Phosphor Bronze Bushings: Unraveling the Industrial Powerhouse

Understanding Phosphor Bronze Bushing: The C53400 Bronze Bearing & Custom Material Choices

As we delve into the world of manufacturing, engineering, and material science, we come across a variety of alloys and compositions that prove instrumental in various applications. Phosphor bronze is one such alloy, renowned for its exceptional strength, toughness, and wear resistance. Today, let’s delve deeper into phosphor bronze bushing, focusing on its chemical composition, phosphor bronze grades, and the characteristics of the popular C53400 bronze bearing.

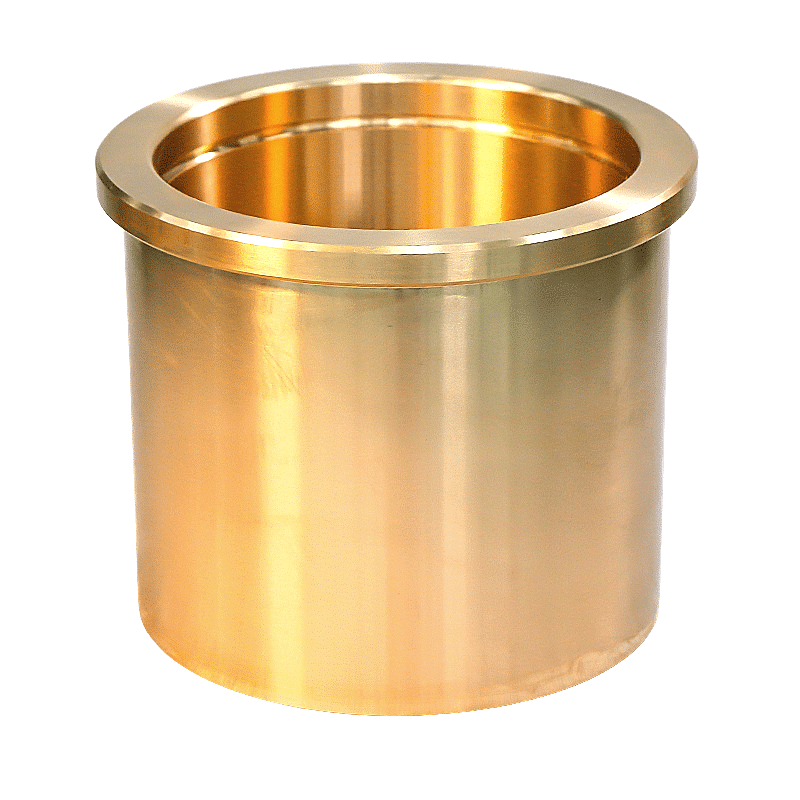

C53400 Bronze Bearing

An Introduction to Phosphor Bronze, Custom Material Bronze Bushing

Phosphor bronze is a copper alloy, with tin and phosphorus being the two significant alloying elements. The phosphorus in the mix provides increased wear resistance and stiffness, while the tin boosts the alloy’s strength and corrosion resistance. While the C53400 is a popular choice, many manufacturers offer custom material bronze bushings that can be tailored to specific application requirements. With these customized offerings, phosphor bronze alloys can be adjusted in terms of tin, phosphorus, lead, and other element ratios to tweak their mechanical properties. Whether you need a bronze bushing with a higher degree of corrosion resistance, enhanced machinability, or improved strength, custom material choices make it possible. By fine-tuning the alloy composition, manufacturers can create bushings perfectly suited to any environment or use case. We don’t just make bushings, we create cost-effective solutions. Our lean manufacturing principles and high production volume equate to savings that we’re more than happy to pass on to you. We believe that quality doesn’t have to break the bank and our pricing strategy reflects that.

Product Quality Index

Energy Generation

Phosphor Bronze – An Essential Material in Modern Engineering

Cheers!

Explore our selection of Phosphor bronze Bearings.

Phosphor bronze, such as the C53400 alloy, is commonly used in bearings, bushings, and fasteners due to its toughness, strength, low coefficient of friction, and fine grain. The C53400 alloy consists of copper with 0.50–11.00% of tin and 0.01–0.35% phosphorus. The tin increases the corrosion resistance and strength of the alloy, while the phosphorus increases its wear resistance and stiffness. In addition to C53400, other phosphor bronze alloys such as C51000, C52100, and C54400 are also available. Phosphor bronze bushings have high mechanical strength, good conductivity, and wear resistance, making them suitable for applications such as sleeve bearings, thrust washers, and cam followers

Phosphor bronze is an alloy that has gained significant importance in modern engineering. This material, consisting primarily of copper with tin and phosphorus, is known for its durability, resilience, and anti-corrosive properties.

