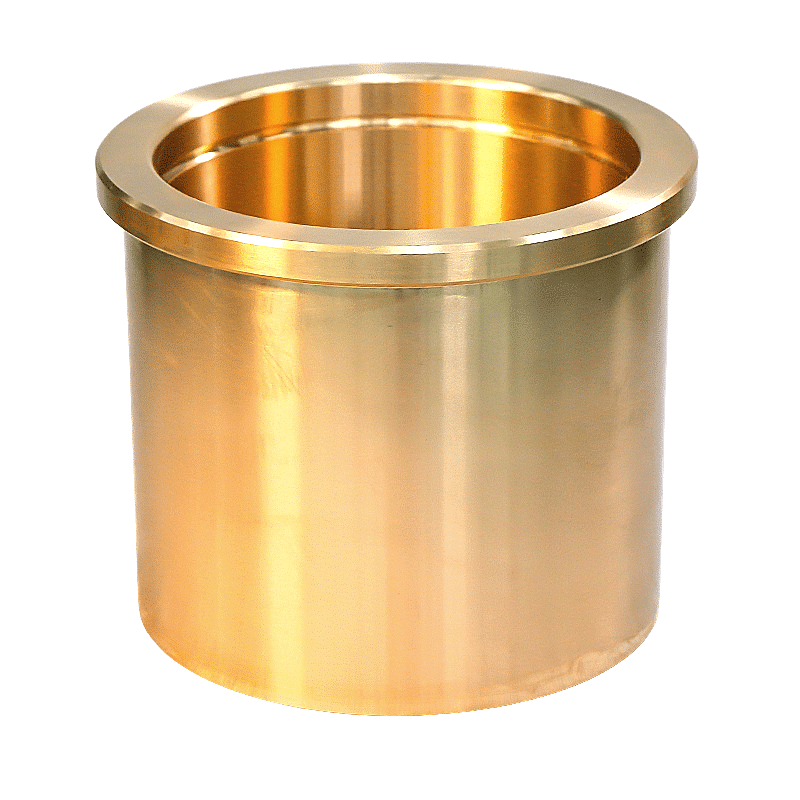

Tin Bronze Bushings: Continuous Cast

Custom Manufacturing with C92900 Bronze Bushings: A Journey into QSn10-1 Continuous Cast Bronze Bushings

Welcome to the fascinating world of bronze bushings, where metal meets technology to create a durable and reliable component. Today, we’ll be taking an in-depth look at C92900 bronze bushings, continuous cast bronze bushings, and delving into the custom manufacturing of the QSn10-1 bronze material.

Unveiling the C92900 Bronze Bushing

C92900 bronze bushing, Custom Material Bronze Bushing

At the core of high-performing machinery lies a secret workhorse – the C92900 bronze bushing. This distinctive type of bearing is crafted from a specific alloy known as C92900. It’s a high-leaded tin bronze, often recognized for its robust performance, excellent machinability, and impressive anti-friction properties. The C92900 bronze bushing is the epitome of quality. It provides a superb balance of strength and durability, making it an optimal choice for heavy-duty applications. From construction equipment to industrial machinery, the versatility of C92900 is truly astounding.

Custom parts from CuSn10-1 bronze bearings are more than just components – they’re solutions crafted to meet specific needs. By taking advantage of the exceptional properties of CuSn10-1 bronze, manufacturers can create custom parts that deliver in terms of reliability, durability, and performance. When you opt for CuSn10-1, you’re investing in a material that brings precision, versatility, and longevity to the table. Trust CuSn10-1 bronze for your custom bearing parts, and experience the difference for yourself.

Product Quality Index

Energy Generation

Custom Manufacturing with QSn10-1 Bronze Material

Phosphor bronze grades encompass a wide range of alloys, each designed to serve a specific purpose. While some grades are more ductile and suitable for forming applications, others offer improved wear resistance and strength, making them ideal for high-stress components such as bearings and bushings.

Bringing Bronze to Life: Your Expert Partner in Phosphor Bronze Bushings and Bearing

Custom Manufacturing with QSn10-1 Bronze Material

Now, let’s delve into the custom manufacturing aspect with a focus on QSn10-1 bronze material. QSn10-1 is a specialized tin bronze, known for its excellent wear resistance, mechanical properties, and good machinability. It’s particularly well-suited to high load, high-speed applications, making it a preferred choice for custom manufacturing projects.

Custom manufacturing is the creation of bespoke components tailored to meet unique specifications and requirements. With QSn10-1 bronze, it’s possible to create specialized bushings designed for unique applications. By manipulating factors like shape, size, and alloy composition, manufacturers can create components that meet exacting standards and deliver outstanding performance in their intended environment.

The adaptability of QSn10-1 bronze material offers engineers the flexibility to design bushings that can fit into any machine design seamlessly. Be it for the automotive industry, heavy machinery, or niche equipment, custom manufacturing ensures an optimal fit and unmatched performance.

C92900 Bronze Bushings, QSn10-1 bronze material

Bronze bushings, particularly the C92900 and continuous cast variants, offer an unmatched blend of strength, durability, and versatility. By opting for custom manufacturing with QSn10-1 bronze material, you gain the power to create unique, high-performance components designed specifically for your application. So, whether you’re in the heavy machinery industry or creating niche equipment, consider bronze bushings for your next project. Their superb properties and customizability might just be what your machinery needs to reach new levels of performance and reliability.

For instance, custom bearings can be made with specific grooves, holes, or mounts to fit seamlessly into the existing machinery. They can also be designed to accommodate different lubricants or to operate effectively in environments that may be too harsh for other materials. This level of customization ensures that your machinery operates with minimal friction and maximum efficiency.

Delivering Precision and Performance

When it comes to delivering durability, strength, and exceptional performance, few materials are as versatile as CuSn10-1 bronze. This specific alloy is renowned in various industries for its unique mechanical properties and adaptability. And when these characteristics are put to use in custom bearings, the results are truly impressive.

Custom Parts from CuSn10-1 Bronze Bearings

CuSn10-1, also known as Tin Bronze, is an alloy composed of roughly 90% copper and 10% tin. This composition gives CuSn10-1 bronze superior wear resistance, corrosion resistance, and excellent mechanical properties, even in high load and high-speed applications.

Bearings made from CuSn10-1 bronze are particularly noteworthy for their capacity to withstand the most demanding operating conditions. These properties, coupled with the alloy’s superior machinability, make it an ideal choice for creating custom bronze bearing parts.

Custom Parts from CuSn10-1 Bronze Bearings

The process of creating custom parts from CuSn10-1 bronze bearings begins with a deep understanding of the end application. This involves factoring in parameters such as load, speed, temperature, and environmental conditions.

Once these factors are defined, engineers can leverage advanced manufacturing processes such as CNC machining to create bespoke bearing parts that precisely fit the requirements. The flexibility of CuSn10-1 bronze allows for a wide range of shapes, sizes, and features to be crafted, ensuring optimal performance in their intended application.

BRONZE OILLESS BEARING MATERIAL

Special parts request