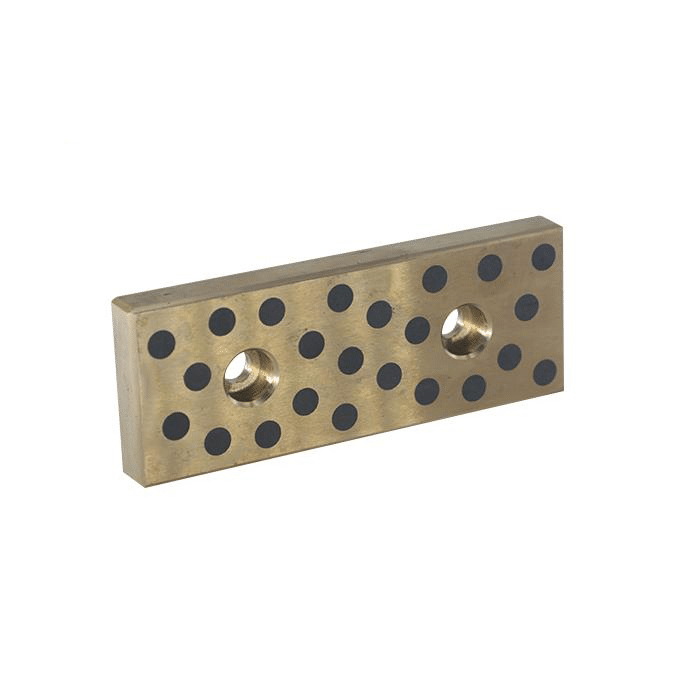

Thin Wear Plates(10thickness)

Services you can trust on

Keep Things Rolling, Stamping Dies Wear Plate, Stamping Die Bushing & Plate Design. Our manufacturing plants have efficient, modern equipment (Lathe CNC, Surface Grinding, Cylinder Grinding, Centerless Grinding and etc.) enabling us to process your custom finishing parts orders quickly and flexibly.

Experienced

Excellence for You

Bronze Parts Solutions

CAD Design, Quality Control

Manufacturing

We inspires our customers & support your businesses.

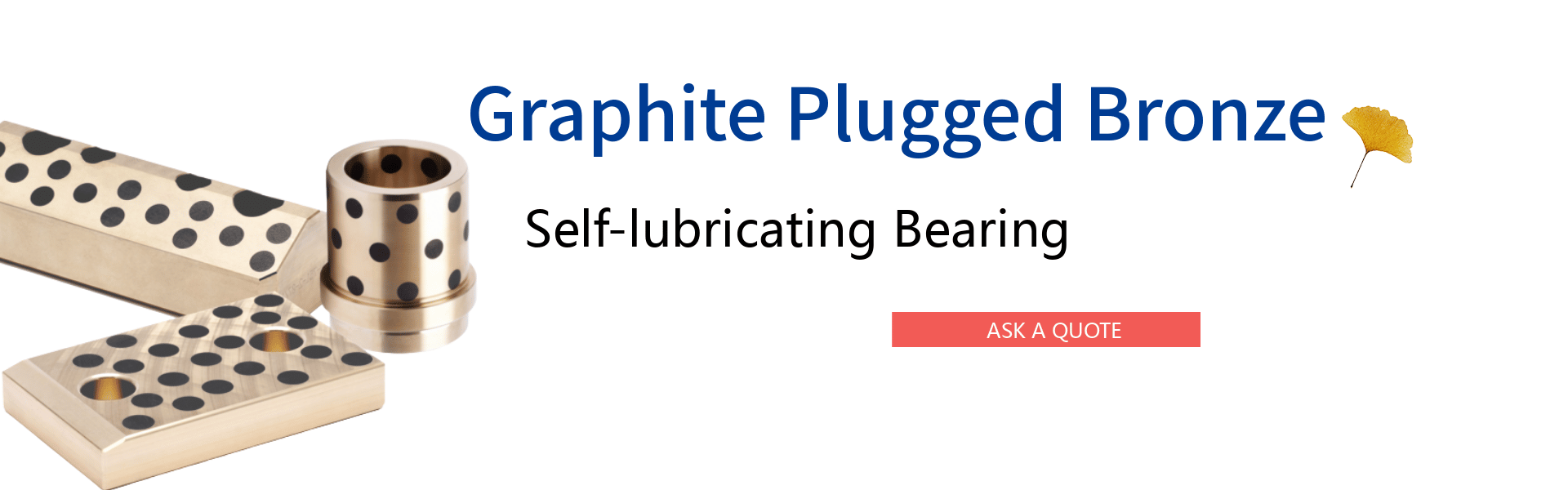

Material Bronze Wear Plate With Graphite, Precision Bronze Parts – BornzeLube.com

