comfortable for the driver and passengers. One crucial element of the DMF is the bushing that connects it to the transmission. Custom straight and flange size bushings are available to ensure that the DMF fits perfectly with the transmission, minimizing noise and vibration.

The DMF bushing is typically made of a composite material that includes a polymer matrix reinforced with glass or carbon fibers. This material is strong and resistant to wear, making it ideal for use in the DMF. However, the bushing must be designed to fit precisely with the transmission and the DMF. This is where custom straight and flange size bushings come into play.

Custom straight and flange size bushings are designed to fit precisely with the transmission and the DMF. They are available in a range of sizes and configurations to ensure a perfect fit. Straight bushings are used when the transmission and DMF are aligned, while flange size bushings are used when the transmission and DMF are not aligned.

The use of custom straight and flange size bushings helps to minimize noise and vibration in the drivetrain. When the DMF is not perfectly aligned with the transmission, it can cause excessive noise and vibration, which can be unpleasant for the driver and passengers. Custom bushings ensure that the DMF is perfectly aligned, reducing NVH (noise, vibration, and harshness) in the drivetrain.

Another advantage of custom bushings is their durability. The composite material used in the bushings is highly resistant to wear and fatigue, ensuring that they will last for many years without needing to be replaced. This reduces the need for maintenance and repair, saving the driver time and money in the long run.

In conclusion, custom straight and flange size bushings are essential components of the DMF. They ensure that the DMF fits perfectly with the transmission, minimizing noise and vibration in the drivetrain. The durability of the composite material used in the bushings ensures that they will last for many years without needing to be replaced. If you are experiencing excessive noise and vibration in your drivetrain, consider upgrading to custom bushings to improve your driving experience.

The PTFE bushing improves dual mass flywheel performance with: Decreased operational harmonic noise and harshness levels Lightweight and compact design Enhanced lubrication reduces system wear and extends design life Unique polymer structure that minimizes application friction

DUAL MASS FLYWHEEL BUSHINGS

The PTFE bushing can improve the performance of the dual mass flywheel (DMF) in several ways:

- Decreased operational harmonic noise and harshness levels: The PTFE bushing’s low-friction properties help to reduce vibrations and noise generated by the DMF during operation, resulting in a smoother and quieter driving experience.

- Lightweight and compact design: PTFE is a lightweight material, which helps to reduce the overall weight of the DMF assembly. This can improve the vehicle’s handling and acceleration, particularly in high-performance applications where every pound matters.

- Enhanced lubrication reduces system wear and extends design life: The PTFE bushing’s self-lubricating properties help to reduce friction and wear between the DMF components, which can extend the life of the assembly and reduce the need for maintenance.

- Unique polymer structure that minimizes application friction: PTFE has a unique polymer structure that provides excellent lubrication and wear resistance, even under high load conditions. This makes it an ideal material for use in high-performance DMF applications where friction and wear must be minimized to maximize performance.

THE PTFE bushing can be a valuable addition to a high-performance DMF assembly, helping to improve performance, reduce noise and vibration, and extend the life of the assembly.

The dual mass flywheel (DMF) is an essential component in modern manual transmission systems. It provides a smooth and efficient power transfer between the engine and the transmission while reducing vibrations and noise. One key element of the DMF is the bushing, which connects it to the transmission. Dual mass flywheel bushings with a lightweight and compact design, enhanced lubrication, and a unique polymer structure can reduce system wear and extend design life while minimizing application friction.

The bushing in the DMF is typically made of a composite material that includes a polymer matrix reinforced with glass or carbon fibers. This material is highly resistant to wear and fatigue, making it ideal for use in the DMF. However, improvements in design have resulted in bushings with a lightweight and compact design that further enhance the performance of the DMF.

The lightweight and compact design of the bushing reduces the overall weight of the DMF, which improves the performance and fuel efficiency of the vehicle. A lighter DMF requires less energy to rotate, reducing the load on the engine and transmission. This results in better acceleration and smoother shifting, enhancing the driving experience for the driver and passengers.

In addition to the lightweight and compact design, DMF bushings with enhanced lubrication can reduce system wear and extend design life. The lubrication helps to reduce friction and wear on the DMF, which can prolong its lifespan and reduce the need for maintenance and repairs. This is particularly important in high-stress environments where the DMF is subjected to extreme heat and pressure.