Composition and Properties

Phosphor bronze typically contains about 0.5-11% tin and 0.01-0.35% phosphorus. The balance is primarily copper. This composition results in a material that is highly resistant to fatigue, wear, and chemical corrosion. It also exhibits excellent elasticity, which is a crucial factor in many engineering applications.

Applications in Engineering

Bushings and Bearings

One of the primary uses of phosphor bronze is in the production of bushings and bearings. Bushings are mechanical components used to reduce friction and wear between rotating or sliding parts. Phosphor bronze’s low coefficient of friction and high fatigue resistance make it an ideal choice for bushings in various industrial applications, including machinery, automotive, and aerospace sectors.

Custom-sized phosphor bronze bearings are also widely sought after. These bearings are tailored to fit specific machinery requirements and are essential in applications where standard sizes do not suffice. The customizability allows engineers to optimize performance and longevity in specialized equipment.

Electrical Components

Phosphor bronze is also widely used in electrical applications due to its good conductivity. Components like springs, connectors, and contacts benefit from its resistance to corrosion and fatigue, ensuring longevity and reliability in electrical systems.

Musical Instruments

Interestingly, phosphor bronze is also popular in the music industry, particularly in the manufacture of strings for acoustic guitars and piano wire. Its durability and tonal qualities make it a preferred material for high-quality musical instruments.

Supply and Customization

The supply of phosphor bronze, especially for specific applications like bushings and bearings, is a specialized market. Suppliers often offer custom sizing services to meet the unique needs of different engineering projects. This level of customization is crucial in modern engineering, where precision and material properties can significantly impact the performance and lifespan of mechanical components.

Phosphor bronze’s unique combination of durability, elasticity, and resistance to wear and corrosion makes it an indispensable material in modern engineering. Its versatility in applications ranging from industrial machinery to musical instruments underscores its importance. With the ability to customize components like bushings and bearings, phosphor bronze continues to play a vital role in advancing technological and engineering innovations.

The Versatility of Phosphor Bronze Grades

Phosphor bronze grades encompass a wide range of alloys, each designed to serve a specific purpose. While some grades are more ductile and suitable for forming applications, others offer improved wear resistance and strength, making them ideal for high-stress components such as bearings and bushings.

Bringing Bronze to Life: Your Expert Partner in Phosphor Bronze Bushings and Bearing

Chemical Composition of Phosphor Bronze

The exact composition of phosphor bronze can differ depending on the specific grade of the alloy. However, the standard phosphor bronze typically contains 3.5-10% tin and 0.01-0.35% phosphorus. The rest of the alloy is predominantly copper. Some variations may include additional elements like lead or zinc to modify specific properties.

The interplay of these elements bestows phosphor bronze with its unique characteristics, making it suitable for intricate applications such as bushings and bearings. It exhibits good plasticity, low friction, excellent machinability, and outstanding resistance to fatigue, corrosion, and wear.

Phosphor bronze bushings are a testament to the versatility and adaptability of this exceptional alloy. They are a reliable choice for numerous applications demanding high strength, wear resistance, and durability. With custom material options, the potential of phosphor bronze bushings expands even further, catering to a multitude of specific industrial requirements.

Oilless Self-Lubricating Bearings, Phosphor bronze bushings

The versatility of phosphor bronze grades allows for their usage in a myriad of industries. From electronics to automotive, industrial machinery to marine applications, the adaptability and durability of phosphor bronze remain unmatched.

Phosphor bronze bushings, and more specifically, the C53400 bronze bearing, offer a fantastic balance of strength, resilience, and wear resistance. The option for custom material choices and the variety of phosphor bronze grades available opens up a world of possibilities for applications requiring reliable and durable materials. Understanding the specific compositions and properties of these alloys can aid in choosing the ideal material for your specific application. With phosphor bronze, you get an alloy that is as versatile as it is durable, offering solutions for a broad range of demanding industrial applications.

Why Phosphor Bronze?

Phosphor bronze, an alloy of copper with tin and phosphorus, boasts significant hardness and elasticity. The presence of phosphorus in the alloy not only increases wear resistance and stiffness but also enhances its deoxidizing properties, which helps in casting and forming processes. Meanwhile, the addition of tin significantly improves corrosion resistance.

C53400 Bronze Bearing: A Prime Example

The C53400 phosphor bronze grade is an excellent example of a widely-used phosphor bronze bushing. This alloy, with the addition of lead, exhibits superior machinability without compromising on its strength or wear resistance, making it highly suitable for bearings in heavy-duty machinery.

Custom Material Choices

Manufacturers often offer custom material bronze bushings, which can be specifically tailored to suit certain application requirements. These custom alloys allow for modifications in mechanical properties by adjusting the percentage of tin, phosphorus, lead, and other elements. This approach aids in meeting specific needs, whether they’re related to corrosion resistance, machinability, or strength.

BRONZE OILLESS BEARING MATERIAL

Special parts request