Qualified Technical Experts for Wear Plate and Bronze Bushing Support. Request an Expert Today! Find an Expert Today. Free Consultation. Get A free Quote. Services: Customer Experience, Customer Loyalty. Best Metal Stamping Bronze Wear Plate Company – Fast Deliver Quality In Every Part, Get Cost-Effective Solutions For High Volume Parts.

Manufacturer of Standard Press & Die Components and Standard Plates.

As an exporter china specializing in supplying tribological technology in this field, we have extensive experience in manufacturing self-lubricating bearings and stamping die components. Our technology and expertise have made an outstanding contribution to harsh and demanding applications in various industries. However, at viiplus, we are constantly striving in research and development to achieve even higher standards of quality bushing, wear plate and Copper Alloy (C86300) with Graphite Plugs product performance.

C86300 CAC304 SAE430B CuZn25Al5

Bronze Bushing & Thin Wear Plates

Material

- #500SP (CAC304 + graphite)

- Mounting Bolts

- Low Head Socket Cap Screw, Slide & Guide Components (Metric)

- Wear Plates Thrust Washers, Sliding Plates · Thin Wear Plates · Flanged Bushings

- JSP Plate JFB Flange Bushing, JDB Bushing

CAC304, HBsC4, C86300, High Strength Brass

CAC304 copper alloy bronze wear material

High force brass, chemical formula is ZCAC304, mechanical properties are different zinc content, mechanical properties are not the same, pressure processing properties have good plasticity, can withstand hot and cold processing. CAC304 high force brass is a variety of alloys consisting of two or more elements is called special brass. Such as aluminum, lead, tin, manganese, nickel, iron, silicon composition of copper alloy, high force brass is one of them. High-force brass has strong wear resistance, high strength, hardness, and chemical resistance. It also has excellent mechanical properties for cutting and machining. It is often made into sheet, bar, rod, tube, casting parts, etc. The chemical formula of CAC3044 is The chemical formula of high-strength brass is about 65% copper and 24% zinc. Aluminum improves the strength, hardness and corrosion resistance of brass. There are three types of room temperature organization of brass: brass containing less than 35% zinc, the microstructure at room temperature consists of a single phase of alpha solid solution, called alpha brass

Design to Operation

CAC304 Wear Plate, Finishing Plates, Fast Delivery & Technical Support

We have our own integrated design team in the office which enables us to develop wear plate and adapt our range of self-lubricating bearings to customers’ specification. Our engineers and designers are equipped with the latest generation of CAD stations to work on your projects. CAD Design, Custom Bronze Slide Plate Plugged Graphite.

CAC304, HBsC4, C86300, High Strength Brass

Shoulder Bushings, Copper Alloy (C86300) with Graphite Plugs

Ejector Bushings, The chemical formula of CAC3044 is: The chemical formula of high-strength brass is about 65% copper and 24% zinc. Aluminum improves the strength, hardness and corrosion resistance of brass. There are three types of room temperature organization of brass: brass containing less than 35% zinc, the microstructure at room temperature consists of a single phase of alpha solid solution, called alpha brass.

CAC304 Bronze Material, Application: Copper and copper alloy castings. Trusted by Millions of customers.

Sliding Plates, Material

#500SP (CAC304 + graphite), Wear Plates Mold and Die Products

Bronze Bushing C86300 CAC304 SAE430B, C86300 Bronze C86300 (Sae 430b CuZn25Al5Fe3Mn4) Is A Tough, Corrosion Resistant Alloy With Outstanding Wear Characteristics. Ideal For High Load, … CuZn25Al6Fe3Mn3 Bronze Wear Slide Plate. Bronze Wear Plate Stamp Parts To Meet The Customers Requirements. Bronze Plate Manufacturers, Suppliers, Good Price. Bronze Plate Sourcing Solution For Buyers. Reduce Costs With Factory Direct Sourcing. Quality China Sliding Plate. Select A Category To Explore Our Collection Of Mold & Die Products. Explore More Bronze Bushings With Oil Groove Design.

Stamping mold products

Solid Bronze The all-round runner.

A Broad Range of Inch and Metric Sizes, including Custom Bushing Sizes. Made in China. Oil Groove Plates Made. Highlights: Quick Quote Available, Customer Service Available.

L-rail V-rail / with forced pull-back V-rail Edge flange guide Guide column/press plate Gasket Independent pillar Multiple surface guide plate Flip side lifter/float pin Cover/combination Ball holder Steel sheath Ring lubrication guide sleeve Lifting rod Sintering guide Copper guide/steel guide External guide/lock block Flangeless guide sleeve Wedge drive guide Long flat plate without sink hole Middle flange guide sleeve/pressure plate Conical locator

Plastic molds

L-rail T-rail Edge flange guide Guides Guide post Porous plate Steel copper sleeve Active Core Blue guide sleeve Middle flange guide sleeve

|

Product name

|

oilless cast bronze bearings with graphite plugs

|

|

Model number

|

|

|

Material

|

Bronze+graphite plug

|

|

size

|

Customize

|

|

Apply to

|

Manufacturing Plant, Machinery Repair Shops, Retail, engine, automobile etc.

|

| CAC304, Meterial #500SP, Bushing and Wear Plate | ||

| Main Composition (%) | Copper (Cu) | 60.0~65.0 |

| Zinc (Zn) | 22.0~28.0 | |

| Iron (Fe) | 2.0~4.0 | |

| Aluminum (Al) | 5.0~7.5 | |

| Manganese (Mn) | 2.5~5.0 | |

| Residual Composition (%) | Tin (Sn) | 0.2 max |

| Lead (Pb) | 0.2 max | |

| Nickel (Ni) | 0.5 max | |

| Silicon (Si) | 0.1 max | |

| Tensile Strength (MPa) | 755 min | |

| Yield Strength (MPa) | 410 min | |

| Elongation (%) | 12 min | |

| Hardness (HBW) | 200 min | |

CAC304 Plate, Finishing Plates, Application Areas

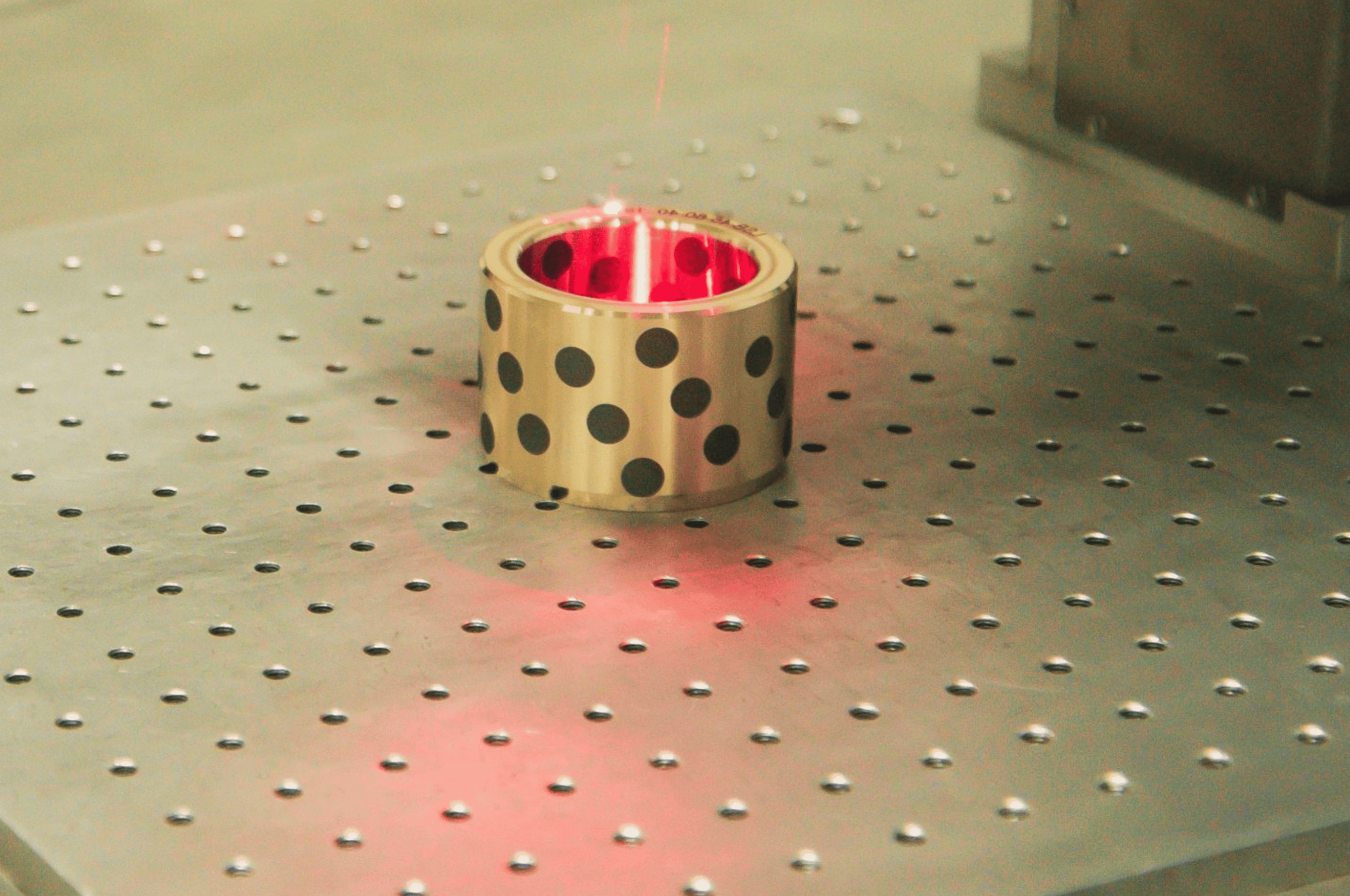

High force brass is very widely used, made by casting into shingles and bushings, domestic now mainly made of high force brass as the substrate of solid lubrication oil-free bearings (referred to as solid lubrication bearings), is the use of high force high strength brass as the substrate, and radially embedded in an orderly arrangement of cylindrical polymer filler for the friction material (generally graphite, molybdenum disulfide,, oil and other lubricants), its superiority lies mainly in its ability to make copper alloy and Non-metallic wear reducing materials have their own complementary advantages, not only has a high load-bearing capacity, but also break through the general bearing rely on oil film grease lubrication boundary, to achieve oil-free lubrication, embedded solid lubrication easy to form a lubricating film, the friction and wear performance has played a great role in improving, stable and reliable. Compared with the composite oil-free bearing, it has the advantages of good machinability, high precision, strong load-bearing capacity and good wear resistance. This self-lubricating guide bush guide plate can be used in many fields such as: construction machinery joint parts, such as excavators, mining shovel machine, rotary drilling rig, concrete pump truck, rock drilling machinery, winch, port crane, etc., and metallurgical machinery continuous casting machinery, water conservancy machinery, conveying machinery, rolling mills, blowing machine film blowing machine, injection molding machine crosshead clamping differential, tire curing machine, trailer balance beam, vacuum switch, etc.

ZCuZn25 corresponds to Japanese standard CAC304, American standard ASTMC86300, also known as high force brass, generally made of graphite self-lubricating bearings called JDB bearings or OILES#500SP1 bearings, usually centrifugal casting process to manufacture the substrate, and then inlaid on the substrate solid lubricants, copper alloy substrate to bear the heavy load, solid lubricants play a role in friction reduction, very suitable for It is very suitable for high load and difficult to maintain.

The material of both copper alloy base and solid lubricant can be changed to suit the specific working condition or better economic performance.

Features: Can be used in oil-free condition. Low-friction performance at high loads and low speeds. Suitable for reciprocating, shaking, and frequent starting and stopping where oil film is difficult to form. Good chemical resistance and corrosion resistance.

Typical applications

1.Support bearings for mining and construction machinery, guide sleeves for large covering stamping dies, bridge bearings and skids, etc.