Finally, the unique polymer structure of the DMF bushing minimizes application friction, improving the performance of the DMF. Friction can cause excessive noise and vibration in the drivetrain, reducing the comfort of the driver and passengers. The unique polymer structure of the bushing reduces friction, minimizing NVH (noise, vibration, and harshness) in the drivetrain.

In conclusion, dual mass flywheel bushings with a lightweight and compact design, enhanced lubrication, and a unique polymer structure can improve the performance of the DMF while reducing system wear and extending design life. The lightweight and compact design reduces the overall weight of the DMF, improving fuel efficiency and performance. Enhanced lubrication reduces friction and wear on the DMF, while the unique polymer structure minimizes application friction, reducing NVH in the drivetrain. If you are looking to improve the performance and durability of your DMF, consider upgrading to bushings with these features.

Dual mass flywheel bushing material PTFE (polytetrafluoroethylene)

High Performance Dual Mass Flywheel Bushings (DMF) Featuring Carbon Steel Backing, Sintered Porous Bronze and PTFE Composite Polymer

High-performance Dual Mass Flywheel (DMF) bushings featuring a carbon steel backing, sintered porous bronze, and PTFE composite polymer are designed to provide superior durability, performance, and reliability.

The carbon steel backing provides exceptional strength and rigidity, ensuring that the bushing can withstand the high levels of stress and heat generated by high-performance engines. The sintered porous bronze material is used to provide a strong yet porous structure that allows for proper lubrication of the bushing during operation. This is crucial for ensuring that the bushing remains smooth and free of friction, even under high load conditions.

The PTFE composite polymer is used as a low-friction layer that provides excellent wear resistance and self-lubricating properties. This ensures that the bushing remains smooth and free of wear, even under the most demanding operating conditions.

Overall, high-performance DMF bushings featuring a carbon steel backing, sintered porous bronze, and PTFE composite polymer are an excellent choice for those who demand the highest levels of performance and reliability from their vehicles. These bushings are engineered to provide exceptional durability and performance, making them ideal for use in high-performance vehicles that are subjected to extreme conditions.

The bushing is a critical component of the dual mass flywheel (DMF) in manual transmission systems, connecting the flywheel to the transmission. A common material used for DMF bushings is PTFE (polytetrafluoroethylene) due to its unique properties that make it suitable for high-stress environments. PTFE is a synthetic fluoropolymer of tetrafluoroethylene that is known for its low friction, high durability, and resistance to wear and corrosion.

The use of PTFE as a material for DMF bushings provides several benefits. First, PTFE has a low coefficient of friction, which reduces the amount of energy required to rotate the flywheel, improving the efficiency of the transmission system. Second, PTFE is highly durable and resistant to wear, which extends the lifespan of the DMF bushing, reducing the need for frequent replacement and maintenance.

Moreover, PTFE has excellent resistance to corrosion, making it ideal for use in high-stress environments where the bushing is exposed to extreme temperatures and pressure. The PTFE coating on the bushing helps to protect it from environmental factors, such as moisture and chemicals, which can cause damage to the bushing.

Another benefit of using PTFE as a material for DMF bushings is its ability to self-lubricate. The low coefficient of friction of PTFE allows for smooth rotation of the flywheel, reducing the wear and tear on the bushing. The self-lubricating property of PTFE also reduces the need for manual lubrication of the bushing, reducing maintenance requirements and increasing the lifespan of the DMF.

The use of PTFE as a material for DMF bushings provides several benefits, including low friction, high durability, resistance to wear and corrosion, and self-lubricating properties. These properties help to improve the efficiency and durability of the DMF and reduce the need for frequent maintenance and replacement. If you are looking to improve the performance and lifespan of your DMF bushing, consider upgrading to a PTFE-coated bushing.

Dual Mass Flywheel Bushing Custom Straight And Flange Size

dimensions

The dual mass flywheel (DMF) is a key component in many modern manual transmission systems. It helps to smooth out the power transfer between the engine and the transmission, reducing vibrations and making the driving experience more comfortable for the driver and passengers. One crucial element of the DMF is the bushing that connects it to the transmission. Custom straight and flange size bushings are available to ensure that the DMF fits perfectly with the transmission, minimizing noise and vibration.

The DMF bushing is typically made of a composite material that includes a polymer matrix reinforced with glass or carbon fibers. This material is strong and resistant to wear, making it ideal for use in the DMF. However, the bushing must be designed to fit precisely with the transmission and the DMF. This is where custom straight and flange size bushings come into play.

