Bronze Bushing: A Comprehensive Guide, providing factory services of superior quality with focus on efficiency.

01.

Better equipment fixes

02.

Satisfaction guaranteed

03.

Ensuring timely delivery

04.

Elevate our experience

Manufacturing on Demand

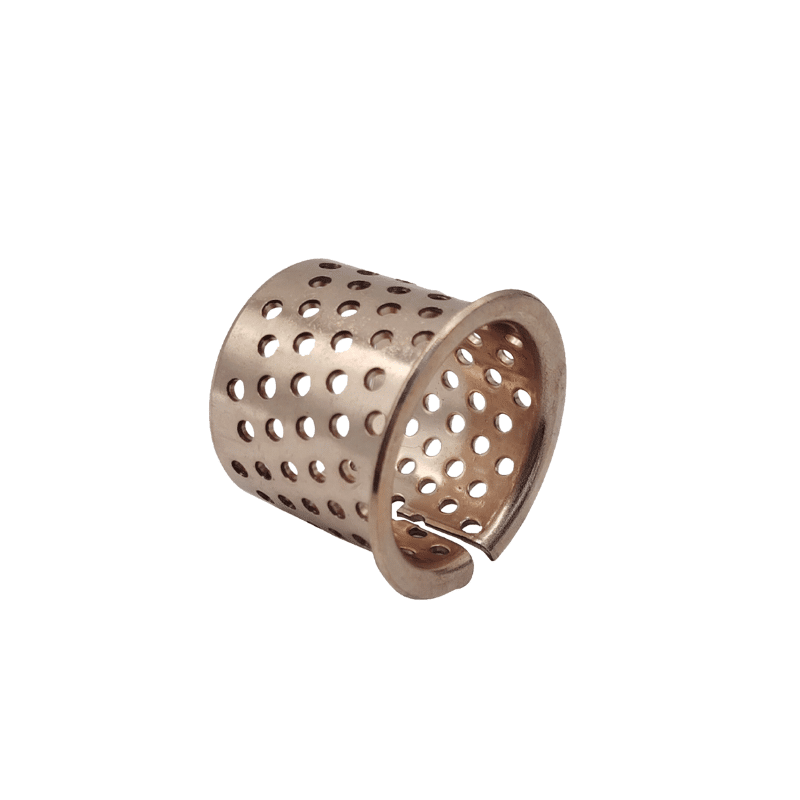

A bronze bushing, a compact and cylindrical part made from bronze, functions as a bearing in a variety of machinery. The advantages of bronze bushings come from bronze’s natural properties. This material is noted for its durability, outstanding resistance to saltwater corrosion, low frictional interaction between metals, and considerable malleability.

Certified and Quality Driven

Bronze also has a melting point of about 950 degrees Celsius. These attributes make bronze bushings highly adaptable, suitable for a range of uses, particularly in environments where they are subjected to intense stress.

High-Volume Production

Our bearings are manufactured to meet rigorous quality standards, ensuring their dependability and performance. They are crafted to equal or surpass industry benchmarks, offering you a reliable product.

Product Quality Index

Energy Generation

Specializing In Standard Bronze Bushing Finished Parts

Specializing In Standard Bronze Bushing Groove Parts

Our team is dedicated to crafting superior Bronze components, focusing on delivering these fundamental elements at competitive rates. Our product portfolio encompasses a diverse array of Brass and Bronze parts, designed to cater to a broad spectrum of industrial requirements.

We maintain a stock of standard Bronze Sleeve Bearings, ready for prompt delivery. These are available in two bore styles: “Grooved” and “Plain.” We provide a selection of groove configurations to suit various applications, such as figure eight, double figure eight, loop, double loop, circular, wick, or straight. These grooves can be customized to fit the length of the part or extend to its ends. Among our offerings, the “Spira-Lube” groove pattern stands out for its efficiency.

Focusing on the Manufacturing of Rotational Center Castings in Various Alloys: Our facility is adept at producing a wide range of castings, especially those with a rotational axis. We employ vertical centrifuges to create various components, including copper bushings, elevator worms, gaskets, and more.

Our casting process is distinguished by its minimal inclusions and defects, ensuring a product of the highest quality. The centrifugal force used in our method improves the metal’s flow, enabling the production of thin-walled castings with efficiency. This process is particularly advantageous for manufacturing items with a rotational center, like bushings, worm gears, and gaskets.

We can manufacture a variety of components, including copper bushings, worm gears, shaft sleeves, and gears, accommodating sizes up to 800X305 mm for smaller parts and up to 2500X1500 mm for larger ones.

Our Standard Bronze Sleeve Bearings find utility across multiple industries, including automotive, manufacturing, aerospace, and marine environments.

They excel in functions such as pumps, motors, agricultural equipment, and conveyor systems.

For suspension systems that demand exceptional resilience, our Bronze Leaf Spring Bushings are the perfect choice. Our range also includes Bronze Thrust Washers and Bearings, which ensure smooth operation and minimize friction. The Bronze Spring Pin Bushings are crucial for maintaining component alignment and reducing wear.

▪ Our Metric Brass Bushings serve as precision elements across various applications.

We offer Brass and Bronze components tailored for high-performance gearing systems. Our Bronze Bushings and Metric Bronze Bushings are engineered for precise fit and enduring durability.

▪ The Bronze Bushings are crafted to provide robust and reliable connections.

The assortment of Standard Bronze Sleeve Bearings we provide is designed to meet a comprehensive range of industrial and mechanical requirements. Made from premium bronze, these bearings are celebrated for their longevity, resistance to wear, and corrosion resistance, fitting them for diverse uses.

Bronze bushings play a huge role in reducing friction.

Types of Bronze Bushings, self-lubricating sliding bearings.

- Sintered bronze bushings: These are made by pressing powdered bronze into shape and heating it. They’re like the bakery-fresh muffins of the bushing world!

- Cast bronze bushings: Bronze is melted and poured into a mold for these. Think of it as the “classic” way to make bushings.

- Oil impregnated bronze bushings: Here, bronze has tiny pores filled with oil. This provides extra lubrication. It’s like giving your bushing a spa day!

- Graphite plugged bronze bushings:These have graphite plugs. The graphite provides smooth movement. Imagine a slip-and-slide for machinery!

- Flanged Bushings: These bushings have a flange on one end to provide axial guidance. They’re commonly used in situations where a component needs support against axial loads.

- Oil/Grease Grooved Bushings: These bushings have grooves on their inner or outer surfaces to hold and distribute lubricants more effectively.

Product Quality Index

Energy Generation

Choosing your Bronze Bushing Supplier

Self-lubricating: Many bronze bushings are capable of holding lubrication within their structure, reducing the need for frequent re-lubrication. Whether you’re looking for a standard size or a custom solution, our Standard Bronze Sleeve Bearing Collection is poised to meet your needs with quality, precision, and reliability.

Bringing Bronze to Life: Your Expert Partner in Phosphor Bronze Bushings and Bearing

Choosing the Right Bronze Bushing for Your Needs

We offers a variety of oil-embedded sleeve bearings, including ultra-low-friction and high-load options, which are beneficial for applications involving frequent starts and stops. They also have vibration-damping options where a layer of rubber is sandwiched between the bronze bearing and the metal shell to reduce wear and machinery noise. Their product range includes different lubrication options like graphite, various grade oils, and PTFE, suitable for a range of applications.

- Factors to consider: When choosing, think about load, speed, and environment. It’s like matching socks to an outfit!

- Cost vs. benefits: While some bushings cost more, they might last longer. Do the math!

- Maintenance considerations: Think about how often you want to maintain your bushing. Some need more love than others.

- Potential pitfalls to avoid: Always check dimensions and specifications. Or else, it’s like trying to fit a square peg in a round hole!

Comprehensive Guide to Bronze Bushings: Types, Benefits, and Applications

Bronze bushings, sometimes simply referred to as bronze bearings, are cylindrical parts used to reduce friction between rotating shafts and stationary support memåbers. Typically made of bronze, these bushings are essential components in many machines, from small appliances to large industrial equipment. Bronze bushings are vital. They make the world move smoother. Next time you see a machine, remember the tiny bronze hero inside!

Bronze bushings are made from bronze alloys, which are primarily composed of copper, with the addition of other metals such as tin, aluminum, manganese, nickel, or zinc, and sometimes non-metals or metalloids like phosphorus, arsenic, or silicon. The specific composition of the alloy can vary, resulting in different types of bronze with unique properties. For example, aluminum bronze is known for its excellent mechanical properties and corrosion resistance, while phosphor bronze is valued for its fine grain, low coefficient of friction, and high fatigue resistance

Durability

Bronze is a hard and tough material, making these bushings long-lasting and resistant to wear and tear. Bronze bushings are available in several alloys like C93200, C95400, and C86300, each suited for specific applications depending on load capacity, speed, and operating temperature

Resistance to Corrosion

Bronze has excellent corrosion resistance, especially against water and many chemicals.

We offer a comprehensive overview of the types, applications, and benefits of bronze bushings in industrial contexts, highlighting their durability, versatility, and suitability for a wide range of mechanical applications.

Good Thermal Conductivity

Bronze can dissipate heat effectively, which helps in applications with high temperatures. We focused on bronze bushings, is another resource that provides a variety of mechanical components