2.Metallurgical equipment in steel mills, casting machines, conveying rails, high temperature blowers, drying ovens and bearings for hot rolling mills under high temperature environment.

3. Food machinery, textile printing and dyeing machinery, paper making machinery, printing machinery, etc. need to reduce the use of pollution occasions. Used in dam work arc gate support hinge bearings, gate bearings, hydraulic turbine bearings and petroleum machinery, etc. need to resist corrosion and water immersion parts.

4. Other industrial bearings. Such as: assembly line, conveyor belt bearings, etc.

Available types.

Straight sleeve, flanged sleeve, flange sleeve, shaft tile, ball bowl, joint bearing, sliding plate, slider, guide, shim, shaped parts, non-standard custom parts, custom parts according to the map.

We can provide you with the following types of bearings

Other Bronze Wear Plate Parts Material

CuSn7Zn4Pb7 Material, (CuSn7Zn4Pb7-C、H62、H63,H65、H68、H70、H85,H95)

Characteristics and scope of application.

Aluminum bronze containing iron and manganese elements, is a high-strength heat-resistant bronze, stable mechanical properties at high temperatures (400 ℃), good friction reduction, good corrosion resistance in the atmosphere, fresh water and seawater, good pressure processing in the hot state, can be strengthened by heat treatment, can be welded, not easy to fiber welding, machinability is still good.

CuAl10Fe5Ni5 material

CuAl10Fe5Ni5-C copper alloy uses

It has high strength and good wear resistance and is used for high-strength screws, nuts, copper sleeves, sealing rings, etc., and wear-resistant parts.

Characteristics: The aluminum content is generally not more than 11.5%, and sometimes the right amount of iron, nickel, manganese, and other elements are added to further improve the performance. Aluminum bronze can be heat-treated and strengthened, and its strength is higher than that of tin bronze, and its resistance to high-temperature oxidation is also better. It has high strength and good wear resistance. It is used for high-strength screws, nuts, bronze sleeves, sealing rings, etc., and wear-resistant parts, and its outstanding feature is its good wear resistance. Aluminum bronze containing iron and manganese elements has high strength and wear resistance, after quenching and tempering can improve the hardness, has good high-temperature corrosion resistance and oxidation resistance in the atmosphere, fresh water, and seawater corrosion resistance is very good, machinability can be welded not easy to fiber welding, good pressure processing in the hot state.

G-CuSn5Zn5Pb5 C93200 G-CuSn5Zn5Pb5 C95400 C95500

We manufacturing bronze wear plate tailored to your needs.

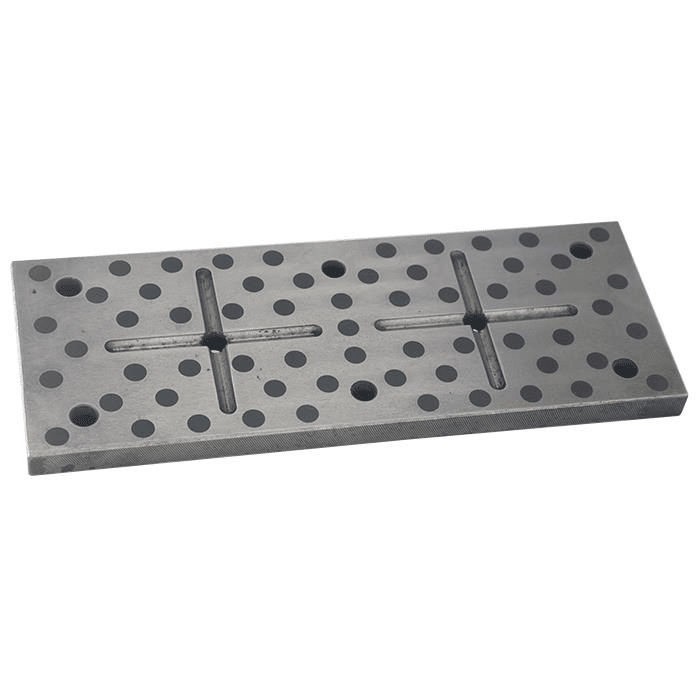

Oil-free slide plates

oil-free slide plates can be designed to accommodate both longitudinal and lateral movements. flat oil-free slide plates feature a higher width-to-length ratio than pads and utilize a lubrication pattern that provides maximum lubrication.

oil-free slide falt plates have a higher width-to-length ratio than liners. generally, oil-free slide plates flat are installed by attaching them to a base plate with machine screws or by building a nest in the base plate.

screw it to the base plate or build a nest on the base plate and put the plate in it.

if a nest is used, there must be an opening. if a nest is used, an opening should be left at the corners to allow for drainage.

if a nest is used, an opening should be left at the corners to allow for drainage, and it should be machined flat in the area where the oil-free slide plates plate touches.

The oil-free slide plates should be machined flat in the area where they touch.

care should be taken to ensure that the size of the butt plate is large enough to completely cover the oil-free slide plates.

large enough to completely cover the lubricating plate during all expected movements.

completely cover the oil-free slide plates during movement. failure to do so will put the oil-free slide plates at risk of contamination and lead to increased wear.

thereby increasing wear. the mating plate must be machined to a higher surface quality on the surface in contact with the oil-free slide bearing bushing bearing.

Bronze Wear Plate & Bushings for General Machinery

Bronze sleeve bushings or bronze bearings are hard and strong, as opposed to brass bushings which are softer & more easily deform. Contact our bronze bearings experts …

Main applications: Solid Bronze bushings are intended for oscillating movements in both rotational and axial directions. Solid Bronze bushings are not intended for rotating movements at medium or high speeds.

Grooved Cast Bronze Bushings Bronze Manufacturing Grooved

We are specialists in cutting lubrication grooves in virtually any pattern. Examples include our “8” Groove and “11” Groove. Other common groove patterns available are figure eight, double figure eight, loop, double loop, circular, wick or straight.

Examples of applications are:

- construction machinery

- transport equipment

- off-shore equipment

Grease groove design,Catalogs and Brochures Available. Fill out our form to get more info.cast bronze graphite slide bushes with graphite plug

Oil-Free Slide Plates Self-lubricated

Better by Design

Forces on Oilless Bronze Bearings. Deep Drawing, Precision Stamping Part.

Quality Design And Supply Of Plain Bearings & Engineering Materials. Bronze Alloy Components. Oil-Groove Bushings. Drill Bushings. Oil Groove bushings feature grooves specifically designed to provide a coolant passageway in a bushing’s ID wall. Metals Engineered Materials. Custom Design Self-Lubricated Plain Bearings. Solid wear plate, bronze with lubricant plugs embedded, DIN 1850/ISO 4379, Maintenance-free Material. Solid Bronze bushings are made of a multi-component bronze, CuZn25Al5, CuSn7ZnPb, Other commonly used bronze alloys: CuAl10Ni, CuSn12Pb, RG7 bronze bushing. which has a very good sliding properties. All surfaces of the solid bronze bushings are machined.

- Fast Delivery

- Quality

- Technical Support

- More cost-effective

Copper Alloy Slide Plate

professionals

Plastic Injection Molding Bronze Wear Plate – Get An Injection Molding Bronze Part Quote, Plastics were becoming the material of choice because the finished goods were inexpensive to produce in mass quantities and abrasives were used to finish plastic injection molds. Oil Bushings are suitable for rotating, oscillating and linear movements, whereas straight (cylindrical) bushings can accommodate radial loads only and flanged. Solid Bronze bushings offer many features and advantages such as: insensitive to dirty environment, resistant to shock loads and vibrations at slow speeds, enable operation with a poor shaft surface finish, good resistance to corrosive conditions, lubrication groove. Lubrication Wear Plate Design & Material Selection: Solid Bronze bushings are intended to be lubricated with oil or grease. Lubrication not only improves the sliding properties, but also reduces wear and prevents corrosion. Grease is usually used when lubrication is periodical, while in exceptional cases, an oil bath is used. Seals are recommended when the bushing is to be used in an aggressive environment. All bushings with bore diameter of 14 mm and above incorporate an axial lubrication grove.

Bronze Slide Plates design for Pipeline Supports

Breathtaking design for home living.

We offers various types of bronze wear plates, ranging from unfinished cast bronze plate to fully finished machined components.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.