Custom straight and flange size bushings are designed to fit precisely with the transmission and the DMF. They are available in a range of sizes and configurations to ensure a perfect fit. Straight bushings are used when the transmission and DMF are aligned, while flange size bushings are used when the transmission and DMF are not aligned.

The use of custom straight and flange size bushings helps to minimize noise and vibration in the drivetrain. When the DMF is not perfectly aligned with the transmission, it can cause excessive noise and vibration, which can be unpleasant for the driver and passengers. Custom bushings ensure that the DMF is perfectly aligned, reducing NVH (noise, vibration, and harshness) in the drivetrain.

Another advantage of custom bushings is their durability. The composite material used in the bushings is highly resistant to wear and fatigue, ensuring that they will last for many years without needing to be replaced. This reduces the need for maintenance and repair, saving the driver time and money in the long run.

In conclusion, custom straight and flange size bushings are essential components of the DMF. They ensure that the DMF fits perfectly with the transmission, minimizing noise and vibration in the drivetrain. The durability of the composite material used in the bushings ensures that they will last for many years without needing to be replaced. If you are experiencing excessive noise and vibration in your drivetrain, consider upgrading to custom bushings to improve your driving experience.

The dual mass flywheel (DMF) is a crucial component in modern manual transmission systems, providing a smooth and efficient power transfer between the engine and the transmission while reducing noise and vibration. One of the key elements of the DMF is the bushing, which connects it to the transmission. The use of self-lubricated bushings in DMFs provides many benefits, including enhanced durability, reduced maintenance requirements, and improved performance.

Traditionally, DMF bushings were made of composite materials that require lubrication to reduce friction and wear. However, self-lubricated bushings have become increasingly popular in recent years due to their enhanced durability and reduced maintenance requirements. These bushings are designed to release lubrication when needed, reducing friction and wear on the DMF without the need for manual lubrication.

The use of self-lubricated bushings in DMFs provides many benefits, including improved durability. Since the lubrication is released automatically, the bushing and DMF are protected from excessive wear and tear, prolonging their lifespan. This reduces the need for maintenance and repair, saving the driver time and money in the long run.

In addition to improved durability, self-lubricated bushings also improve the performance of the DMF. By reducing friction, the bushing ensures that the DMF rotates smoothly, providing a smooth and efficient power transfer between the engine and the transmission. This results in better acceleration and smoother shifting, enhancing the driving experience for the driver and passengers.

Furthermore, self-lubricated bushings also reduce the noise and vibration in the drivetrain. Traditional DMF bushings can cause excessive noise and vibration due to friction and wear. The use of self-lubricated bushings reduces this problem, improving the comfort of the driver and passengers.

In conclusion, the use of self-lubricated bushings in DMFs provides many benefits, including improved durability, reduced maintenance requirements, and improved performance. These bushings release lubrication automatically, reducing friction and wear on the DMF without the need for manual lubrication. This enhances the durability of the DMF and bushing while improving the performance and comfort of the drivetrain. If you are looking to improve the performance and durability of your DMF, consider upgrading to self-lubricated bushings.

“DIMMENSIONNEL PALIER BUSHING” seems to be a combination of English and French words. “Dimensionnel” means “dimensional” in English, and “palier” translates to “bearing” or “bushing”. So, “DIMMENSIONNEL PALIER BUSHING” could be interpreted as “dimensional bushing”.

In the context of Dual Mass Flywheel (DMF) bushings, dimensional bushing would likely refer to the physical dimensions of the bushing (length, inner diameter, outer diameter, etc.). These dimensions are crucial for ensuring a proper fit within the DMF system. They need to match the dimensions of the space in which they are to be fitted, as well as the parts they are meant to interact with.

Unfortunately, I can’t provide specific dimensions for a DMF bushing as these can vary widely based on the make and model of the vehicle, and the specific design of the DMF system. Also, it is important to note that, as of my knowledge cutoff in September 2021, bushings in DMFs are typically not serviceable separately, meaning they are integrated into the flywheel assembly and not intended to be replaced independently.

If you are looking for specific dimensions of a DMF bushing, I would recommend consulting a part catalog for the specific make and model of vehicle, contacting the manufacturer, or speaking with a professional mechanic or engineer. They would have the most accurate and up-to-date information.

APPLICATIONS

- Agricultural equipment

- Off-highway, truck, and automotive

- Aviation

- Business machines

- Garden, lawn, and outdoor equipment

- Hydraulics and values

- Home applicances and consumer goods

- Materials handling

- Medical and dental

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally